Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-35-23-320-501 Non-Mechanical Metal Removal

Safety Precautions | ||

Introduction | ||

Electrochemical Metal Removal (ECMR) and Electrodischarge Metal Removal (EDMR) Processes | ||

Laser Beam Metal (LBMR) Removal Process | ||

Metallurgical Sample Preparation | ||

Acceptance Standards for EDMR | ||

Acceptance Standards for ECMR | ||

Acceptance Standards for EBMR | ||

Acceptance Standards for LBMR | ||

Chemical Milling Acceptance Standards | SUBTASK 70-35-23-290-005 |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED) | LOCAL | CoMat 01-007 | ||

| CoMat 01-250 CUPRIC CHLORIDE CuCl2 | LOCAL | CoMat 01-250 | ||

| CoMat 01-320 SULFURIC ACID | LOCAL | CoMat 01-320 | ||

| CoMat 01-327 NITRIC ACID | LOCAL | CoMat 01-327 | ||

| CoMat 01-346 SULFURIC ACID | LOCAL | CoMat 01-346 | ||

| CoMat 01-357 HYDROFLUORIC ACID (HF) | LOCAL | CoMat 01-357 | ||

| CoMat 01-363 HYDROCHLORIC ACID (HCl),REAGENT GRADE | LOCAL | CoMat 01-363 | ||

| CoMat 01-464 OXALIC ACID | LOCAL | CoMat 01-464 | ||

| CoMat 01-465 CUPRIC CHLORIDE | LOCAL | CoMat 01-465 | ||

| CoMat 03-452 THERMOPLASTIC MOUNTINGPOWDER"LUCITE" | 5U637 | CoMat 03-452 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-082 | ||

| CoMat 05-090 DIAMOND PASTE | 09410 | CoMat 05-090 | ||

| CoMat 05-091 DIAMOND PASTE | 09410 | CoMat 05-091 | ||

| CoMat 05-165 WATERPROOF SILIC. CARB.ABRAS. PAPER | LOCAL | CoMat 05-165 | ||

| CoMat 08-113 EPOXY | 5U637 | CoMat 08-113 |

Spares

NONESafety Requirements

WARNING

WARNING

WARNING

WARNING

Procedure

WARNING

EVERY POSSIBLE CARE MUST BE TAKEN TO AVOID THE SOLUTION COMING INTO CONTACT WITH THE EYES OR BARE SKIN. PROTECTIVE CLOTHING INCLUDING RUBBER GLOVES AND GOGGLES MUST BE PROVIDED FOR THE OPERATORS WHEN PREPARING AND USING THE NITRIC ACID SOLUTION. RUBBER GLOVES MUST BE CHECKED REGULARLY FOR PIN HOLES AND REPLACED IF NECESSARY. IF SKIN BECOMES CONTAMINATED WITH THE SOLUTION IT MUST BE RINSED WITH COPIOUS AMOUNTS OF CLEAN RUNNING WATER.ALL BURNS, HOWEVER SLIGHT, MUST BE TREATED AT THE NEAREST MEDICAL DEPARTMENT OR FIRST AID POST. THE MEDICAL PERSONNEL MUST BE TOLD WHICH SOLUTION (THE ACIDS INVOLVED) HAS CAUSED THE BURN.Safety notices must be placed in a conspicuous place.

Eye-wash bottles and HF burn jelly must be provided as close as possible to the place of work.

Strong acid solutions.

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURER'S MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS. THESE CONTAIN INFORMATION SUCH AS HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES. IT IS ALSO THE RESPONSIBILITY OF THE OPERATOR TO TAKE LOCAL REGULATIONS IN TO CONSIDERATION.

WARNING

THE OPERATORS MUST ALWAYS WEAR THE PROTECTIVE CLOTHING SUPPLIED, WHICH INCLUDES RUBBER GLOVES AND EYE PROTECTION.

WARNING

IF ACID SOLUTIONS GET INTO THE EYES FULLY FLUSH, WITH CLEAN WATER, THEN GET MEDICAL TREATMENT IMMEDIATELY.General.

SUBTASK 70-35-23-860-001 Safety Precautions

During this metal removal procedure, a direct current passes between the part (anode) and the shaped tool(s) (cathode) through a suitable electrolyte without sparks, arcs, or high temperature.

This process is the reverse of electroplating in that anodic dissolution removes metal from the part.

Electrochemical Metal Removal (ECMR).

During this metal removal process, electrical energy discharges between the tool and the part. The resulting sparks vaporize very small craters and erode the tool shape into the part and cause a thin remelted surface.

EDMR takes place in the presence of a flowing dielectric fluid. When wire EDMR is specified, the electrode must be a continuously moving wire and the dielectric fluid must agree with the EDM (Electrodischarge Machine) equipment manufacturer's recommendations.

Electrodischarge Metal Removal (EDMR).

Electrochemical Metal Removal and Electrodischarge Metal Removal - IAE 97.

This process is primarily used as a hole drilling or cutting method, that applies a concentrated electron beam, in one or more pulses of various millisecond durations, on a part.

There is sufficient heat given off in each pulse to partially vaporize the material at the point of concentration. More than one pulse is permitted to produce a hole.

Electron Beam Metal Removal (EBMR).

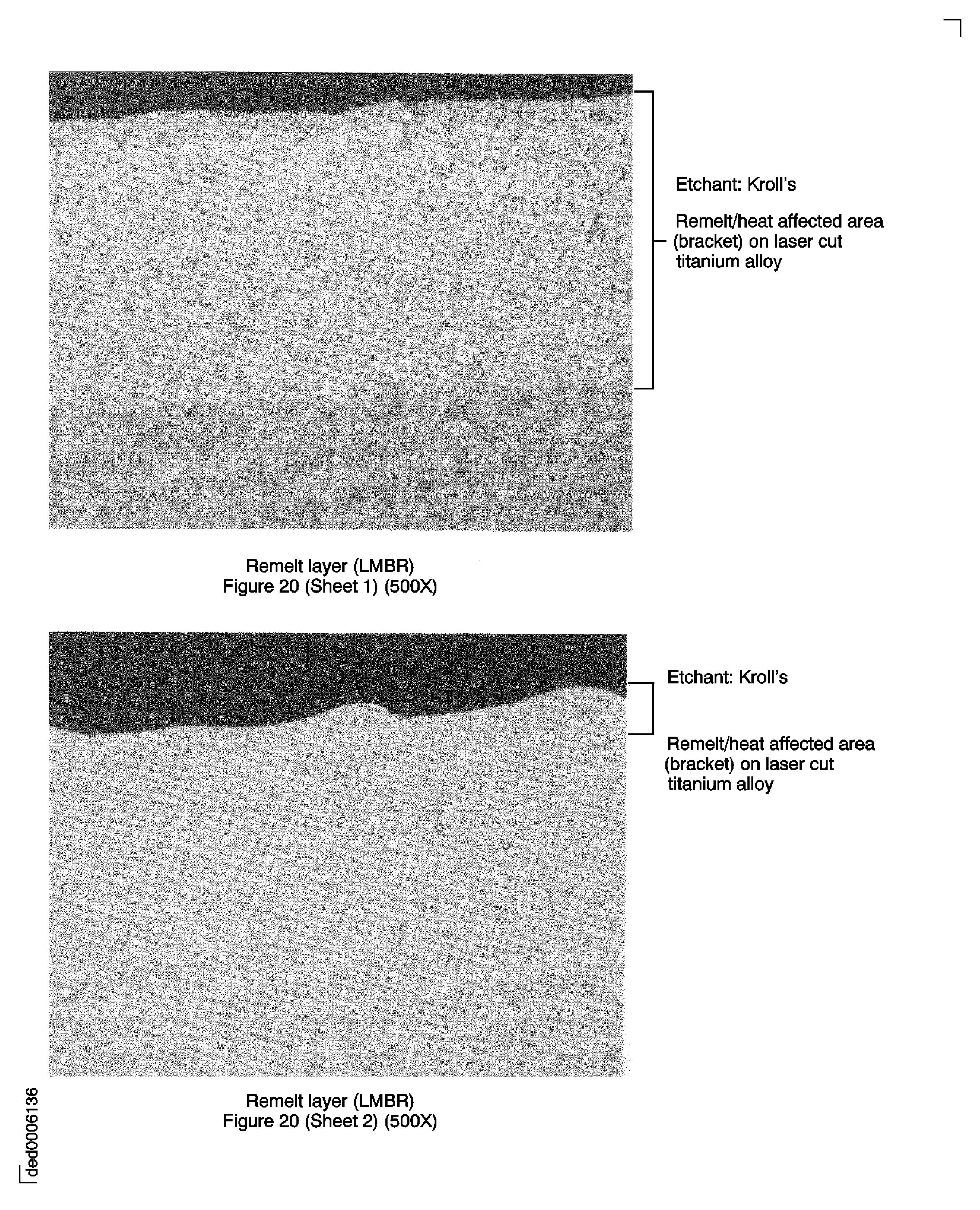

Laser* Beam Metal Removal (LBMR).

This process is primarily used as a hole drilling or cutting method, that applies concentrated light energy pulses of 0.3 to 1.0 millisecond duration on a part by optical means.

There is sufficient heat given off in each pulse to not fully vaporize the material at the point of concentration. More than one pulse is permitted to produce a hole.

*Light Amplification by Stimulated Emission of Radiation.

Electron Beam Metal Removal and Laser* Beam Metal Removal - IAE 119.

Types of Processes.

Arc-burning or direct shorting between the electrode and the workpiece (usually due to contamination of the electrolyte), can result in recast material with cracks up to 0.070 inch (1.778 mm) deep.

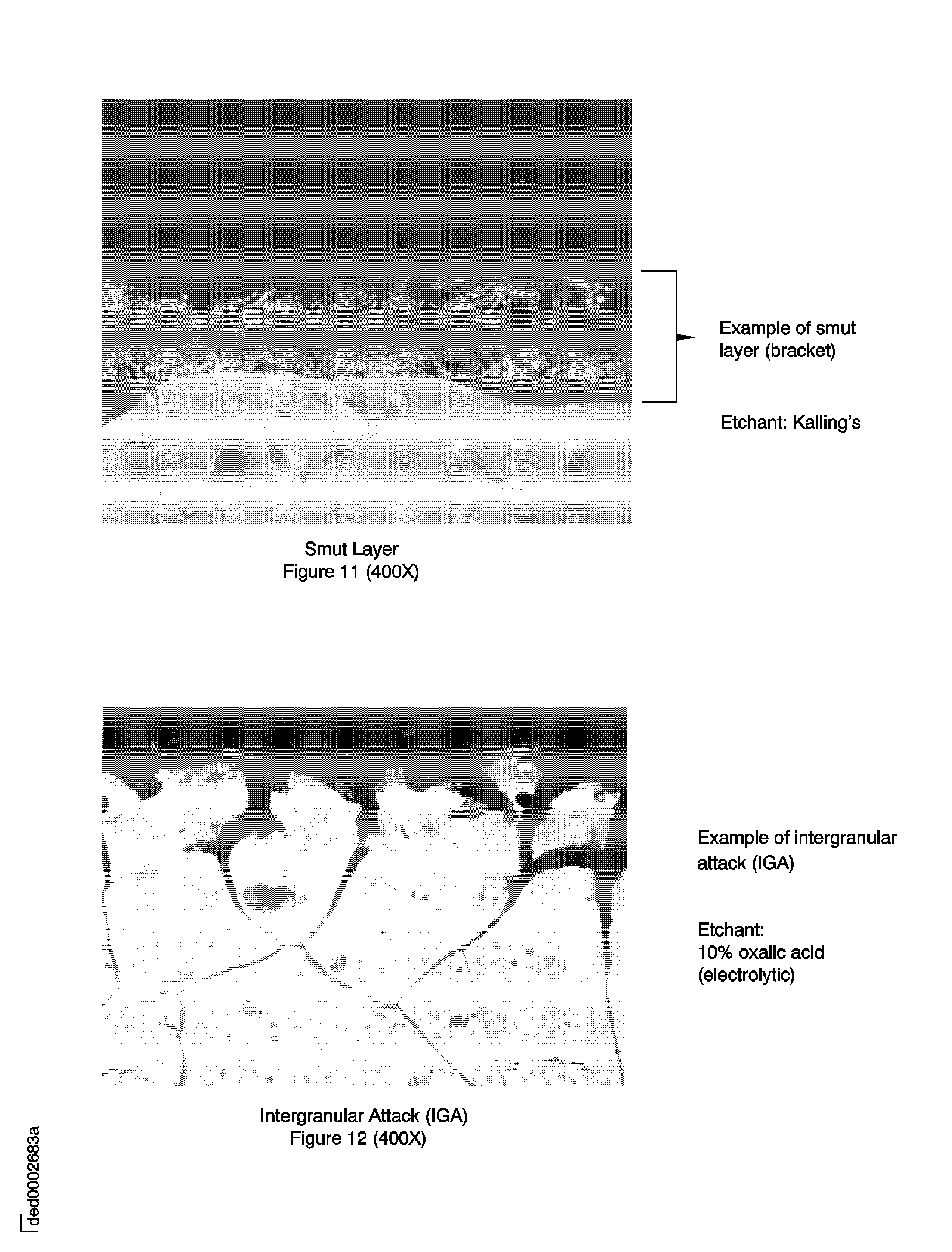

In the ECMR process, degradation of fatigue strength can be further increased by preferential attack of grain boundaries in the machined area and outside this area where the charged electrolyte could flow without the benefit of correct masking.

The application of ECMR, EDMR and LBMR in a repair operation is extremely attractive from the standpoint of cost and convenience. But, because these processes have their limitations, they must not be unconditionally substituted for the routine mechanical stock removal processes. When you apply ECMR, EDMR or LBMR, it is recommended that you get an IAE review and opinion. They must be used only under the specific conditions given in this section. Do not assume that an acceptable application of ECMR, EDMR, or LBMR on a part for one engine model would be acceptable for similar parts on other engine models. Each application must be treated individually. The application requirements for ECMR and EDMR are to be found in Step, and for LBMR in Step.

SUBTASK 70-35-23-860-002 Introduction

Unless the surface layer produced by the process is removed (see Step), ECMR and EDMR must not be used on highly stressed parts and rotating parts.

Unless the surface layer produced by the process is removed (see Step), EDMR must not be used on:

Unless the surface layer produced by the process is removed (see Step), plating and plasma spraying must not be applied over the surfaces prepared by ECMR and, especially, EDMR.

EDMR procedure must be controlled and meet the conditions of Step Quality Standards, so that there is a limit to the depth of the transformed surface layer and that it will be removed to the amount necessary.

EDMR Procedure.

SUBTASK 70-35-23-860-003 ECMR and EDMR (IAE 97) Process

LBMR must not used on rotating parts except for certain blade applications as shown below and on other parts only when the surface layer produced is removed, see Step.

Unless the surface layer produced is removed, see Step, plating and plasma spraying must not be applied over surface prepared by LBMR.

LBMR procedure must be controlled and meet the conditions of Step Quality Standards, so that there is a limit to the depth of the transformed surface layer and that it will be removed to the amount necessary.

LBMR Procedure.

SUBTASK 70-35-23-860-004 LBMR (IAE 119) Process

Mount the metallographic specimen with CoMat 08-113 EPOXY, CoMat 03-452 THERMOPLASTIC MOUNTINGPOWDER"LUCITE" or equivalent mounting compound.

Mounting of Metallographic Specimen.

Wet grind the specimen manually; go step-by-step from 120 thru 600 grit silicon carbide paper; use CoMat 05-082 WATERPROOF SILICON CARBIDE thru CoMat 05-165 WATERPROOF SILIC. CARB.ABRAS. PAPER.

Final polish first CoMat 05-091 DIAMOND PASTE (6 micron) and then with CoMat 05-090 DIAMOND PASTE (1 micron).

Preparation of Specimen.

Kalling's reagent:

100 ml CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED), plus 100 ml CoMat 01-363 HYDROCHLORIC ACID (HCl),REAGENT GRADE plus 5 g CoMat 01-250 CUPRIC CHLORIDE CuCl2 or CoMat 01-465 CUPRIC CHLORIDE (cupric chloride).

NOTE

Application time for electrolytic etching must not be more than 10 seconds; too much etching of the specimen could result in the masking of defects.Oxalic acid, 10 percent (electrolytic):

100 ml water plus 10 g CoMat 01-464 OXALIC ACID.

Kroll's reagent:

83 ml water plus 12 ml CoMat 01-327 NITRIC ACID, plus 5ml CoMat 01-357 HYDROFLUORIC ACID (HF).

Etchant composition used on the specimens illustrated in this procedure (see figures at end of document) are as follows:

Cobalt etch:

92 ml CoMat 01-363 HYDROCHLORIC ACID (HCl),REAGENT GRADE (hydrochloric acid), plus 3 ml CoMat 01-327 NITRIC ACID (nitric acid), plus 5ml CoMat 01-320 SULFURIC ACID or CoMat 01-346 SULFURIC ACID.

Etching of Specimen.

Micrographs representative of the metallographic features to be found on samples are to be found at the end of this document. If viewing electronically, the magnification of the image will change if you enlarge or reduce the image size; adjust the magnification accordingly. Take care not view the micrographs and samples at different magnifications.

Illustration of Metallographic Features.

SUBTASK 70-35-23-860-006 Metallurgical Sample Preparation - Metal Removal

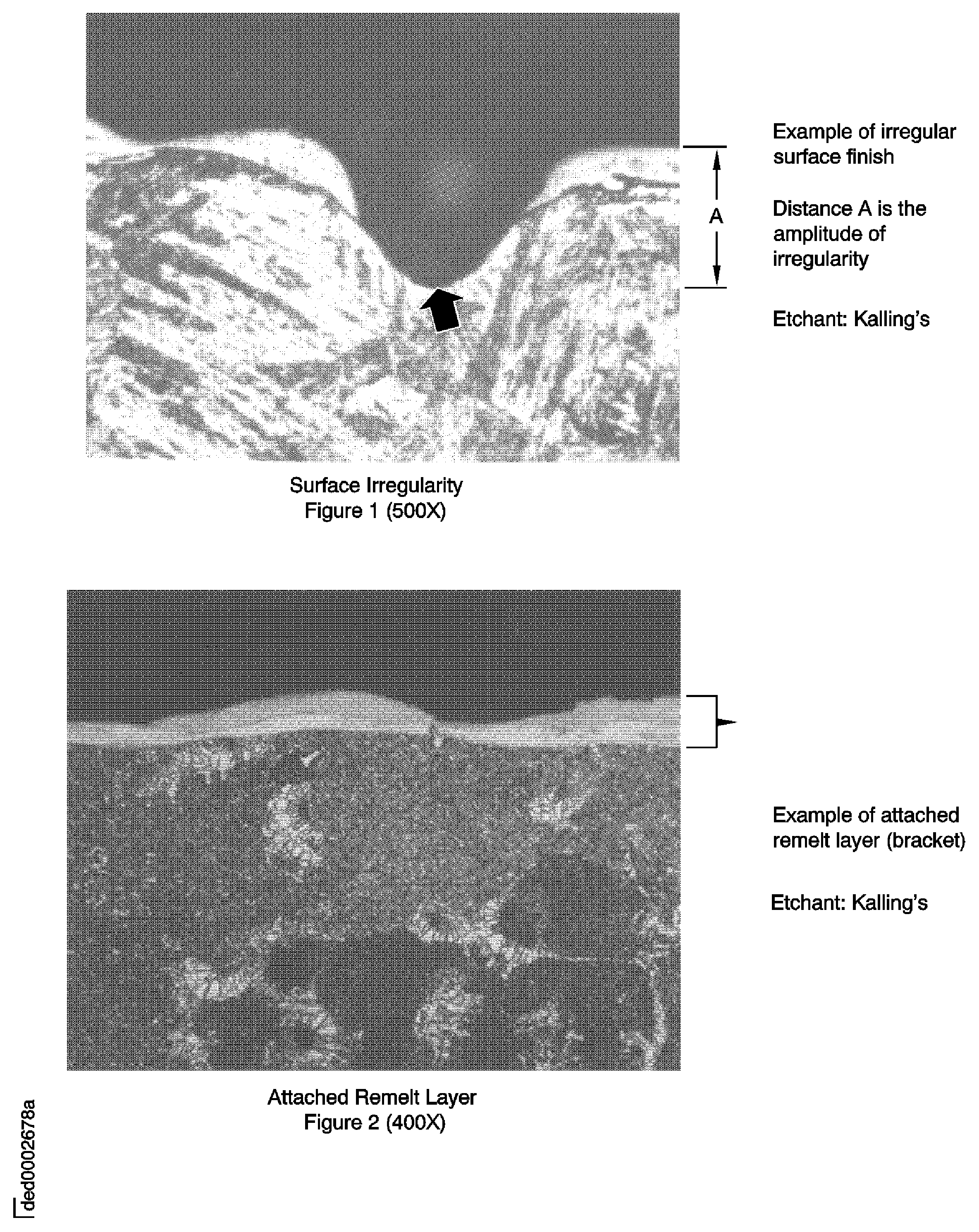

Surface Irregularity.

Refer to Figure.

NOTE

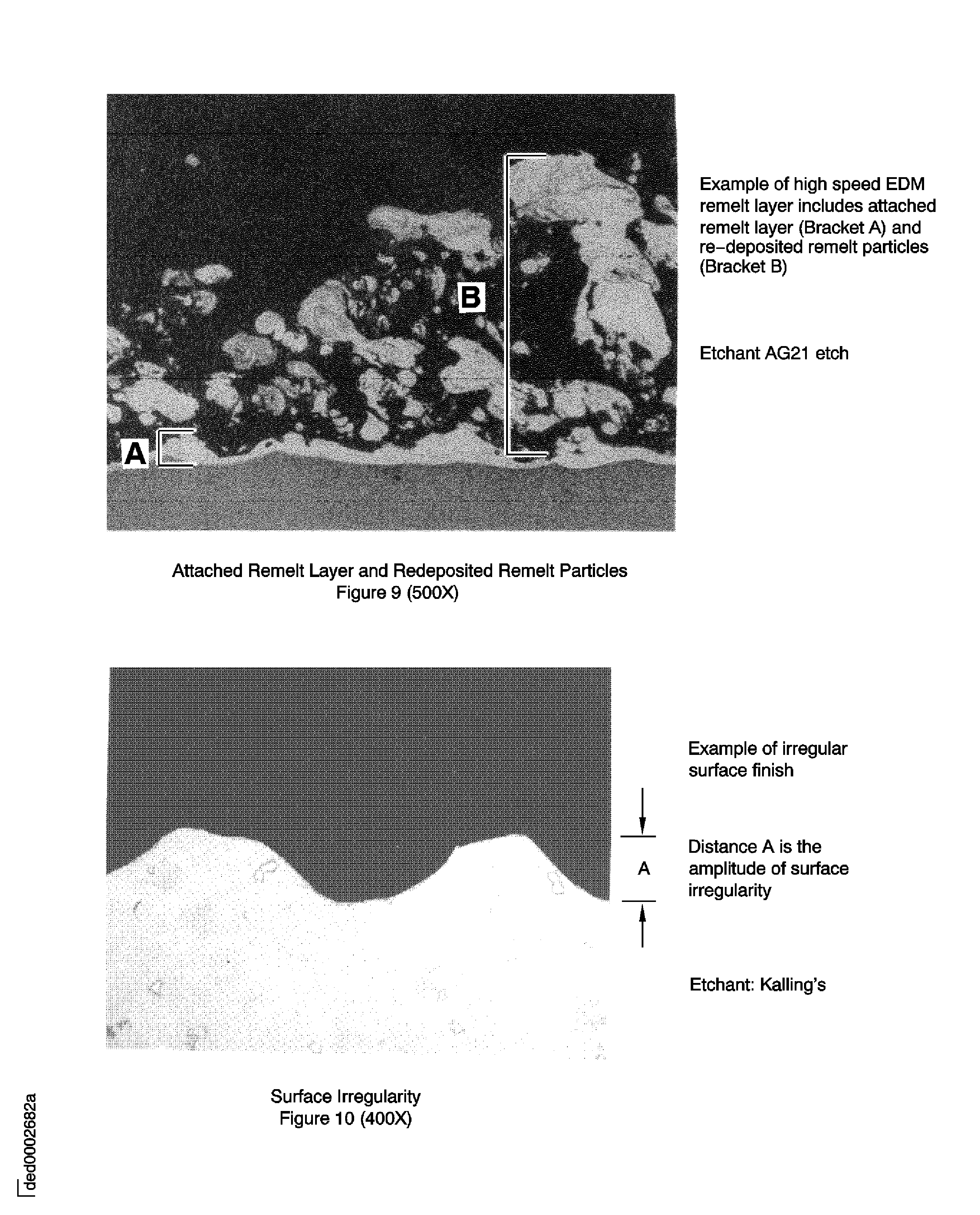

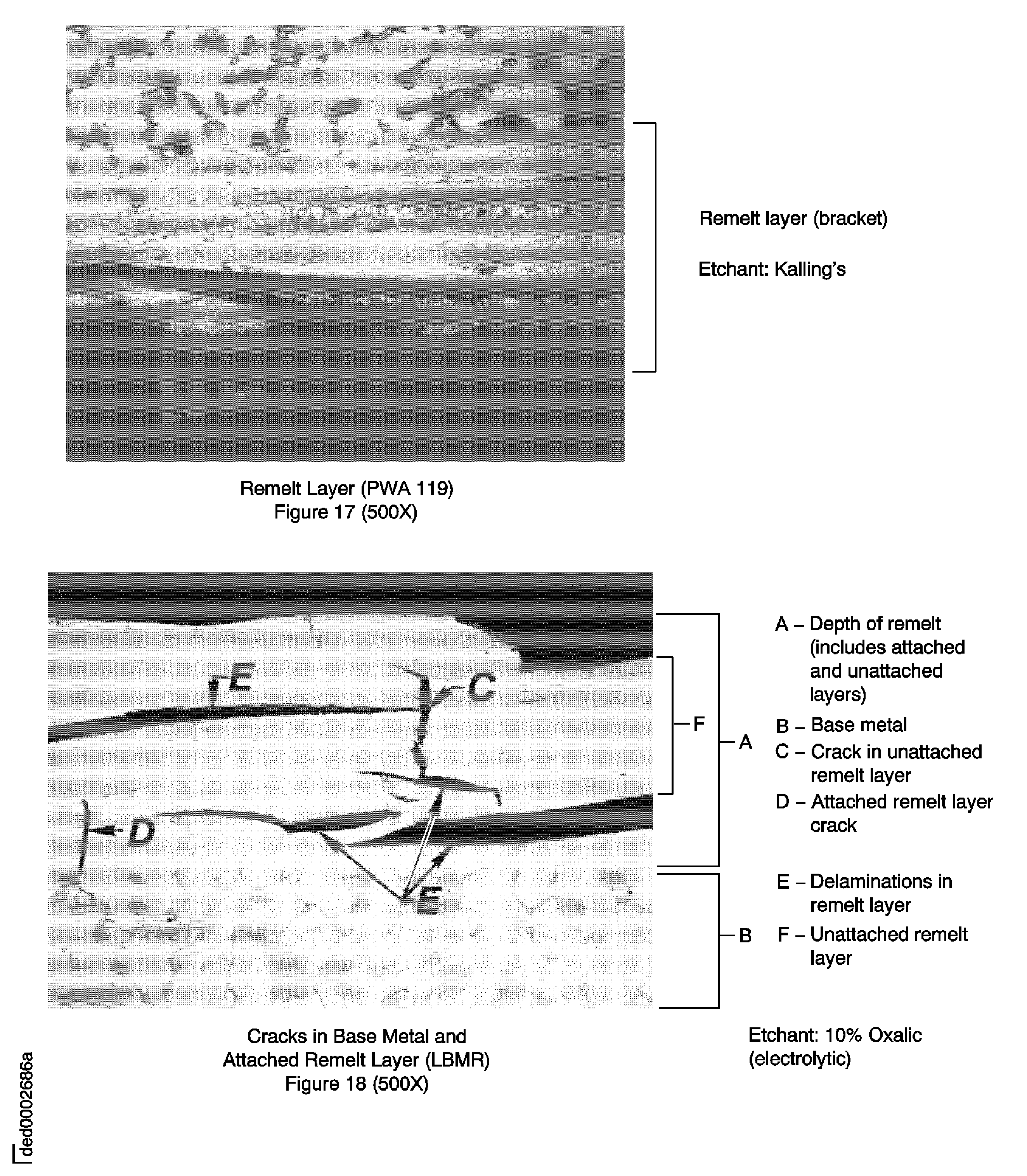

Remelt depth includes any heat affected area adjacent to recast material.Remelt Layer.

Refer to Figure.

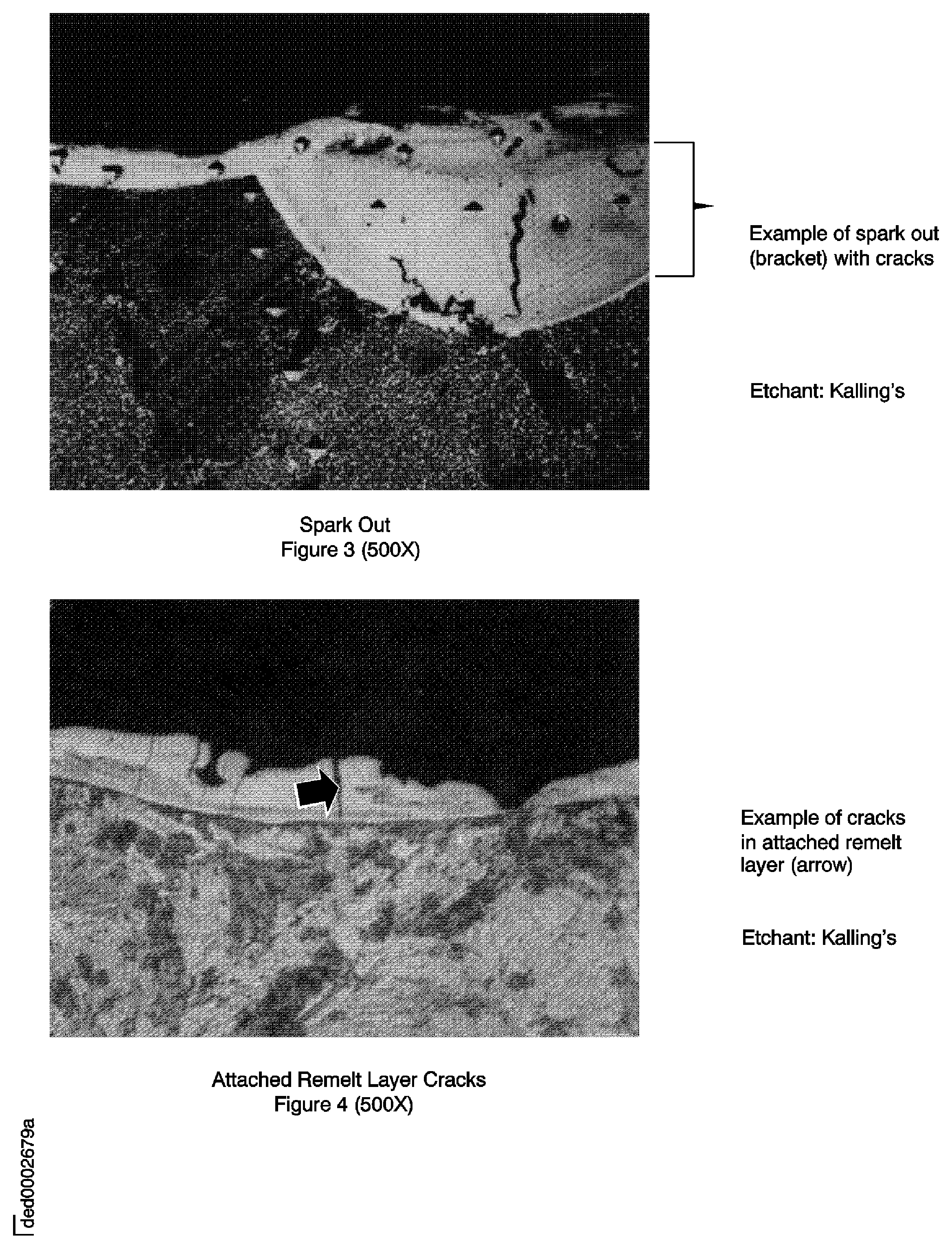

Spark Out.

Refer to Figure.

Remelt Layer Cracks.

Refer to Figure.

For Disks, Gearshafts, Hubs, Rotor Seals, Rotor Spacers, Shafts, Blade Baffles/Tubes, and Blade Retaining Plates.

Surface Irregularity.

Refer to Figure.

NOTE

Remelt depth includes any heat affected area adjacent to recast material.Remelt Layer.

Refer to Figure.

Spark Out.

Refer to Figure.

Remelt Layer Cracks.

Refer to Figure.

For the Parts and the Assemblies of Bolts, Nozzle Nuts, Probes, Tierods, and Cobalt Base Vane Baffles.

Surface Irregularity.

Refer to Figure.

Remelt layer thickness up thru 0.0015 inch (0.038 mm) is permitted. See Figure.

Remelt layer thickness greater than 0.0015 inch (0.038 mm) up thru 0.0025 inch (0.064 mm) must be examined again.

Read and report remelt layer as predominant and maximum conditions that permit isolated indications up thru 0.0025 inch (0.064 mm) as an acceptable condition.

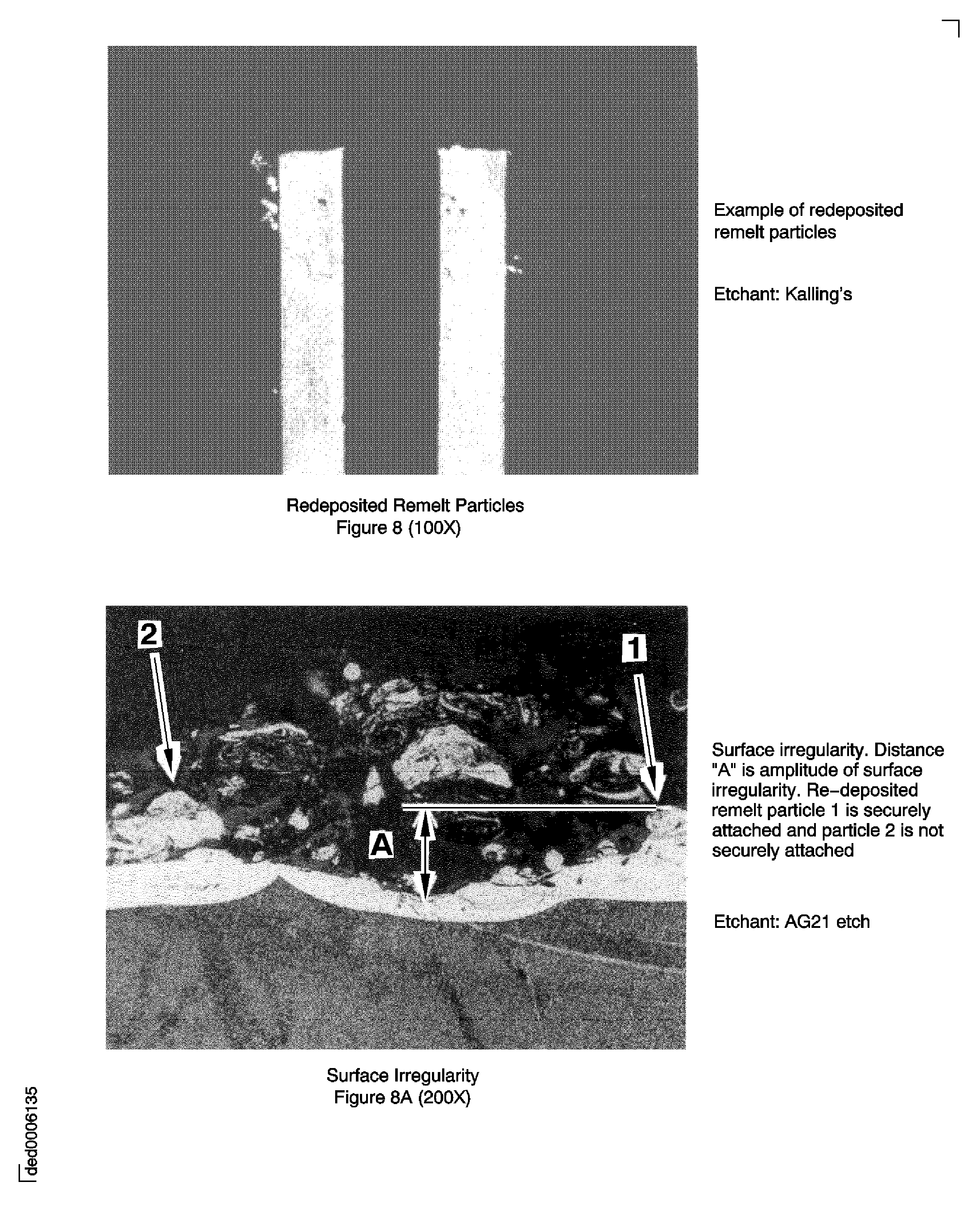

For vane cluster honeycombs, any indication of redeposited remelt must be examined again. Refer to Figure.

NOTE

Remelt depth includes any heat affected area adjacent to recast material.Remelt Layer.

Spark Out.

Refer to Figure.

Remelt Layer Cracks.

Refer to Figure.

For All Other Parts and Assemblies.

This includes Bosses, Braces, Brackets, Bushings, Cases, Case Segments, Clamps, Combustion Chambers, Cones, Covers, Ducts, Duct Segments, Elbows, Flame Holders, Guides, Housing, Liners, Nipples, Nuts, Plates, Pins, Rings, Metal Seal Rings, Nonrotor Seals, Heat Shields, Sleeves Nonrotor Spacers, Bearing Stops, Air Bleed Straps, Struts, Support, Tees, and Tubes.

Spark Out.

Refer to Figure.

Remelt Layer Cracks.

Refer to Figure.

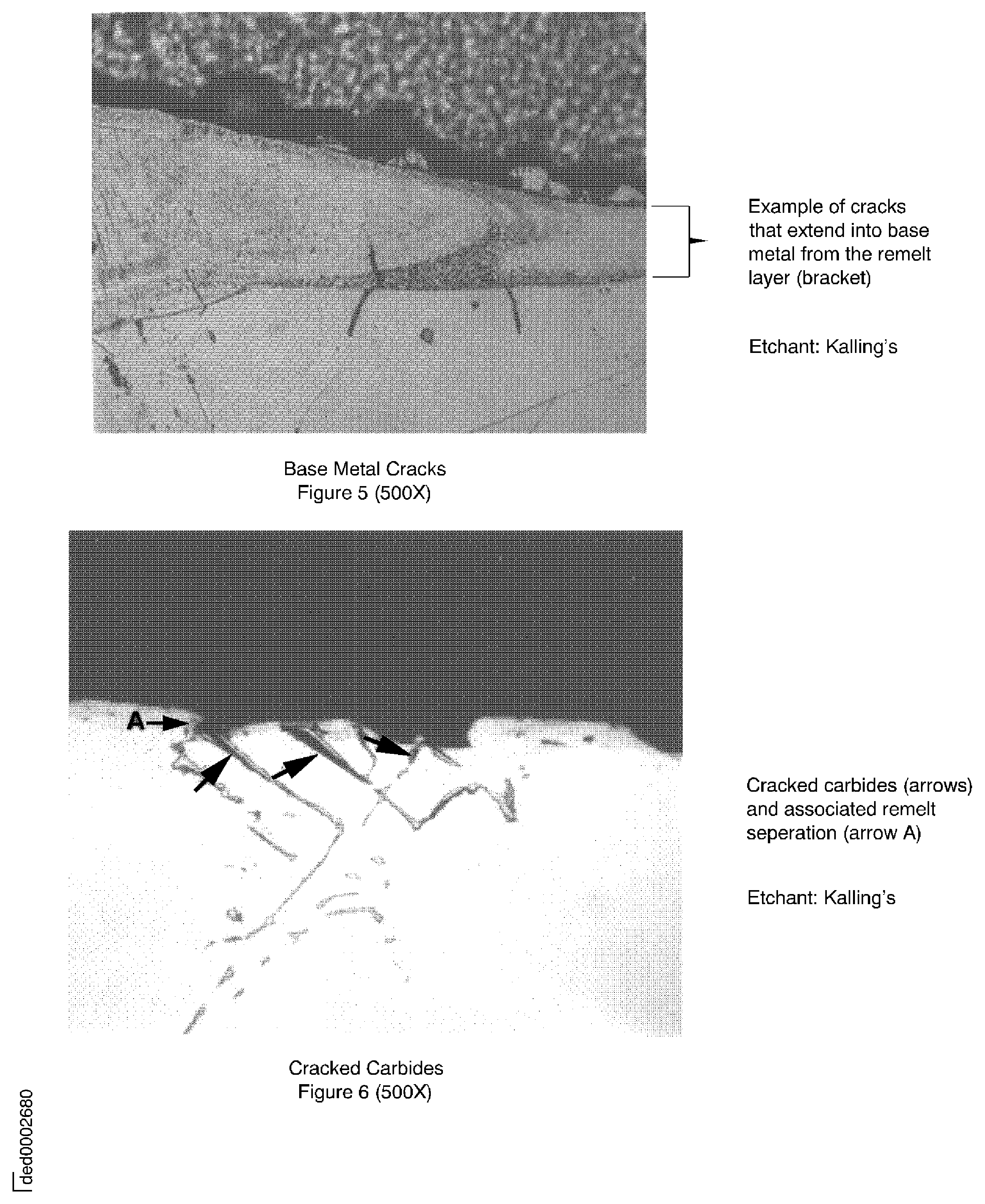

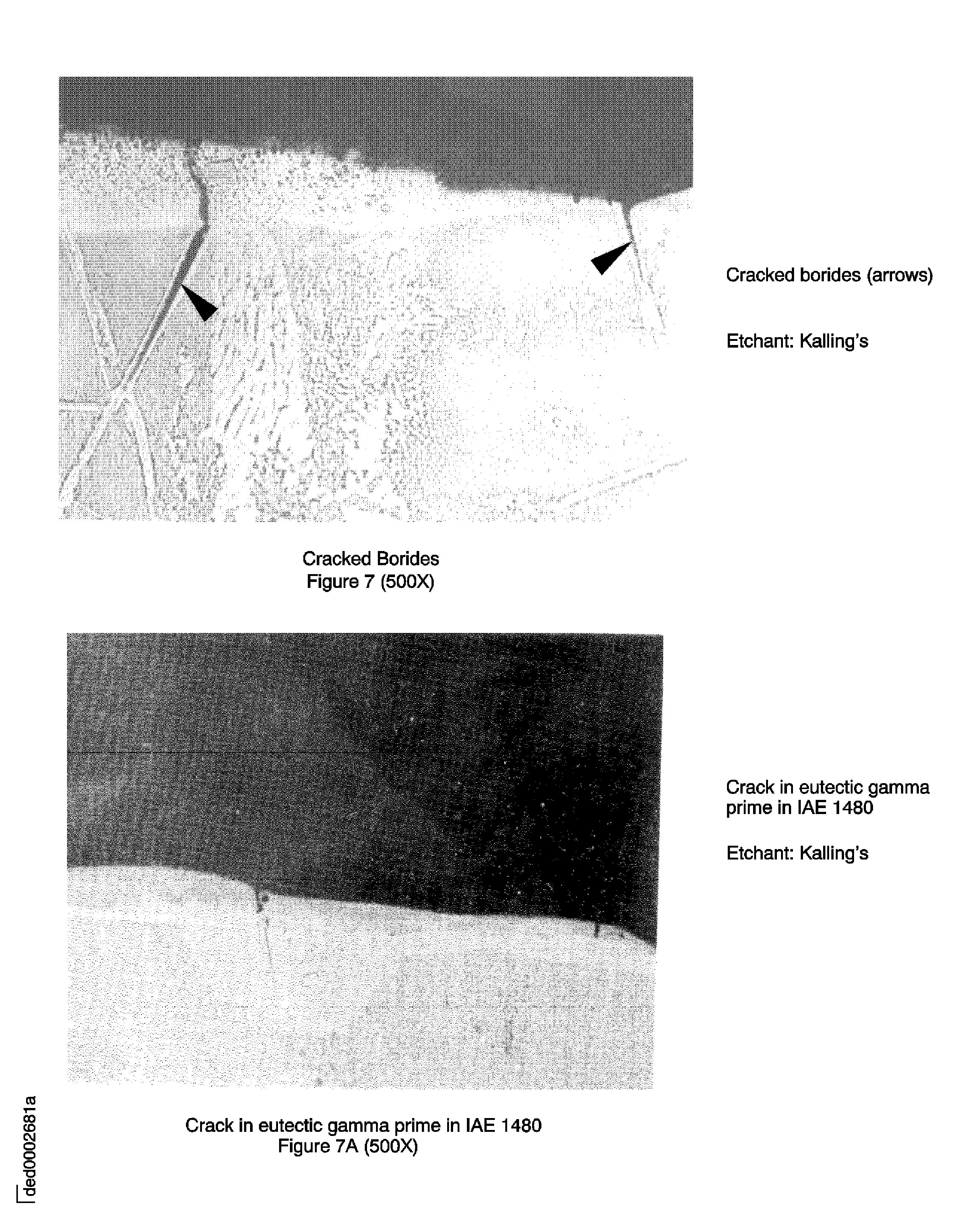

All base metal cracks must be rejected.xcept isolated cracks in attached remelt layer of holes in first stage HPT blades are permitted. For turbine blades, occasional cracks only in carbides and/or associated with eutectic gamma prime in IAE 1480, IAE 1440, and IAE 1499 and commercial blade applications of IAE 1484 are also permitted. (See Figures 6, 7, and 7A).

Base Metal and Remelt Cracks.

Refer to Figure (Base Metal Cracks and Cracked Carbides), and Figure (Cracked Borides) and Figure 7A (Crack in eutectic gamma prime).

NOTE

For holes where LBMR is specifically identified as an acceptable alternative to EDMR, it is permitted to evaluate EDMR holes to the LBMR Quality Standards (refer to LMBR Acceptance Standards for holes in Single Crystal and Directionally Solidified Turbine Blades) as an alternative to the EDMR Quality Standards.NOTE

Surface irregularity measurement is applicable only to the attached remelt layer and is to include redeposited remelt particles securely bonded to the attached remelt layer. See Figure Figure 8A. Surface irregularity is not applicable to turbine airfoil and platform cooling holes.For Blades.

Spark Out.

Refer to Figure.

Remelt Layer Cracks.

See Figure.

All base metal cracks must be rejected except on IAE 1447 vanes where cracks in carbides or borides (TLP-bonded airfoils) in the base metal are permitted. Occasional cracks in carbides and/or associated with eutectic gamma prime in IAE 1480 and IAE 1440, and commercial vane applications of IAE 1484 and IAE 1426 are also acceptable. See Figures 6, 7, and 7A.

Base Metal and Remelt Cracks.

Refer to Figure (Remelt Cracks and Cracked Carbides), and Figure (Cracked Borides) and 7A (Crack in eutectic gamma prime).

NOTE

Surface irregularity measurement is applicable only to the attached remelt layer and is to include redeposited remelt particles securely bonded to the attached remelt layer. See Figure Figure 8A. Surface irregularity is not applicable to turbine airfoil and platform cooling holes.For Nickel Base Vanes (Other than IAE 655).

NOTE

Surface irregularity measurement is applicable only to the attached remelt layer and is to include redeposited remelt particles securely bonded to the attached remelt layer. See Figure Figure 8A. Surface irregularity is not applicable to turbine airfoil and platform cooling holes.Surface Irregularity.

Spark Out.

Refer to Figure.

Remelt Layer Cracks.

Refer to Figure.

For IAE 655 Vanes, Cobalt Base Castings.

SUBTASK 70-35-23-290-001 Acceptance Standards for Electrodischarge Metal Removal (EDMR)

Surface irregularity amplitude (see Figure) greater than 0.0015 inch (0.038 mm) must be examined again.

Surface Irregularity.

Intergranular Attack.

Refer to Figure.

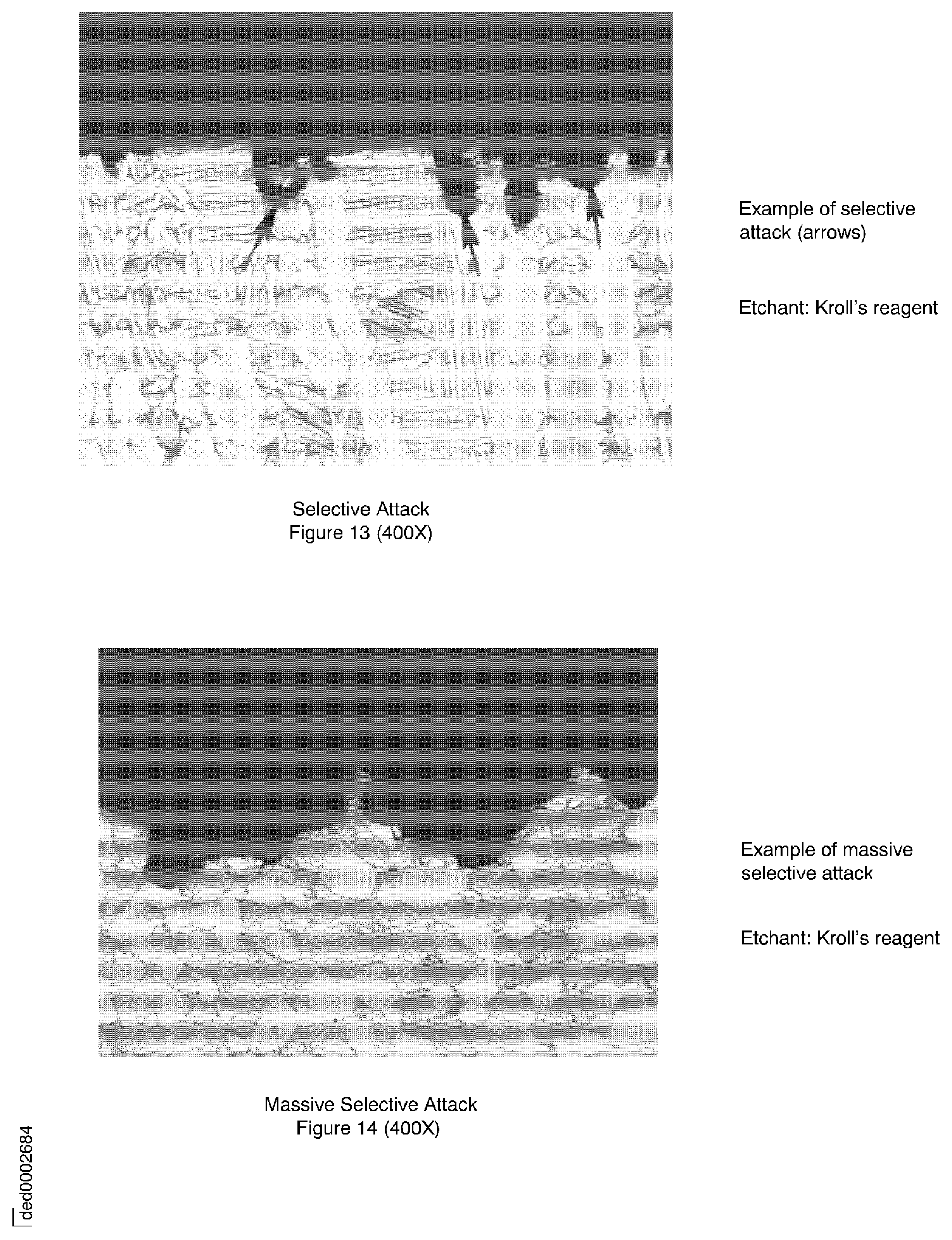

Selective Attack.

Refer to Figure.

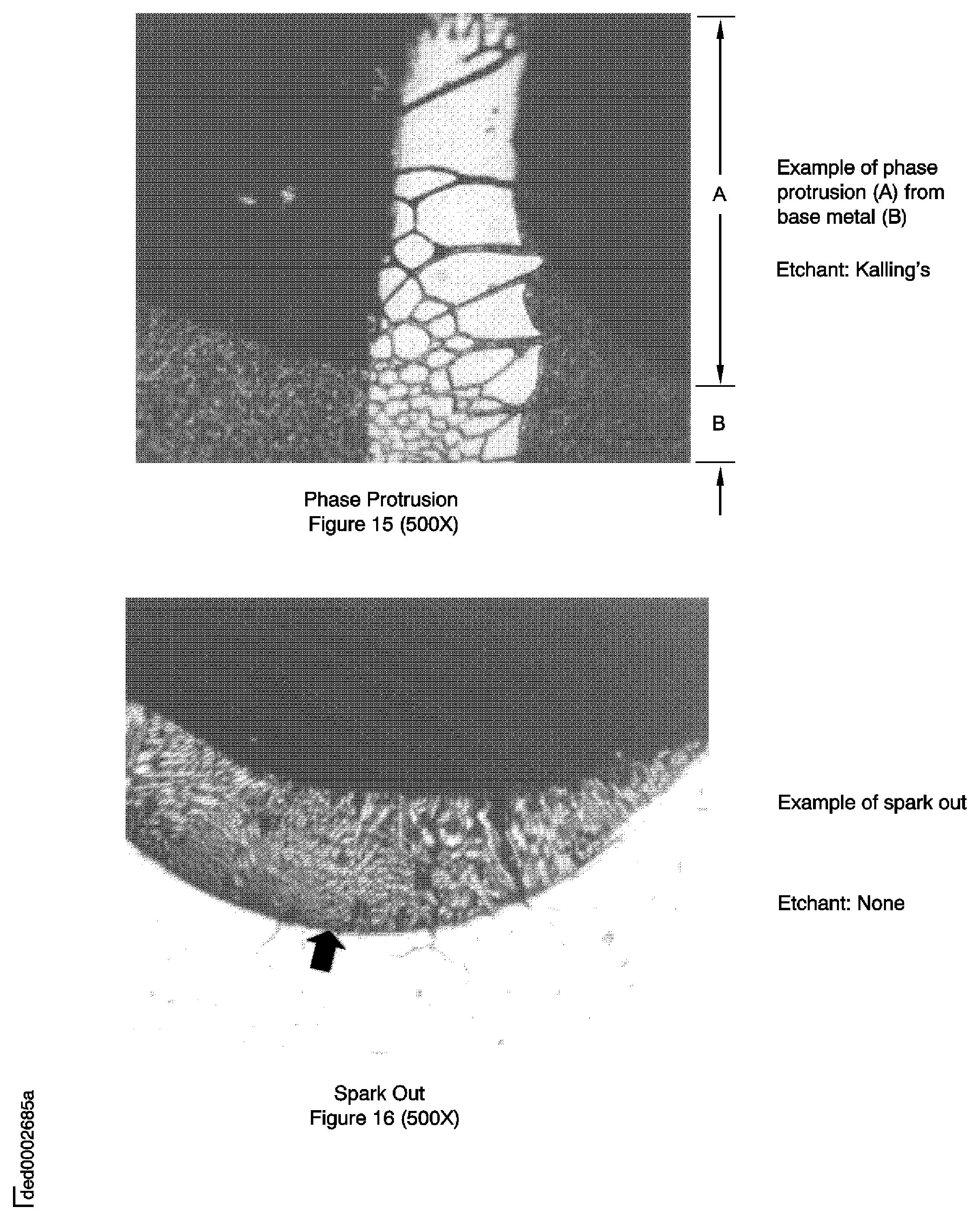

Phased Protrusion (Applicable to Castings Only).

Refer to Figure.

Spark Out.

Refer to Figure.

For Blades, Blade Baffles, Clevises, Swirl Guides, Root Wedges and Blade Retaining Plates.

Surface irregularity amplitude (see Figure) greater than 0.0015 inch (0.038 mm) must be examined again.

Surface Irregularity.

Intergranular Attack.

Refer to Figure.

Selective Attack.

Refer to Figure.

Phased Protrusion (Applicable to Castings Only).

Refer to Figure.

Spark Out.

Refer to Figure.

For Parts and Assemblies of Bolts, Nozzle Nuts, Probes, Tierods, Vanes, and Vane Baffles.

Intergranular Attack.

Refer to Figure.

Selective Attack.

Refer to Figure.

Phased Protrusion (Applicable to Castings Only).

Refer to Figure.

Spark Out.

Refer to Figure.

For All Other Parts and Assemblies.

This includes Bosses, Braces, Brackets, Bushings, Cases, Case Segments, Clamps, Combustion Chambers, Cones, Covers, Ducts, Duct Segments, Elbows, Flame Holders, Guides, Housings, Liners, Nipples, Nuts, Plates, Pins, Rings, Metal Seal Rings, Nonrotor Seals, Heat Shields, Sleeves, Nonrotor Spacers, Bearing Stops, Air Bleed Straps, Struts, Supports, Tees, and Tubes.

SUBTASK 70-35-23-290-002 Acceptance Standards for Electrochemical Metal Removal (ECMR)

Surface Irregularity.

Refer to Figure.

For holes less than or equal to 0.200 inch (5.080 mm) in length, a remelt layer thickness up thru 0.010 inch (0.254 mm) is permitted.

For holes less than or equal to 0.400 inch (10.160 mm) in length, a remelt layer thickness up thru 0.020 inch (0.508 mm) is permitted.

For holes greater than 0.400 inch (10.160 mm) in length, a remelt layer thickness up thru 0.030 inch (0.762 mm) is permitted.

Remelt layers which are permitted as a function of hole length, in inches (mm), are as follows:

Holes less than or equal to 0.200 inch (5.080 mm) in length, with a remelt layer thickness greater than 0.010 inch. (0.254 mm).

Holes less than or equal to 0.400 inch (10.160 mm) in length with a remelt layer thickness greater than 0.020 inch (0.508 mm).

Holes greater than 0.400 inch (10.160 mm) in length with a remelt layer thickness greater than 0.030 inch (0.762 mm).

Remelt layers which must be examined again as a function of hole length, in inches (mm), are as follows:

NOTE

Remelt layer depth includes any heat affected area adjacent to recast material.Remelt Layer.

Refer to Fig. 70-35-23-990-010 and Figure.

Cracks in Base Metal.

Refer to Figure.

NOTE

Cracks in the base metal which do not extend into or fully through a firmly attached remelt layer will be considered to be as deep as their visible length plus the thickness of the attached remelt layer above the crack.Cracks in Base Metal plus Attached Remelt Layer.

Refer to Figure.

Cracks in Attached Remelt Layer.

Refer to Figure.

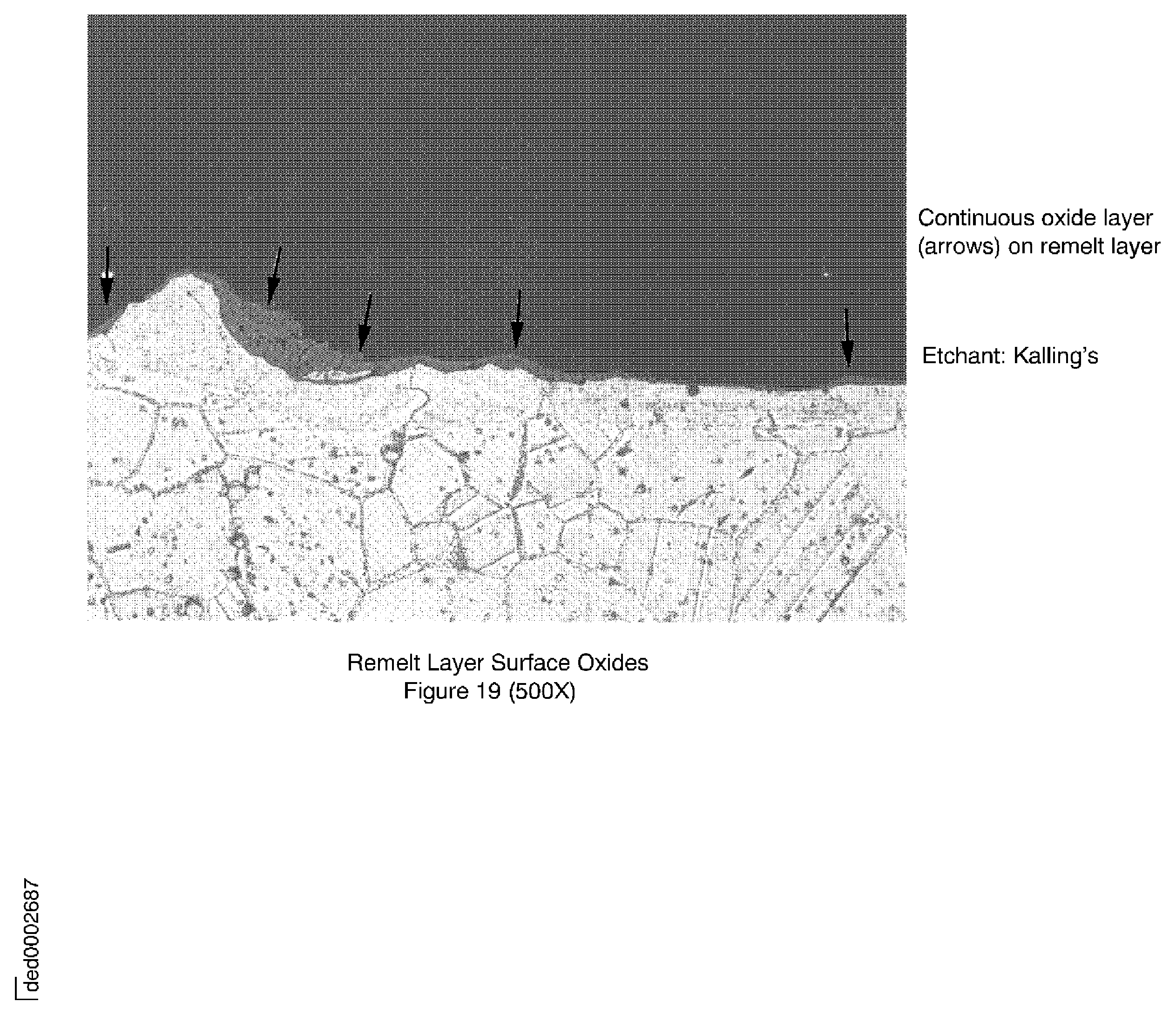

Remelt Layer Surface Oxide.

Refer to Figure.

For IAE 647 Vane Platform Holes and Cooling Holes in Cobalt Based Alloys.

Surface Irregularity.

Refer to Figure.

Cracks in Base Metal.

Refer to Figure.

NOTE

Cracks in the base metal which do not extend into or fully through a firmly attached remelt layer will be considered to be as deep as their visible length plus the thickness of the attached remelt layer above the crack.Cracks in Base Metal plus Attached Remelt Layer.

Refer to Figure.

Cracks in Attached Remelt Layer.

Refer to Figure.

Remelt Layer Surface Oxides.

Refer to Figure.

For IAE 647 Vane Airfoil Holes.

Surface Irregularity.

Refer to Figure.

Cracks in Base Metal.

Refer to Figure.

Cracks in Base Metal plus Attached Remelt Layer.

Refer to Figure.

NOTE

Cracks in the base metal which do not extend into or fully through a firmly attached remelt layer will be considered to be as deep as their visible length plus the thickness of the attached remelt layer above the crack.Cracks in Attached Remelt Layer.

Refer to Figure.

Remelt Layer Surface Oxides.

Refer to Figure.

For Holes in Single Crystal and Directionally Solidified Turbine Blades.

Refer to Figure.

Surface Irregularity.

For holes less than or equal to 0.200 inch (5.080 mm) in length, a remelt layer thickness up thru 0.015 inch (0.381 mm) is permitted.

For holes less than or equal to 0.400 inch (10.060 mm) in length, a remelt layer thickness up thru 0.020 inch (0.508 mm) is permitted.

For holes greater than 0.400 inch (10.160 mm) in length, a remelt layer thickness up thru 0.030 inch (0.762 mm) is permitted.

Remelt layers which are permitted as a function of hole length, in inches (mm), are as follows:

Holes less than or equal to 0.200 inch (5.080 mm) in length with a remelt layer thickness greater than 0.015 inch (0.381 mm).

Holes less than or equal to 0.400 inch (10.160 mm) in length with a remelt layer thickness greater than 0.020 inch (0.508 mm).

Holes greater than 0.400 inch (10.160 mm) in length with a remelt layer thickness greater than 0.030 inch (0.762 mm).

Remelt layers which must examined again as a function of hole length, in inches (mm), are as follows:

Remelt Layer.

Refer to Figure.

Cracks in Base Metal.

Refer to Figure.

Cracks in Base Metal plus Attached Remelt Layer.

Refer to Figure.

Cracks in Attached Remelt Layer.

For IAE 264 Coated Platform and Airfoil Holes and Conical Holes in Outer Airseals.

Refer to Figure.

Surface Irregularity.

Refer to Figure.

Cracks in Base Metal.

Refer to Figure.

Cracks in Base Metal plus Attached Remelt Layer.

Refer to Figure.

NOTE

Cracks in the base metal which do not extend into or fully through a firmly attached remelt layer will be considered to be as deep as their visible length plus the thickness of the attached remelt layer above the crack.Cracks in Attached Remelt Layer.

For 1st HPT Blade Platform Holes.

Refer to Figure.

Surface Irregularity.

Refer to Figure.

Cracks in Base Metal.

NOTE

Cracks in the base metal which do not extend into or fully through a firmly attached remelt layer will be considered to be as deep as their visible length plus the thickness of the attached remelt layer above the crack.Cracks in Base Metal plus Attached Remelt Layer.

Refer to Figure.

Refer to Figure.

Cracks in Attached Remelt Layer.

Remelt Layer Surface Oxides.

Refer to FigFigure.

For Cast and Wrought Combustion Chambers Domes (Bulkheads).

SUBTASK 70-35-23-290-004 Acceptance Standards for Laser Beam Metal Removal (LBMR)

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal

Figure: Nonmechanical metal removal

Nonmechanical metal removal