Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-43-01-400-501 Connection Of Electrical Plugs

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Glenair TG69 pliers | LOCAL | Glenair TG69 pliers |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-012 ISOPROPANOL ALCOHOL (CH3)2CHOH | LOCAL | CoMat 01-012 | ||

| CoMat 02-069 DISPOSABLE CLEANING TISSUES | 33591 | CoMat 02-069 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 |

Spares

NONESafety Requirements

WARNING

Procedure

WARNING

ALWAYS MAKE SURE THERE IS SUFFICIENT VENTILATION WHEN ISOPROPANOL IS USED. DO NOT BREATHE THE VAPOR OR LET IT TOUCH THE SKIN.

CAUTION

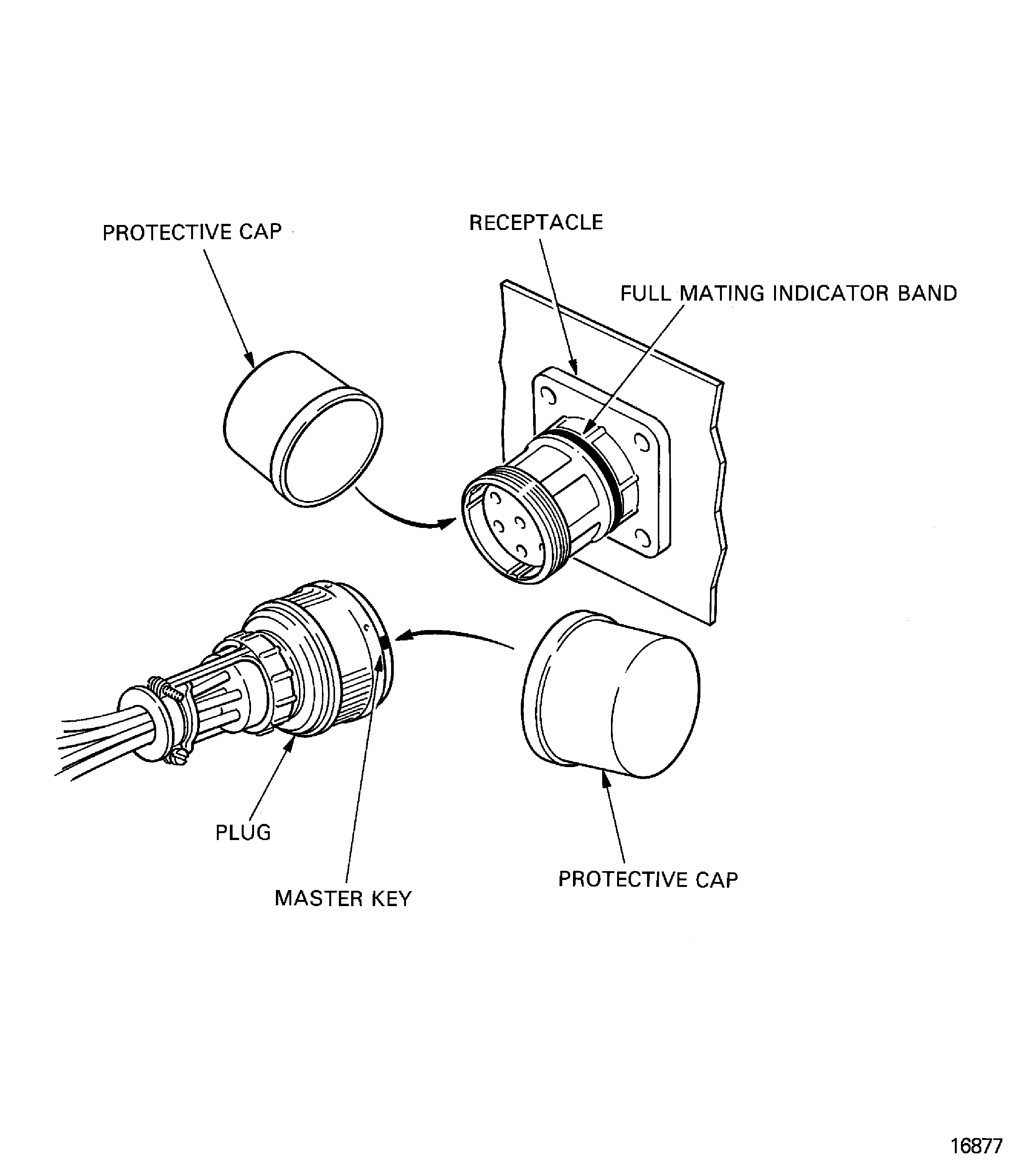

DO NOT USE A SPRAY GUN OR COMPRESSED AIR AT A PRESSURE OF MORE THAN 15 PSI (104 KPA).Remove the protective caps from the plug and the related receptacle (Refer to Figure); keep the caps in a clean and dry bag.

If the plug or the receptacle is in such a position that the unwanted fluid can not drain away; use a clean cloth or CoMat 02-069 DISPOSABLE CLEANING TISSUES to remove the fluid. Alternatively, use compressed air to remove the fluid.

Examine the plug and the receptacle for contamination caused by liquid or solid unwanted materials. If necessary, clean with CoMat 01-012 ISOPROPANOL ALCOHOL (CH3)2CHOH; but always obey the instructions that follow.

SUBTASK 70-43-01-400-001 Prepare the Plug and the Receptacle (Pyle-National)

Align the master key on the plug with the receptacle master key-way (Refer to Figure).

CAUTION

THE FULL MATING INDICATOR BAND ON THE RECEPTACLE IS NOT A STOP LINE. THIS BAND MUST ALWAYS BE FULLY CONTAINED BY THE LEADING EDGE OF THE PLUG KNURLED NUT.NOTE

Where access to the receptacle is not easy, Glenair TG69 pliers can be used; but do not use a mechanical device on the rear knurl of the plug.With the threads correctly engaged, install the plug coupling nut in a clockwise direction on to the receptacle threads. Push the plug, with a side-to-side movement, into the mating receptacle and continuously tighten the coupling nut by hand, while you do this, until it is tight. Make sure that the red visual indicator can not be seen.

When necessary, safety with CoMat 02-126 LOCKWIRE.

SUBTASK 70-43-01-400-002 Connect the Plug (Pyle-National)

Figure: Pyle-National plug and receptacle

Pyle-National plug and receptacle