Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-02-10-220-501 IAE 1422 Microstructure For Metal Temperature Analysis

General

NOTE

Refer to the SPM TASK 70-02-03-220-501 for the procedure to do a metal temperature analysis on nickel base alloys.

IAE 1422 is the specification for nickel-base, 9.0 percent chromium, 10.0 percent cobalt, 12.0 percent tungsten, 1 percent columbium (niobium), 2.0 percent titanium, 5.0 percent aluminum, 1.6 percent hafnium, 0.015 percent boron, vacuum melted, directionally-solidified investment casting. The microstructure standards for the heat treated and coated alloy are contained in separate paragraphs in this section.

The microstructure of the blade root or shroud sections is not affected due to the relatively low metal temperature obtained during engine operation. This microstructure supplies an optimum baseline for comparison with the airfoil hot zone for metal temperature determination.

Figure shows typical microstructure below 2000 deg F (1093 deg C) of IAE 1422 DS nickel base alloy, which is:

Heat treated at 2210 to 2270 deg F (1210 to 1243 deg C).

Cooled to below 1200 deg F (649 deg C) at a rate equivalent to air cool or faster.

Heated to 1950 to 2000 deg F (1066 to 1094 deg F) for four hours and cooled at a rate equivalent to air cool or faster.

Precipitation Heat Treated at 1575 to 1625 deg F (857 to 885 deg C) for 32 hours and air cooled.

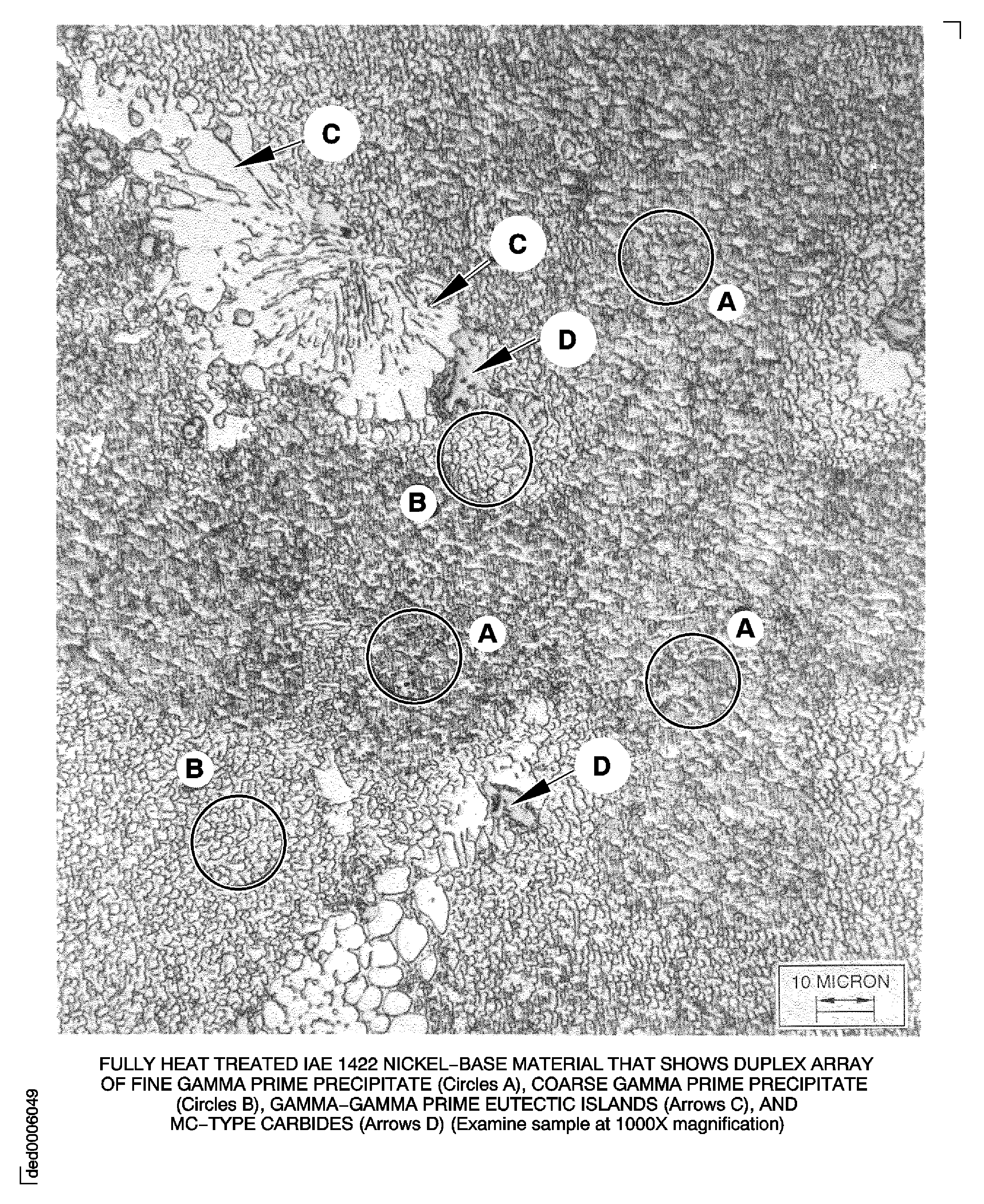

The typical microstructure of this fully heat treated super-alloy is characterized by a duplex array of gamma prime precipitate (Ni3Al,Ti) in a gamma matrix (nickel base solid solution). See Figure. This array consists of:

A fine, regularly spaced, quasi-rectangular gamma prime precipitate in dendritic arms.

A somewhat coarser gamma prime precipitate bordering the periphery of eutectic gamma prime islands which are located at interdendritic regions.

Grain boundaries

Also two types of MC carbides:

HfC and (45Ti, 35Nb, W, Hf)C, generally associated with eutectic gamma prime.

M23C6 (Cr rich) decorating the grain boundaries.

Effects of Temperature on the Microstructure

The most obvious effects of high temperature on the matrix gamma prime precipitate are changes in:

Concentration

Size

Distribution

Other microstructural changes are:

Coalescence of the phases and gamma-prime eutectic

Decomposition and solutioning of carbides

Stability of matrix (that is, incipient melting).

Fig. 70-02-10-990-006 thru Figure represent microstructures for static furnace temperature attainments to 2200 deg F (1204 deg C), 2250 deg F (1232 deg C), and 2300 deg F (1260 deg C).

Description of Micrographs Illustrating Microstructural Features

NOTE

Figure shows fully heat treated IAE 1422 with a duplex array of fine gamma prime precipitate (Circles A), coarse gamma prime precipitate (Circles B), gamma-gamma prime eutectic islands (Arrows C), and MC-type carbides (Arrows D).

NOTE

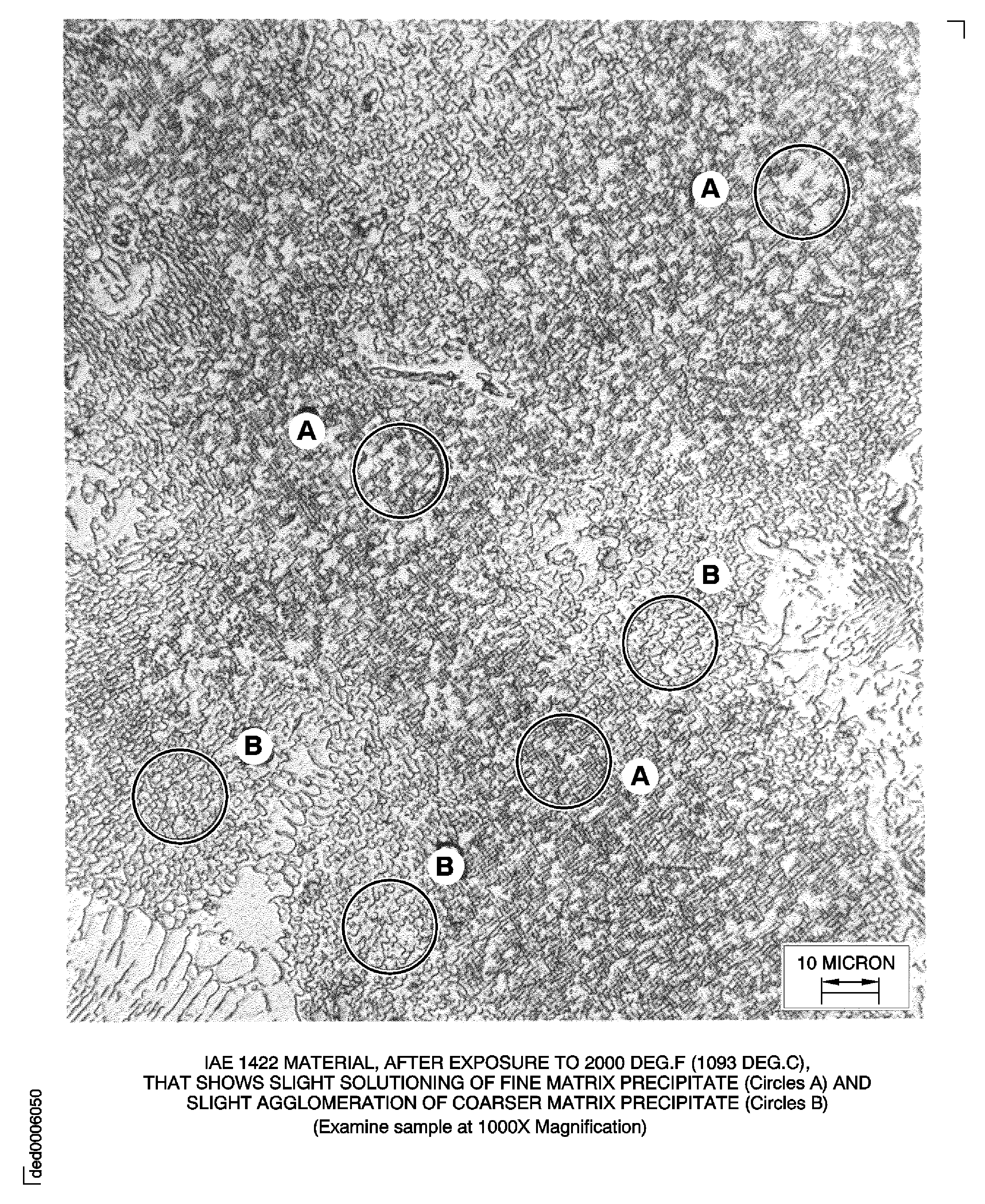

Figure shows the slight solutioning of the fine matrix precipitate (Circles A), and slight agglomeration of coarser matrix precipitate (Circles B).

NOTE

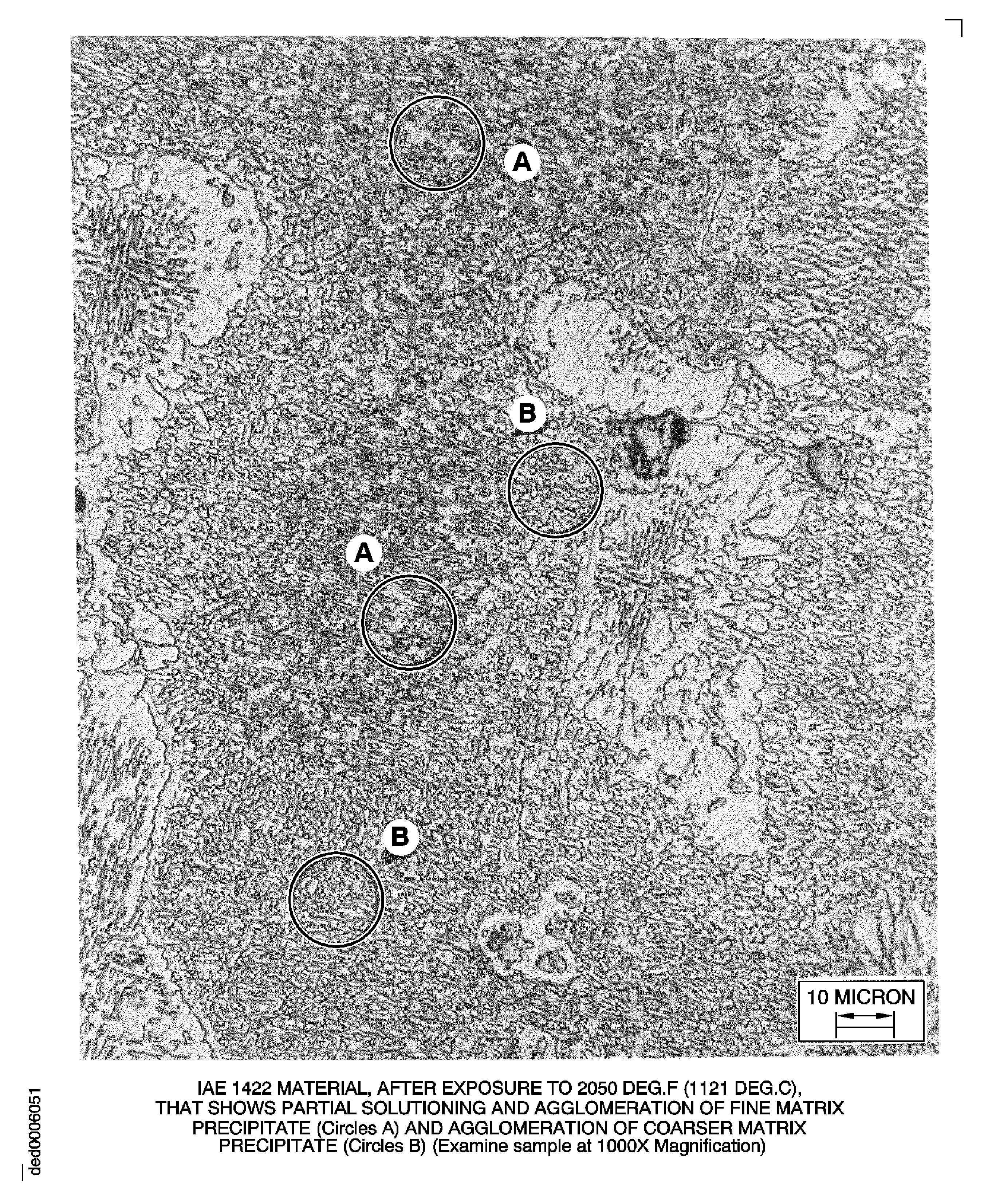

Figure shows the partial solutioning and agglomeration of fine matrix precipitate (Circles A), and agglomeration of coarser matrix precipitate (Circles B).

NOTE

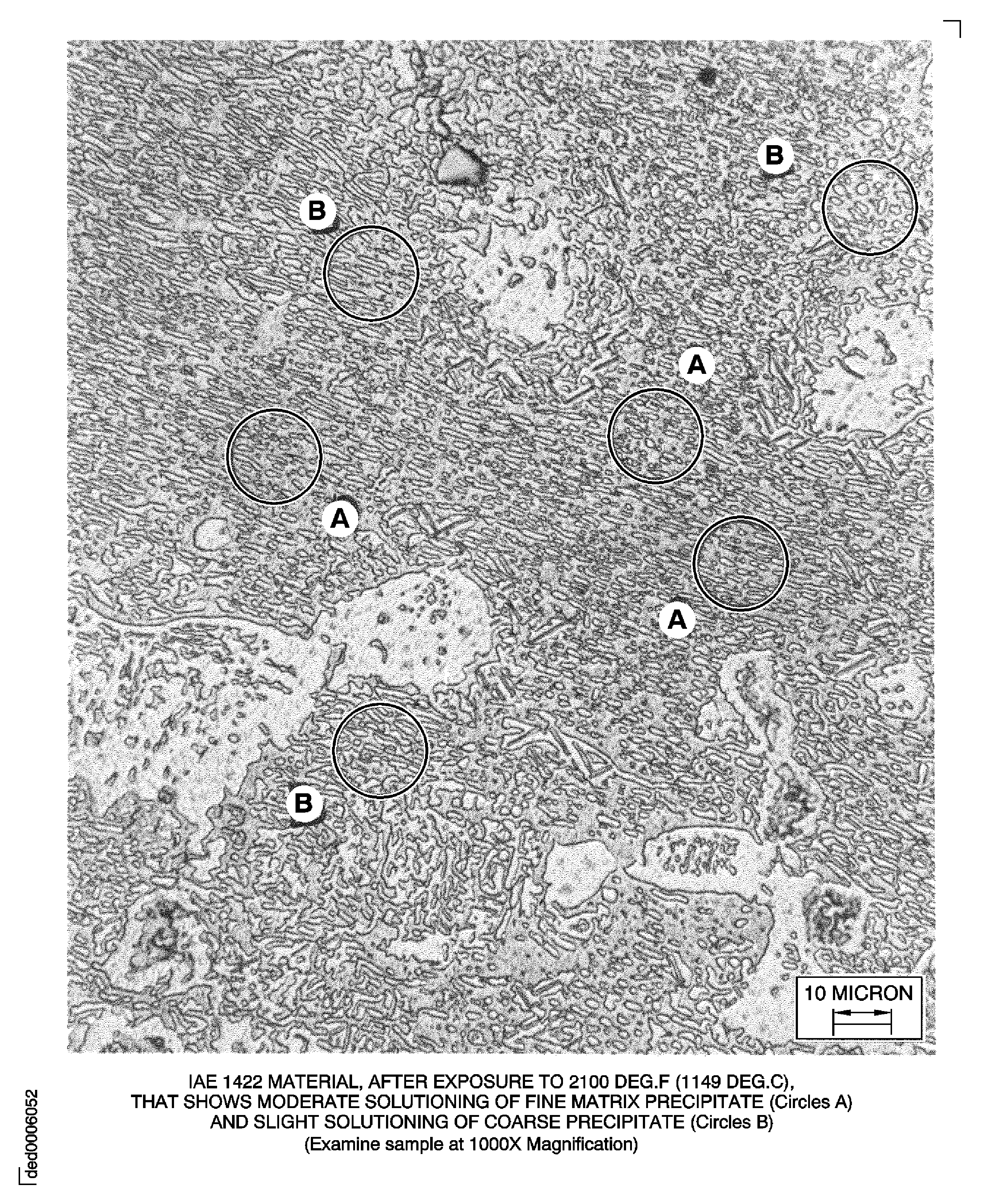

Figure shows moderate solutioning of fine matrix precipitate (Circles A), and slight solutioning of coarse precipitate (Circles B).

NOTE

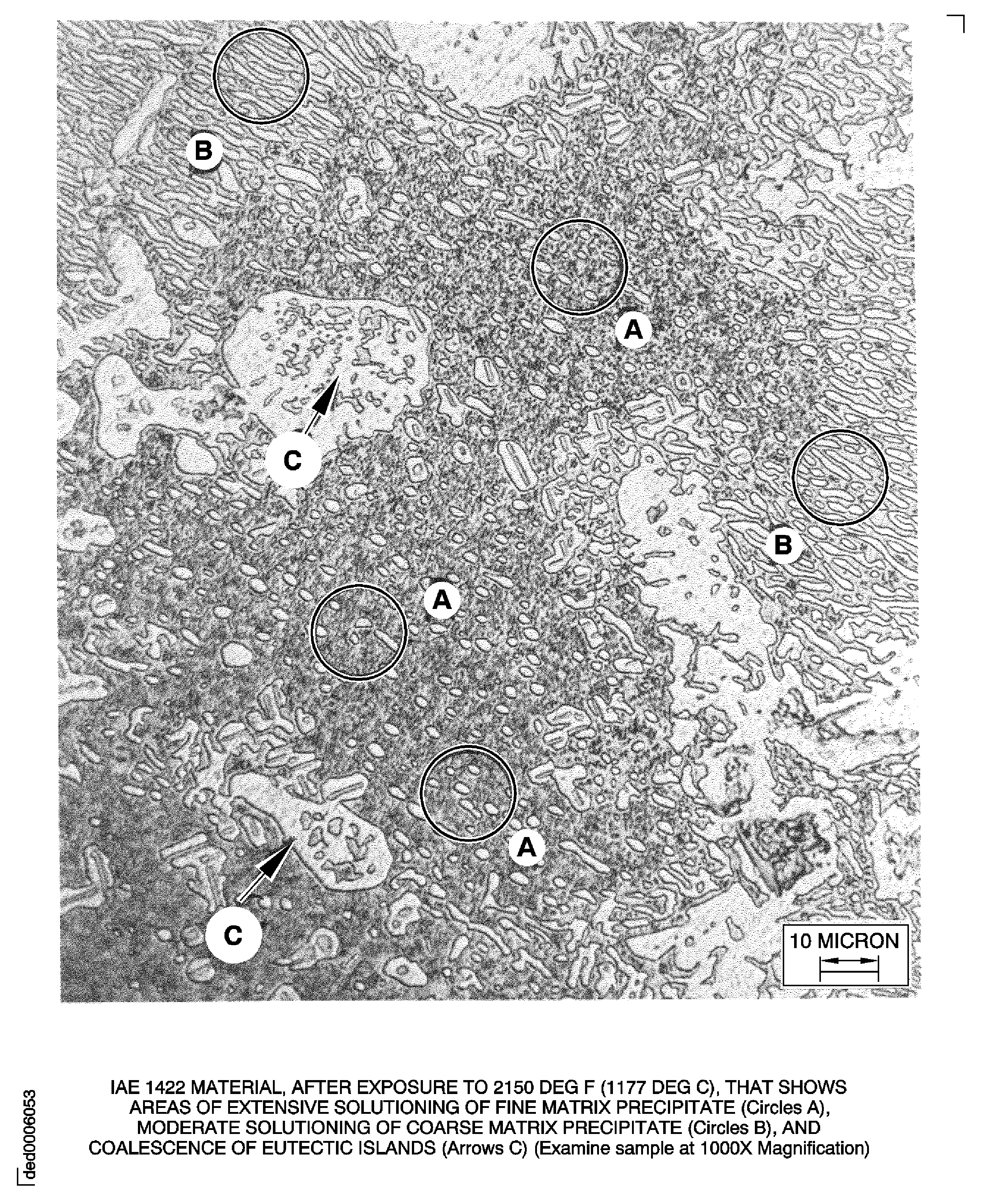

Figure shows areas of extensive solutioning of fine matrix precipitate (Circles A), moderate solutioning of coarse precipitate (Circles B), and coalescence of eutectic islands (Arrows C).

NOTE

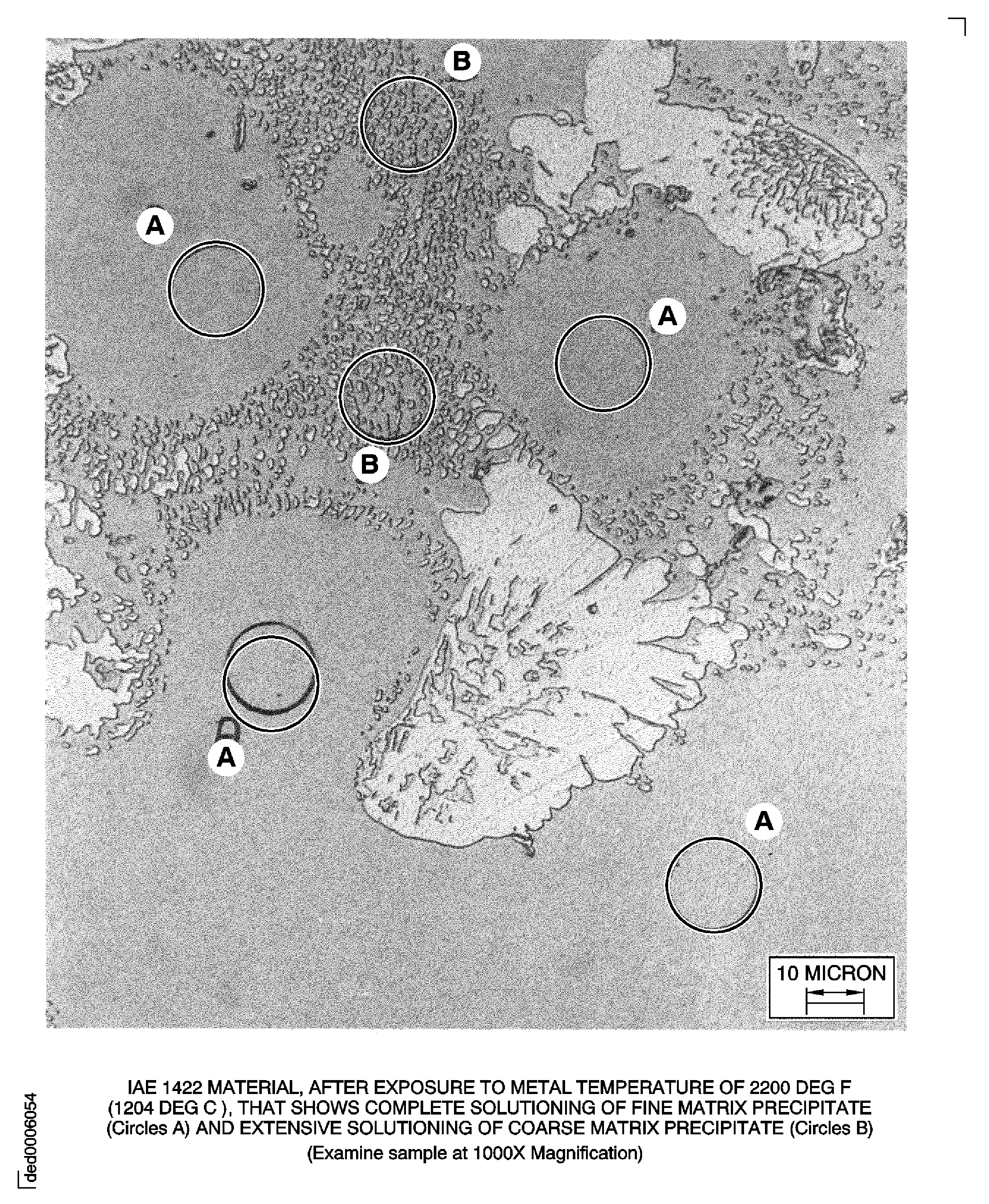

Figure shows complete solutioning of fine matrix precipitate (Circles A), and extensive solutioning of coarse matrix precipitate (Circles B).

NOTE

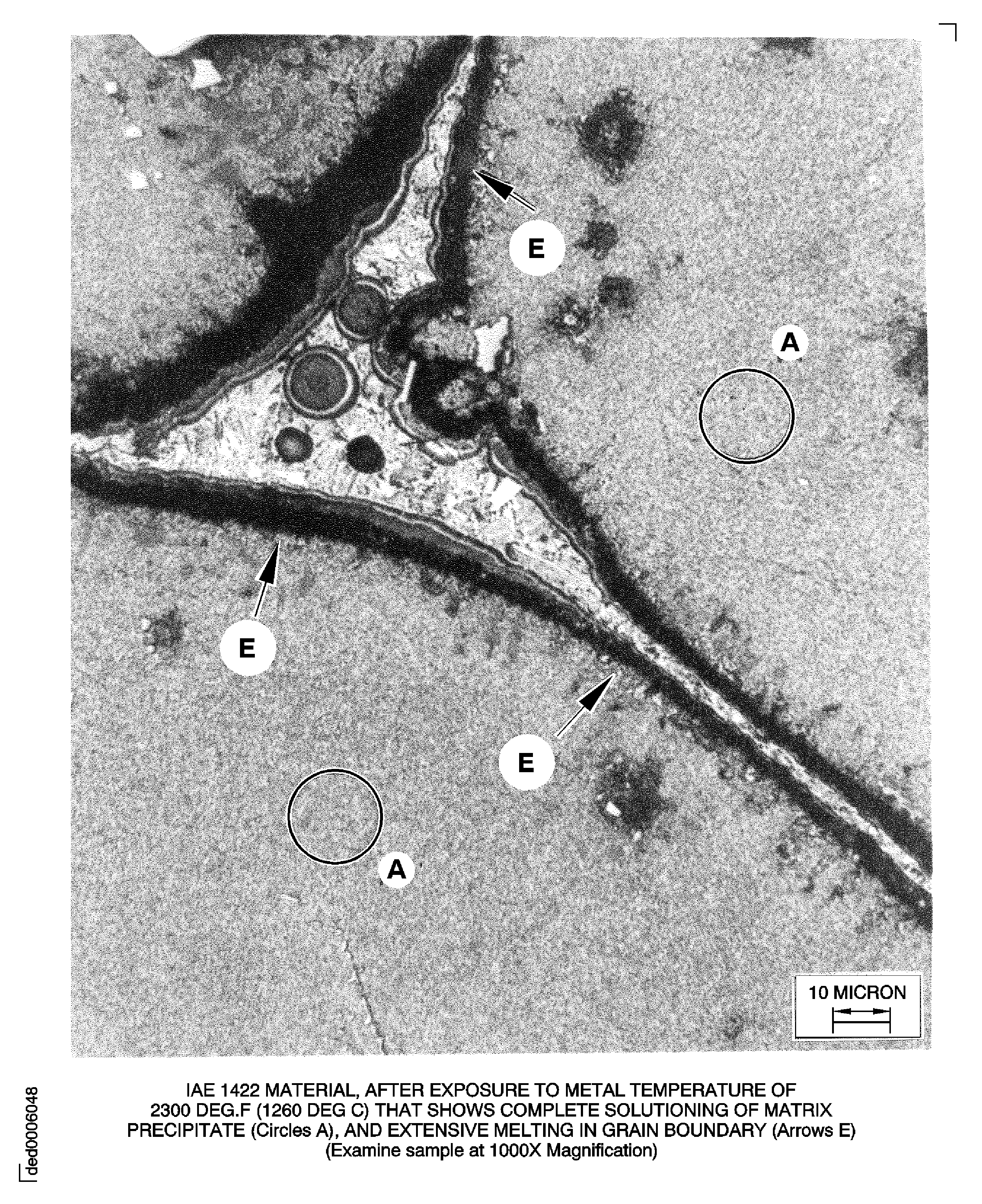

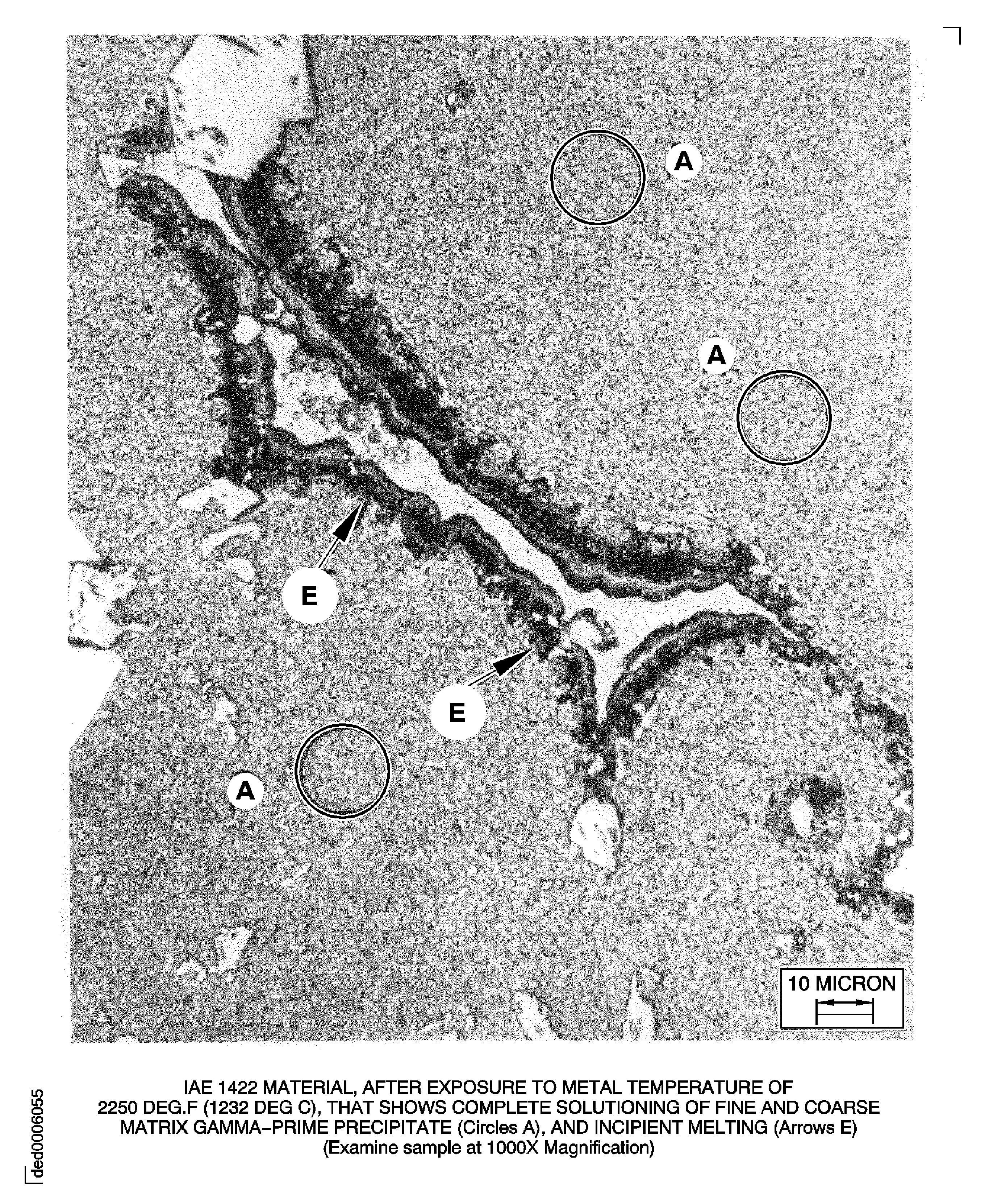

Figure shows complete solutioning of fine and coarse matrix gamma-gamma prime precipitate (Circles A), and incipient melting (Arrows E).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Optical microscopic equipment | LOCAL | Optical microscopic equipment | 1000x |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Figure: Fig 70-02-10-990-001

Fig 70-02-10-990-001

Figure:

Figure:

Figure:

Figure:

Figure:

Figure:

Figure: