Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-35-08-300-501 Install And Repair Wire Thread Inserts

Equipment and Material | ||

General | ||

Remove the Wire Thread Insert | ||

Machine the Hole | ||

Apply Protection | ||

Install the Wire Thread Insert | ||

Do a Crack Test on the Repaired Area | ||

Do an Inspection of the Wire Thread Inserts | ||

Do an Inspection on the Repair Insert for Machining and Installation | ||

Machine the Hole | ||

Apply Protection after Machining the Hole | ||

Install the Repair Inserts | ||

Install the Wire Thread Inserts | ||

Do a Crack Test on the Repaired Area | ||

Do an Inspection on the Wire Thread Insert | ||

Approved Hand Tools (Tables 1, 2A, 2B, 3, and 4) |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 | ||

| CoMat 10-059 ENGINE LUBRICATING OIL | 0AM53 | CoMat 10-059 |

Spares

NONESafety Requirements

NONEProcedure

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURER'S MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS. THESE CONTAIN INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.NOTE

Unless approved by an International Aero Engines AG repair, do not install wire thread inserts.This TASK gives instructions for the replacement of damaged inserts and the repair of damaged threads with the use of new inserts. It also gives instructions for the installation and repair of inserts in light alloy materials.

SUBTASK 70-35-08-860-002 General

After selection of the applicable insert apply a layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the threads; also apply a layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the threads of magnesium components. Refer to Figure.

SUBTASK 70-35-08-350-002 Install the Wire Thread Insert

Do a crack test on the repaired area. Refer to the SPM TASK 70-23-01-230-501, SPM TASK 70-23-04-230-501, SPM TASK 70-23-03-230-501 or SPM TASK 70-23-02-230-501.

SUBTASK 70-35-08-230-001 Do a Crack Test on the Repaired Area

Do a dimensional inspection on the component to make sure boss proportions are sufficient for machining. Refer to Figure.

SUBTASK 70-35-08-220-002 Do an Inspection on the Repair Insert for Machining and Installation

After selection of the applicable insert apply a layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to threads; also apply a layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the threads of magnesium components. Refer to Figure.

Do a visual inspection of the insert. Refer to Figure.

SUBTASK 70-35-08-350-003 Install the Repair Inserts

After selection of the applicable insert apply a layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to threads; also apply a layer of CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE to the threads of magnesium components. Refer to Figure.

SUBTASK 70-35-08-350-004 Install the Wire Thread Insert

Do a crack test on the repaired area. Refer to the SPM TASK 70-23-01-230-501, SPM TASK 70-23-03-230-501, SPM TASK 70-23-04-230-501 or SPM TASK 70-23-02-230-501.

SUBTASK 70-35-08-230-002 Do a Crack Test on the Repaired Area

SUBTASK 70-35-08-860-003 Approved Hand Tools

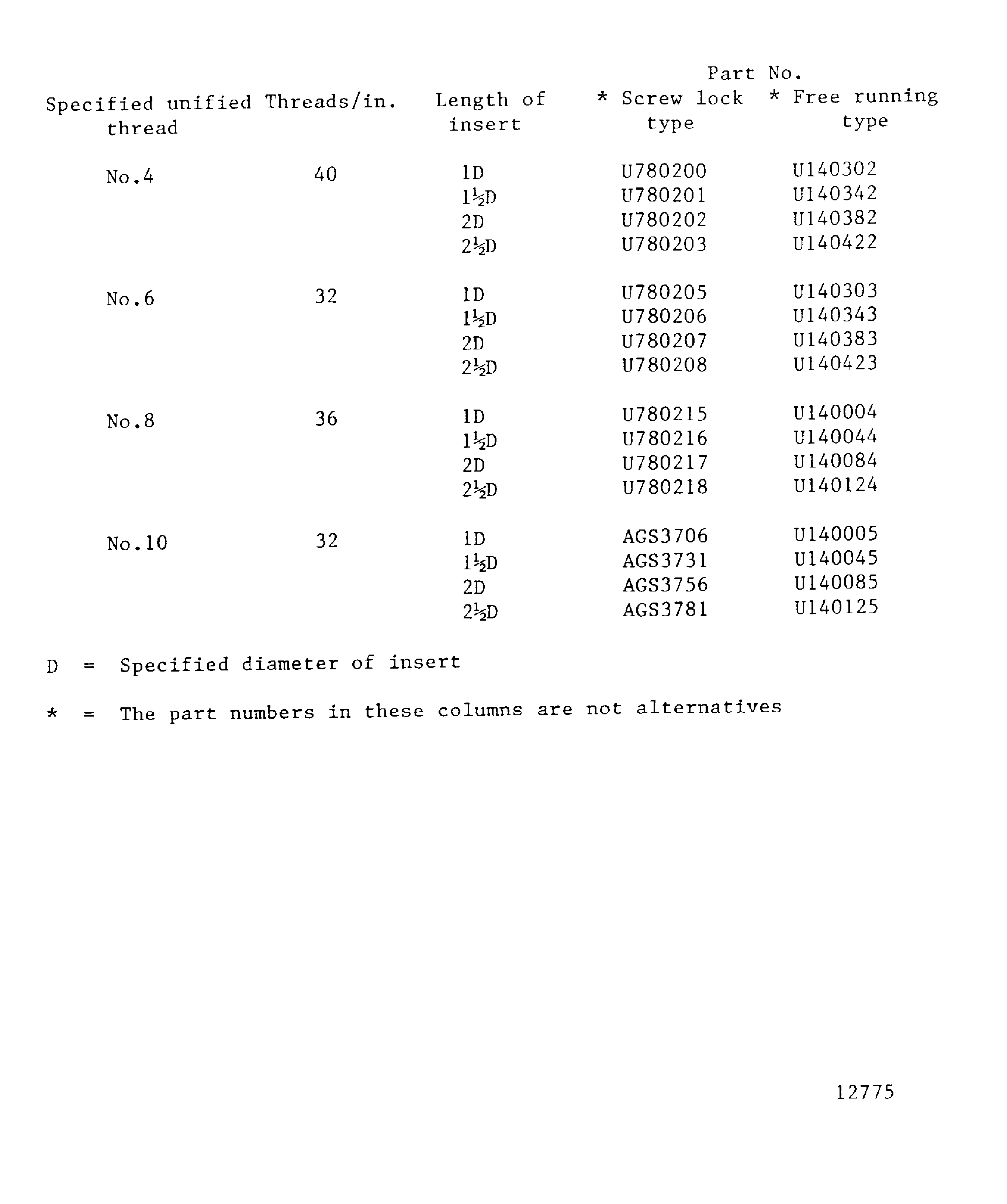

Table 3. Table 1 Approved Hand Tools by Size Number Specified Unified Thread

No. 4

No. 6

No. 8

No. 10

Item

Threads/in.

40

32

36

32

Extraction tool

2R19579

2R19579

2R19579

2R19605

1

Insertion tool (pre-wind type)

2R19580

2R19590

2R19597

2R19606

2

Tang removal tool

2R19581

2R19591

2R19598

2R19607

3

Roughing tap

2R19582

2R19592

2R19599

2R19608

4

Plug tap

2R19583

2R19593

2R19600

2R19609

5

Bottoming tap

2R19584

2R19594

2R19601

2R19610

6

Special gage for tapped hole

2R19585

2R19595

2R19602

2R19611

7

Cross thread gage

NIL

NIL

2R19603

2R19612

8

Torque check plug

2R19586

2R19596

2R19604

2R19613

9

Torque adapter

2R19587

2R19587

2R19587

2R19587

10

Torquemaster

2R19588 (all threads)

11

Torque setting rig

2R19589

2R19589

2R19589

2R19589

12

Table 4. Table 2A Approved Hand Tools by Dimension (0.25 in. to 0.4375 in.) Specified Unified Thread

0.250 in.

0.3125 in.

0.375 in.

0.4375 in.

Item

Threads/in.

28

24

24

20

Extraction tool

2R19616

2R19616

2R19634

2R19643

1

Insertion tool (pre-wind type)

2R19617

2R19625

2R19635

2R19644

2

Tang removal tool

2R19618

2R19626

2R19636

2R19645

3

Roughing tap

2R19619

2R19627

2R19637

2R19646

4

Plug tap

2R19620

2R19628

2R19638

2R19647

5

Bottoming tap

2R19621

2R19629

2R19639

2R19648

6

Special gage for tapped hole

2R19622

2R19630

2R19640

2R19649

7

Cross thread gage

2R19623

2R19631

2R19641

2R19650

8

Torque check plug

2R19624

2R19632

2R19642

2R19651

9

Torque adapter

2R19587

2R19587

2R19587

2R19587

10

Torquemaster

2R19588 (all threads)

11

Torque setting rig

2R19589

2R19589

2R19589

2R19589

12

Table 5. Table 2B Approved Hand Tools by Dimension (0.500 in.) Specified Unified Thread

0.500 in.

Item

Threads/in.

20

Extraction tool

2R19643

1

Insertion tool (pre-wind type)

2R19652

2

Tang removal tool

2R19653

3

Roughing tap

2R19654

4

Plug tap

2R19655

5

Bottoming tap

2R19656

6

Special gage for tapped hole

2R19657

7

Cross thread gage

NIL

8

Torque check plug

2R19658

9

Torque adapter

2R19587

10

Torquemaster

2R19588 (all threads)

11

Torque setting rig

2R19589

12

Table 6. Table 3 Approved Hand Tools Insert Thread

No. 10

0.250 in.

0.3125 in.

0.375 in.

Item

Threads/in.

32

28

24

24

Special drill

1R19697

1R19706

1R19716

1R19725

9

Counterbore tool (cutter)

1R19698

1R19707

1R19717

1R19726

10

Tap

1R19699

1R19708

1R19718

1R19727

11

Insert driver

1R19700

1R19709

1R19719

1R19728

12

Table 7. Table 4 Tools Used To Cut By Hand Insert Thread

No. 10

0.250 in.

0.3125 in.

0.375 in.

Item

Threads/in.

32

28

24

24

Pilot Screw

1R19701

1R19710

1R19720

1R19729

13

Counterbore tool (cutter)

1R19702

1R19711

1R19721

1R19730

14

Counterbore stop

1R19703

1R19712

1R19722

1R19731

15

Hollow cutter

1R19704

1R19713

1R19723

1R19732

16

Radius cutter

1R19705

1R19714

1R19724

1R19733

17

Figure: Wire thread insert dimensions

Wire thread insert dimensions

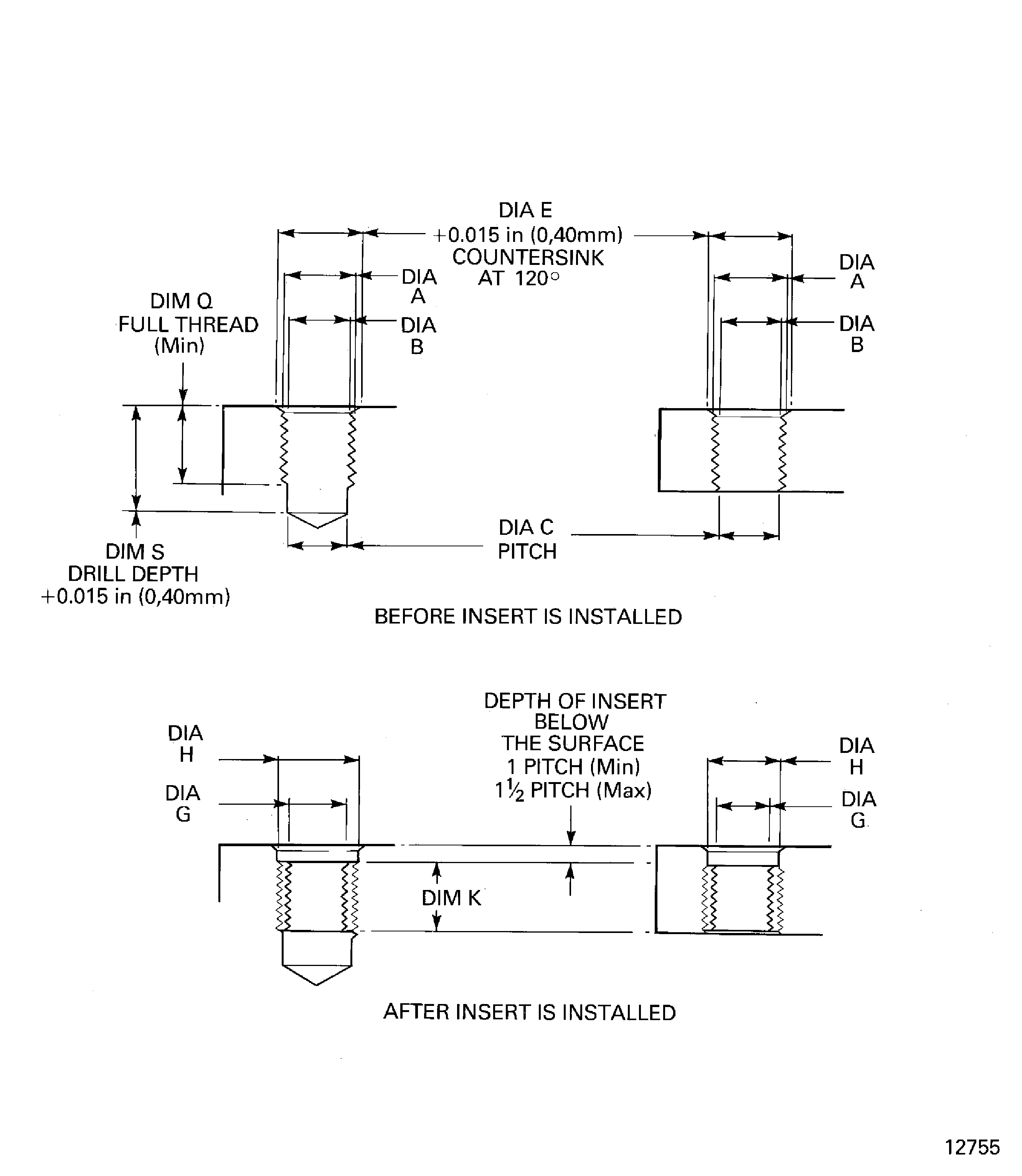

Figure: Threaded hole dimensions for wire thread inserts

Threaded hole dimensions for wire thread inserts

Figure: Threaded hole dimensions for wire thread inserts

Threaded hole dimensions for wire thread inserts

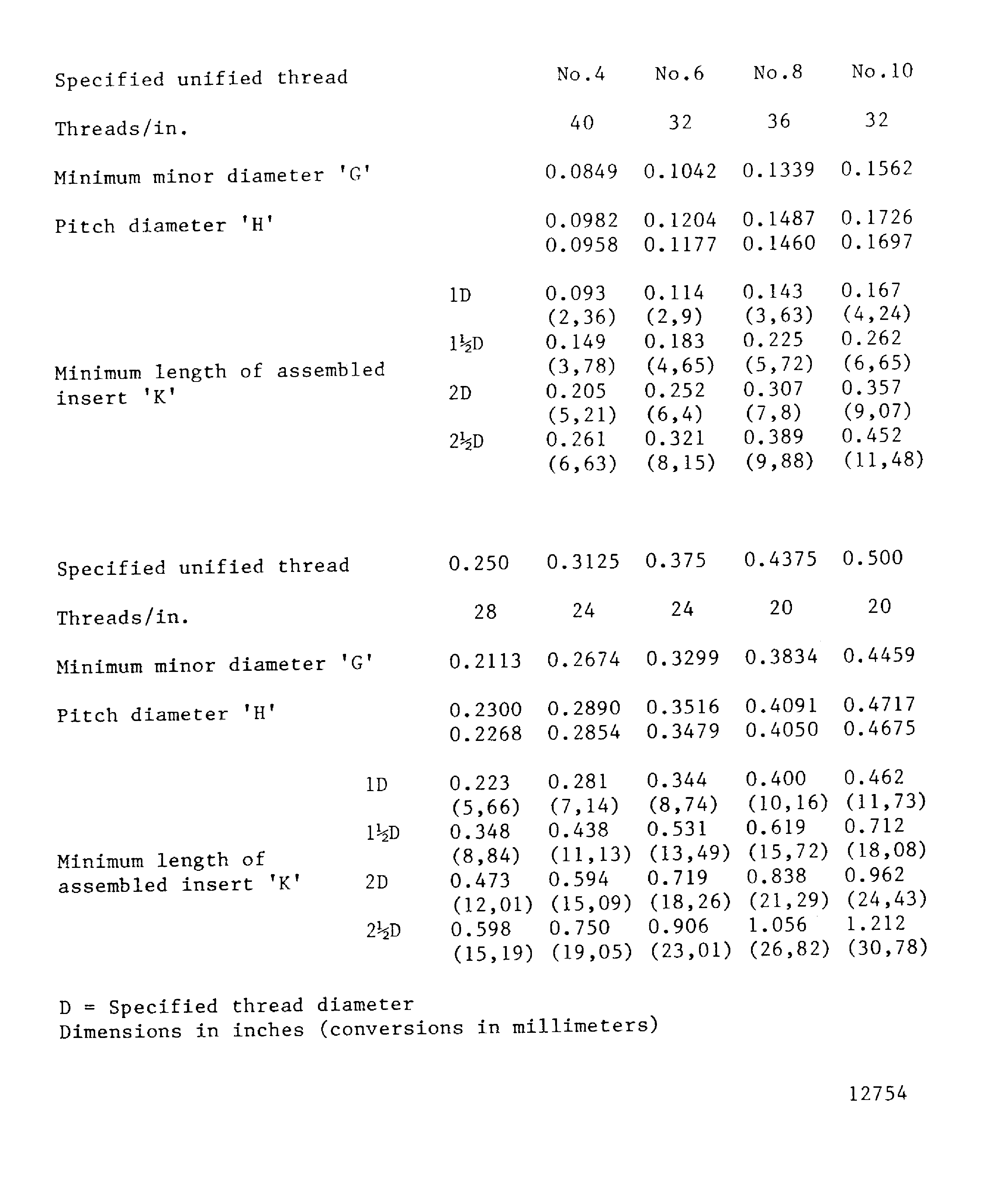

Figure: Dimensions of assembled inserts

Dimensions of assembled inserts

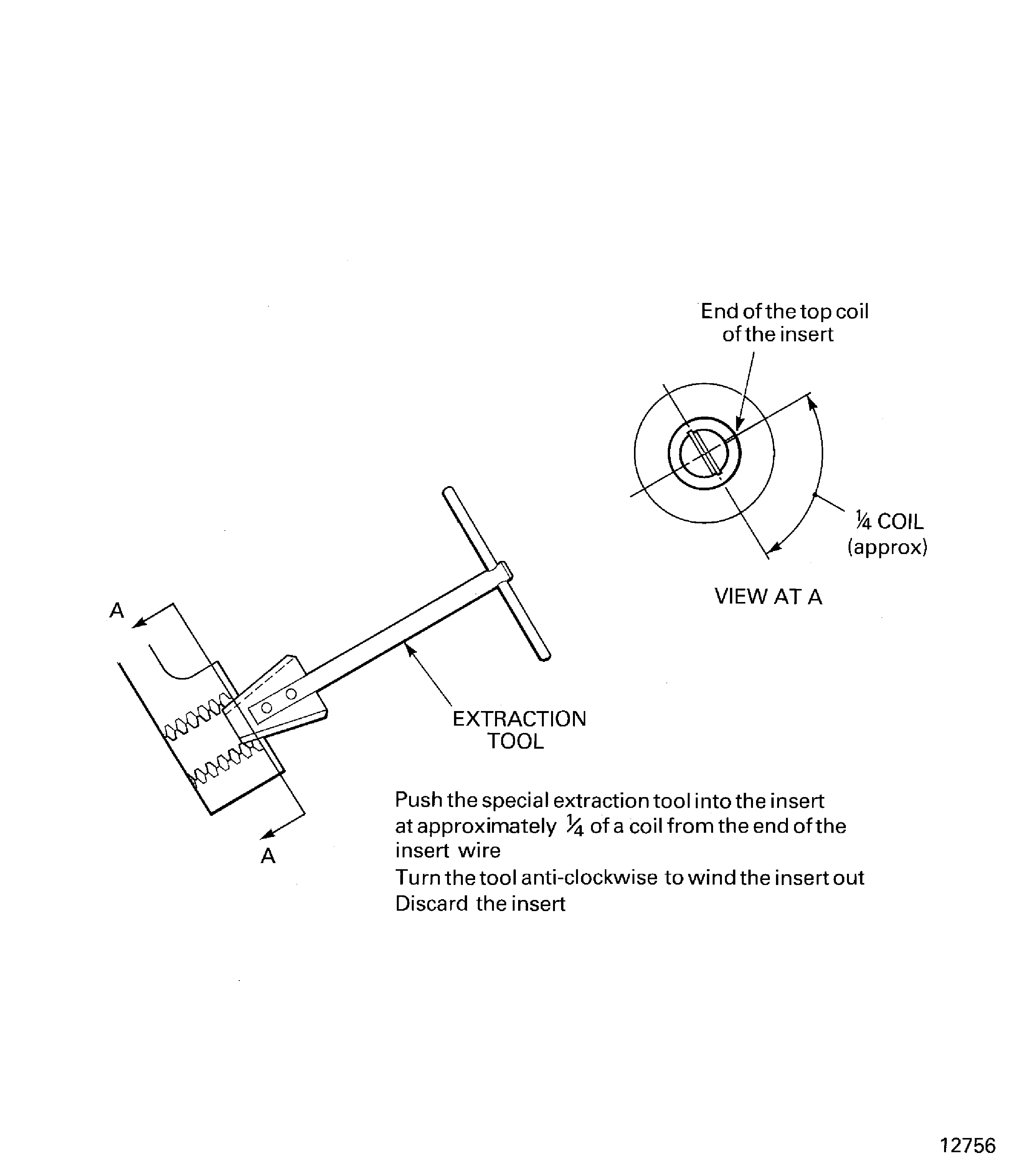

Figure: Removal of the inserts

Removal of the inserts

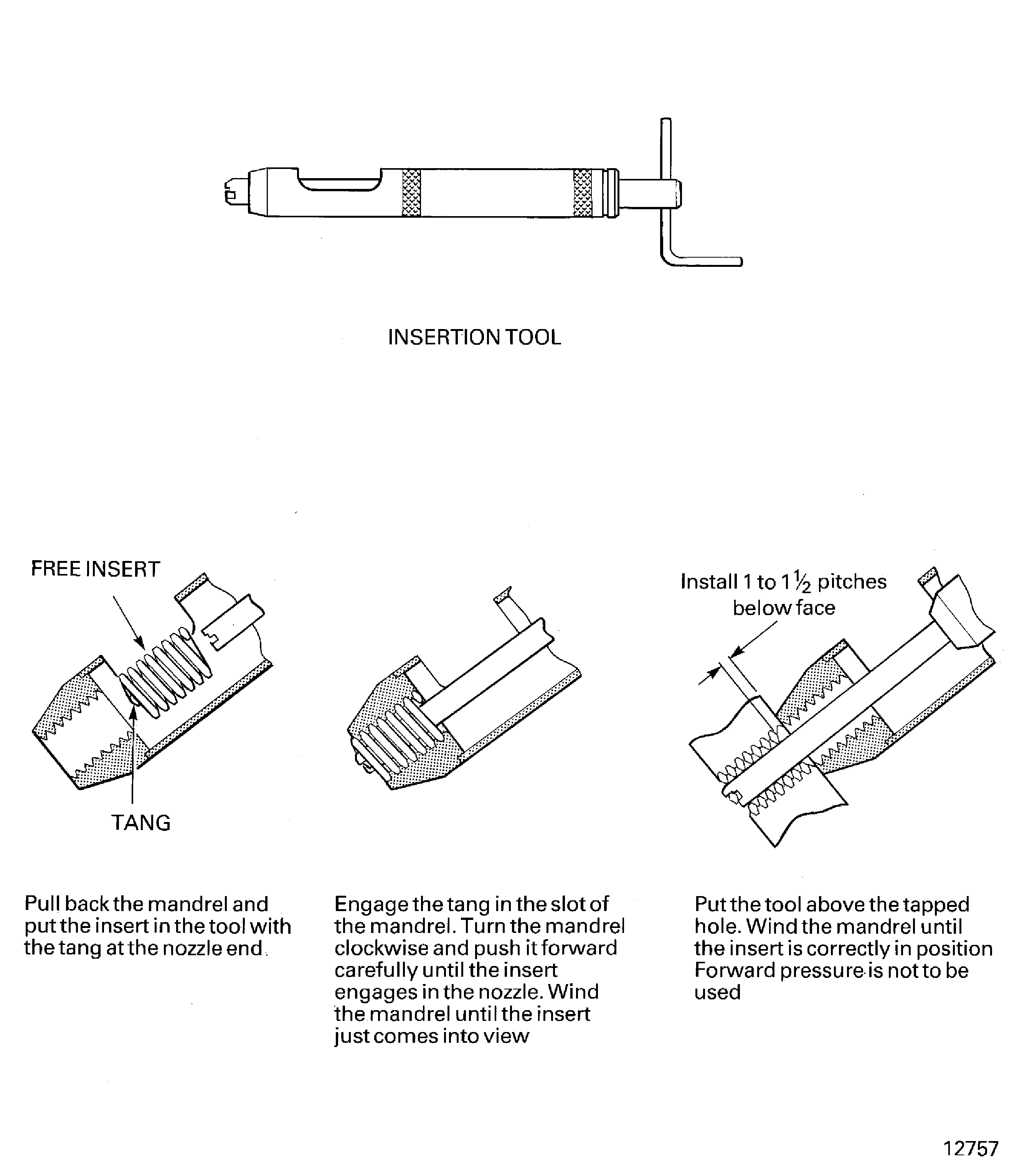

Figure: Installation procedure

Installation procedure

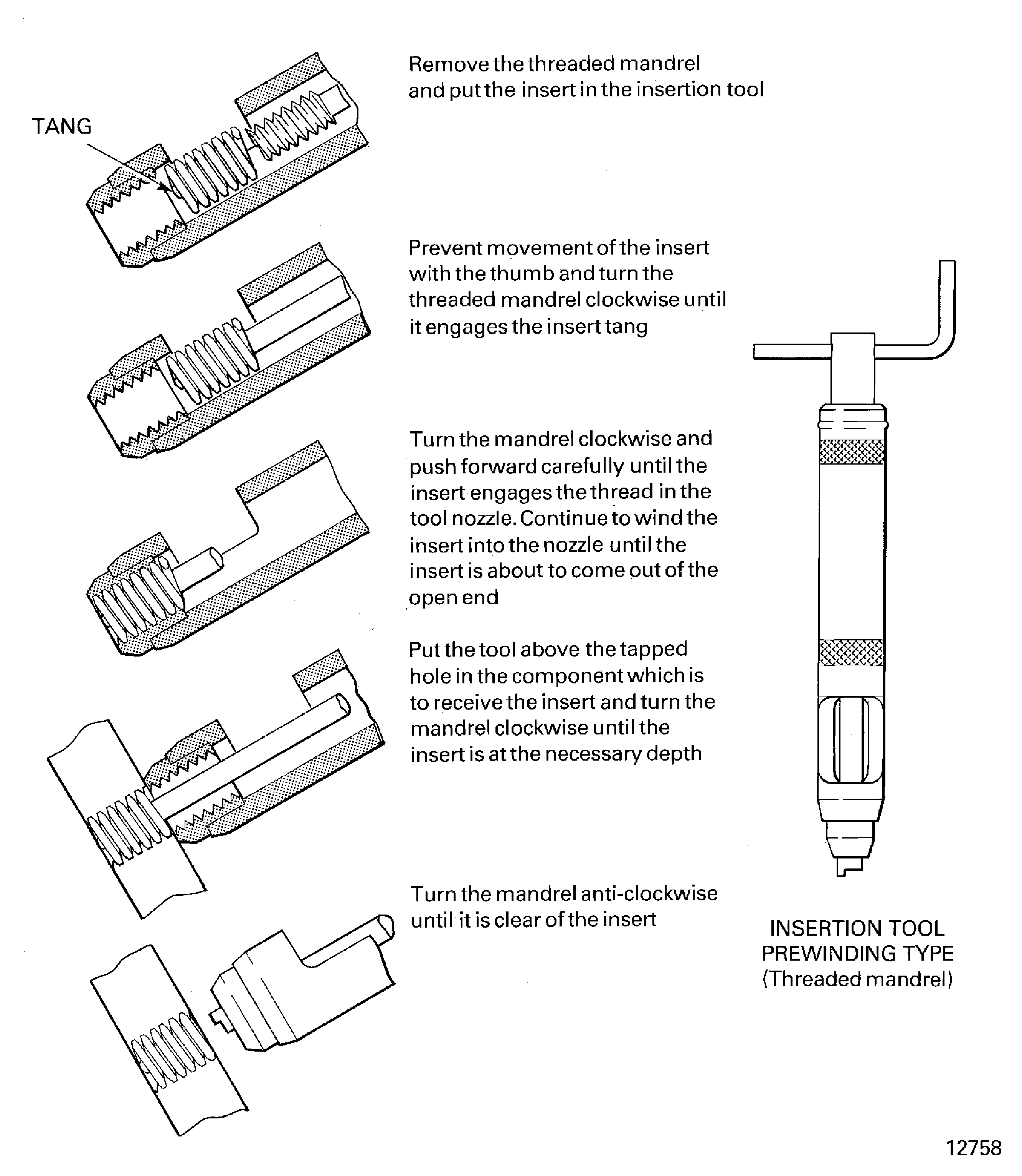

Figure: Installation procedure

Installation procedure

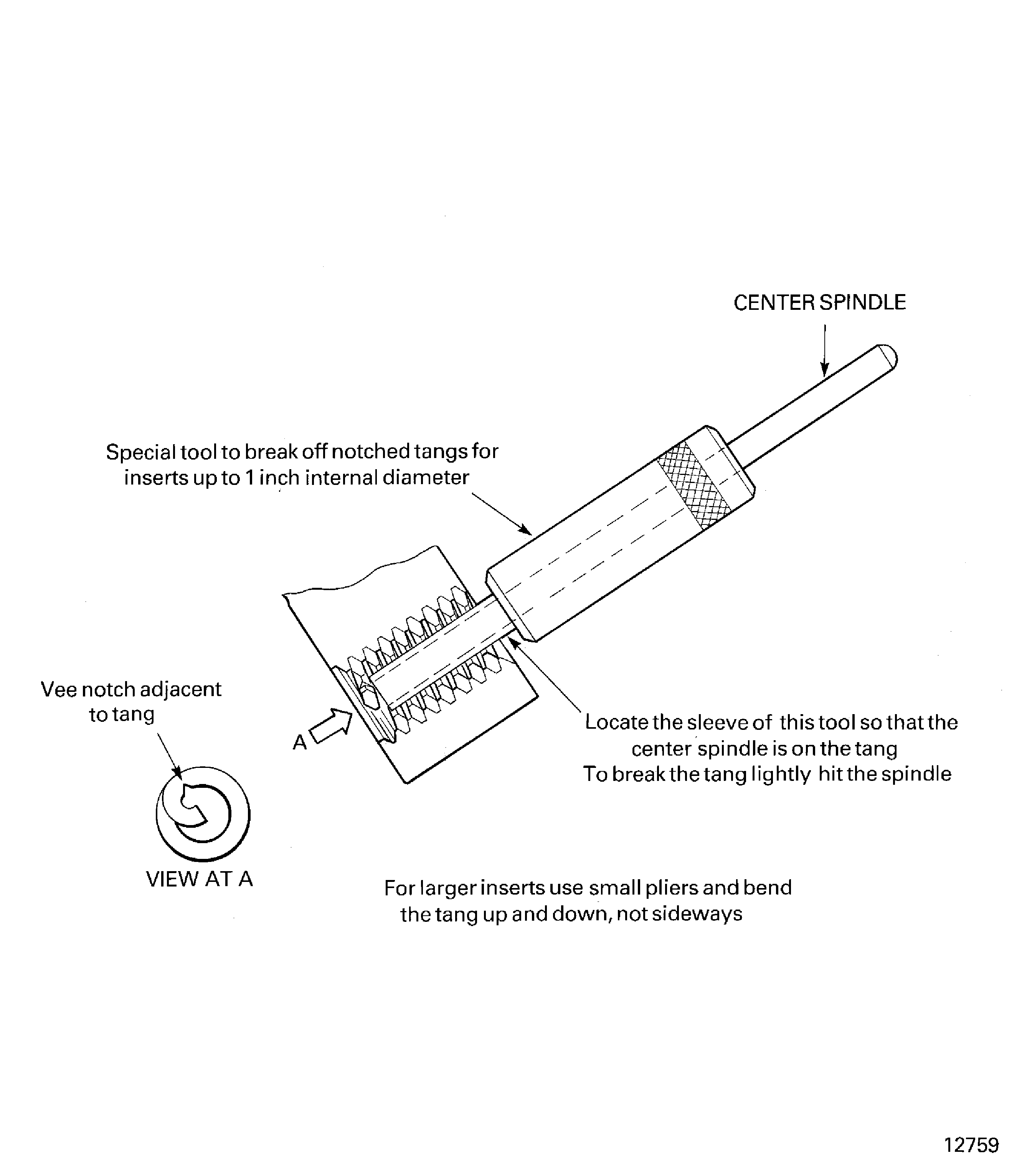

Figure: Removal of the insert tang

Removal of the insert tang

Figure: Changes to tools to make them fit wire thread inserts in assembled parts

Changes to tools to make them fit wire thread inserts in assembled parts

Figure: Changes to tools to make them fit wire thread inserts in assembled parts

Changes to tools to make them fit wire thread inserts in assembled parts

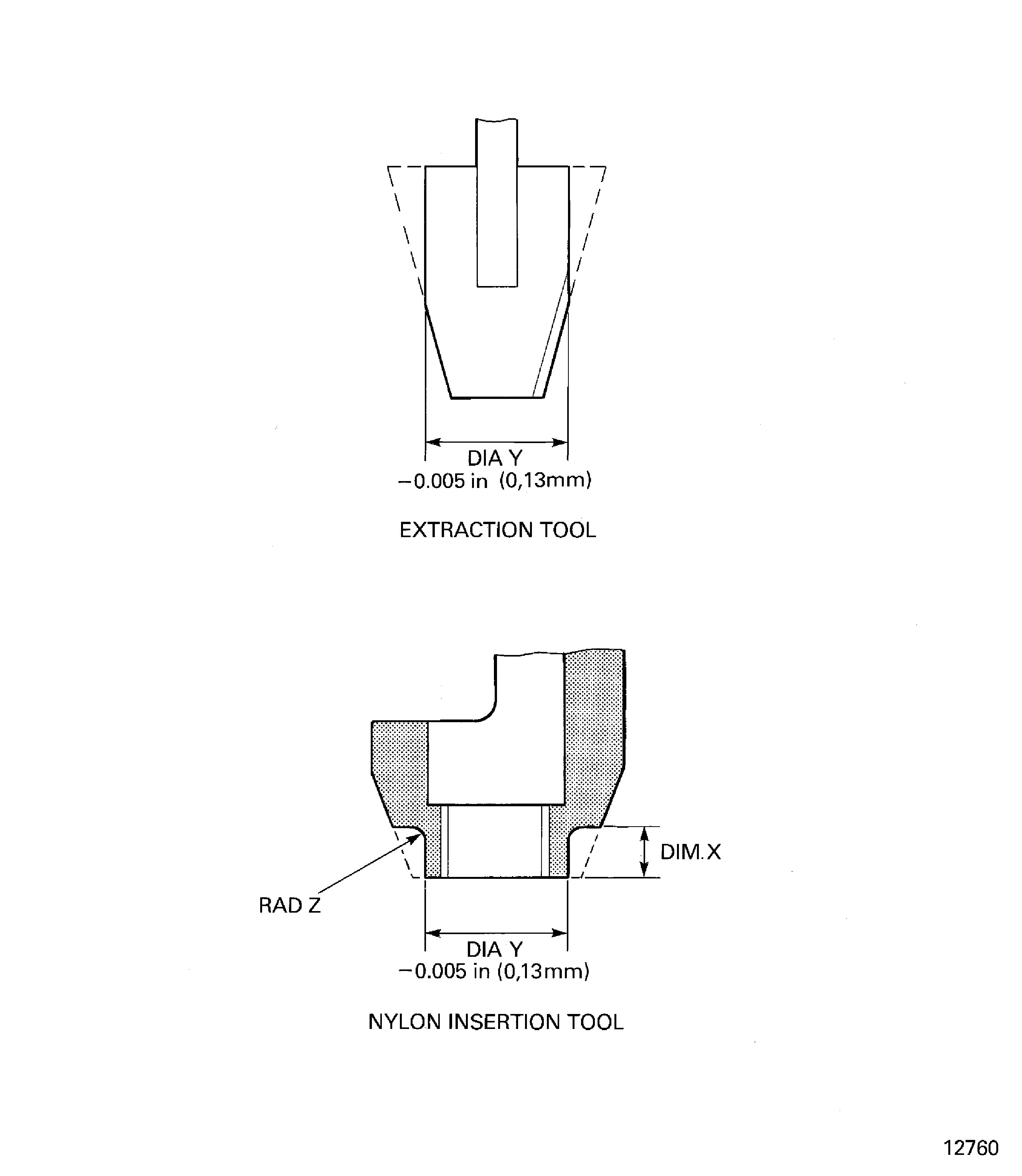

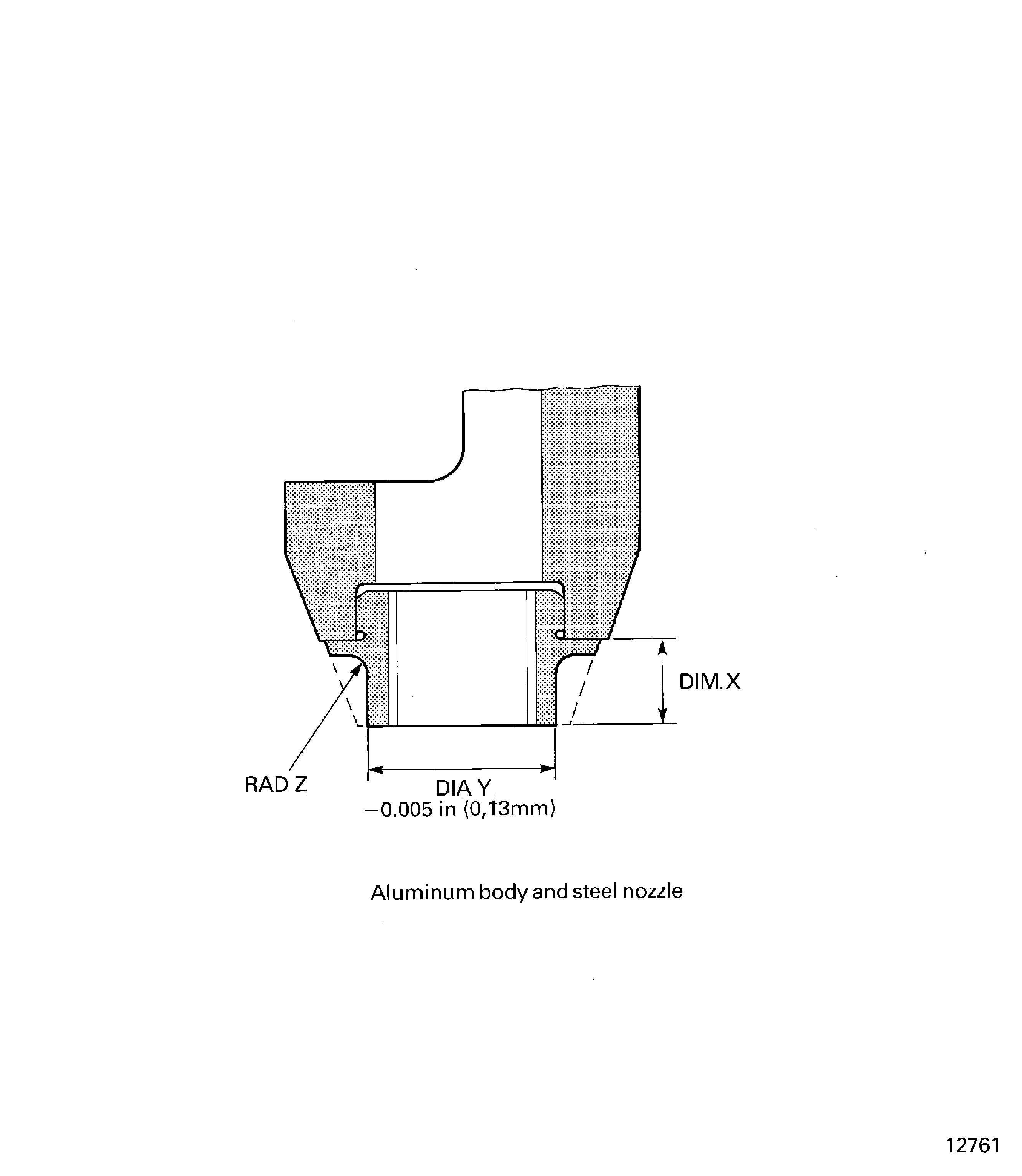

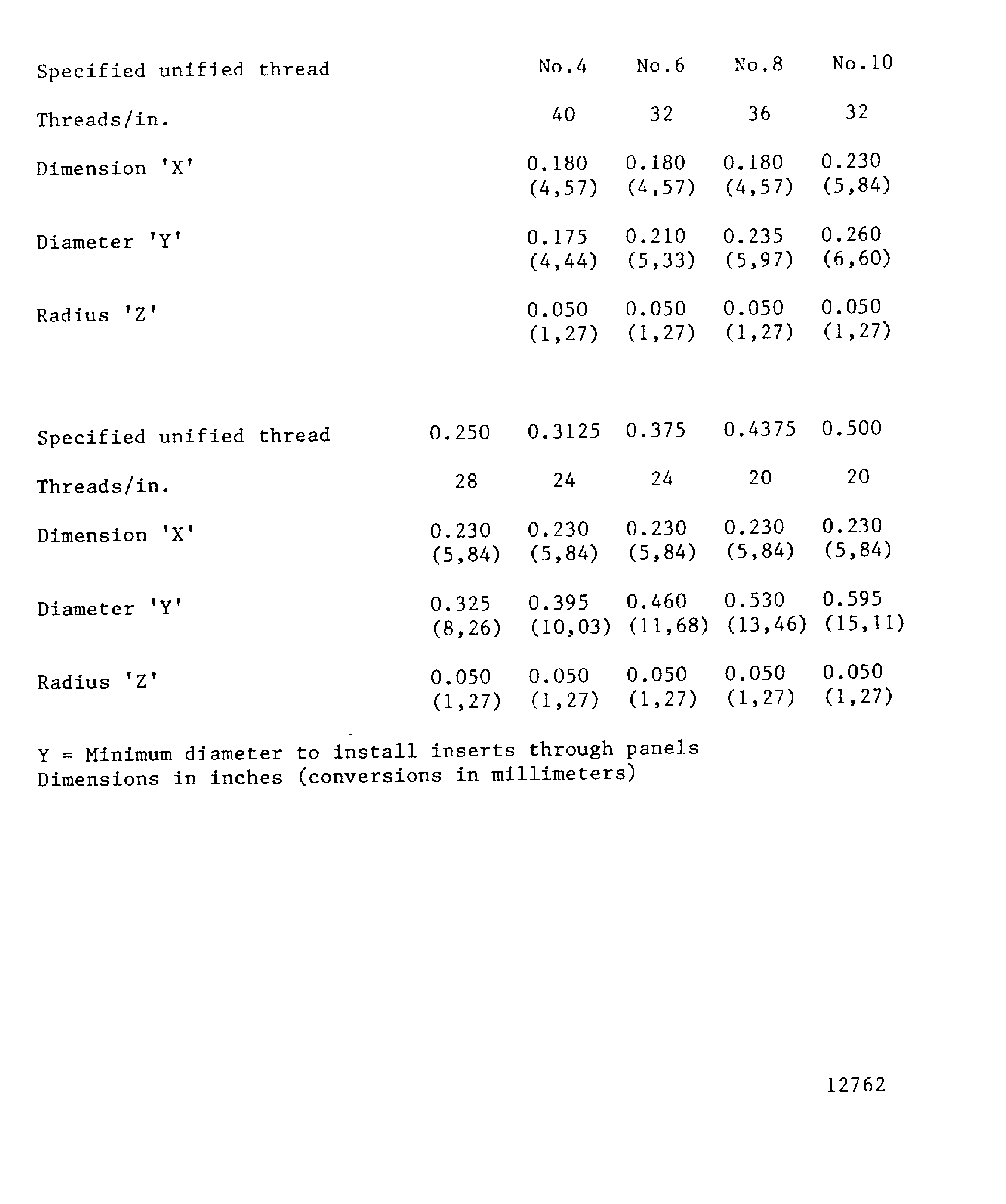

Figure: Tool dimensions to fit wire thread inserts in assembled parts

Tool dimensions to fit wire thread inserts in assembled parts

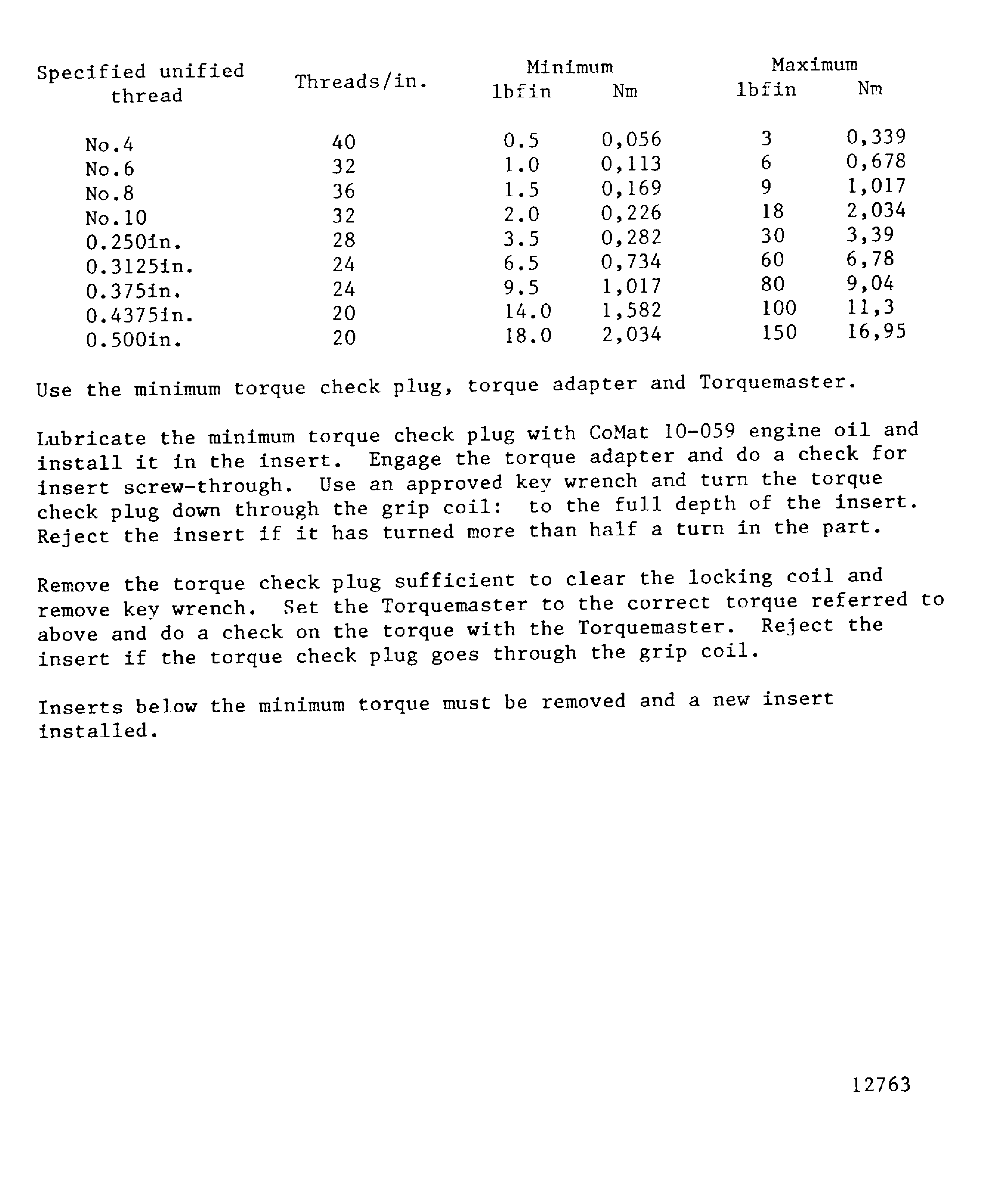

Figure: Torque check of screw lock inserts

Torque check of screw lock inserts

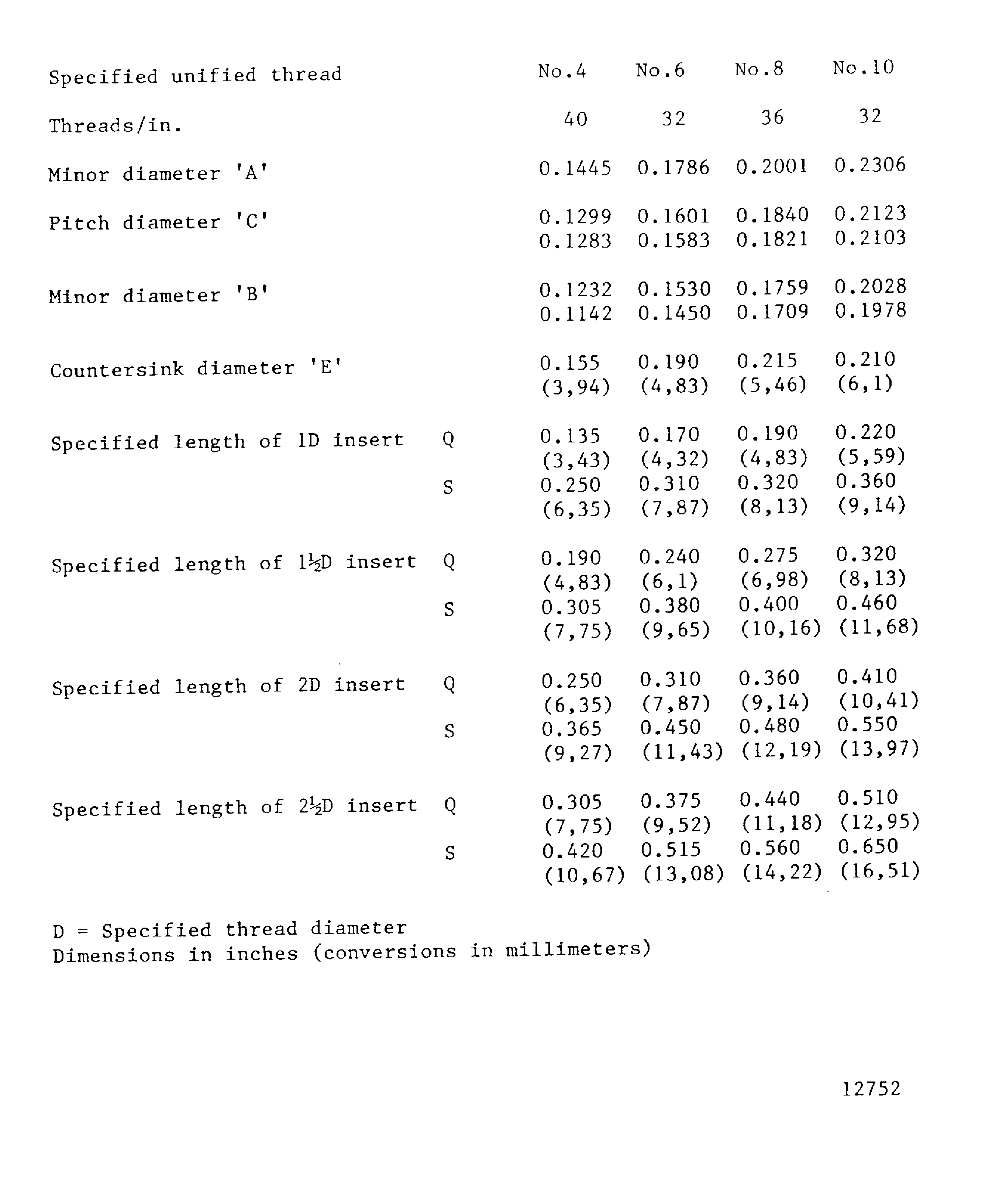

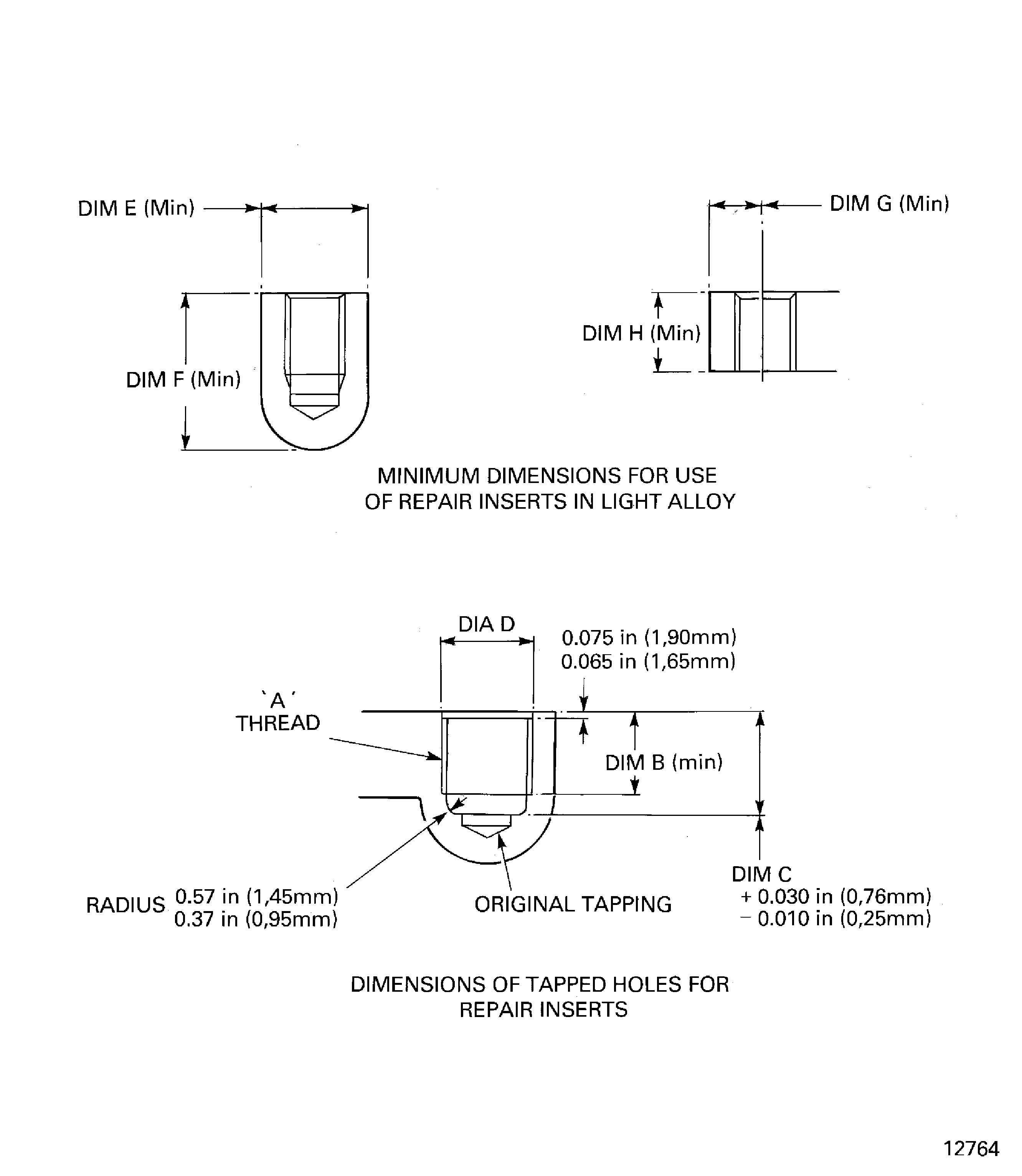

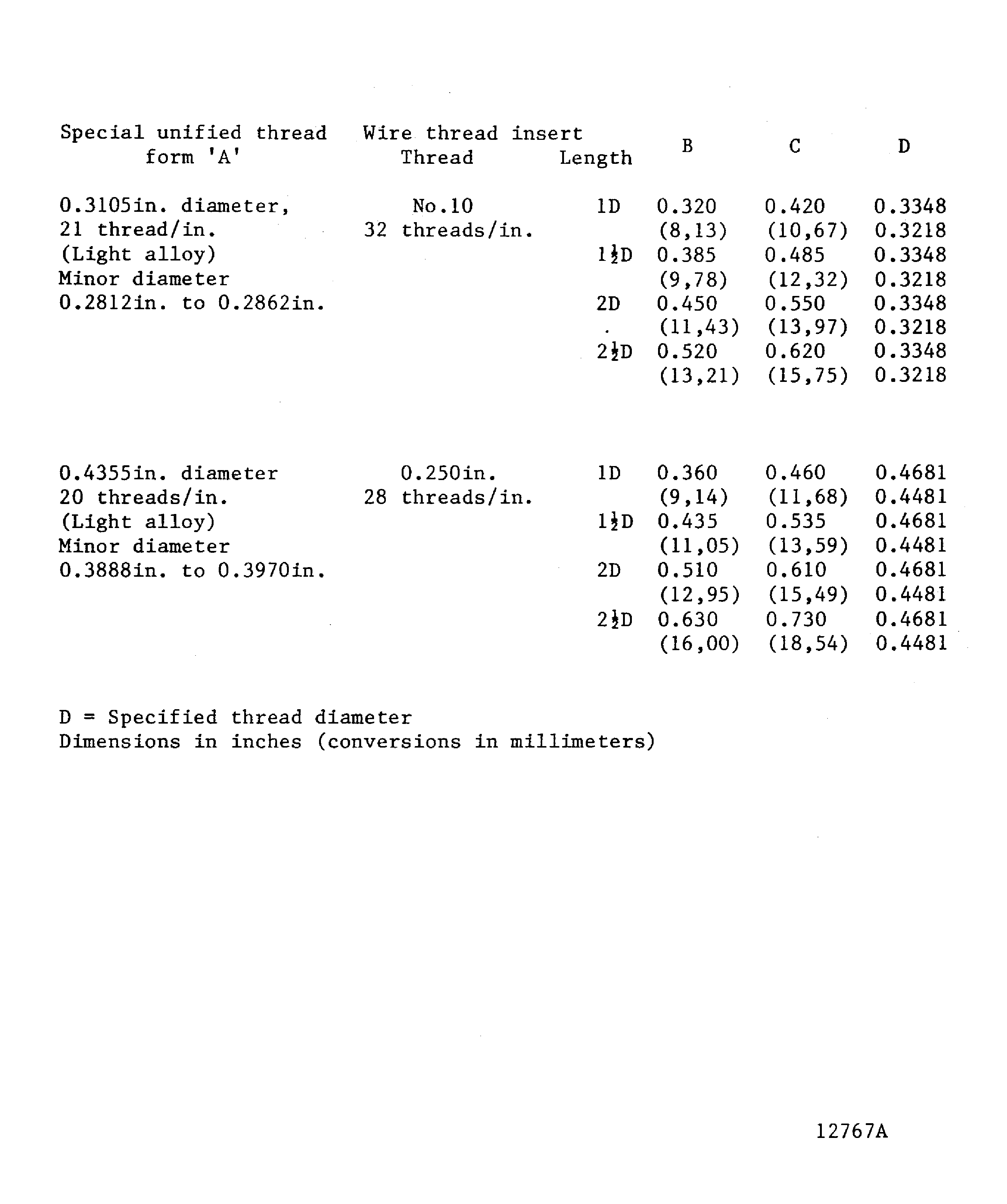

Figure: Dimensions for inserts in light alloy materials

Dimensions for inserts in light alloy materials

Figure: Dimensions for inserts in light alloy materials

Dimensions for inserts in light alloy materials

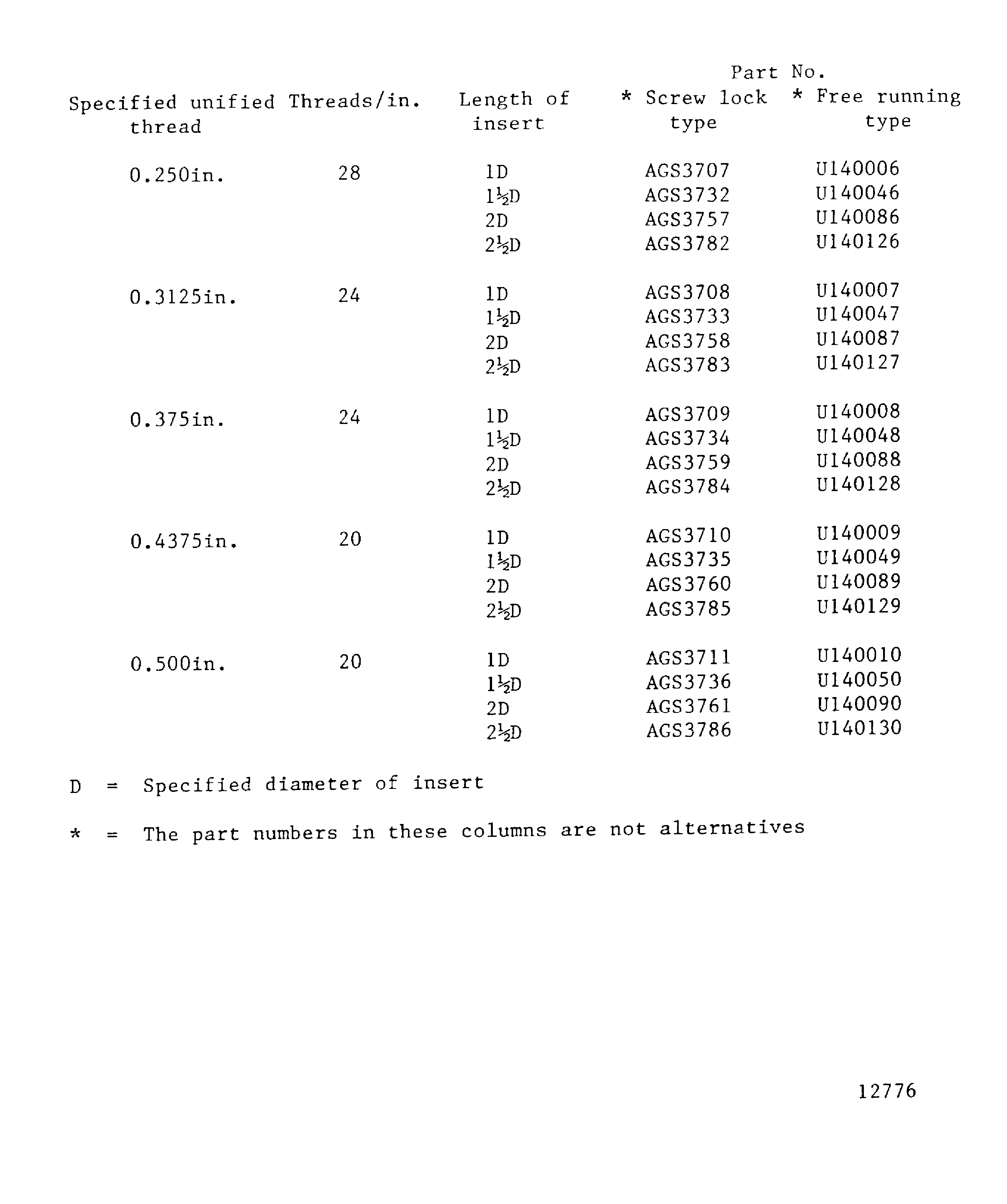

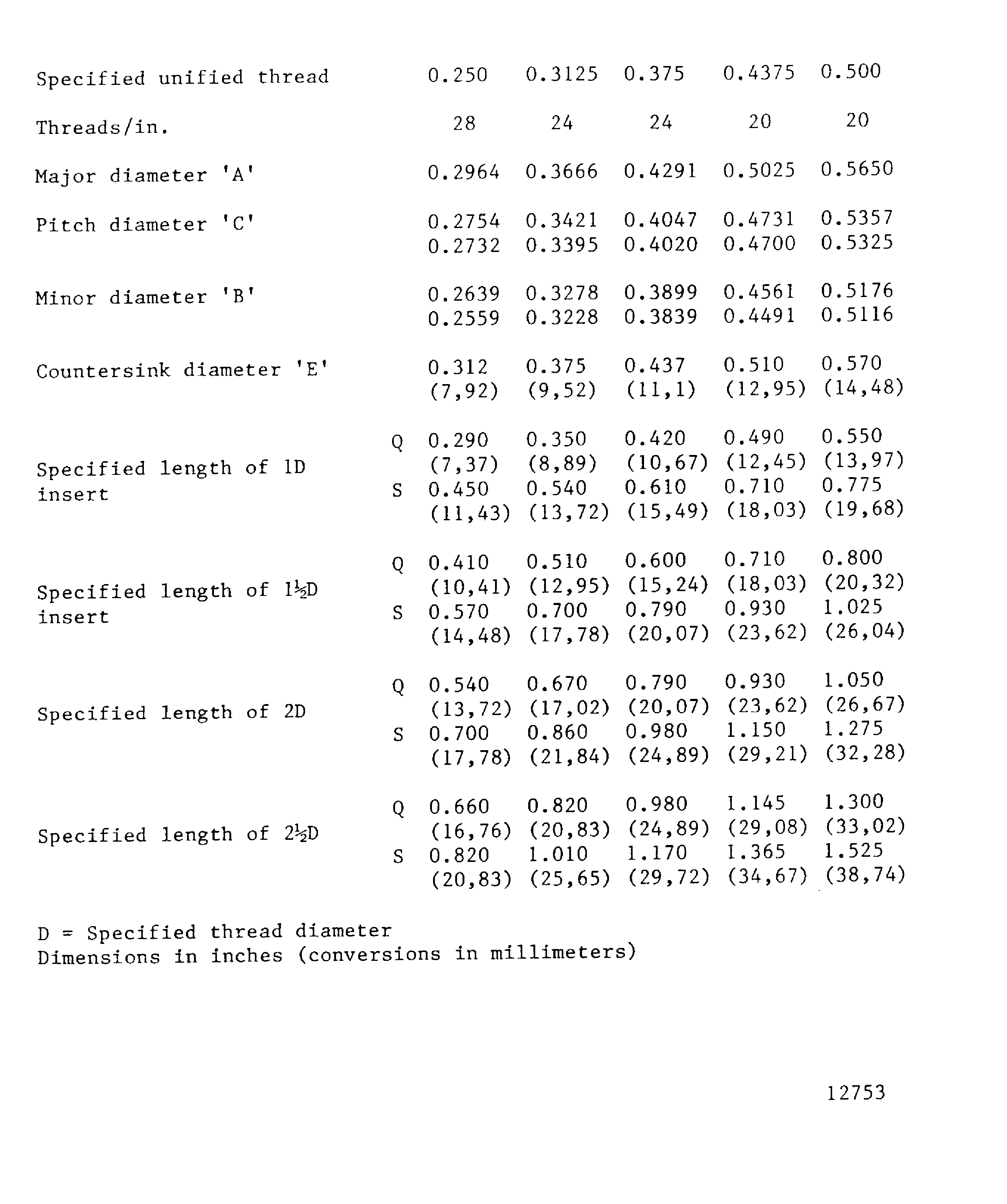

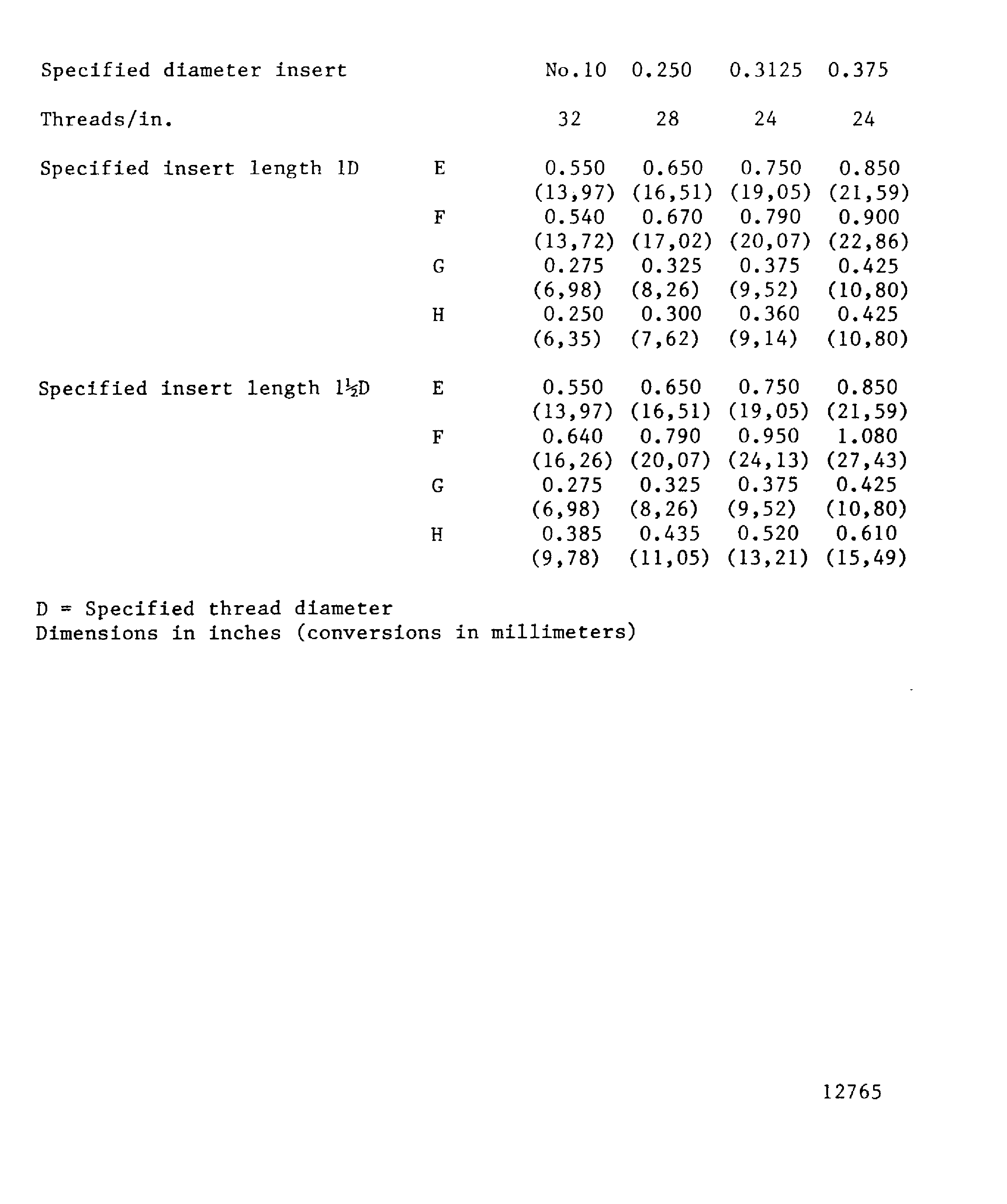

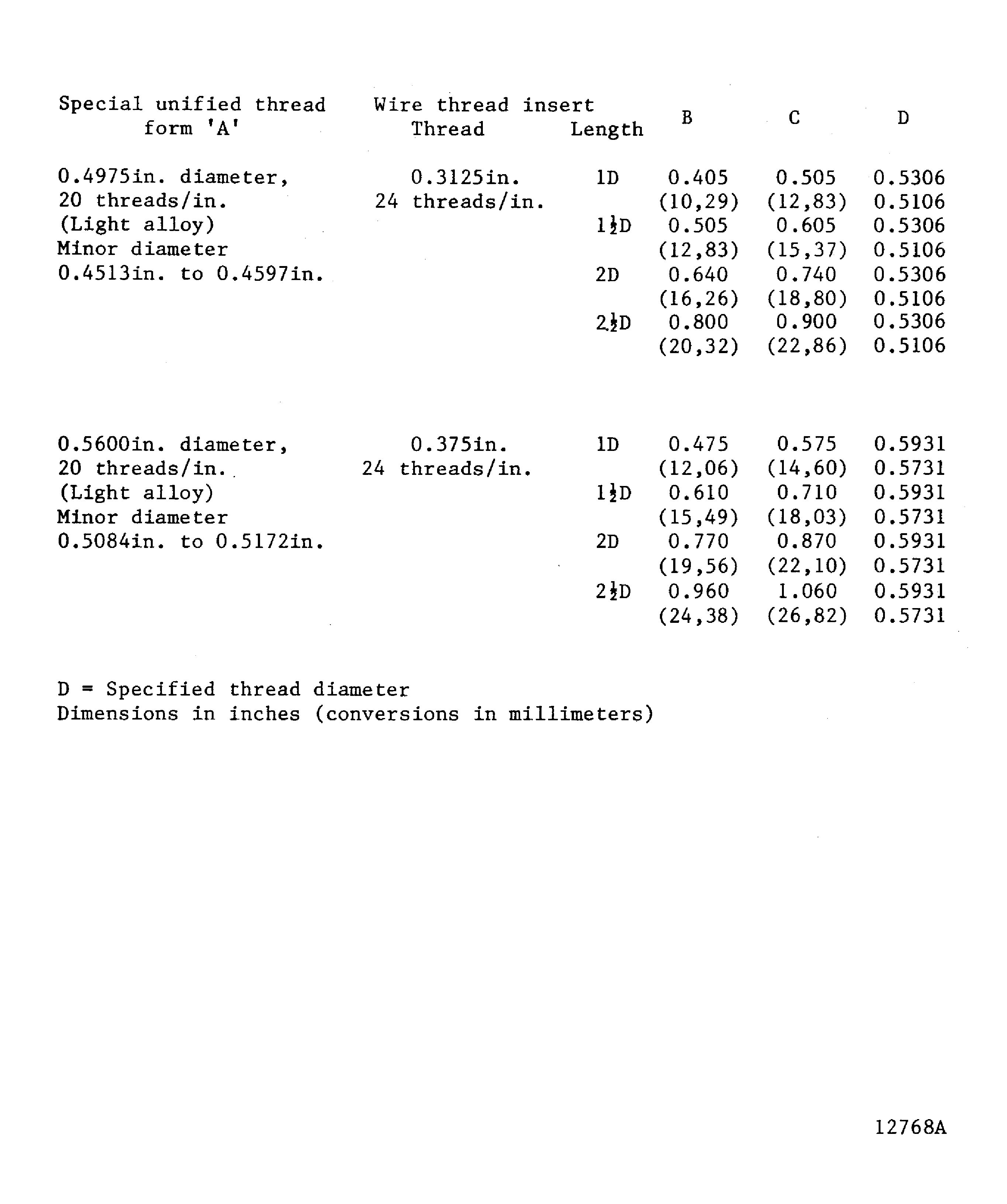

Figure: Dimensions for inserts in light alloy materials

Dimensions for inserts in light alloy materials

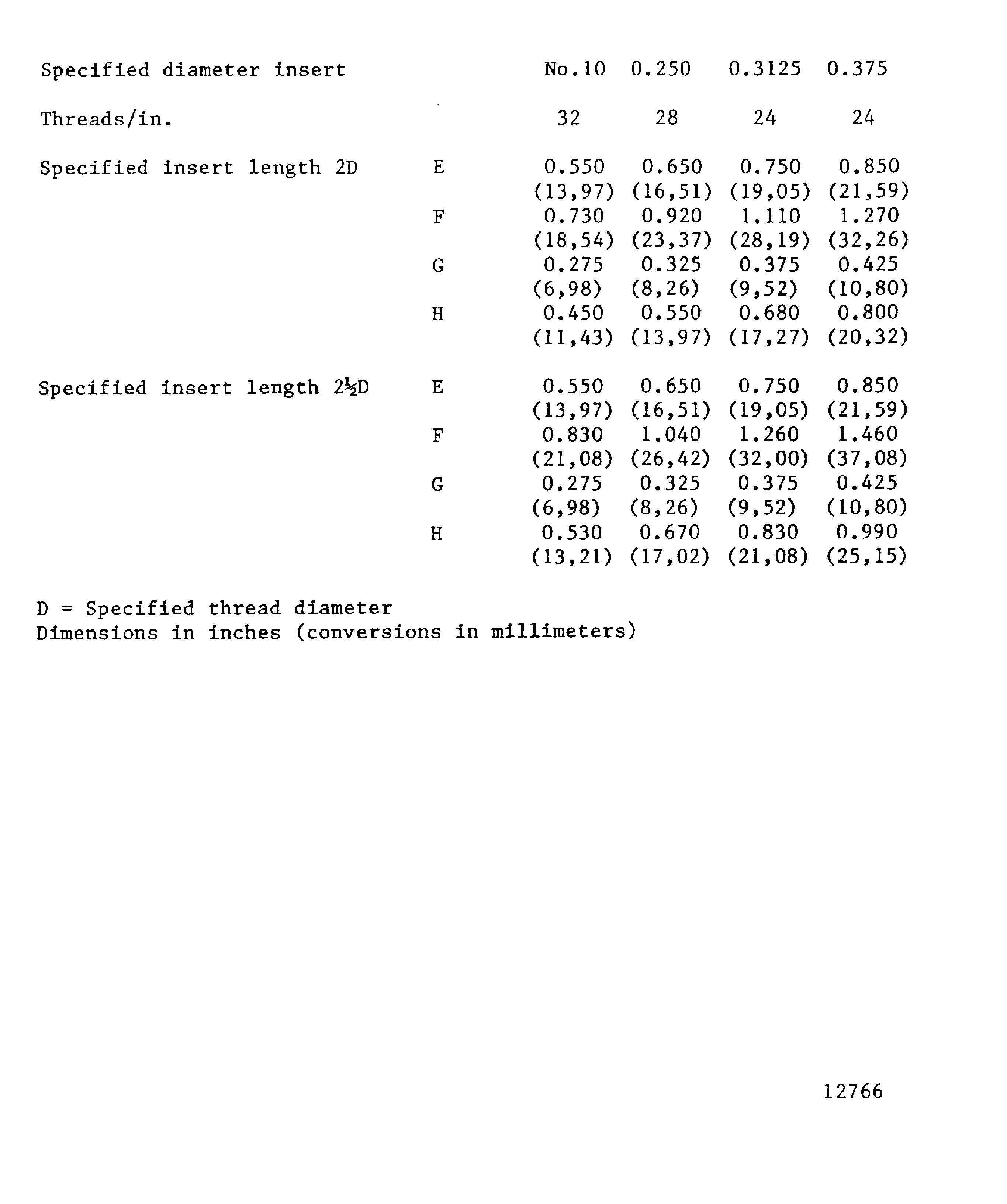

Figure: Dimensions for inserts in light alloy materials

Dimensions for inserts in light alloy materials

Figure: Dimensions for inserts in light alloy materials

Dimensions for inserts in light alloy materials

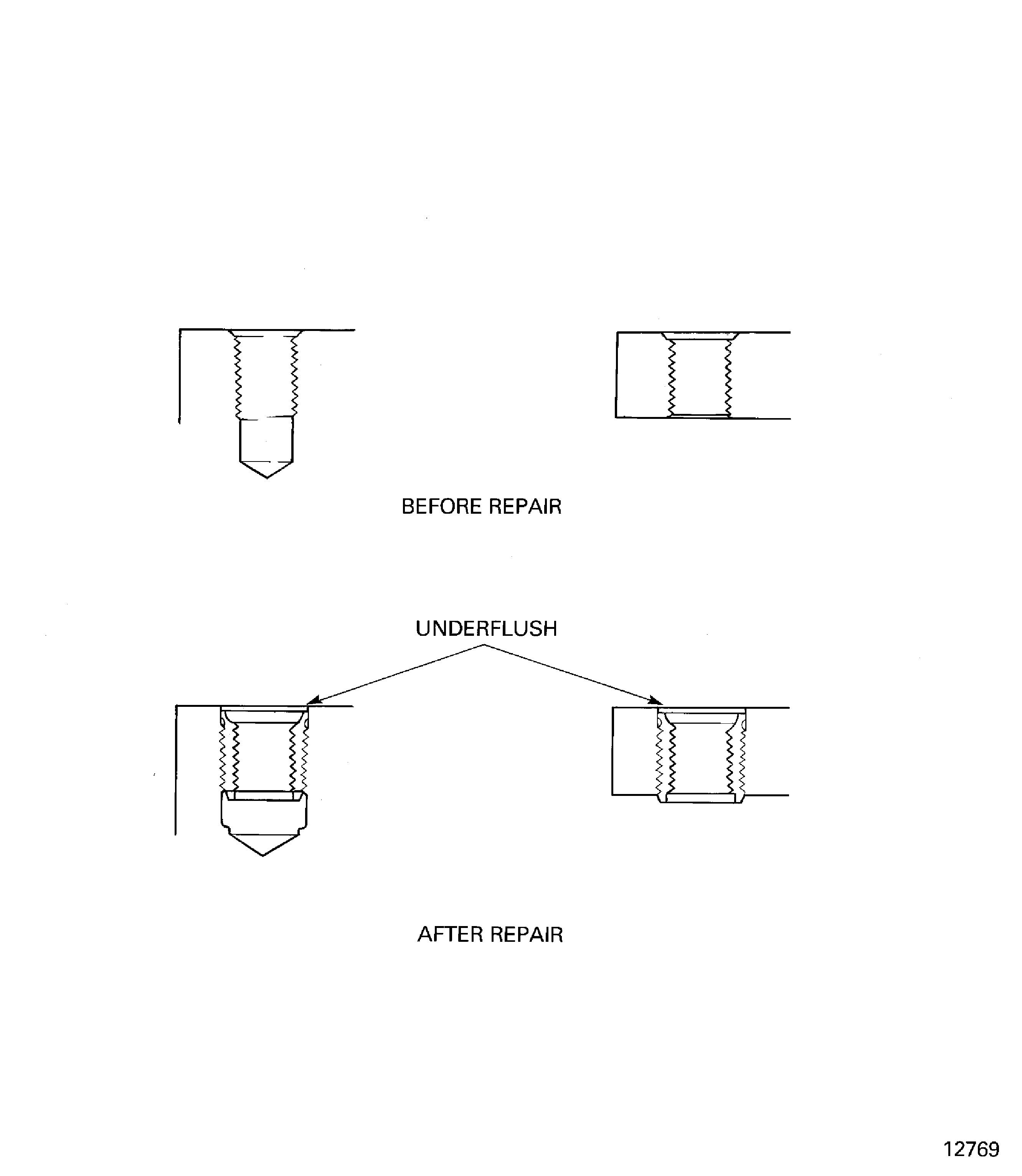

Figure: Repair inserts

Repair inserts

Figure: Repair inserts

Repair inserts

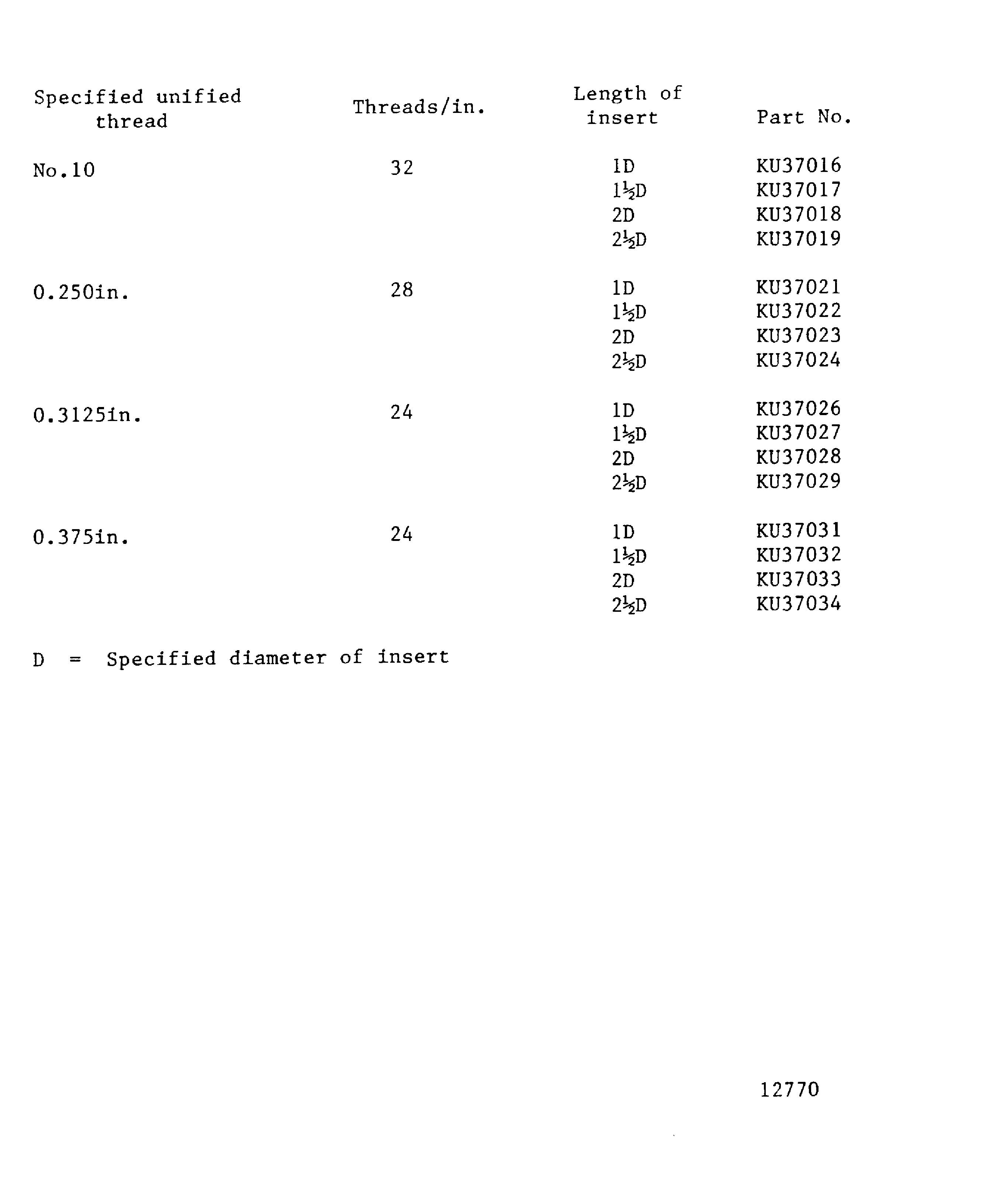

Figure: Wire thread inserts

Wire thread inserts

Figure: Wire thread inserts

Wire thread inserts