Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 70-02-09-220-501 Inconel 713C (IAE 655) Metal Temperature Analysis

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURER'S MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS INFORMATION. THESE CONTAIN INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.Safety Precautions

General

Refer to the SPM TASK 70-02-03-220-501 for the procedure to do a metal temperature analysis on nickel base alloys.

Inconel 713C (IAE 655) is the specification for nickel-base, 14.0 percent Chromium, 6.0 percent Aluminum, 4.5 percent Molybdenum, 2.0 percent Niobium (Columbium), 1.0 Titanium, 0.08 percent Zirconium, 0.01 percent Boron investment casting.

The typical microstructure of the coated or uncoated superalloy is characterized by a generally uniform array of matrix gamma prime (Ni3Al,Ti) precipitate in a gamma matrix. Islands of eutectic gamma prime and Niobium, Titanium-rich MC-type carbides are also present, located predominantly along grain boundaries and interdendritic areas.

Effects of Temperature on the Microstructure

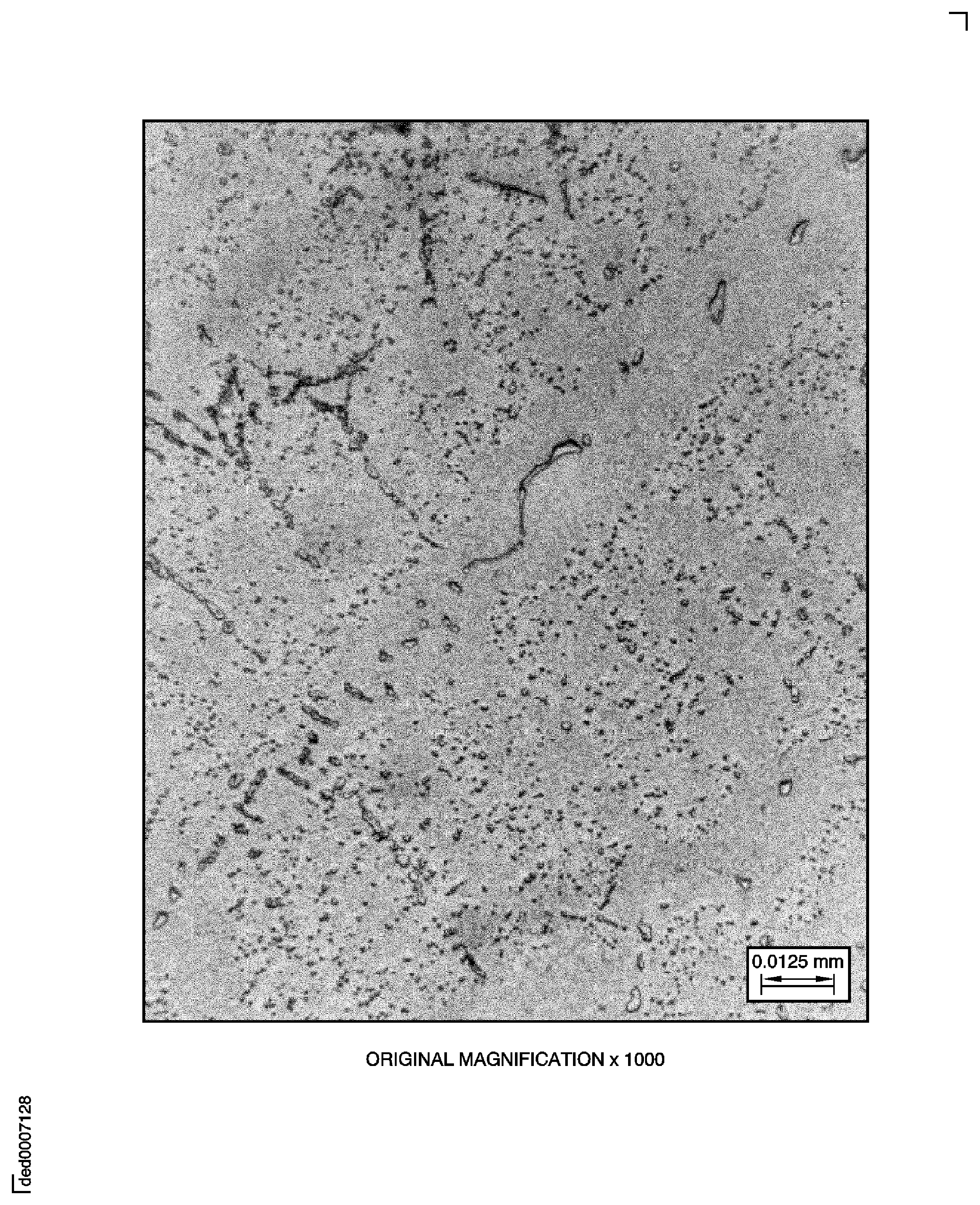

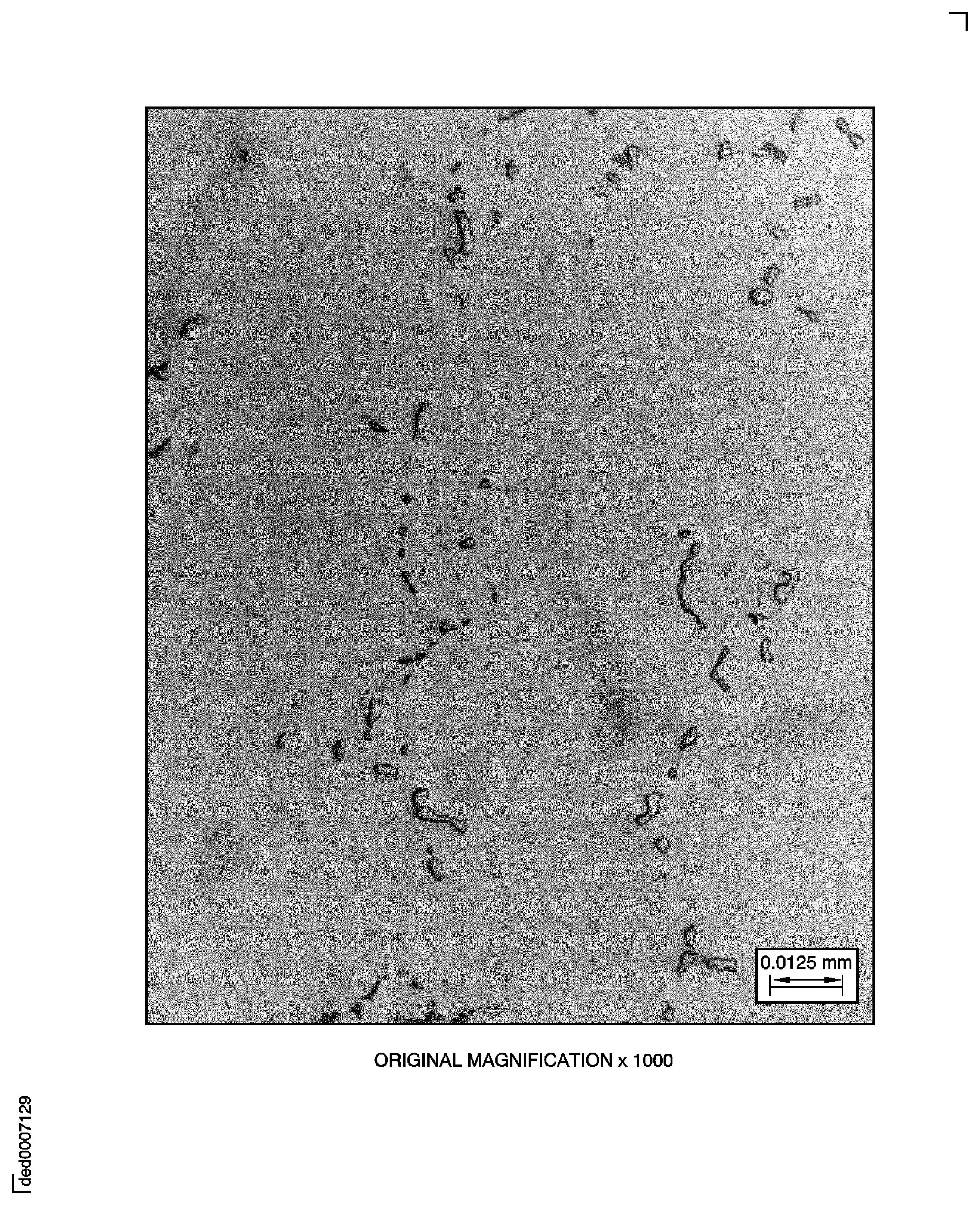

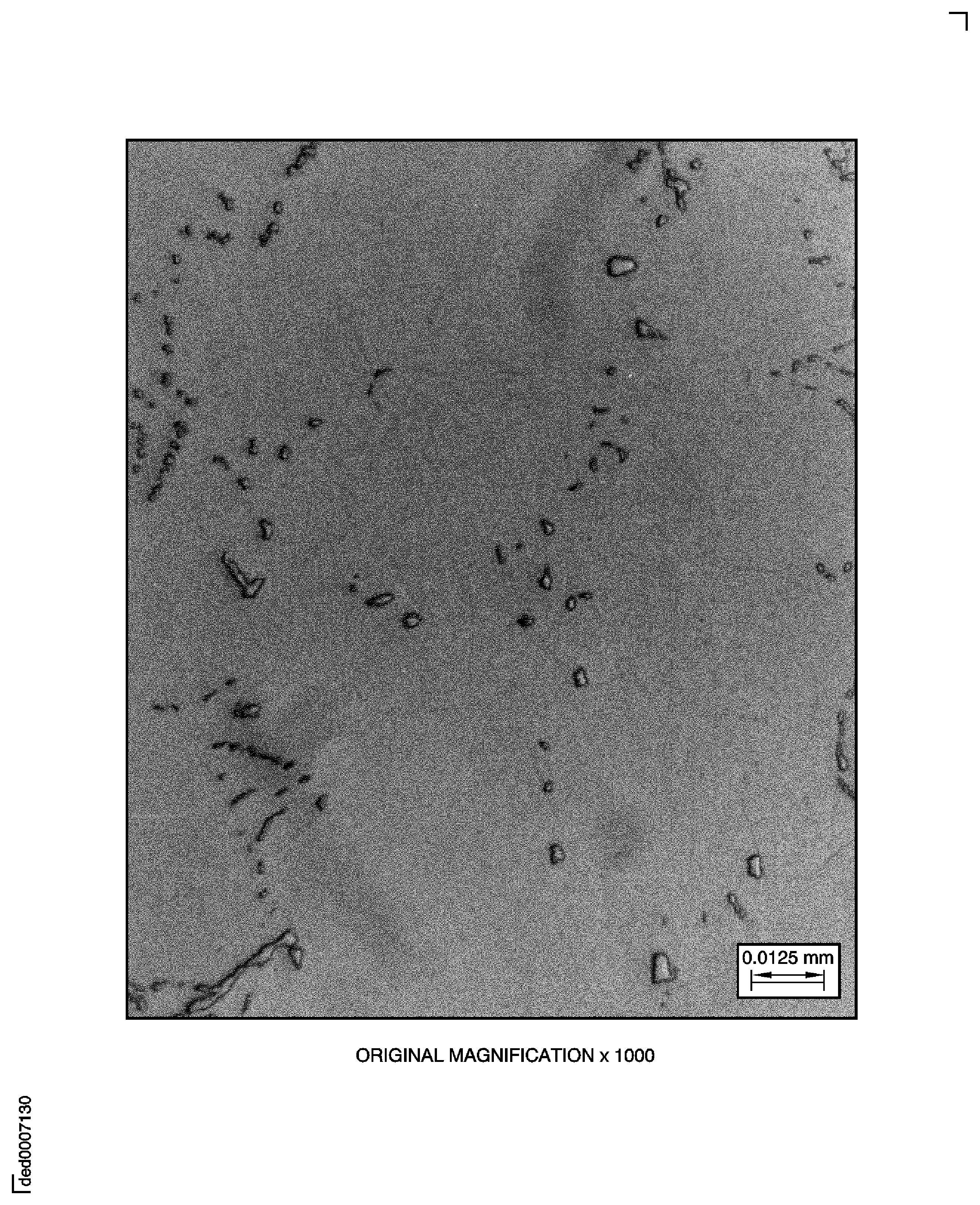

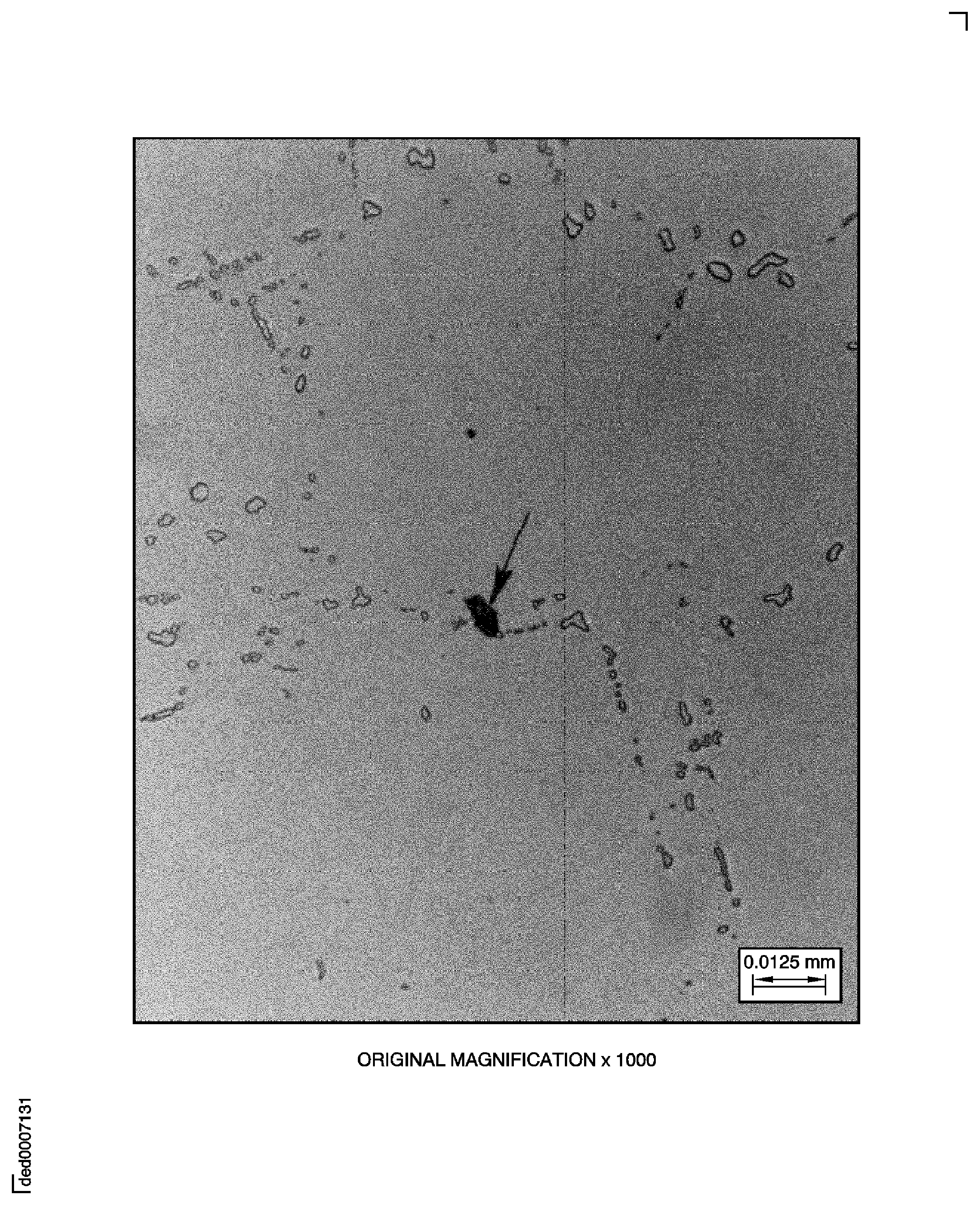

The effect of temperature on the microstructure is shown in Figure 70-02-09-990-001 through Figure 70-02-09-990-008. The most obvious effects of high temperature on the microstructure of Inconel 713C (IAE 655) nickel base superalloy are the changes in size, shape, and distribution of the matrix gamma prime precipitate.

Metallographic Standards

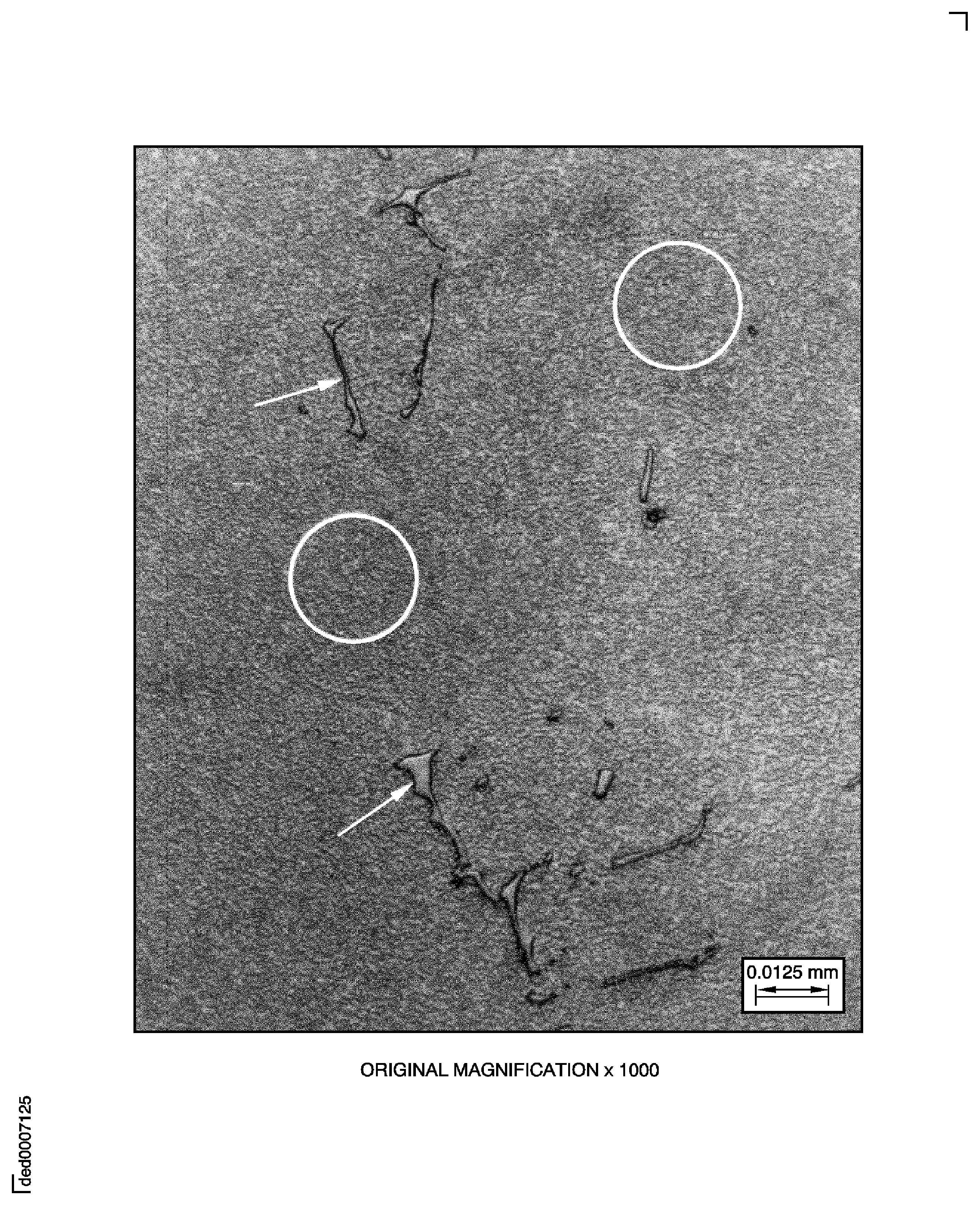

A metal temperature below 2000 deg F (1094 deg C) causes no significant changes in the matrix gamma prime precipitate. See Figure.

A metal temperature of 2000 deg F (1094 deg C) causes a slight agglomeration of the gamma prime precipitate, the result of which is a uniform distribution of spheroidized particles. See Figure.

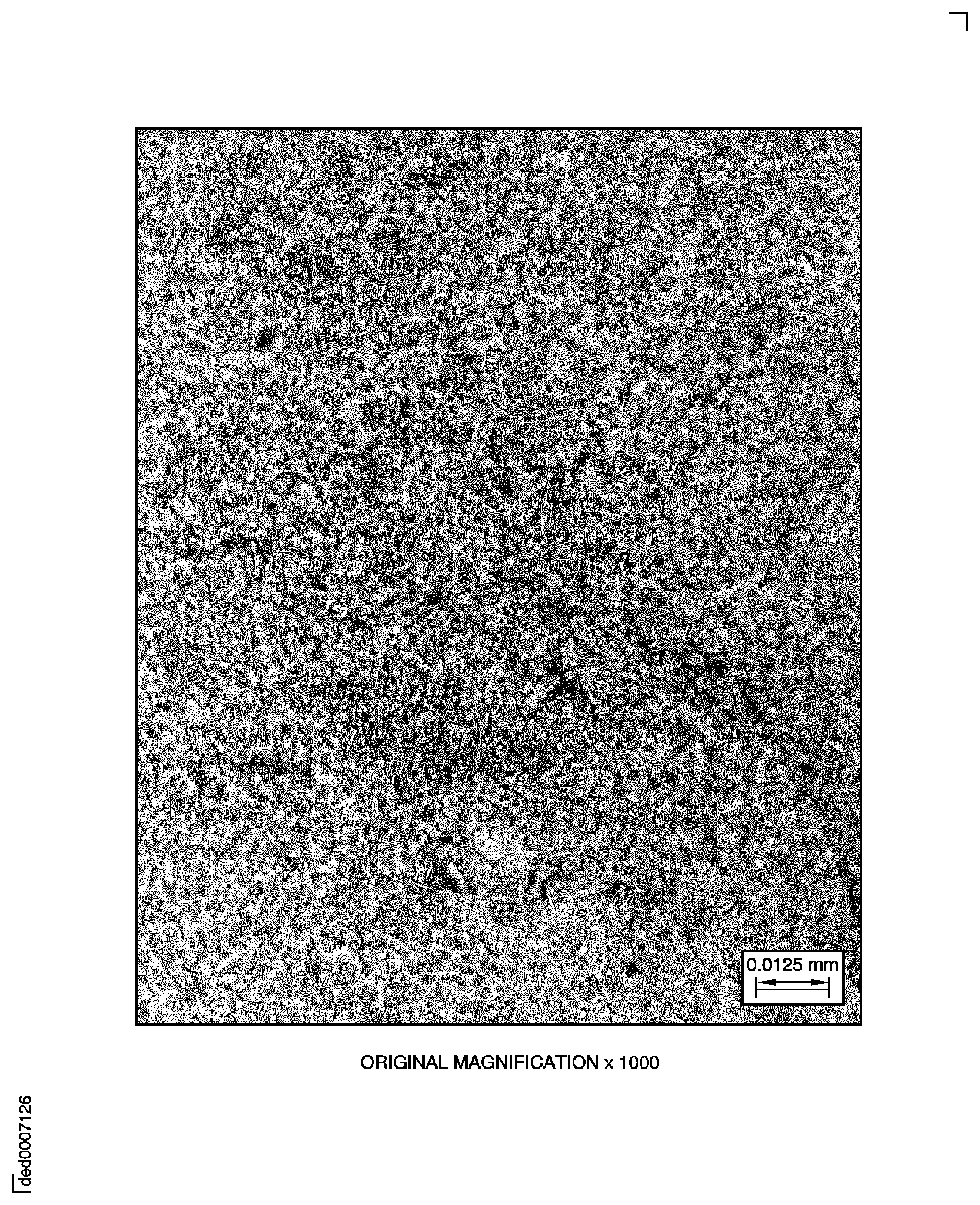

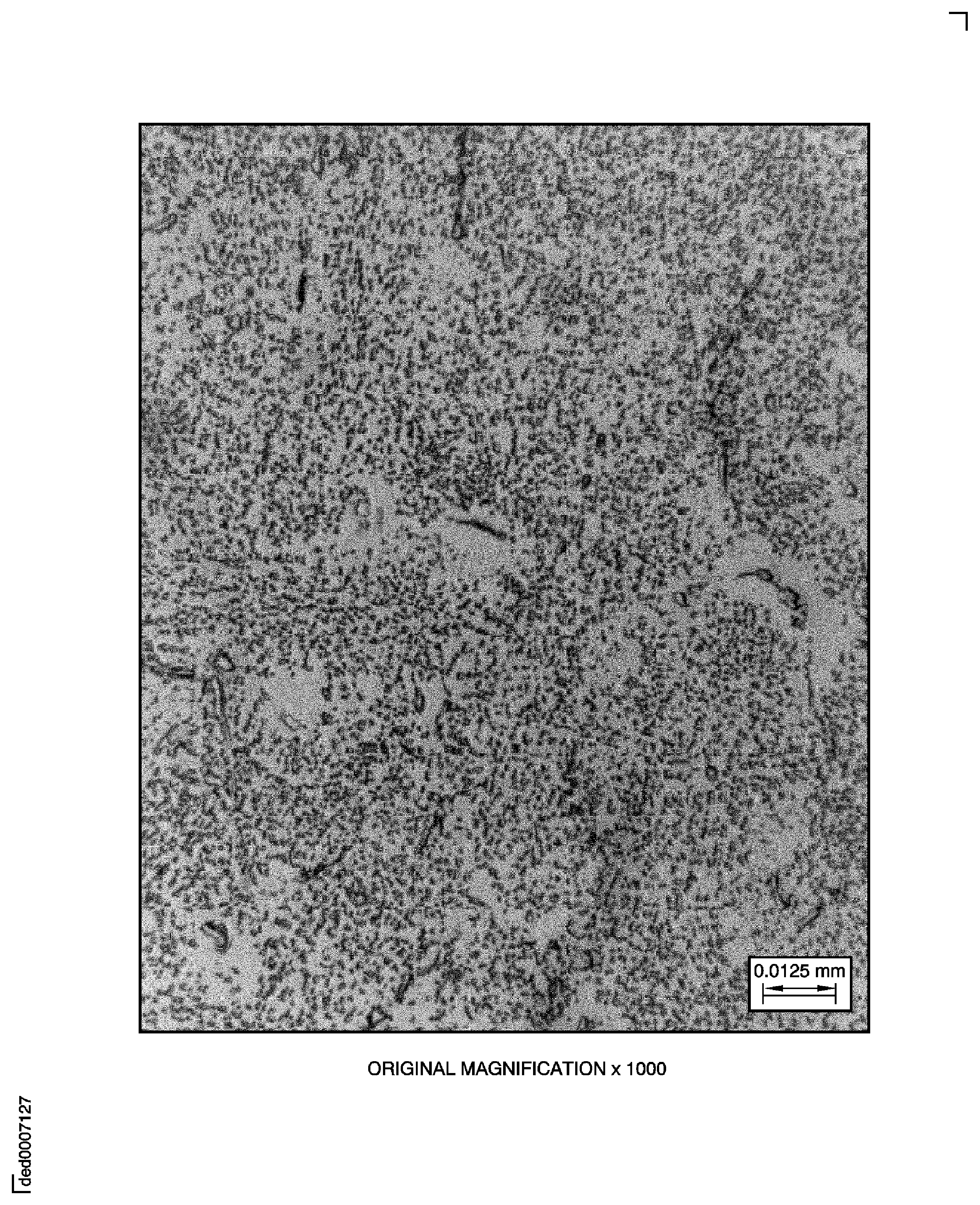

A metal temperature between 2050 and 2100 deg F (1121 and 1149 deg C) causes decomposition (solutioning) of the precipitate. The extent of the decomposition of the precipitate increases with increased temperature. The result is a decrease in the uniformity of the distribution of precipitate in the microstructure and an increase in the interparticle spacing. See Figure and Figure.

A metal temperature of 2150 deg F (1177 deg C) causes complete decomposition (solutioning) of the gamma prime precipitate. See Figure.

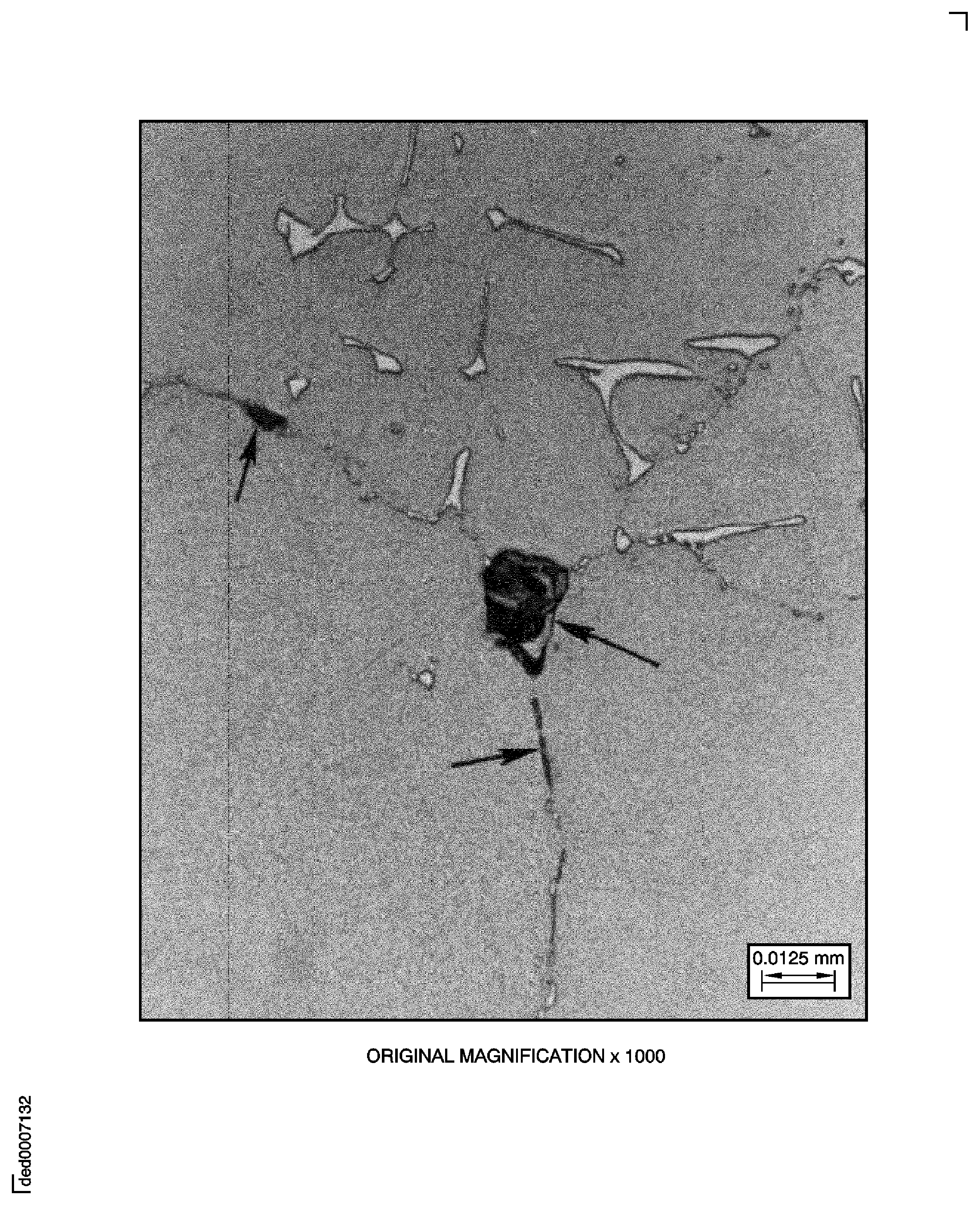

A metal temperature of 2200 deg F (1204 deg C) may cause incipient melting to become evident. See Figure.

Description of Illustrations

Inconel 713C (IAE 655) heated to a metal temperature below 2000 deg F (1094 deg C) shows the typical dense, uniform array of approximately rectangular gamma prime precipitate in gamma matrix (Circles) and MC-type carbides (Arrows). (1000x)

Inconel 713C (IAE 655) heated to a metal temperature of 2000 deg F (1094 deg C) shows typical increased particle size and moderate decomposition (solutioning) of gamma prime precipitate and spheroidization of gamma prime particles. (1000x)

Inconel 713C (IAE 655) heated to a metal temperature of 2050 deg F (1121 deg C) shows typical extensive decomposition (solutioning) of gamma prime precipitate. (1000x)

Inconel 713C (IAE 655) heated to a metal temperature of 2100 deg F (1149 deg C) shows typical near complete decomposition (solutioning) of gamma prime precipitate. (1000x)

Inconel 713C (IAE 655) heated to a metal temperature of 2150 deg F (1177 deg C) shows typical complete decomposition (solutioning) of gamma prime precipitate. (1000x)

Inconel 713C (IAE 655) heated to a metal temperature of 2200 deg F (1204 deg C) shows typical complete decomposition (solutioning) of gamma prime precipitate with possible small areas of incipient melting. (1000x)

Inconel 713C (IAE 655) heated to a metal temperature of 2250 deg F (1232 deg C) shows typical complete decomposition (solutioning) of gamma prime precipitate and an area of incipient melting (Arrow). (1000x)

Inconel 713C (IAE 655) heated to a metal temperature of 2300 deg F (1260 deg C) shows typical melting (Arrows) in grain boundaries. (1000x)

NOTE

Use optical microscope equipment at 1000x magnification to examine the microstructure specimens.

Figure:

Figure:

Figure:

Figure:

Figure:

Figure:

Figure:

Figure: