Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-36-03-360-501 Moulding Process For Polyurethane Resin

Safety Precautions

Specification of Process

This specification covers the moulding process and the quality necessary for CoMat 07-069 POLYURETHANE RESIN.

Application

This CoMat 07-069 POLYURETHANE RESIN is used for a sealing, caulking and cavity filling compound at temperatures of upto 250 deg F (121 deg C).

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 05-121 SILICON CARBIDE GRIT | IAE72 | CoMat 05-121 | ||

| CoMat 05-122 SILICON CARBIDE GRIT | IAE72 | CoMat 05-122 | ||

| CoMat 05-123 SILICON CARBIDE GRIT | IAE72 | CoMat 05-123 | ||

| CoMat 05-124 SILICON CARBIDE GRIT | IAE72 | CoMat 05-124 | ||

| CoMat 07-068 PRIMER | IE401 | CoMat 07-068 | ||

| CoMat 07-069 POLYURETHANE RESIN | 24664 | CoMat 07-069 |

Spares

NONESafety Requirements

WARNING

Procedure

Apply dry abrasive blast (Refer to the SPM TASK 70-12-02-120-501) to mould area by CoMat 05-121 SILICON CARBIDE GRIT or CoMat 05-122 SILICON CARBIDE GRIT or CoMat 05-123 SILICON CARBIDE GRIT or CoMat 05-124 SILICON CARBIDE GRIT.

Wipe blasted surface by CoMat 01-076 METHYL ETHYL KETONE reagent grade using clean unsized cheese cloth.

WARNING

WHEN YOU USE COMAT 01-076 METHYLETHYLKETONE YOU MUST MAKE SURE THERE IS SUFFICIENT VENTILATION. YOU MUST USE THE CORRECT PROTECTIVE CLOTHING. YOU MUST NOT SMOKE. DO NOT PUT THE SOLVENT NEAR A SOURCE OF HEAT.Prepare.

Within 30 minutes after cleaning, apply CoMat 07-068 PRIMER to moulding surface with the use of a brush. Thickness to be between 0.0002 to 0.0004 in. (0.005 to 0.010 mm).

Under coating.

Mix CoMat 07-069 POLYURETHANE RESIN at 105 deg to 176 deg F (40 deg to 80 deg C) in a percentage of 99.5 to 100.5 parts by weight part A to 10.5 to 11.5 parts by weight part B.

Moulding.

SUBTASK 70-36-03-360-001 Moulding Procedure

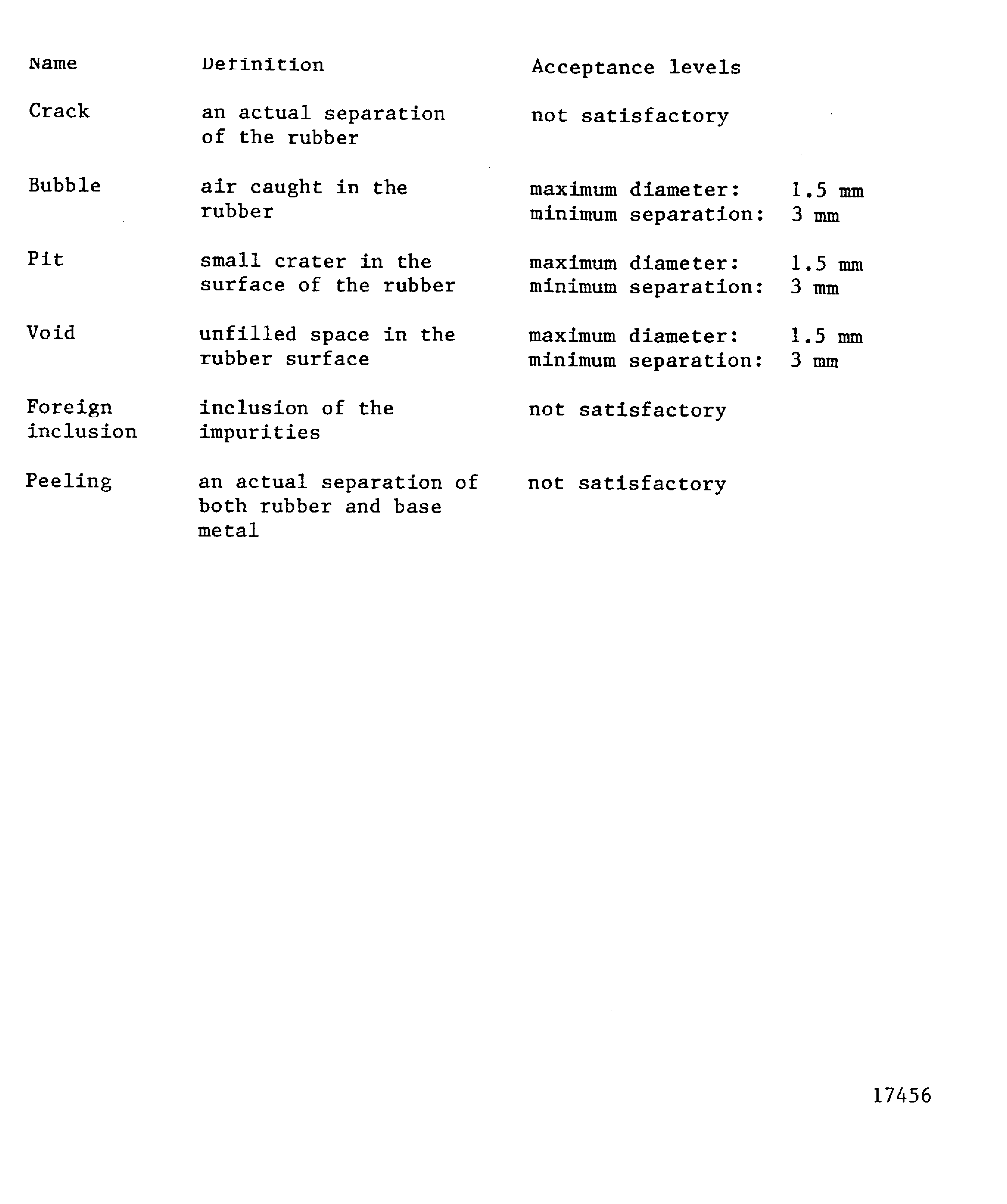

Unless differently specified in the Engine Manual, defects and their acceptance levels shown in Figure.

Acceptance levels.

SUBTASK 70-36-03-220-001 Inspection of Moulding

Figure: Defects and permitted levels

Defects and permitted levels