Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-42-08-400-501 General Instructions For The Uses Of Safety Cable

Introduction

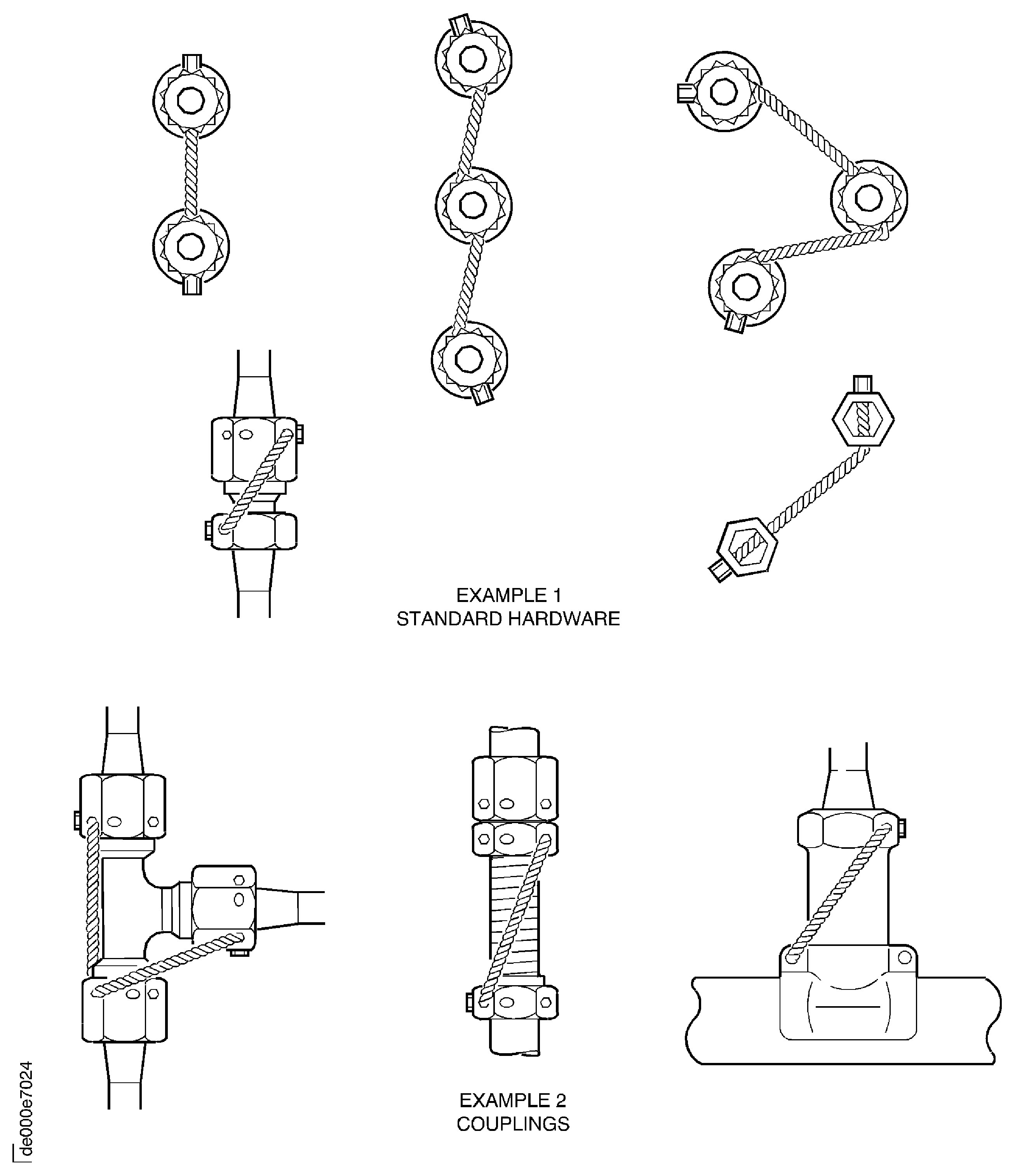

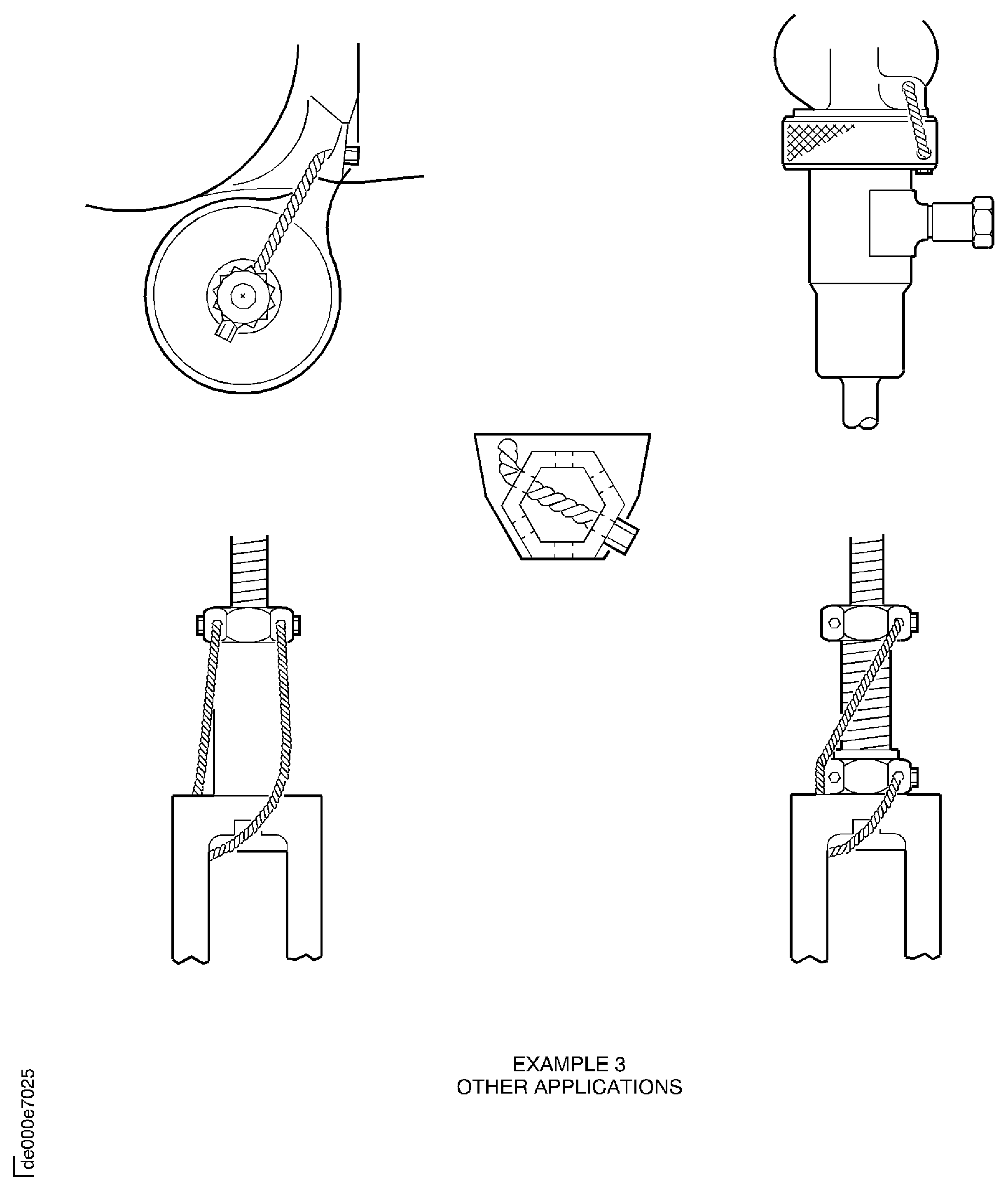

The instructions that follow are safety cable installation instruction procedures for fasteners such as bolts, screws, tube coupling nuts, hose connectors, and electrical connectors.

Refer to SUBTASK 70-42-08-400-003 for the applicability of safety cable as an alternative to lockwire/safety wire.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-272 SAFETY CABLE KIT | LOCAL | CoMat 02-272 | ||

| CoMat 02-273 SAFETY CABLE KIT | LOCAL | CoMat 02-273 | ||

| CoMat 02-274 SAFETY CABLE KIT | LOCAL | CoMat 02-274 | ||

| CoMat 02-275 SAFETY CABLE KIT | LOCAL | CoMat 02-275 | ||

| CoMat 02-276 SAFETY CABLE KIT | LOCAL | CoMat 02-276 | ||

| CoMat 02-277 SAFETY CABLE KIT | LOCAL | CoMat 02-277 | ||

| CoMat 02-278 SAFETY CABLE KIT | LOCAL | CoMat 02-278 | ||

| CoMat 02-279 SAFETY CABLE KIT | LOCAL | CoMat 02-279 | ||

| CoMat 02-280 SAFETY CABLE FERRULE | LOCAL | CoMat 02-280 | ||

| CoMat 02-281 SAFETY CABLE FERRULE | LOCAL | CoMat 02-281 | ||

| CoMat 02-282 SAFETY CABLE KIT | LOCAL | CoMat 02-282 | ||

| CoMat 02-283 SAFETY CABLE KIT | 70958 | CoMat 02-283 | ||

| CoMat 02-284 SAFETY CABLE KIT | LOCAL | CoMat 02-284 | ||

| CoMat 02-285 SAFETY CABLE KIT | LOCAL | CoMat 02-285 | ||

| CoMat 02-286 SAFETY CABLE KIT | LOCAL | CoMat 02-286 | ||

| CoMat 02-287 SAFETY CABLE KIT | LOCAL | CoMat 02-287 | ||

| CoMat 02-288 SAFETY CABLE KITS | LOCAL | CoMat 02-288 | ||

| CoMat 02-289 SAFETY CABLE FERRULES | LOCAL | CoMat 02-289 | ||

| CoMat 02-290 SAFETY CABLE FERRULES | LOCAL | CoMat 02-290 |

Spares

NONESafety Requirements

WARNING

Procedure

At all external and fan stream locations where the safety wire hole is sufficiently large for the cable, it is permitted to use only Safety Cable Part No AS3510-0218C (0.032 inch (0.813 mm) diameter) and safety cable ferrule Part No AS3510-02F.

Safety cable is permitted at limited locations as an alternative to lockwire/safety wire. It is permitted to use SPM TASK 70-42-08-400-501 Safety Cable as an alternative to lockwire/safety wire as specified below.

Locations where the safety wire hole is more than 0.100 inch (2.540 mm) diameter (the safety cable ferrule will pull through a hole larger than this)

Internal areas of the engine

Internal areas of gearboxes

Internal areas of accessories

Heat shields (as lacing)

Vendor-controlled (Category 1) components.

Safety cable is not permitted at the subsequent locations:

SUBTASK 70-42-08-400-003 Applicability of Safety Cable as an Alternative to Lockwire/Safety Wire

Consumable materials.

Cable diameter 0.032 inch (0.8 mm)

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable ferrules

Safety cable ferrules

Cable diameter 0.020 inch (0.5 mm )

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable kits

Safety cable ferrules

Safety cable ferrules

SUBTASK 70-42-08-400-002 Equipment and Materials

CAUTION

DO NOT USE SAFETY CABLE IF THE HOLES ARE MORE THAN 0.100 INCH (2.54 MM) DIAMETER. THE FERRULES ON THE ENDS OF THE CABLE ARE 0.106 TO 0.108 INCH (2.693 TO 2.743 MM) DIAMETER AND WILL FALL THROUGH HOLES LARGER THAN THIS.Always install safety cable through the safety cable or safety wire holes given on the part.

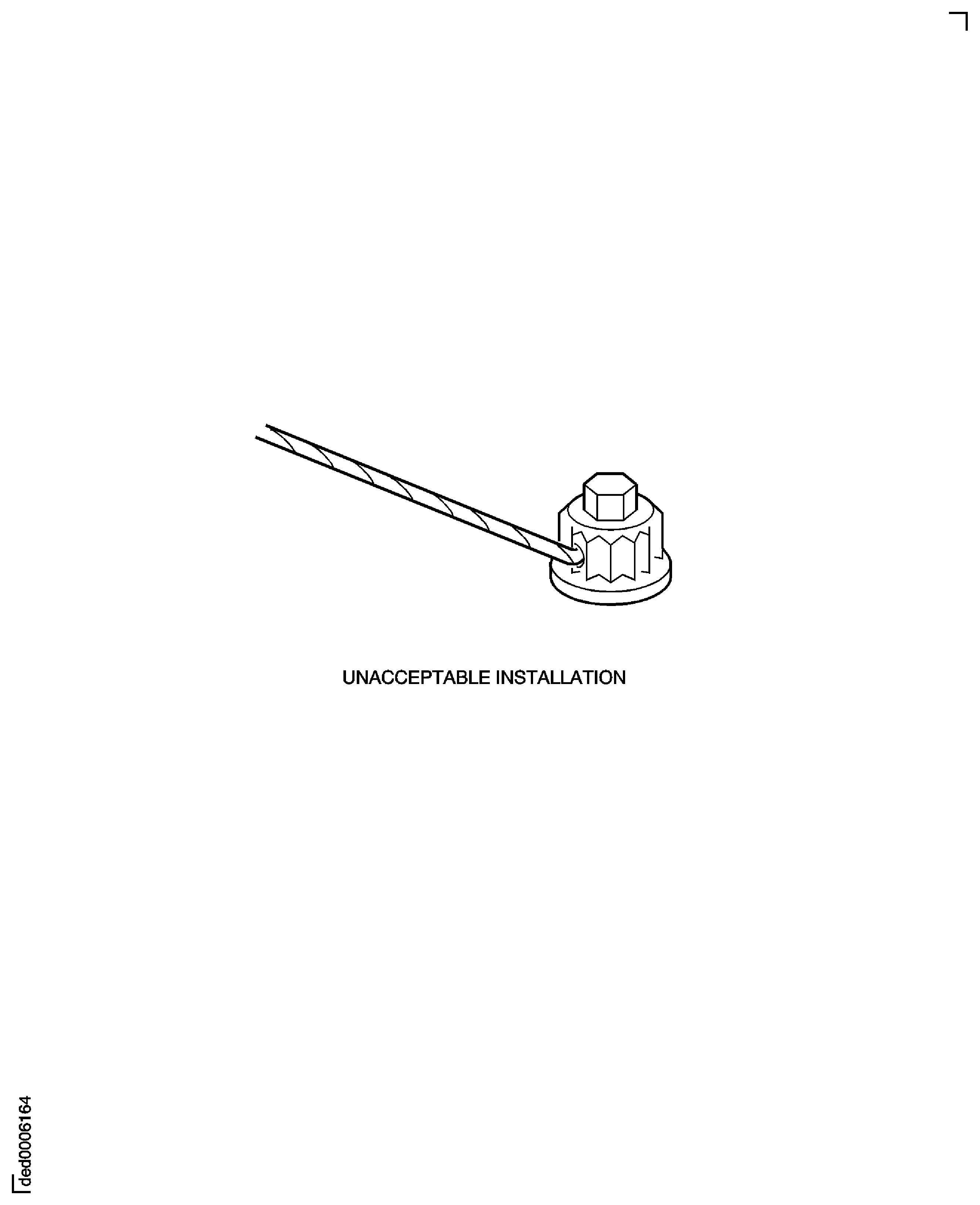

The threading of safety cable down through bolt lightening holes is not permitted. An Unacceptable Installation is illustrated in Figure.

Installation holes.

Crimp the ferrule to the cable using one of the crimping tools in Equipment and Materials (refer to Step ).

Crimp requirements (pull-off load).

Basic rules.

Where safety cable is specified on the assembly illustrations, use the procedure that follows to install the cable.

It is recommended that there are no turns, more than 90 deg, if possible, when the cable goes through the fasteners. The result is the installation of safety cable with either a positive or neutral pull. The better condition is to have the cable positive. Where this is not possible because of interference across an edge of a gusset, bracket, or other part, the use of a neutral condition is permitted.

Adjacent units.

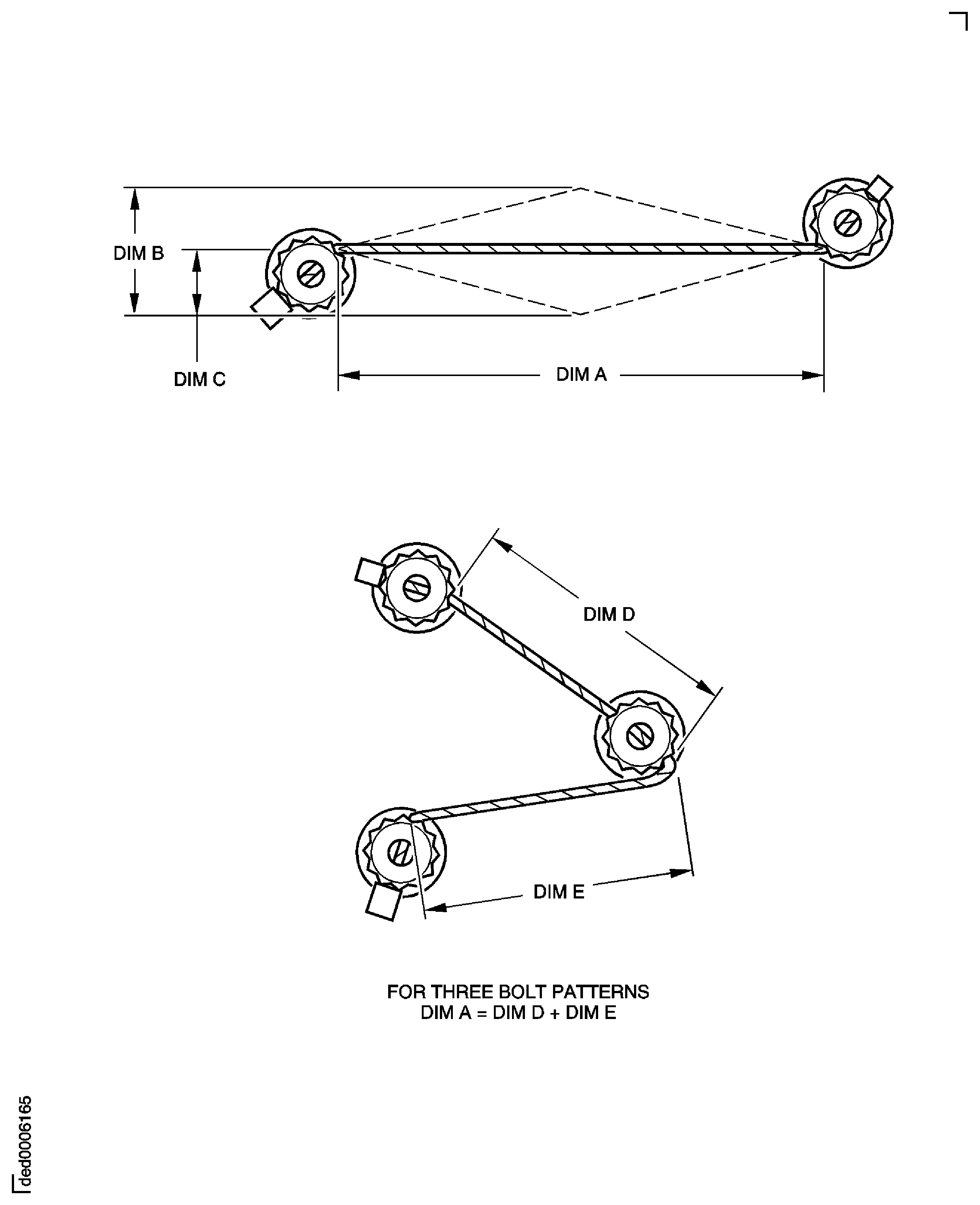

Cable installation tools will give the specified flex limits. (Refer to Step.) The maximum cable flex limits between end points must be no greater than given in the table following and illustrated in Figure when light finger pressure (approximately 2 pounds) is applied at mid-span.

Table 7. Safety Cable Flex Limits Dimension A

Dimension B

Dimension C

Inch

mm

Inch

mm

Inch

mm

0.5

12.7

0.125

3.175

0.062

1.575

1.0

25.4

0.250

6.350

0.125

3.175

2.0

50.8

0.375

9.525

0.188

4.775

3.0

76.2

0.375

9.525

0.188

4.775

4.0

101.6

0.500

12.700

0.250

6.350

5.0

127.0

0.500

12.700

0.250

6.350

6.0

152.4

0.625

15.875

0.312

7.925

Cable flex limits.

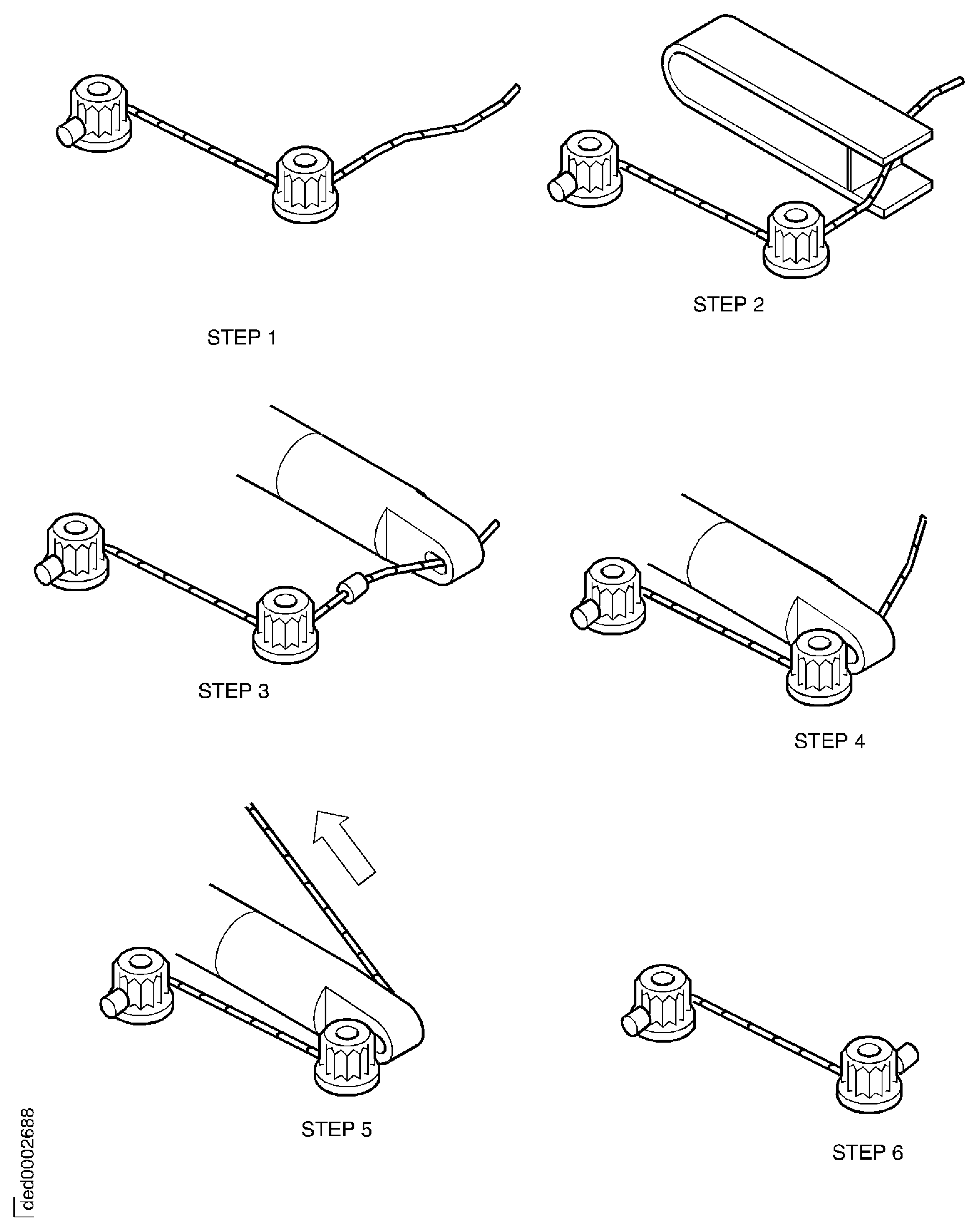

Insert the end of the cable through the second part and pull it through (Refer to Figure Step 1). If there is a third part to be safety cabled, pass the cable through this in the same manner.

Insert the free end of the cable through a ferrule in the ferrule magazine. Pull the safety cable through the ferrule and use the safety cable to pull out the ferrule from the magazine (Refer to Figure Step 2).

Insert the free end of the cable through the crimping tool. Make sure the large hole of the crimping head is on the same side as the ferrule (Refer to Figure Step 3).

Move the crimping tool along the cable until the crimping head is against the part. Make sure the ferrule is inside the hole in the crimping head (Refer to Figure Step 4).

If the ferrule will not go into the crimping head, remove the tool from the cable and then push the handles completely together. When the handles are released, they will open automatically. Insert the cable back through the crimping head and move the tool along the cable until the crimping head is against the part. Make sure that the ferrule is inside the crimping head.

Place the cable into the tensioning device on the crimping tool and tension the cable (Refer to Figure Step 5).

CAUTION

DO NOT CRIMP THE FERRULE UNLESS THE CORRECT TENSION HAS BEEN APPLIED BY THE TENSIONING DEVICE.Crimp the ferrule and cut the cable. Obey the manufacturer's instructions (Refer to Figure Step 6).

Measure the distance between the safety cabled parts; write this down as Dimension A. If three parts are safety cabled together, measure the distance between each of the parts (Dimensions D and E) and add the measurements together, that is, D + E = A. (Refer to Safety Cable Flex Limits, Figure.).

Push against the safety cable with a light finger pressure half way between the components that have been wire locked. If the cable feels loose, do a dimensional check as follows to make sure that the cable is serviceable:

Procedure.

Installation.

SUBTASK 70-42-08-400-001 Safety Cable Installation

Figure: Examples of safety cable methods

Examples of safety cable methods

Figure: Examples of safety cable methods

Examples of safety cable methods

Figure: Safety cabling procedure

Safety cabling procedure

Figure: Unacceptable Installation

Unacceptable Installation

Figure: Safety Cable Flex Limits

Safety Cable Flex Limits