Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-35-27-300-501 Installation Of Helical Coil Threaded Inserts

Introduction

This procedure can be used to replace helical coil inserts (tanged or Tangless (R)) or repair damage to threads unless specified differently.

Helical coil threaded inserts are used both in initial part manufacture, which is typical for parts made of aluminum, and as a method to repair damage to threads.

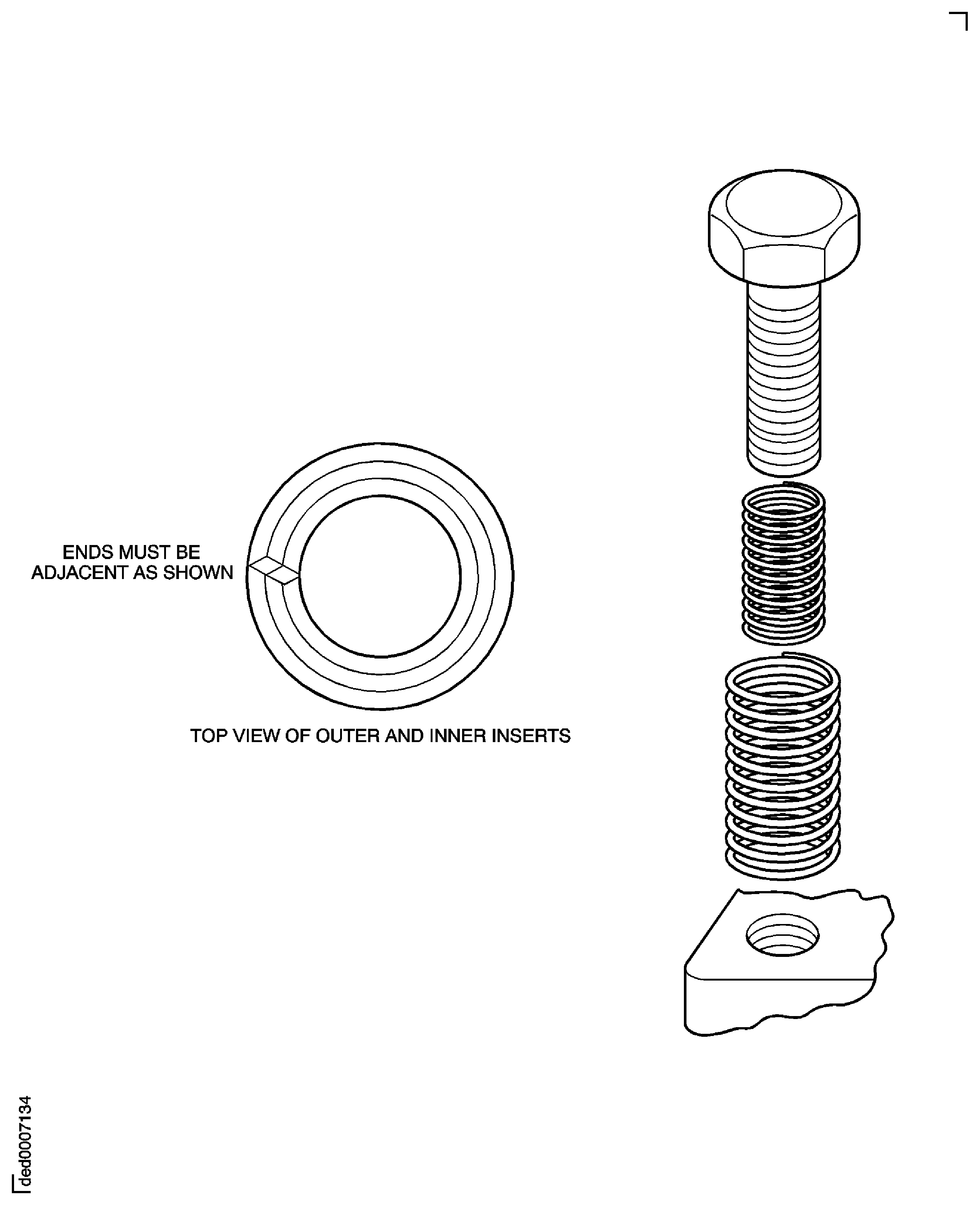

Double helical coil threaded inserts are available for threads that have damage beyond the limits of standard helical coil thread insert specifications. See Figure.

Helical coil threaded inserts are available in all standard sizes in National Fine and National Coarse Series up to 1.5 inch (38.1 mm) size as well as 8 pitch threads, metric threads, and tapered pipe threads.

Over-sized helical coil threaded inserts can be used if the minimum wall thickness is kept.

Tangless inserts have advantages when compared to tanged inserts.

Tangless inserts do not have tangs to remove and discard, this helps prevent possible Foreign Object Damage (FOD).

Tangless inserts can reduce the time necessary for installation of threaded inserts.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

CAUTION

Procedure

NOTE

For applications up to 800 deg F (427 deg C), use stainless steel (AMS 7245) inserts.NOTE

For applications at 800 to 1000 deg F (427 to 538 deg C), use Inconel X-750 (AMS 7246) inserts.To determine the correct size of the new insert, compare the new insert specifications with the initial finished thread hole size. Use the manufacturer's installation instructions as an aid in the correct insert selection.

For aluminum, refer to the SPM TASK 70-33-22-300-503 for the procedure to anodize touch-up the aluminum by brush or swab methods.

Treat the insert hole and other areas where it is possible the protective coating was removed. Do the subsequent procedure:

To replace helical coil threaded inserts that were installed during the initial manufacture of the part, do the subsequent steps:

NOTE

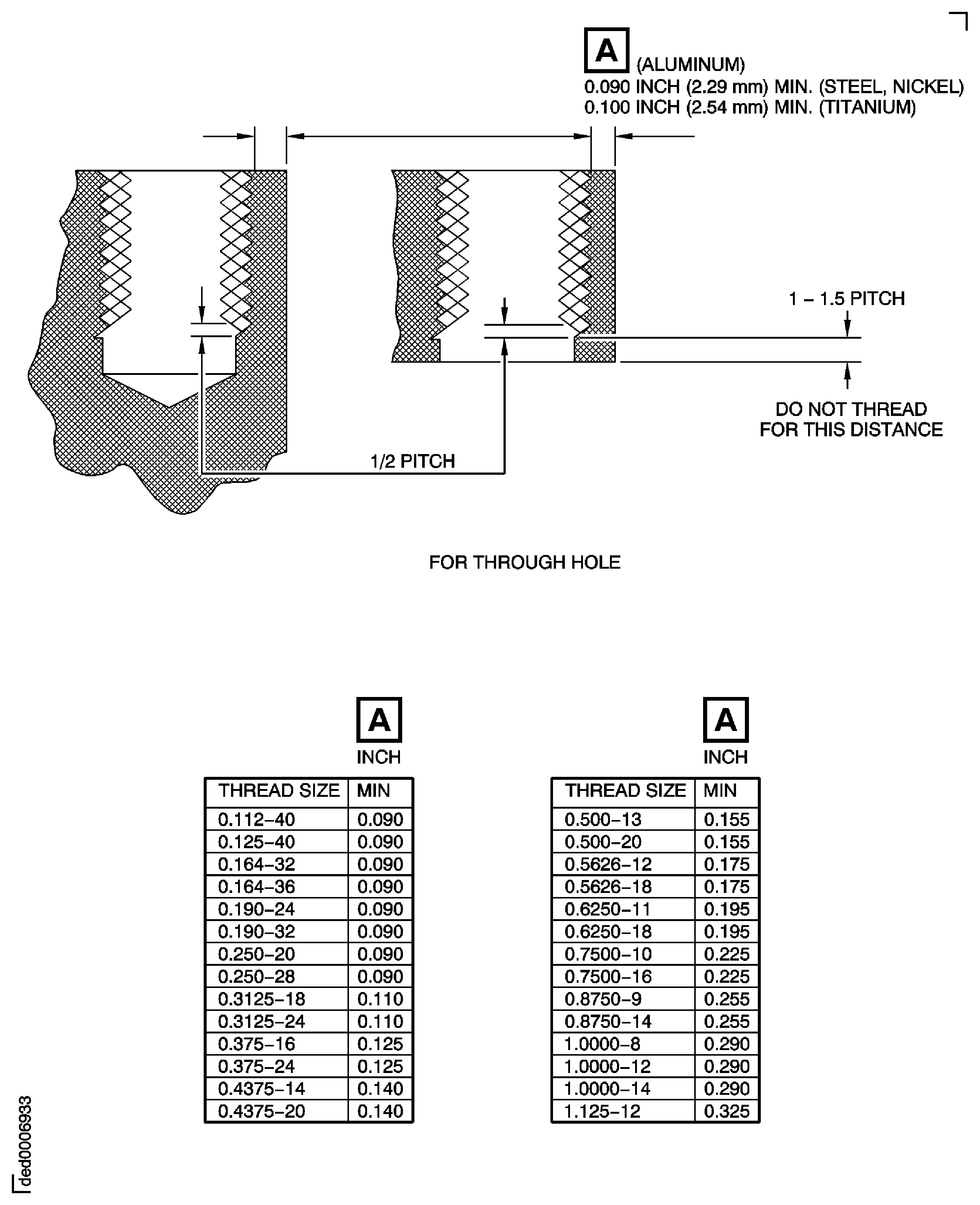

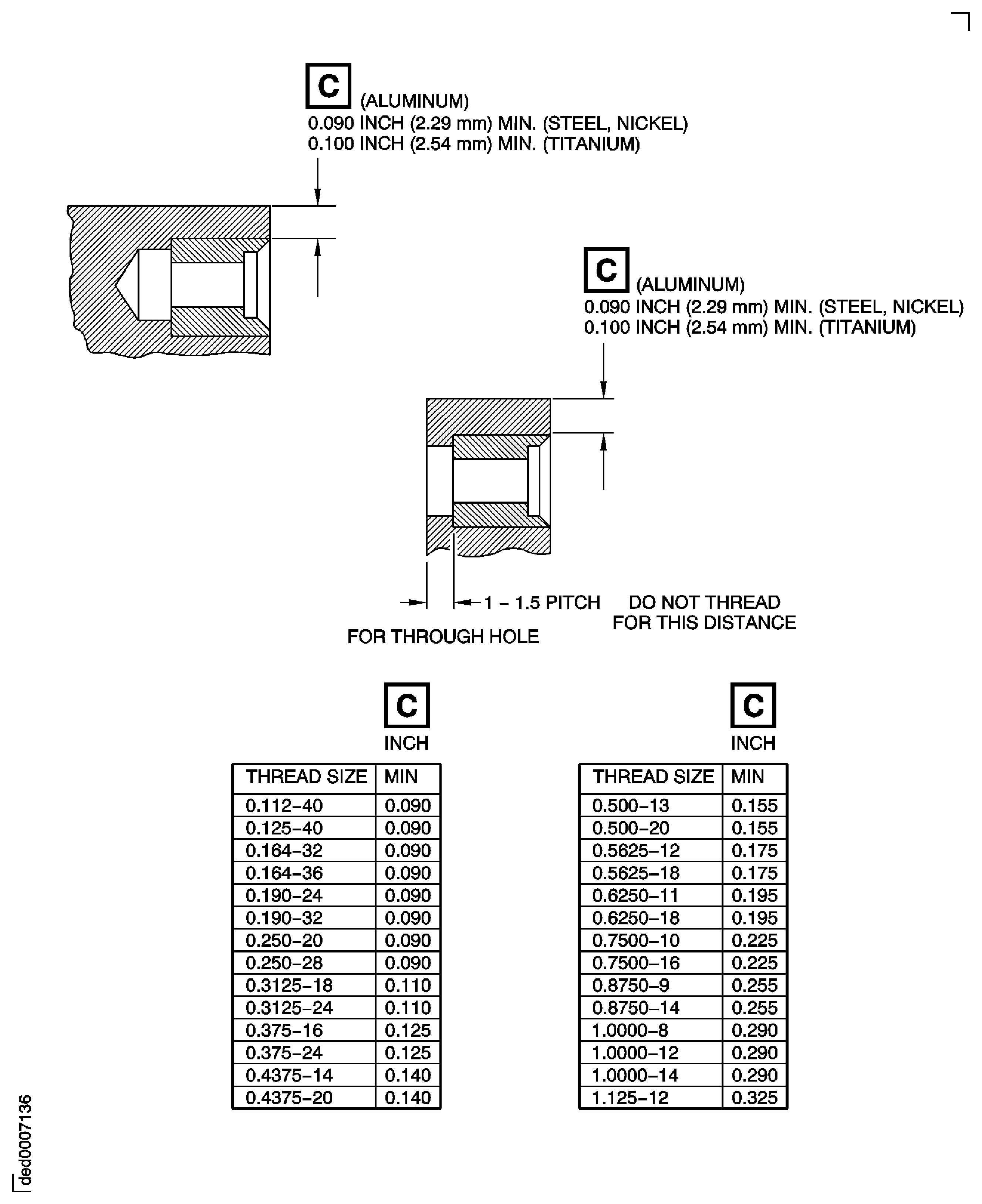

For applications up to 800 deg F (427 deg C), use stainless steel (AMS 7245) inserts.For applications at 800 to 1000 deg F (427 to 538 deg C), use Inconel X-750 (AMS 7246) inserts.To determine the correct size of the new insert, compare the new insert specifications with the initial finished thread hole size. Use the manufacturer's installation instructions as an aid in the correct insert selection.A sufficient wall thickness is necessary for the repair of damaged thread holes with helical coil inserts. Determine if there is sufficient wall thickness. See Figure.

For aluminum, refer to the SPM TASK 70-33-22-300-503 for the procedure to anodize touch-up the aluminum by brush or swab methods.

To replace helical coil threaded inserts that were installed to repair damage to threads, do the subsequent steps:

NOTE

For applications up to 800 deg F (427 deg C), use stainless steel (AMS 7245) inserts.NOTE

For applications at 800 to 1000 deg F (427 to 538 deg C), use Inconel X-750 (AMS 7246) inserts.To determine the correct size of the new insert, compare the new insert specifications with the initial finished thread hole size. Use the manufacturer's installation instructions as an aid in the correct insert selection.

A sufficient wall thickness is necessary for the repair of damage to thread holes with double threaded helical coil inserts. Determine if there is sufficient wall thickness. See Figure.

For aluminum, refer to the SPM TASK 70-33-22-300-503 for the procedure to anodize touch-up the aluminum by brush or swab methods.

Treat the insert hole and other areas where it is possible the protective coating was removed. Do the subsequent procedure:

Install the inner insert so that the end of the last coil is flush with the end of the outer insert. See Figure.

Install the double helical coil threaded insert. Refer to the manufacturer's instructions.

When it is necessary to use a double helical coil threaded insert to repair threads that have damage beyond the limits of standard helical coil threaded insert specifications, do the subsequent steps:

SUBTASK 70-35-27-350-001 Procedure to Install Helical Coil Inserts

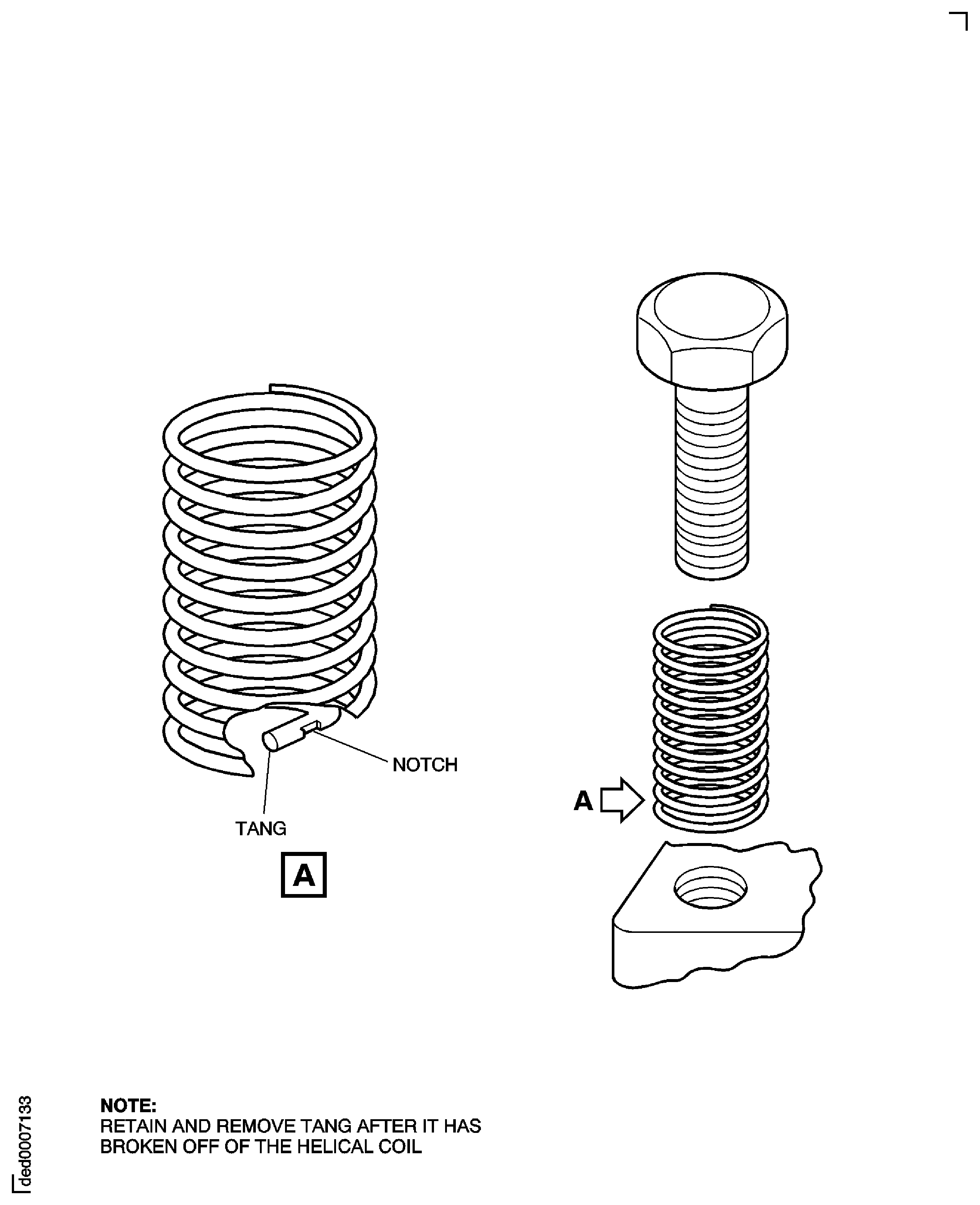

Figure: Helical Coil Threaded Insert

Helical Coil Threaded Insert

Figure: Double Helical Coil Threaded Insert For Oversized Holes

Double Helical Coil Threaded Insert For Oversized Holes

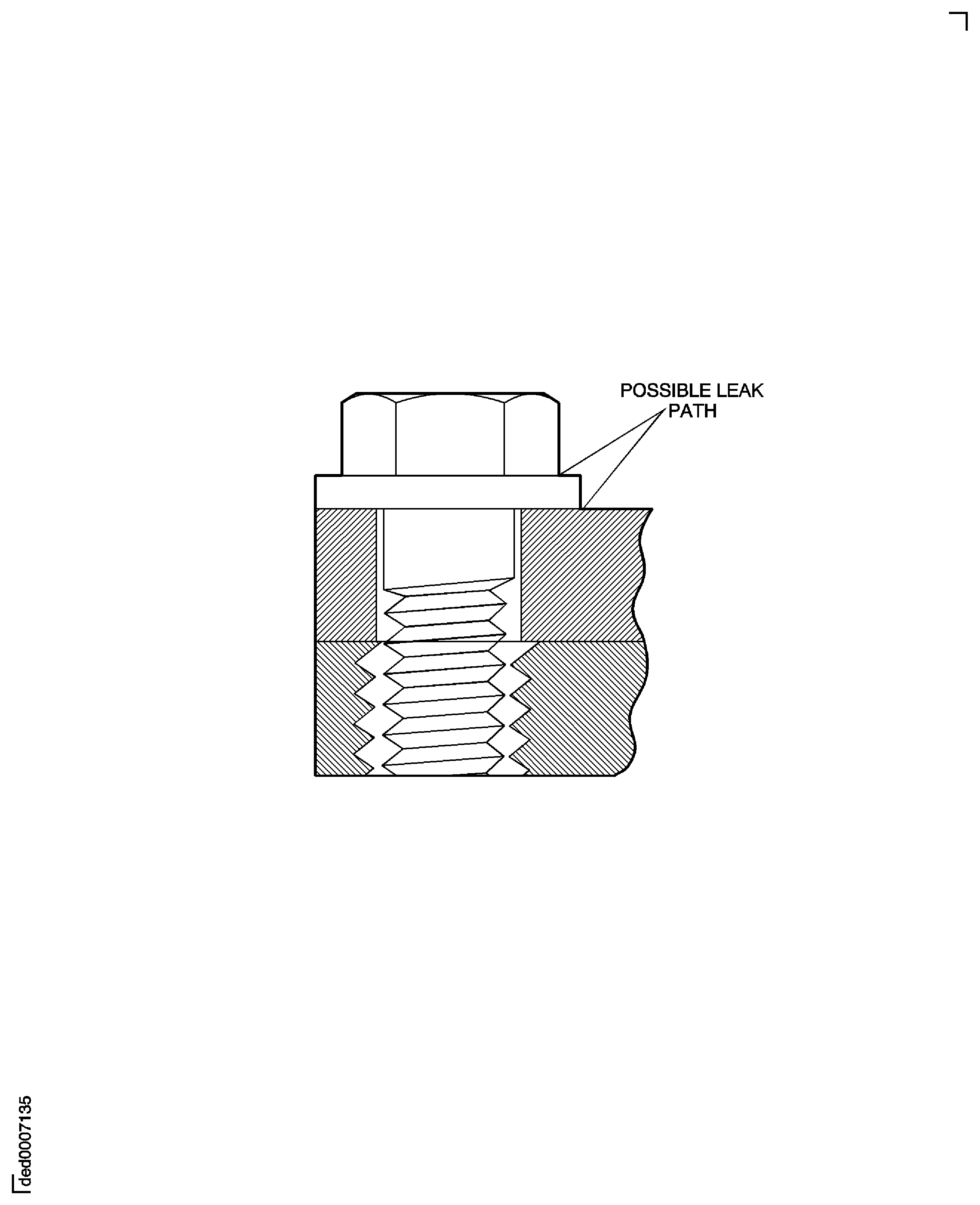

Figure: Helical Coil Threaded Insert In Through Hole

Helical Coil Threaded Insert In Through Hole

Figure: Determination of Sufficient Wall Thickness For Parts Which Use Helical Coil Inserts For Thread Damage Repair

Determination of Sufficient Wall Thickness For Parts Which Use Helical Coil Inserts For Thread Damage Repair

Figure: Determination of Sufficient Wall Thickness For Parts Which Use Double Helical Coil Threaded Inserts For Thread Damage Repair

Determination of Sufficient Wall Thickness For Parts Which Use Double Helical Coil Threaded Inserts For Thread Damage Repair