DMC:V2500-00-70-42-01-00A-712A-D|Issue No:001.00|Issue Date:2013-03-20

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991:

SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.

Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021)

The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).

Common Information

TASK 70-42-01-400-501 Check For Reuse Of Self-Locking Fasteners

General

This TASK gives the procedure to make sure the self-locking nuts, the bolts and the helical coil inserts (used in the engine) can be used again.

Make a test on them to make sure they will keep a specified torque capacity.

You must discard them if the lock function is not satisfactory; do not try to repair them.

Torque Limits

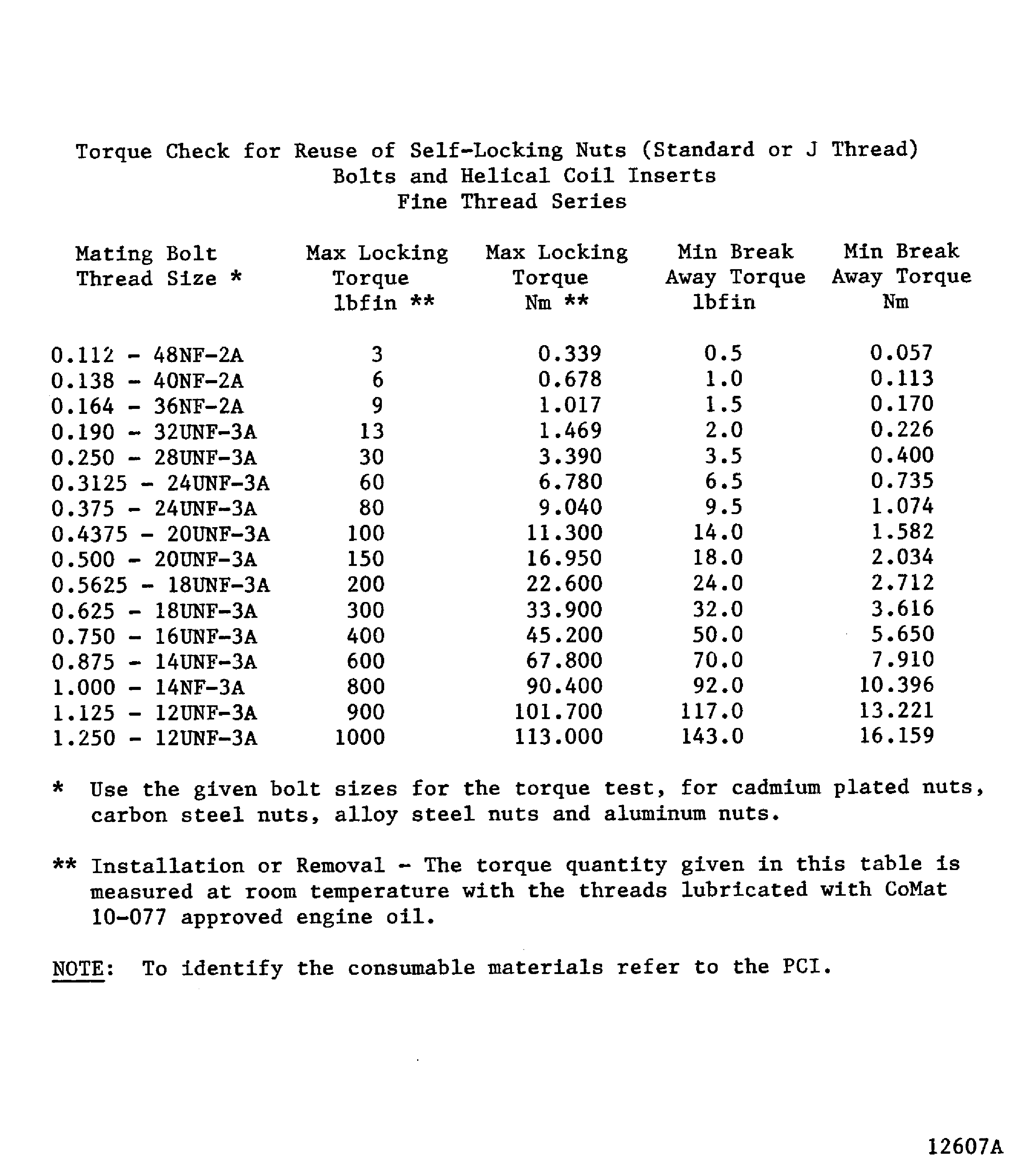

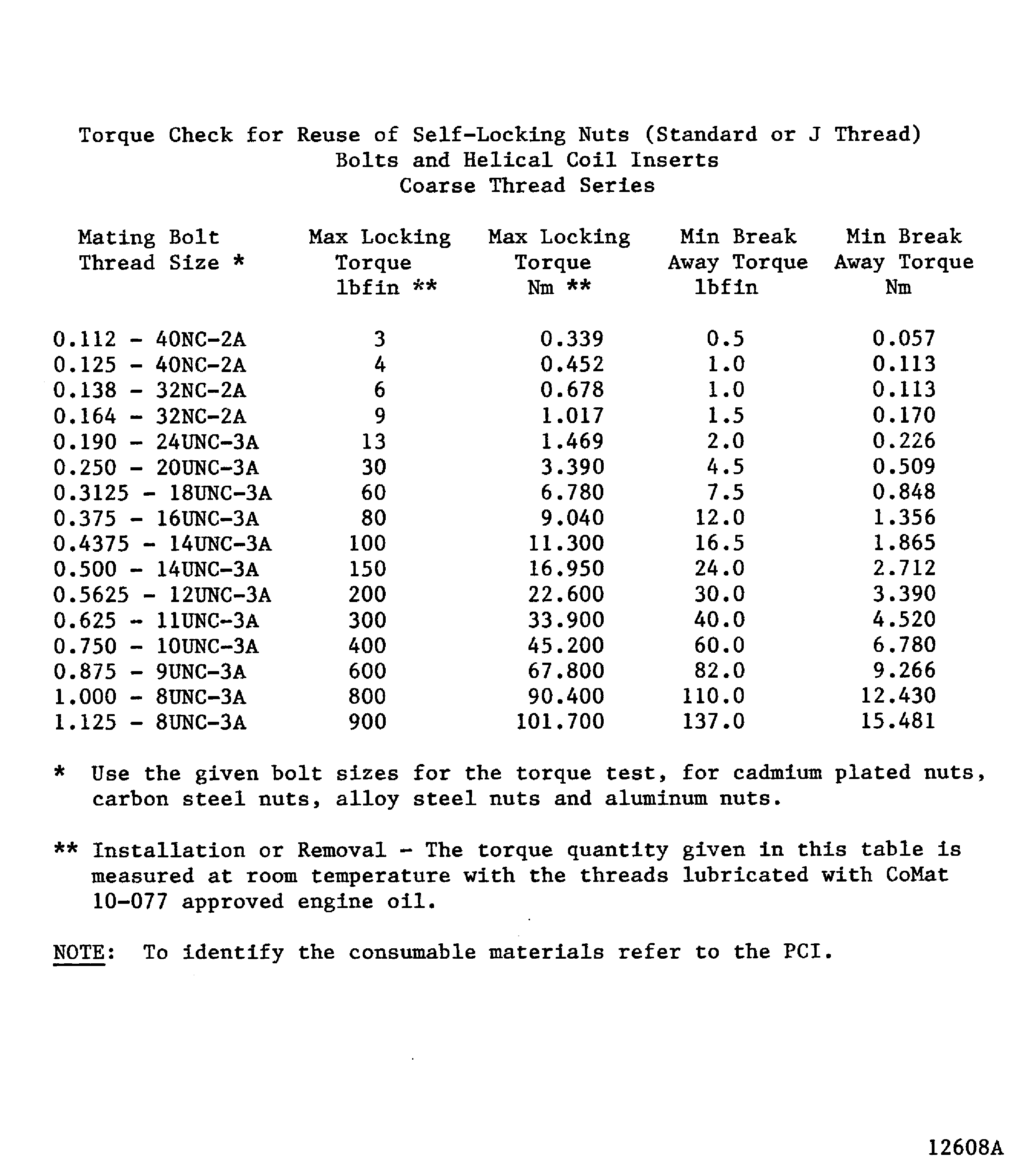

You must make sure the self-locking nuts, the bolts and the helical coil inserts agree with the necessary torque values in Figure or Figure.

Minimum breakaway torque.

This is the minimum torque necessary to initially turn an installed nut on a bolt or a bolt in a self-locking nut or helical coil insert. The minimum breakaway torque must not be less than the value given in Figure or Figure.

This is the torque necessary to continuously turn a loosened nut on a bolt or a bolt in a self-locking nut or helical coil insert. The maximum locking torque must not be more than the given value in Figure or Figure.

NOTE

To identify the consumable materials refer to the PCI.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

Spares

NONESafety Requirements

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS AND SAFE HANDLING, USE AND CONTROL MEASURES AND ALOS TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.

Procedure

SUBTASK 70-42-01-400-001 Monitor the Test Procedure for the Self-Locking Nuts

When you do the test on the nuts made of stainless steel, corrosion and heat resistant steel, nickel alloy and AMS6304; you must use the bolts with the dimensions as follows.

Use the bolts with the major, minor and pitch diameters 0.003 in. (0.76 mm) less than the given dimensions in Figure and Figure.

Do this for the bolt sizes of 0.190-32UNF-3A, 0.190-24UNC-3A and larger.

SUBTASK 70-42-01-400-002 Monitor the Test Procedure for the Unplated Nuts

When you do the test on the nuts made of unplated stainless steel, corrosion resistant steel, nickel alloy and AMS6304 steel (with the threads overcut for plating at assembly) do as follows.

The nut threads must have a thickness of silver plate of 0.0003 to 0.0006 in. (0.008 to 0.015 mm).

Make sure the nuts are used with unplated bolts of the correct size. Refer to Figure and Figure and make sure you use the necessary values and sizes given.

SUBTASK 70-42-01-400-003 Monitor the Test Procedure for the Unplated Nuts which are not Disassembled

Monitor the procedure that you use when you do a test on these unplated nuts. These nuts are always attached to the relevant assembly (for example brackets or an equivalent component) as follows.

Stainless steel, corrosion resistant steel, nickel alloy and AMS6304 steel nuts.

The nuts are not subsequently plated at assembly.

When you do a test on the assembly or component do as follows.

The bolts you use to test the component (to the necessary values in Figure or Figure) must be silver plated to a thickness of 0.0003 to 0.0006 in. (0.008 to 0.015 mm).

When you use plated bolts 0.190 in. diameter or larger you must reduce the diameter, as follows.

Reduce the major, minor and thread pitch diameters 0.003 in. from the class 3A limits.

When you use plated bolts smaller than 0.190 in. in diameter make sure they have the class 2A tolerances in Figure or Figure.

SUBTASK 70-42-01-400-004 Monitor the Test Procedure for Unplated Carbon or Alloy Steel Nuts

When you do the test on an unplated carbon or alloy steel nut do as follows.

Make sure the nut is cadmium plated to a thickness of 0.0002 to 0.0005 in. (0.005 to 0.013 mm).

Test the nut with a cadmium plated bolt which has a thread given in Figure or Figure.

SUBTASK 70-42-01-400-005 Monitor the Test Procedure for Unplated Aluminum Nuts

When you do the test on an unplated aluminum nut do as follows.

Make sure you use a cadmium plated bolt which has a thread given in Figure or Figure.

Requirements After Job Completion

Follow-On Conditions

NONE