Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-42-04-400-501 Cup Washer Installation

Installation Procedure

Cup type keywashers must be used one time only. A new cup type keywasher must be used at each assembly.

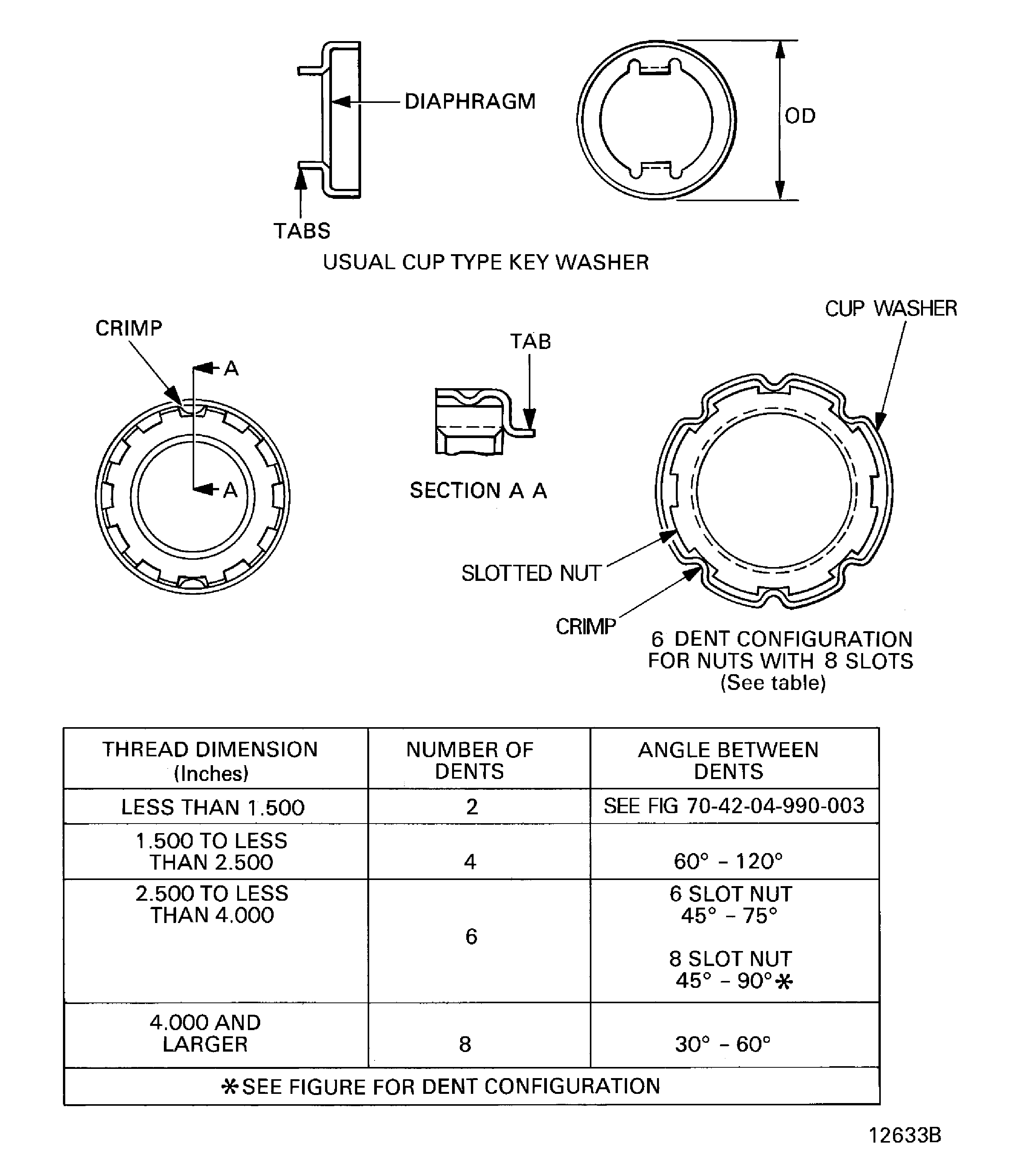

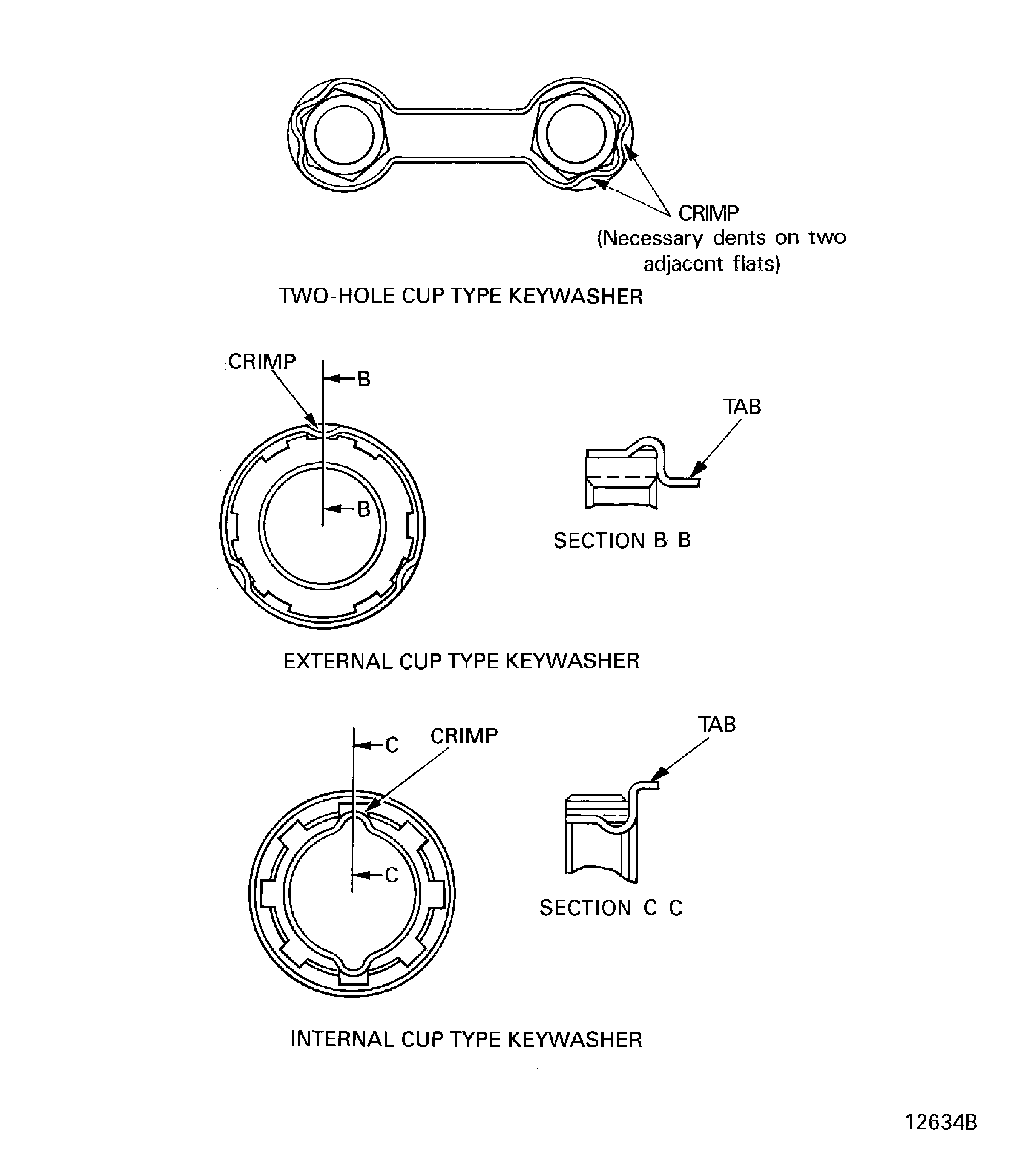

The outside diameter (OD) of a cup type keywasher must be crimped (dented) as shown in Figure, Figure or Figure. The cup type keywasher must be crimped at two or more positions so that it locks the nut or bolt in position. The inside diameter (ID) of an internal cup type keywasher must also be crimped, refer to Figure; section CC.

Crimping tools

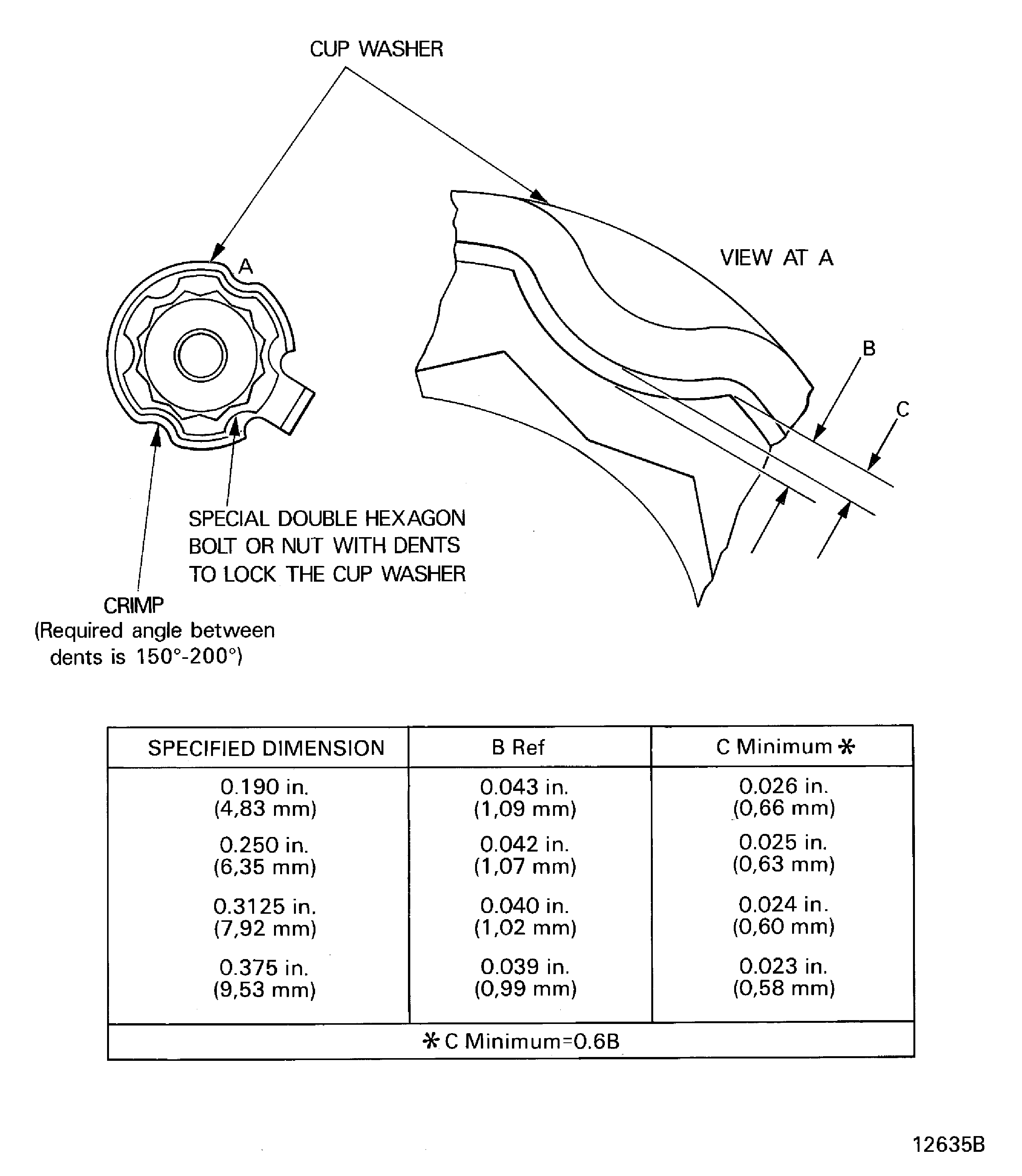

The surface of the tool that is used to cause the crimps (dents) must be spherical in shape. The spherical radius must not be less than 0.050in. (1.27 mm).

Squeeze action crimping tool

This type of tool is used to crimp (dent) the outside diameter of cup type keywashers into slots in the nut or bolt, refer to Figure; section AA. This type of tool is recommended and must be used when possible.

Drift type tool

A drift tool is a ring with prongs on the ID which is moved in an axial direction on the cup type keywasher to crimp (dent) the outside diameter, refer to Figure; section BB.

Punch

This type of tool is put in the correct position on the outside diameter of the cup type keywasher and then hit with a hammer.

Number of dents necessary

A nut or bolt must be locked in position by the cup type keywasher after it is correctly engaged and tightened. Refer to Figure for the correct number of dents necessary. If the number of slots in the nut or bolt is less than the necessary number of dents; the cup type keywasher must be crimped at each possible position.

A cup type keywasher which has one tab only, must be crimped as shown in Figure.

Position control

Movement of the cup type keywasher during the procedure to torque tighten can break the internal tabs. Make a mark on the cupwasher and adjacent surface with CoMat 02-081 PENCIL - METAL MARKING(HARD). A change in the position of the cup type keywasher can then be seen during the procedure to torque tighten.

A cup type keywasher is correctly installed when:

A new cup type keywasher is installed. Do not use this keywasher again.

The dents in the cup type keywasher are approximately the same shape and size, and not broken, cracked or torn.

The dents are made into the slots in the nut or bolt, if slots are available.

The cup type keywasher has not moved during assembly.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-081 PENCIL - METAL MARKING(HARD) | 86874 | CoMat 02-081 |

Spares

NONESafety Requirements

CAUTION

CAUTION

Procedure

Figure: Crimping cup type keywashers

Crimping cup type keywashers

Figure: Crimping cup type keywashers

Crimping cup type keywashers

Figure: Crimping cup type keywashers with one tab

Crimping cup type keywashers with one tab