Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 70-21-00-220-501 General Information For Visual Inspection

General

NOTE

Personnel Qualifications: Only a qualified person is permitted to do a visual inspection. Inspectors must have normal or corrected vision, and have regular eye examinations.Handle parts with care to prevent nicks, dents, scratches, and other damage.

Inspect parts to applicable specified limits in Interactive Electronic Technical Publication (IETP). Observed damage or service-generated conditions not mentioned in the IETP are not acceptable. Common examples of nonconforming conditions are:

Cracks (unless specified differently, cracks are not repairable).

Corrosion (pitting, erosion, etc.).

Handling and surface damage (nicks, dents, raised material, etc.).

Wear (galling, scoring, etc.).

Tears.

Lighting.

Use fluorescent tube lights or Light Emitting Diode (LED) lights for visual inspection lighting.

To get the best results during visual inspection and to make it possible to read gages accurately, the white light intensity at the inspection table top or part/engine surface must be 100 footcandles (1000 lux) minimum.

For disassembly, cleaning, assembly, and repair operations, the white light intensity at the part/engine surface must be 50 footcandles (500 lux) minimum.

Magnification.

Unless otherwise specified, do not use magnification to do the inspection. It is permitted to use a magnification of 3 - 10X as an aid to examine an observed/found condition to see if it is an indication of damage.

How to use a stylus.

Hold the stylus lightly, near the top, between your thumb and forefinger.

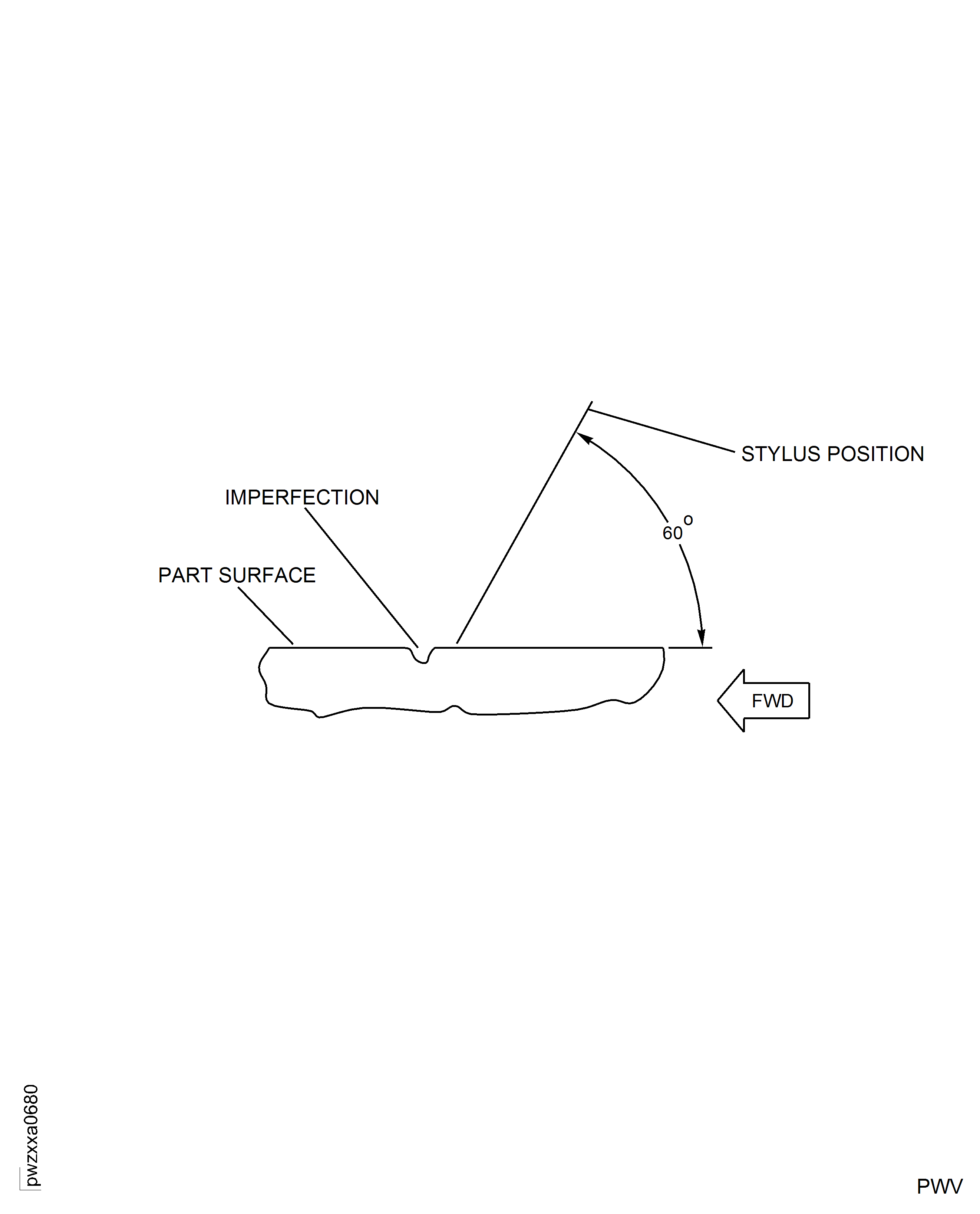

Incline/slope the stylus at a 60 degree angle to the part surface in the direction of the imperfection. See Figure. If the 60 degree stylus position is not possible because of the shape of the part, hold the stylus at a 90 degree angle to the inspection surface.

Push the stylus forward over the surface to and across the imperfection. Do not apply pressure other than the weight of the stylus itself, in a direction approximately 90 degree to the general lay of the imperfection.

If the point of the stylus does not catch (hesitate) in the surface imperfection, the imperfection is acceptable.

The size limits specified for imperfections are absolute; however, for length, width, and depth values, it is permitted to use all practical means to do a check of the size.

General visual inspection instructions for all inspectors.

Unless specified differently by the Engine Manual or Service Bulletin repair/modification requirements, the inspector/operator, who does the visual inspection of parts, must make sure to:

Remove, before the start of the physical measurement, all conditions or material that can cause measurements not to be accurate.

Make smooth or remove burrs, minor galling, pitting and scratches with hand held abrasive paper or cloth or with fine stones.

NOTE

When to break sharp edges during the inspection is the decision of the inspector.Where required, break sharp edges 0.003 in. to 0.015 in. (0.08 mm to 0.38 mm).

Acceptance Limits

The part inspection data contained in the IETP is primarily intended to determine the acceptability for continued use of service-operated parts and is not intended for the inspection of new replacement parts.

New replacement parts provided by IAE are acceptable for engine installation without inspection since these parts are inspected and accepted under IAE's FAA-issued manufacturing certificate for each engine model.

Visual inspection of new parts may reveal conditions that were accepted during original part FAA-approved manufacturing process.

All Parts - Rotating And Non-Rotating

Visual imperfections that will be removed by subsequent machining are acceptable. Unless specified differently, cracks are not reparable.

Superficial imperfections are acceptable.

Burnish marks are acceptable.

Water discoloration, light gray or light brown in color, is acceptable.

Non-Rotating Parts Only

Shallow imperfections are acceptable. This condition requires a stylus for evaluation.

Chatter marks on all surfaces that meet surface texture (finish) requirements are acceptable.

Drilled holes.

Circumferential tool marks up to 0.003 in. (0.076 mm) deep, are permitted in the bore of drilled holes if:

They do not affect an area that is more than 10 percent of the part thickness or hole depth.

They are free of raised metal.

They are not within 10 percent of part thickness dimension from either end of the hole.

They do not break into the radius area at either end of the hole.

Counterbored holes.

Steps in the counterbore diameter up to 0.003 in. (0.076 mm) deep are acceptable if:

They are smooth.

They do not affect an area greater than 10 percent of the counterbore area.

Scallops.

Circumferential tool marks up to 0.003 in. (0.076 mm) deep, are permitted in the surface of scallops if:

They are free from raised material.

They do not break an edge.

They do not extend from one scallop to an adjacent scallop in a single line.

Surface with drilled holes.

False drill starts with a maximum depth that is the smaller of 0.005 in. (0.127 mm) or 10 percent of the part thickness are acceptable if:

They are round-bottomed.

They are free from raised material.

They are free from sharp edges.

They are 0.100 in. (2.540 mm) minimum away from the nearest edge.

Welds.

Unless specified differently by the Engine Manual, Component Maintenance Manual, CIR Manual, Service Bulletin repair/ modification requirements, discontinuities (such as pits, voids, dross, and shrinkage) are acceptable.

Procedures To Measure Surface Conditions

Refer to SPM TASK 70-22-03-220-501 for the procedures to measure surface conditions.

Figure: Correct Position To Hold AStylus

Correct Position To Hold AStylus