DMC:V2500-00-70-42-05-00A-712A-D|Issue No:002.00|Issue Date:2018-02-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991:

SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.

Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021)

The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).

Common Information

TASK 70-42-05-400-501 General Instructions For The Uses Of Lockwire

Safety Wire Installation

The instructions that follow are safety wire installation instruction procedures for fasteners such as bolts, screws, tube coupling nuts, hose connectors, electrical connectors.

NOTE

Safety cable is permitted at limited locations as an alternative to lockwire. Where TASK 70-42-05-400-501 General Instructions For The Uses Of Lockwire is specified, it is permitted to use TASK 70-42-08-400-501 General Instructions For The Uses Of Safety Cable as an alternative if the location is one of the specified permitted locations in TASK 70-42-08-400-501.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.

Procedure

SUBTASK 70-42-05-400-001 Safety Wire Basic Rules

The correct safety wire to use will be specified in the Engine Manual assembly instructions.

Safety wire must have two strands twisted together (double-twisted), unless specified differently.

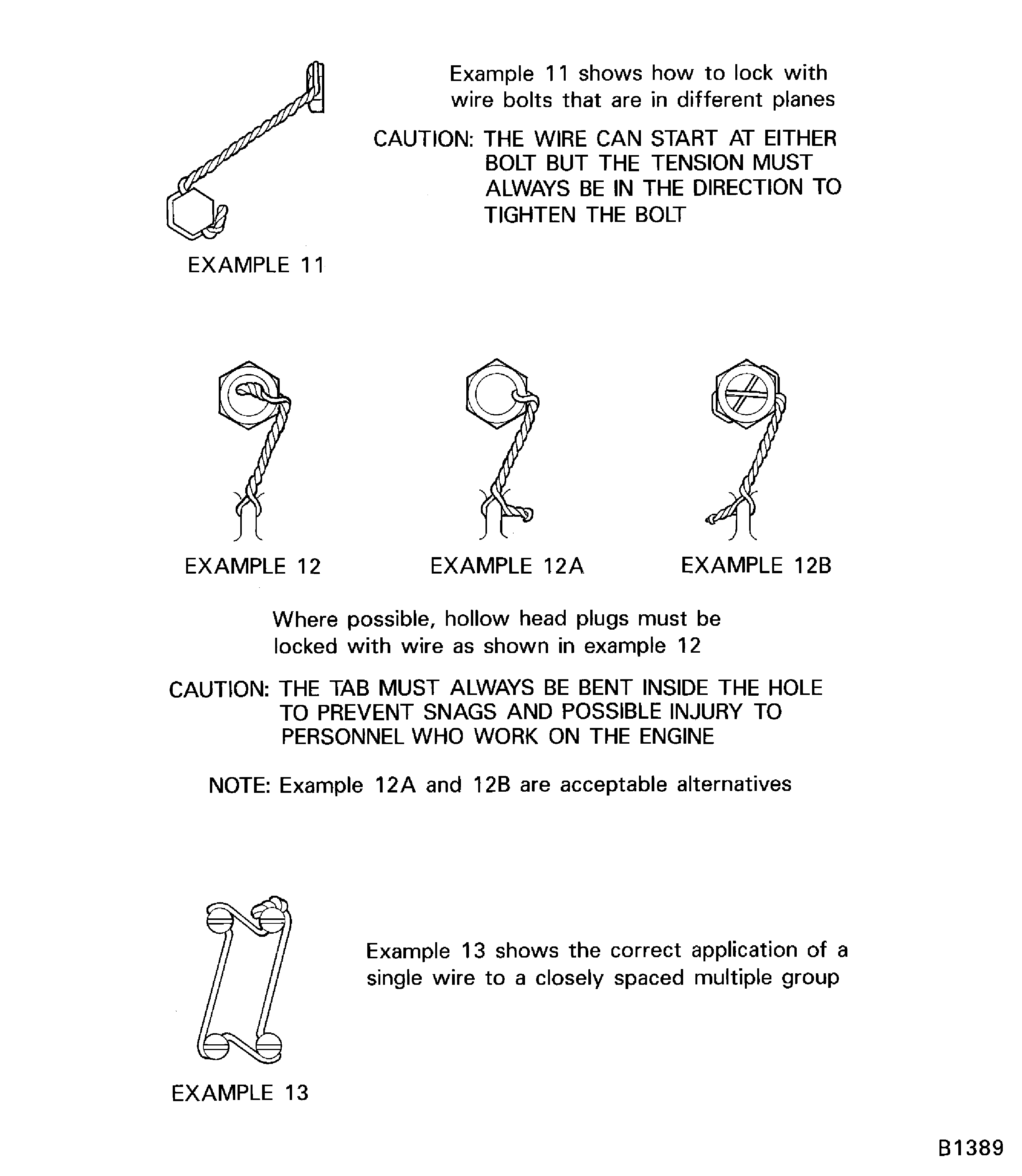

Single strand safety wire is permitted only where specified. Refer to Figure example 13.

The maximum span of the safety wire between tension points must be 6.00 in. (152.40 mm), unless differently specified.

Maximum length of safety wire.

The length of wire used to lock one unit or a group of units in a series must not be more than 24.00 in. (609.60 mm), unless specified differently.

Maximum number of units in a series.

Do not lock more than 4 units in a series with one continuous length of wire, unless specified differently.

If there are more than 4 units in a series and the text or illustration specifies Safety Wire Together, divide this group into smaller groups of 2, 3 or 4 units, then lock with wire the smaller groups in series.

CAUTION

REMOVE BURRS AND SHARP EDGES FROM DAMAGED HOLES.

CAUTION

THERE MUST NOT BE A DECREASE IN THE FUNCTION OF EITHER PART.

Safety wire must go through the given holes.

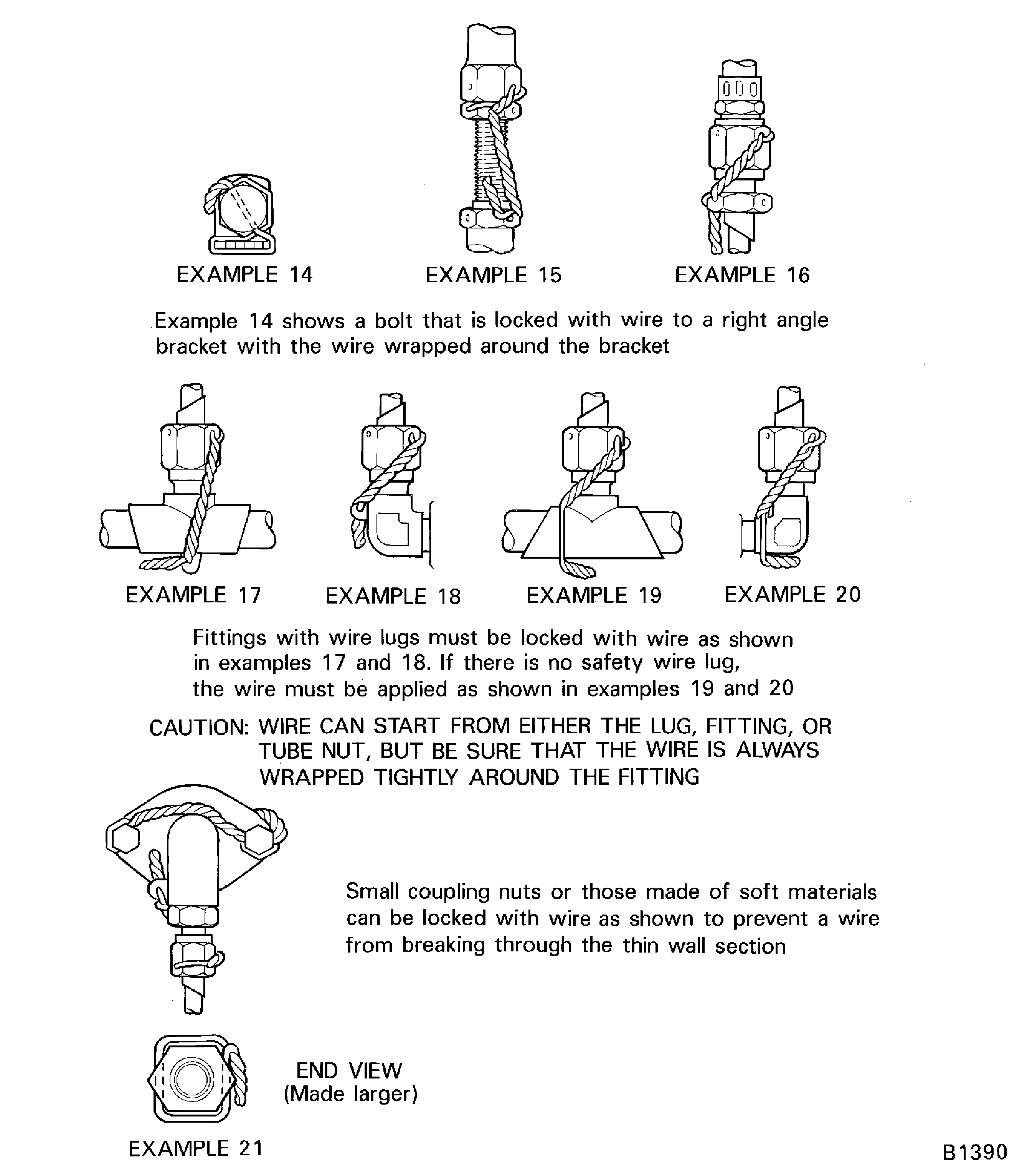

If there is no hole in the part, lock the part with wire to an adjacent part. Refer to Figure, examples 14, 19 and 20.

Condition of safety wire.

Use correct tools and techniques. The safety wire must not become nicked, kinked or damaged during installation.

It is permitted to have abrasions caused by commercial pliers that twist wire.

Make sure to round off the edges of the plier surfaces that grip. This will prevent wire damage.

SUBTASK 70-42-05-400-002 Safety Wire Procedure

It is very important that safety wire is installed in such a way that if the part becomes loose it will be tightened by the wire.

There must be no additional tension on the wire other than the initial tension to stop the part from becoming loose.

The assembly instructions will specify if slack is necessary between tension points.

It is important that neither the safety wire not its adjacent parts be subjected to wear, chafing or too much load after installation.

Torque of parts locked with safety wire.

It is very important to correctly tighten the units before you lock them with safety wire.

It is also very important that the wire holes are in the correct position in relation to one another.

Wire holes will align when the units have the correct torques.

Do not overtighten or loosen the units to get a correct alignment of the wire holes.

If necessary use another unit to get a correct alignment within the specified torque limits.

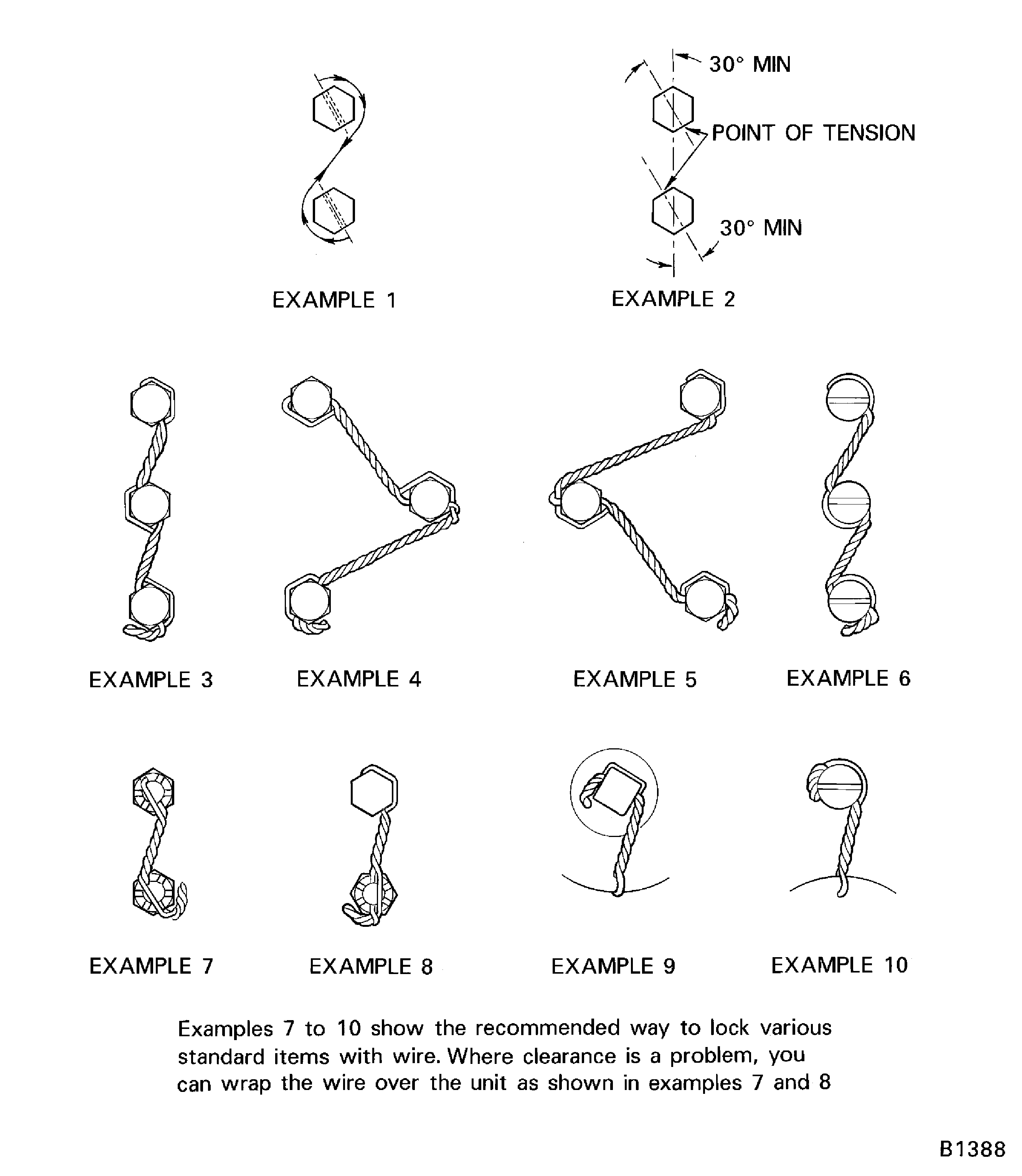

To lock 2 or more units together with safety wire, position the holes in the units as shown in Figure, example 1 thru 6. This will cause the intermediate units in a series to pull in a direction to tighten in relation to the adjacent units in the series.

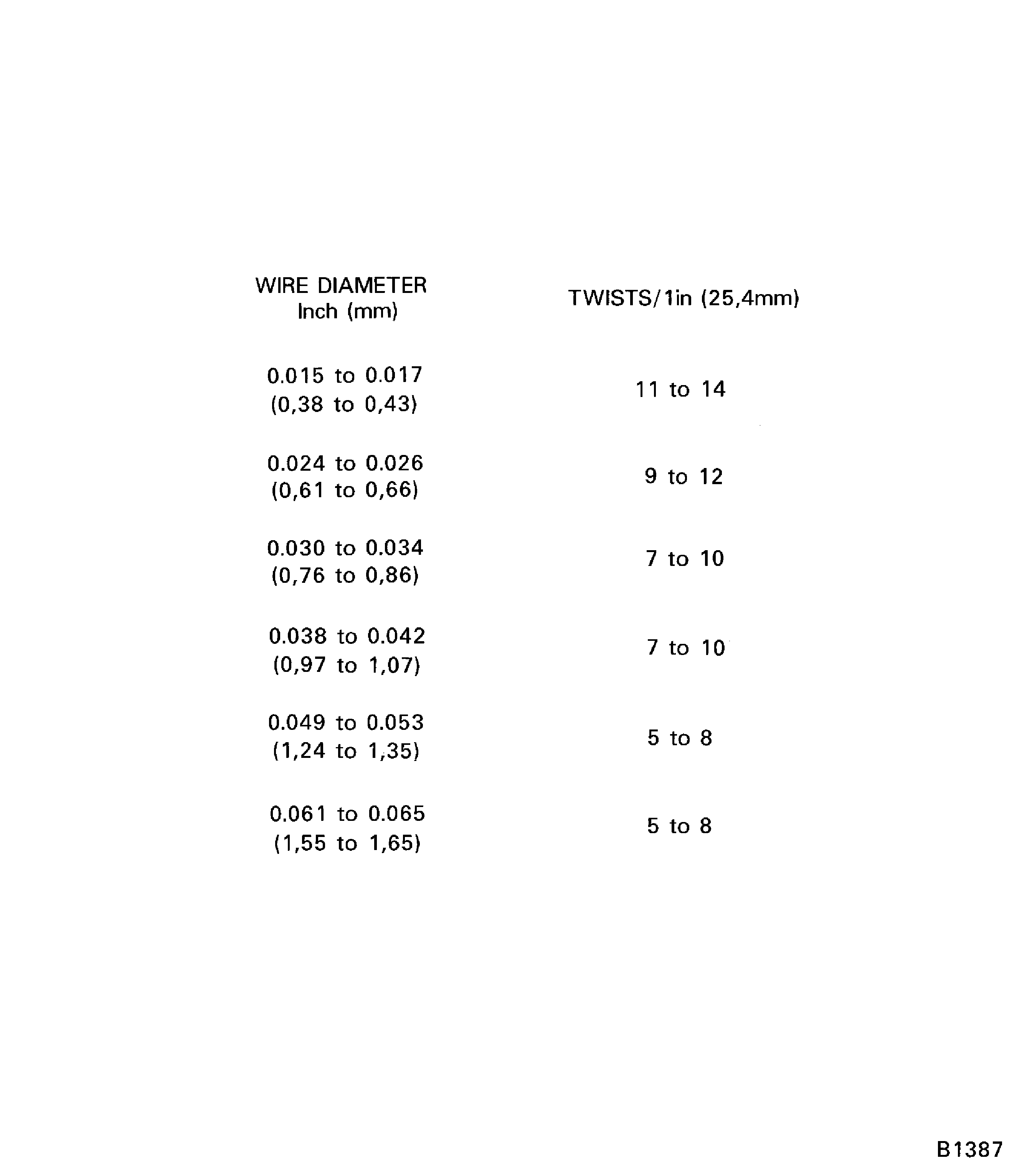

Pull safety wire tight as you twist it. This will give an even and professional appearance. For the recommended number of twists for each inch of wire, refer to Figure.

One twist is a twist of the wires through an arc of 180 degrees, equal to half of a complete turn.

CAUTION

MAKE SURE THERE ARE NO CRACKS IN THE WIRE.

The twisted part of the wire must be within 0.1250 in. (3.18 mm) from the hole in any unit.

When you pull the wire tight or when you use approved safety wire pliers, it is recommended that you pull the wire in such a way as to put no torque on the threaded part. It is permitted to pull in a direction that will tighten rather than loosen the threaded part.

If the torque on the threaded part becomes reduced, you must remove the safety wire and tighten the unit again to the specified torque limits.

Wire that passes over the top of a bolt is an acceptable alternative to the illustrated wire that goes around the head. For the correct twist direction that will force the loop down around the head of a bolt or screw, refer to Figure, example 3 to 6.

CAUTION

DO NOT TWIST OFF THE ENDS OF SAFETY WIRE WITH PLIERS.

CAUTION

MAKE SURE THAT THE CUT WIRE ENDS DO NOT FALL INTO THE ENGINE.

Cut off the unwanted wire at the end of the last unit of a series. Leave at least 3 full twists.

Bend this tab, that remains, into the part to avoid sharp ends or those which stick out. These ends could be a safety hazard or they could vibrate in the airstream.

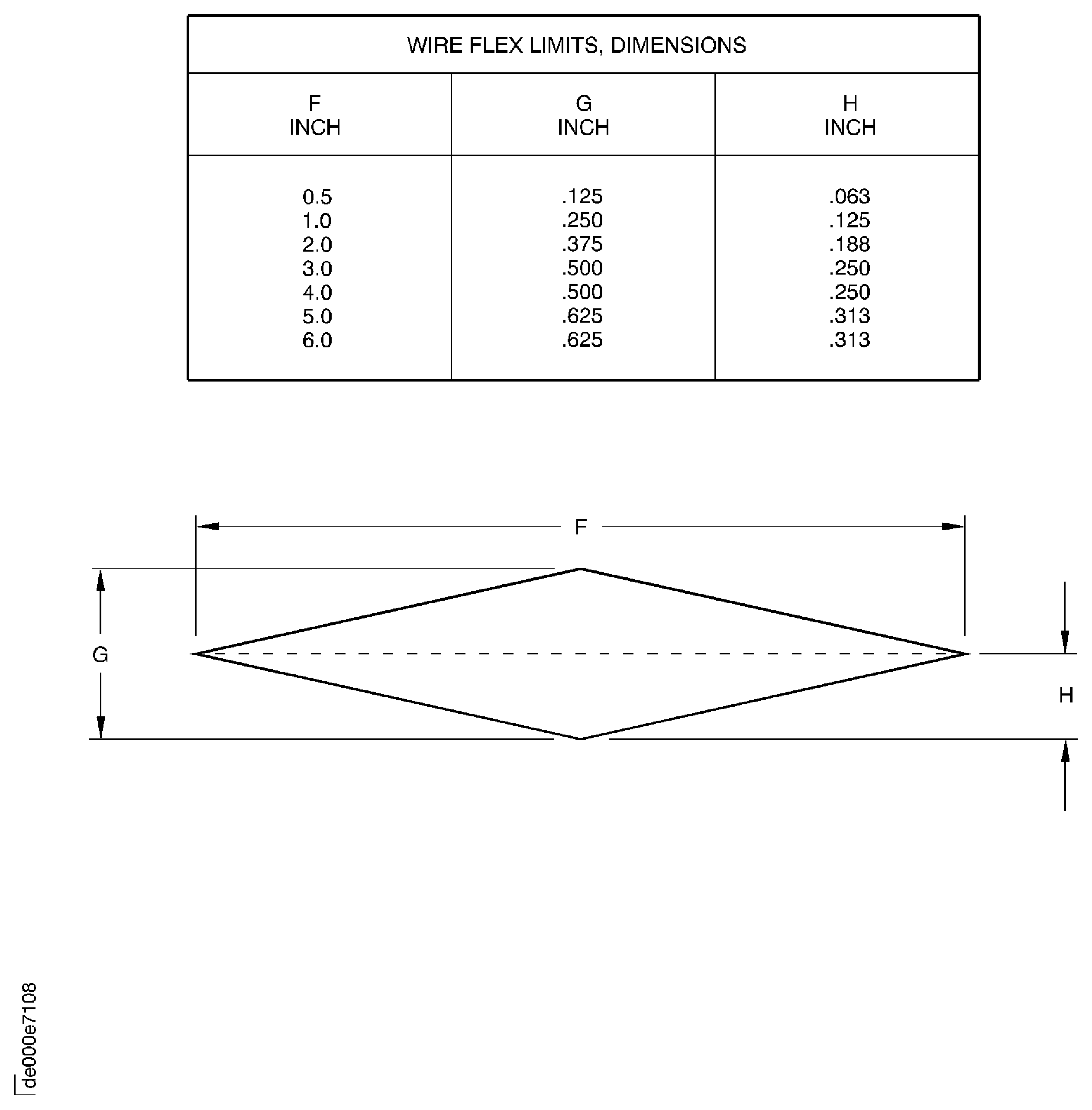

Total flex for twisted wire must not exceed the limits of Figure when light finger pressure (approximately 2 lbs) is applied at mid-span.

SUBTASK 70-42-05-400-003 Specific Safety Wire Applications

NOTE

Figure,

Figure and

Figure do not show every possible combination of specific safety wire application. Any combination must agree with the basic rules.

Refer to Figure examples 1 to 28.

For usual double strand safety wire installation, refer to Figure, Figure, Figure examples 1 thru 12B and 14.

For usual single strand safety wire installation, refer to Figure example 13.

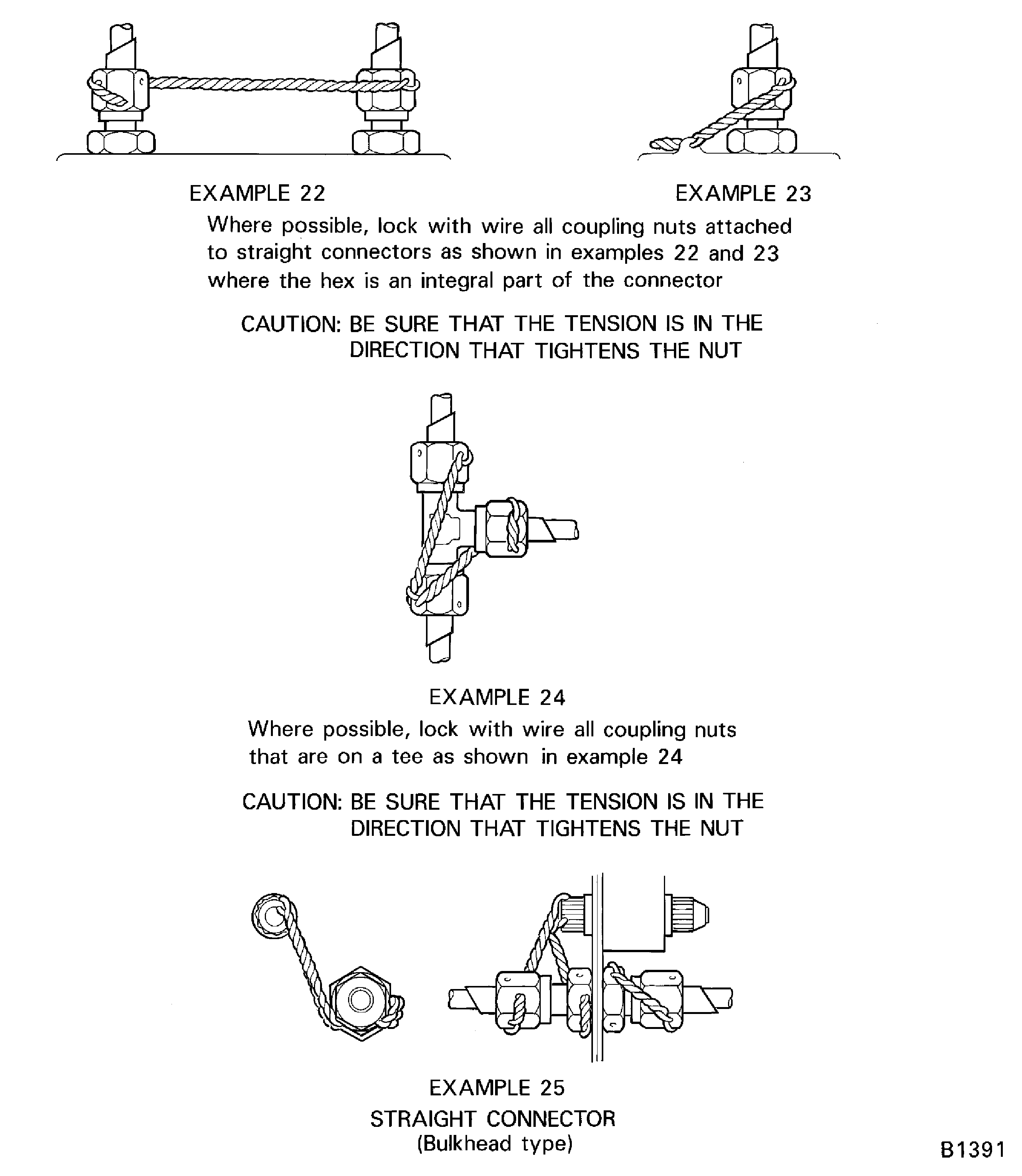

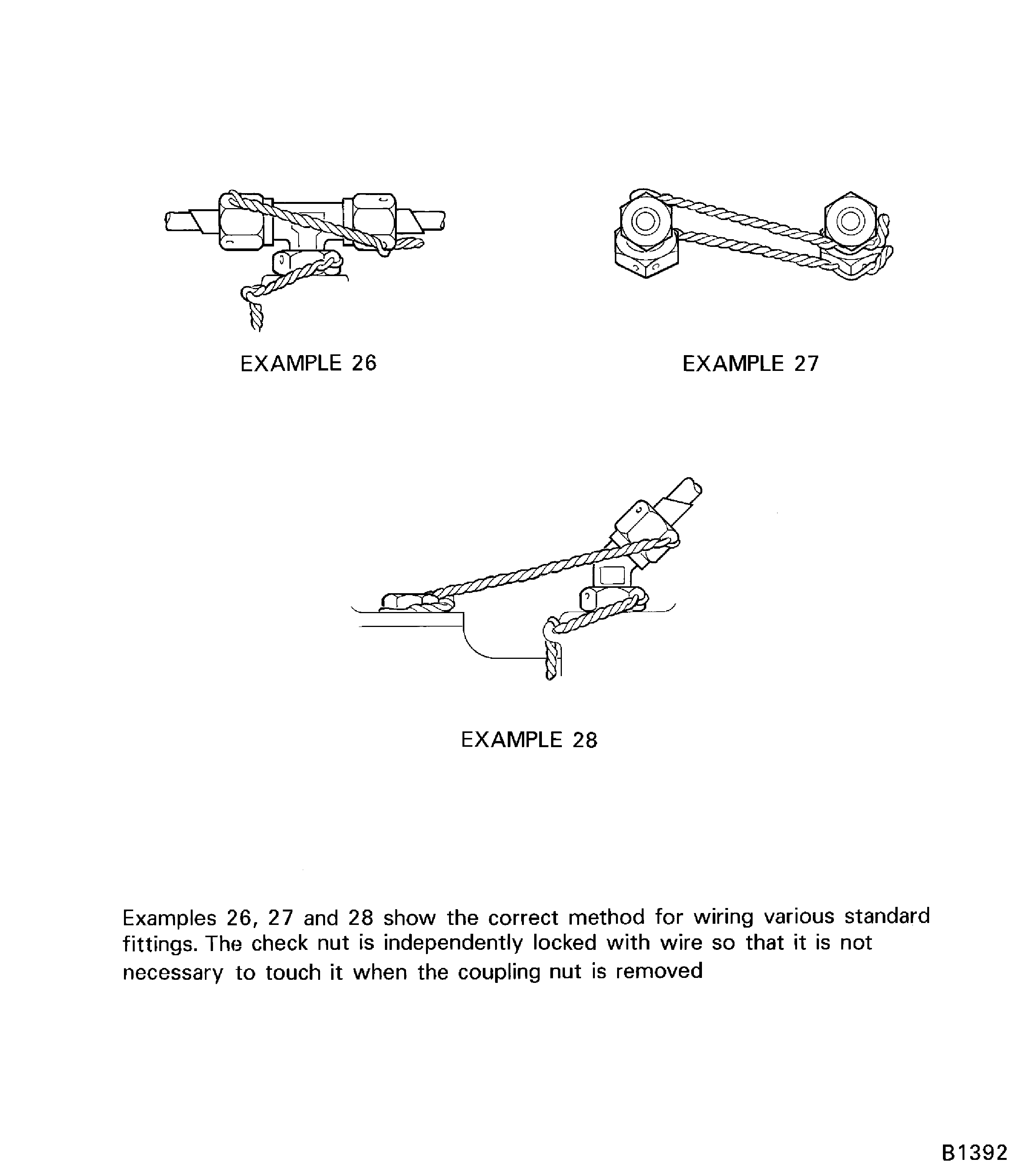

Tube coupling nuts and hose and electrical connectors refer to Figure, Figure and Figure examples 15 thru 28.

Thin wall safety wire holes.

Where drilling of safety wire holes causes a thin wall section, lock the nut with safety wire as shown in Figure example 21.

If you wrap the nut as shown in Figure example 21 you will not break the thin wall section.

SUBTASK 70-42-05-400-004 Safety Wiring of Electrical Connectors

NOTE

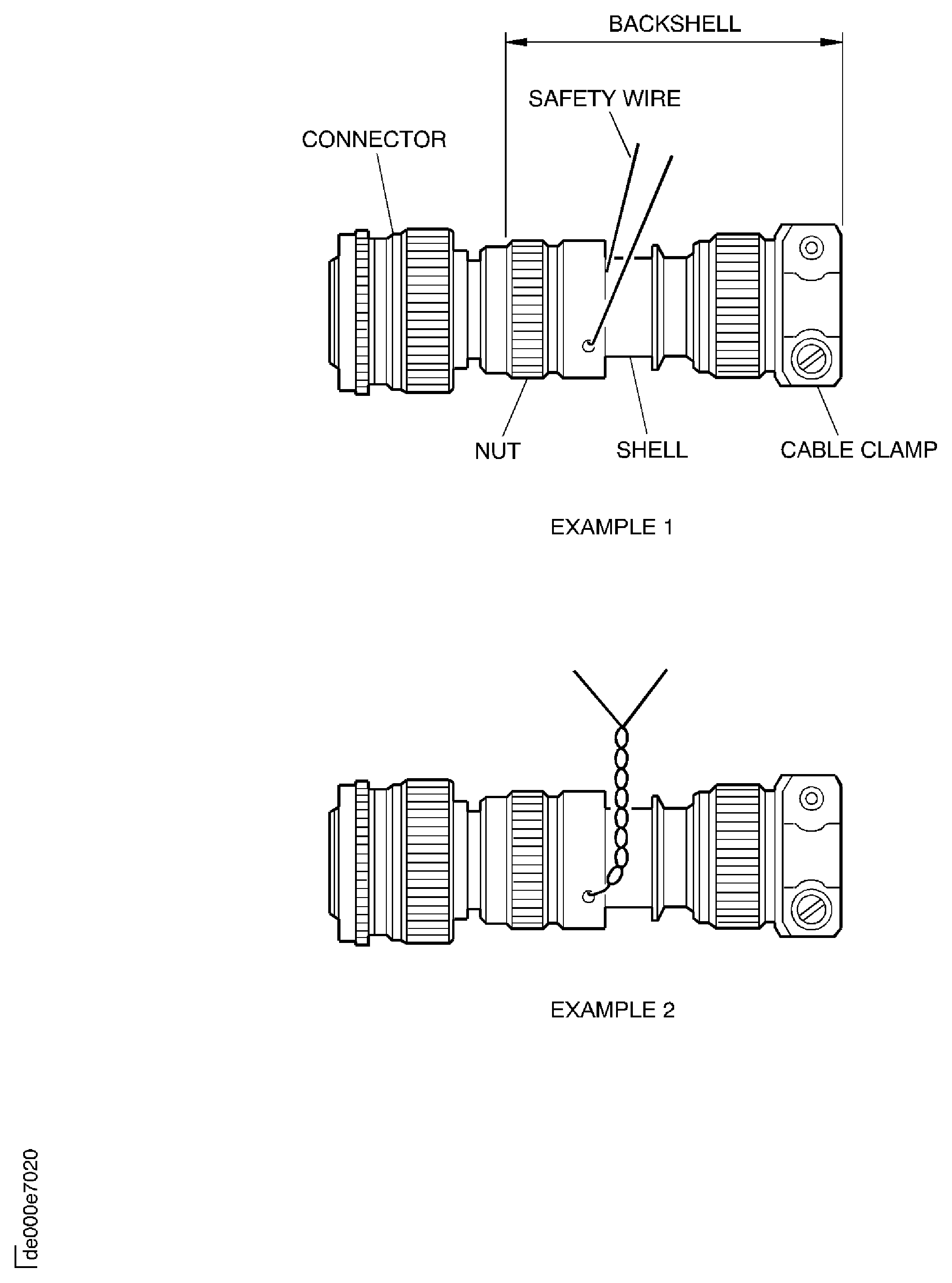

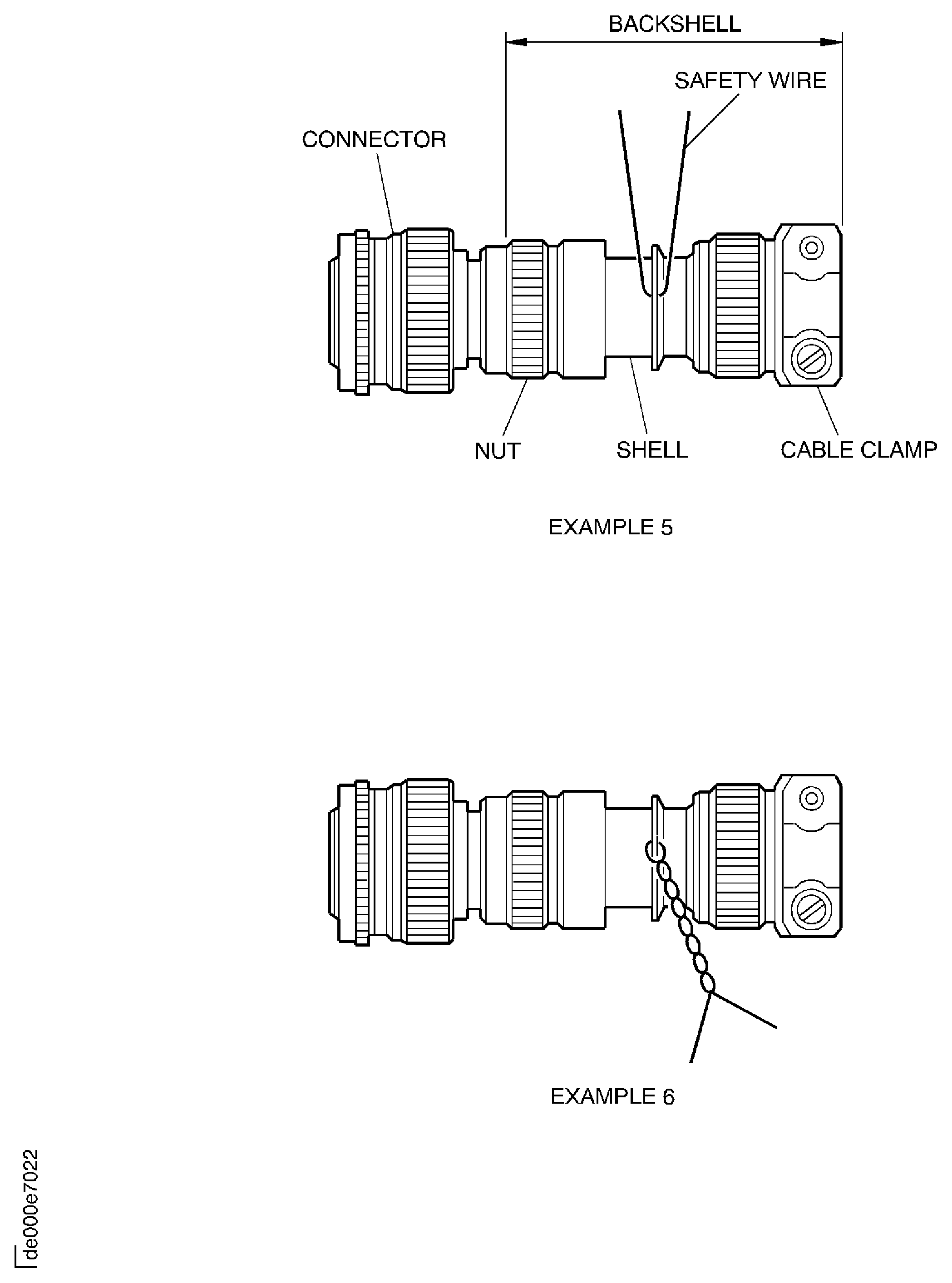

Before installing the safety wire, make sure that the backshell and the cable clamp are completely secured. Install safety wire as shown in figures.

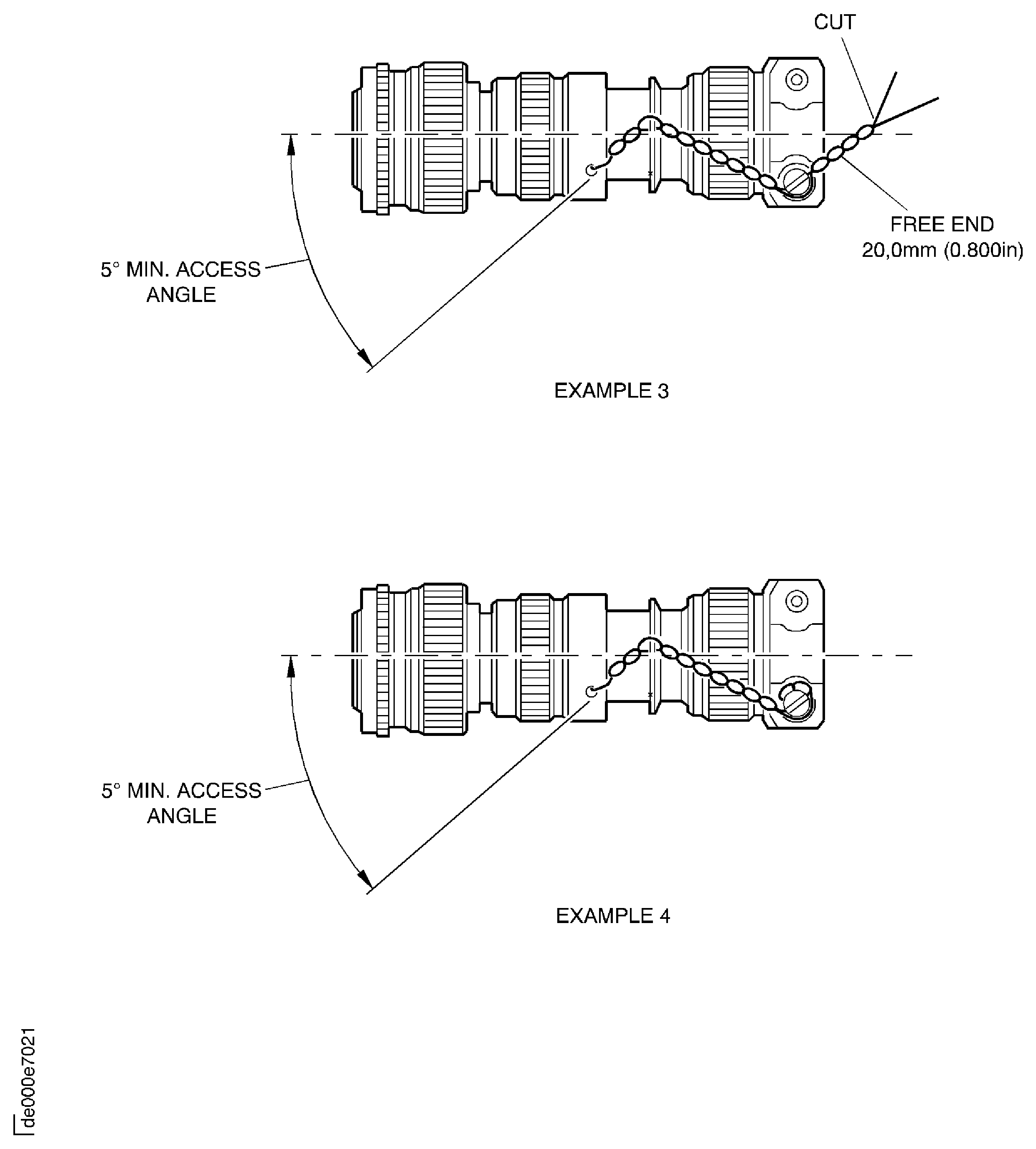

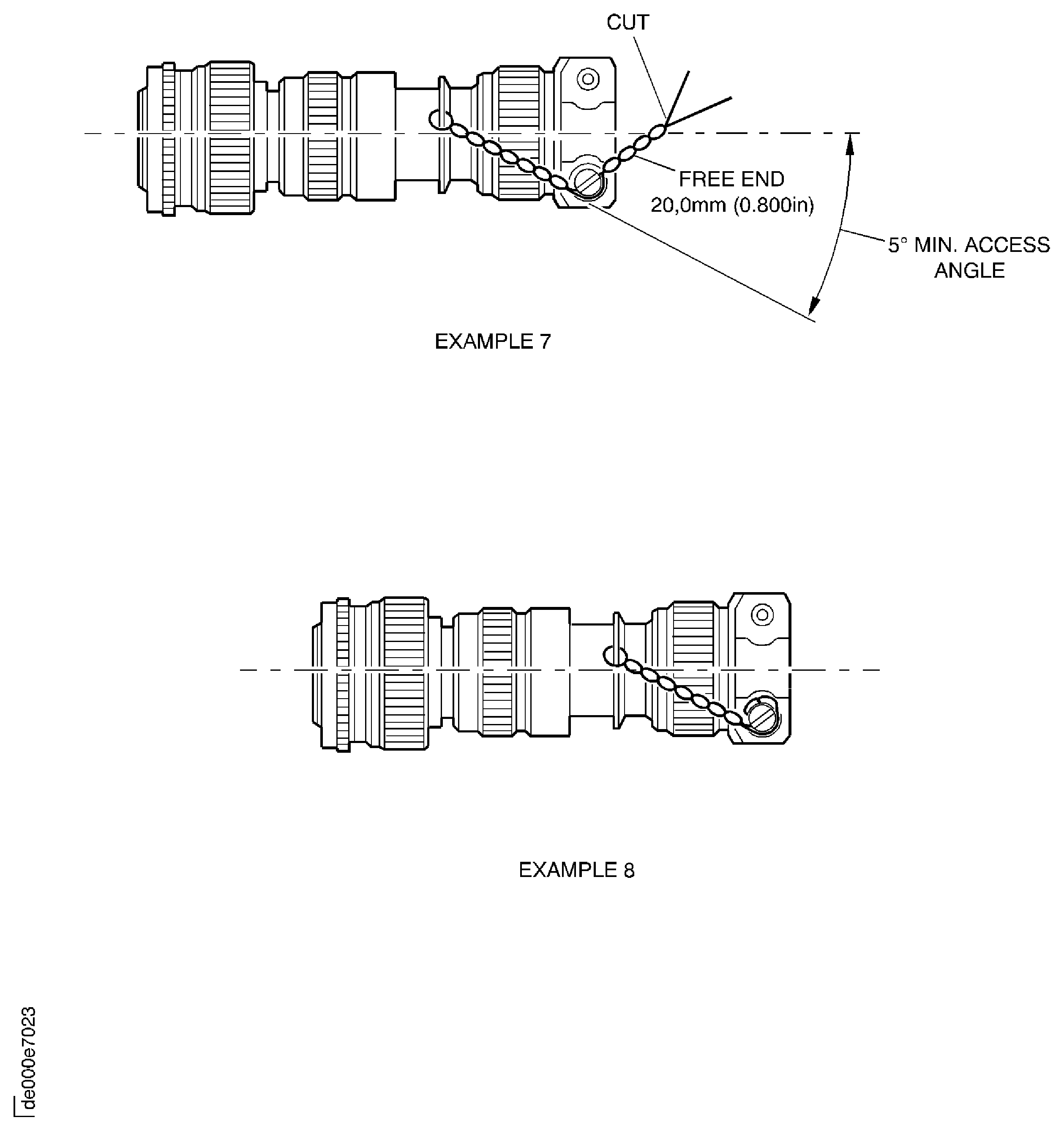

Refer to Figure, examples 1 to 8.

Cut off safety wire to the required length and pass it to the hole in the backshell nut. Set both ends of the wire to the same length. Refer to Figure, example 1.

NOTE

Do not stretch the lock wire excessively.

Wire twister pliers must be used to twist the safety wire uniformly, 10 to 14 twists per 1.00 in. (25 mm) for 0.20 in. (0.5 mm) diameter wire. Refer to Figure, example 2.

Separate the twisted safety wire at the hole in the shell and pass either one through the hole. Retwist the safety wire, keeping it taut and join to one of the holes in the clamp screws.

Cut off the safety wire. Refer to Figure, example 3.

Bend the excess safety wire. Refer to Figure, example 4.

Cut off safety wire to the required length and pass it through the hole in the backshell body. Set both ends of the wire to the same length. Refer to Figure, example 5.

NOTE

Do not stretch the lock wire excessively.

Wire twister pliers must be used to twist the safety wire uniformly, 10 to 14 twists per 1.00 in. (25 mm) for 0.20 in. (0.5 mm) diameter wire. Refer to Figure, example 6.

Separate the twisted safety wire at the hole in the shell and pass either one through the hole. Retwist the safety wire, keeping it taut and join to one of the holes in the clamp screws.

Cut off the safety wire. Refer to Figure, example 7.

Bend the excess safety wire. Refer to Figure, example 4.

Requirements After Job Completion

Follow-On Conditions

NONE