Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-31-16-310-501 Nickel Alloy Brazing

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-010 ARGON GAS | LOCAL | CoMat 03-010 | ||

| CoMat 03-117 ARGON GAS | 0AM53 | CoMat 03-117 | ||

| CoMat 03-138 HYDROGEN GAS (PROTECTIVE ATMOSPHERE) | 0B434 | CoMat 03-138 | ||

| CoMat 03-150 DELETED | 0AM53 | CoMat 03-150 | ||

| CoMat 03-249 BRAZING FILLER MATERIAL,Ni-BASE | LOCAL | CoMat 03-249 | ||

| CoMat 03-250 BRAZING FILLER MATERIAL,Ni-BASE | 01FK3 | CoMat 03-250 | ||

| CoMat 03-251 BRAZING FILLER MATERIAL,Ni-BASE | LOCAL | CoMat 03-251 |

Spares

NONESafety Requirements

WARNING

Procedure

Identification PWA 36950-3 (Ref), Braze filler metal (See note 1.) CoMat 03-249 BRAZING FILLER MATERIAL,Ni-BASE or CoMat 03-150 DELETED, or CoMat 03-251 BRAZING FILLER MATERIAL,Ni-BASE. Wide gap filler metal (See note 2.) CoMat 03-250 BRAZING FILLER MATERIAL,Ni-BASE.

Filler metal must be identified by this specification number and suffix number as follows.

SUBTASK 70-31-16-310-002 Materials

NOTE

Preforms must be used for tube-to-fitting joints.Specified wide gap filler materials can be used in addition to identified filler metal for vane and shroud assemblies, and for other parts when specified.Flux must not be used.Refer to Figure.

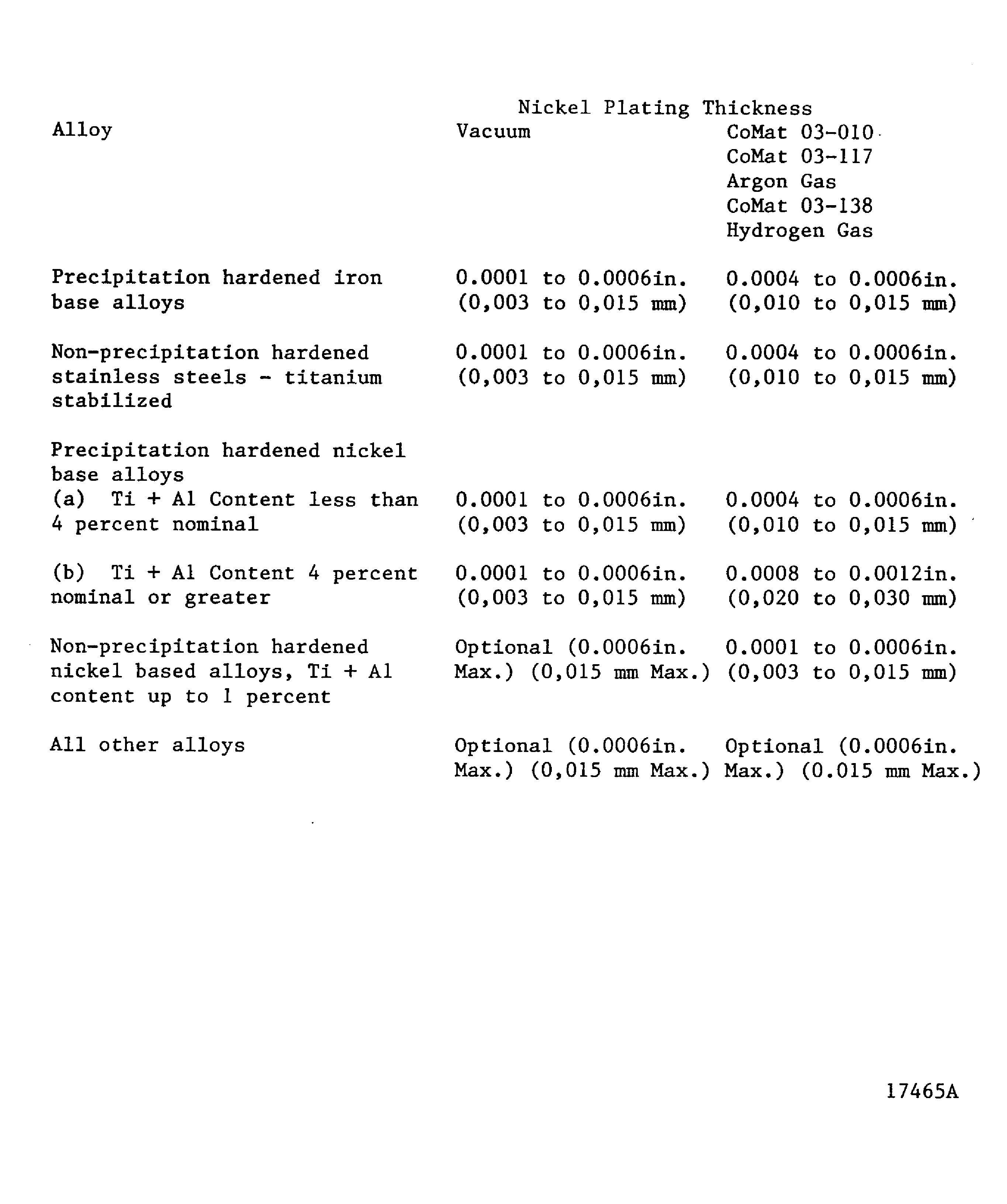

SUBTASK 70-31-16-310-003 Brazing Atmosphere

Refer to Figure.

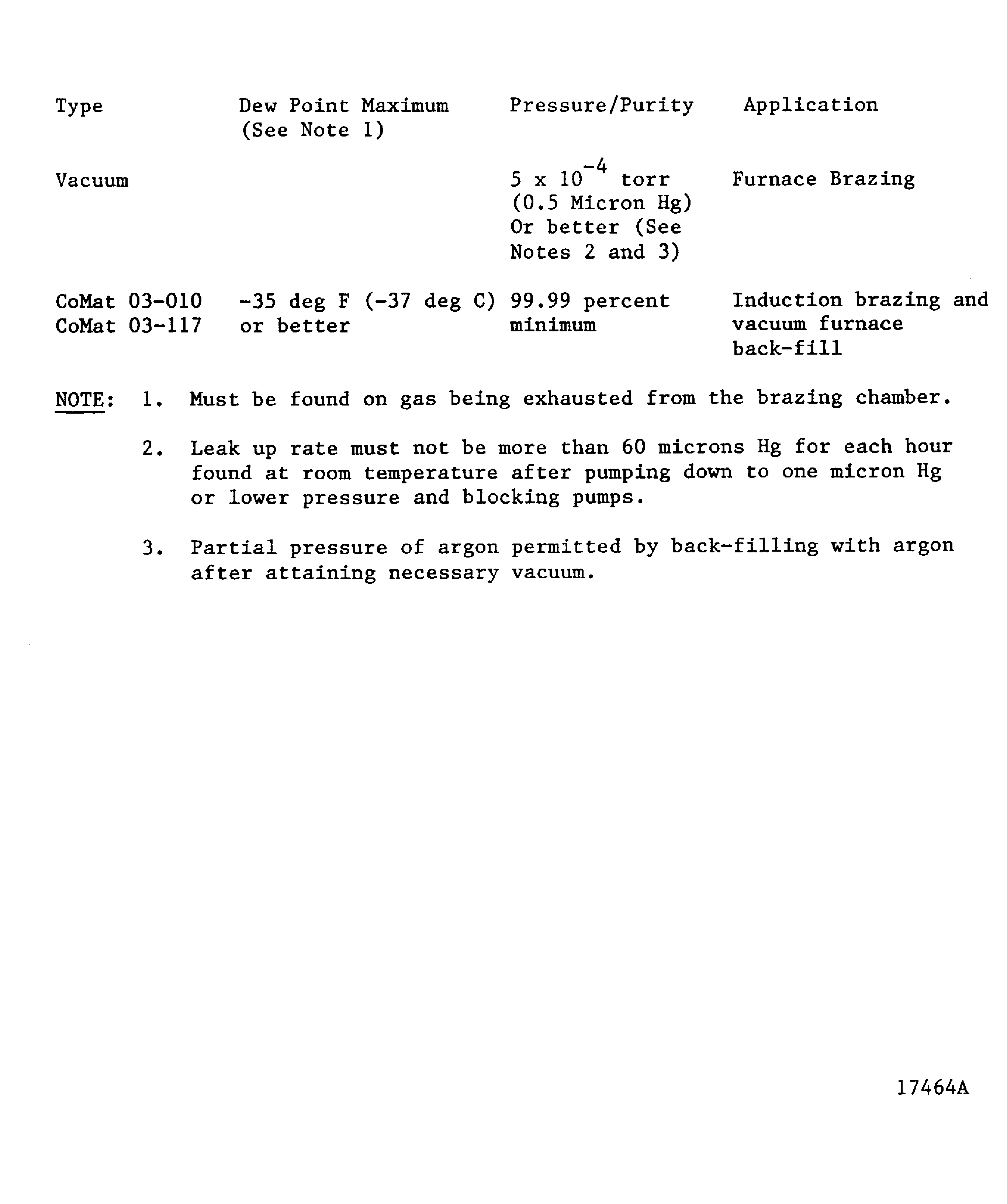

For induction or furnace brazing in a protective atmosphere, or in a vacuum, surfaces of these materials to be joined by silver, gold, or nickel braze alloy must be nickel plated in the brazing area (TASK 70-33-06-300-503) to the applicable thickness specified in Figure.

Nickel plating (where specified).

SUBTASK 70-31-16-310-004 Preparation

Heating of parts to be brazed must be done in a furnace apart from alloys which do not get hard by heat treatment which can be heated by electrical induction. Parts must be heated to a stabilization temperature and held until both temperature and pressure have stabilized as follows. Identification PWA 36950-3 (Ref). Stabilization temperature 1675 deg to 1750 deg F (913 deg to 954 deg C). Brazing temperature maximum (See note 1) 1950 deg F (1065.6 deg C). Temperature must then be raised quickly to the brazing temperature (See note 2).

SUBTASK 70-31-16-310-005 Procedure

NOTE

Part temperature must not be more than this maximum during brazing cycle.Time at brazing temperature must be more than 30 minutes. When extended time at temperature is necessary to aid diffusion, it must be as specified in note 3.When suffix letter D is specified after suffix number, total time at brazing temperature must be 170 to 190 minutes.

CAUTION

COOLING RATES SPECIFIED BY THE ENGINE MANUAL MAY BE DIFFERENT FROM THE STANDARD PRACTICES/PROCEDURE MANUAL (SPM). ADHERENCE TO ENGINE MANUAL REPAIR INSTRUCTIONS SUPERSEDES THE SPM REPAIR INSTRUCTIONS.Decrease the temperature of assemblies to the "Braze Quench" temperature at a rate (slow or fast) to prevent cracks and minimize internal stress and distortion.

Alloys which get hard by heat treatment must be cooled at a rate not less than 35 deg F (19 deg C)/minute from below the "Braze Quench" temperature to 1100 deg F (593 deg C) and not less than 15 deg F (8 deg C)/minute from 1100 deg F (593 deg C) to 1000 deg F (538 deg C). Use any rate below 1000 deg F (538 deg C). There is no requirement to hold parts at the "Braze Quench" temperature during cooling from the braze temperature.

SUBTASK 70-31-16-310-006 Cooling

Local rebrazing of compressor vane and shroud assemblies is permissible to fill braze voids using critical braze alloy wire. Heating must be by plasma or gas tungsten arc torch for each approved procedure. Assemblies which include materials which get hard must be solution heat treated or austenitized, as applicable after rebrazing.

SUBTASK 70-31-16-310-007 Rebrazing

A check of the exterior of the joint must show a full line or ring of brazing alloy between the component parts at end of joint to which brazing alloy was put in use and when applicable, must show at least a metallic stain of brazing alloy at opposite end of joint, to show full entry of brazing alloy in the joint.

Appearance.

Brazed parts must agree to the subsequent specifications.

SUBTASK 70-31-16-310-008 Properties

Figure: Brazing atmosphere

Brazing atmosphere

Figure: Nickel plating

Nickel plating