Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 70-25-00-250-501 Eddy Current Inspection General Data

General

Eddy current inspection is a procedure used to find discontinuities at or near the surface of a component; it will not cause damage to the component. This procedure can only be used on components that are electrical conductors.

Only approved Inspectors are permitted to do eddy current inspections.

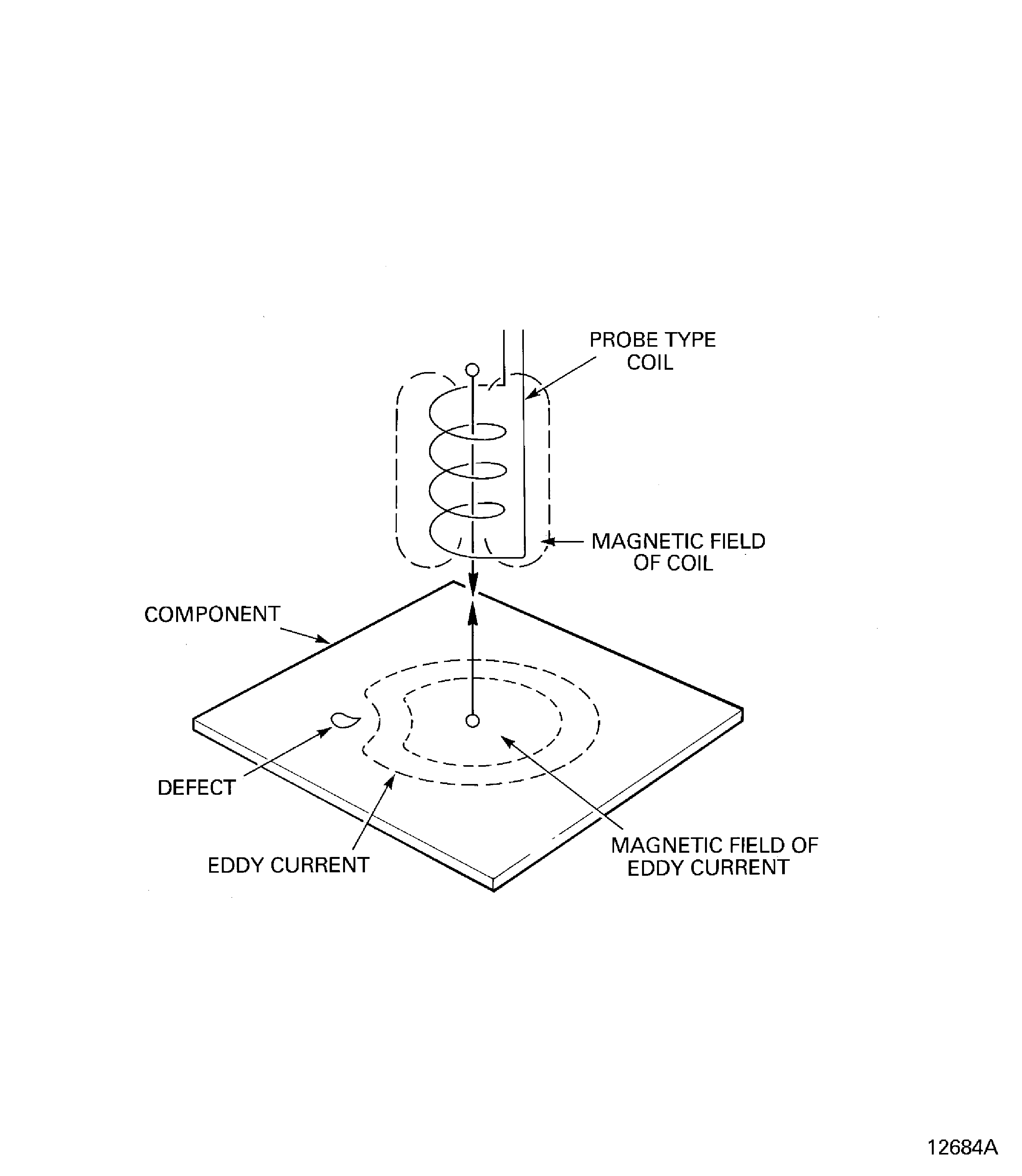

To start eddy currents in the surface of a component; an electrical current of applicable frequency is supplied to a test coil (probe). Refer to Figure. The coil causes a magnetic field of the same frequency which makes eddy currents in the component. A defect in the component changes the intensity of the eddy current which also has an effect on the magnetic field; this effect changes the condition of the test coil (probe). An electronic analysis can be made of the changes in the condition of the probe. These changes can be seen on an analog meter or a cathode ray tube display.

Figure: Eddy current inspection

Eddy current inspection