Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-46-01-400-501 Installation Of Oversize Studs

General

Replace the studs which are extended, loose or have damaged threads, with 'oversize studs'.

When it is necessary to replace an 'oversize stud' replace it with a larger 'oversize stud'.

If the threads of a stud hole are damaged it is possible to drill and retap the hole. A special stepped stud can be used as shown in Figure.

When an 'oversize stud' is installed in to a stud hole, make sure that the anchor end of the stud does not go through the bottom of the hole and catch with other parts. If it does, file off the anchor end of the stud and identify the stud with a revised oversize mark.

When a stud is installed which has a cotter pin or safety wire hole, the length must be measured from the bottom of the stud hole.

Refer to the specified repair data applicable to the studs that are replaced.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-081 COMPOUND, ANTIGALLING | 05972 | CoMat 06-081 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Spares

NONESafety Requirements

WARNING

Procedure

NOTE

The torque limits given in procedures A. and B. are for driving studs which have a minimum ultimate tensile strength of 125,000 pounds per square inch (equivalent to a minimum hardness of 26 HRC).Studs which have a minimum hardness of 34 HRC, the maximum torque values can be increased by 25 percent.Use the torque limits given in Figure for driving studs where the thread sizes on each end of the stud are equal.

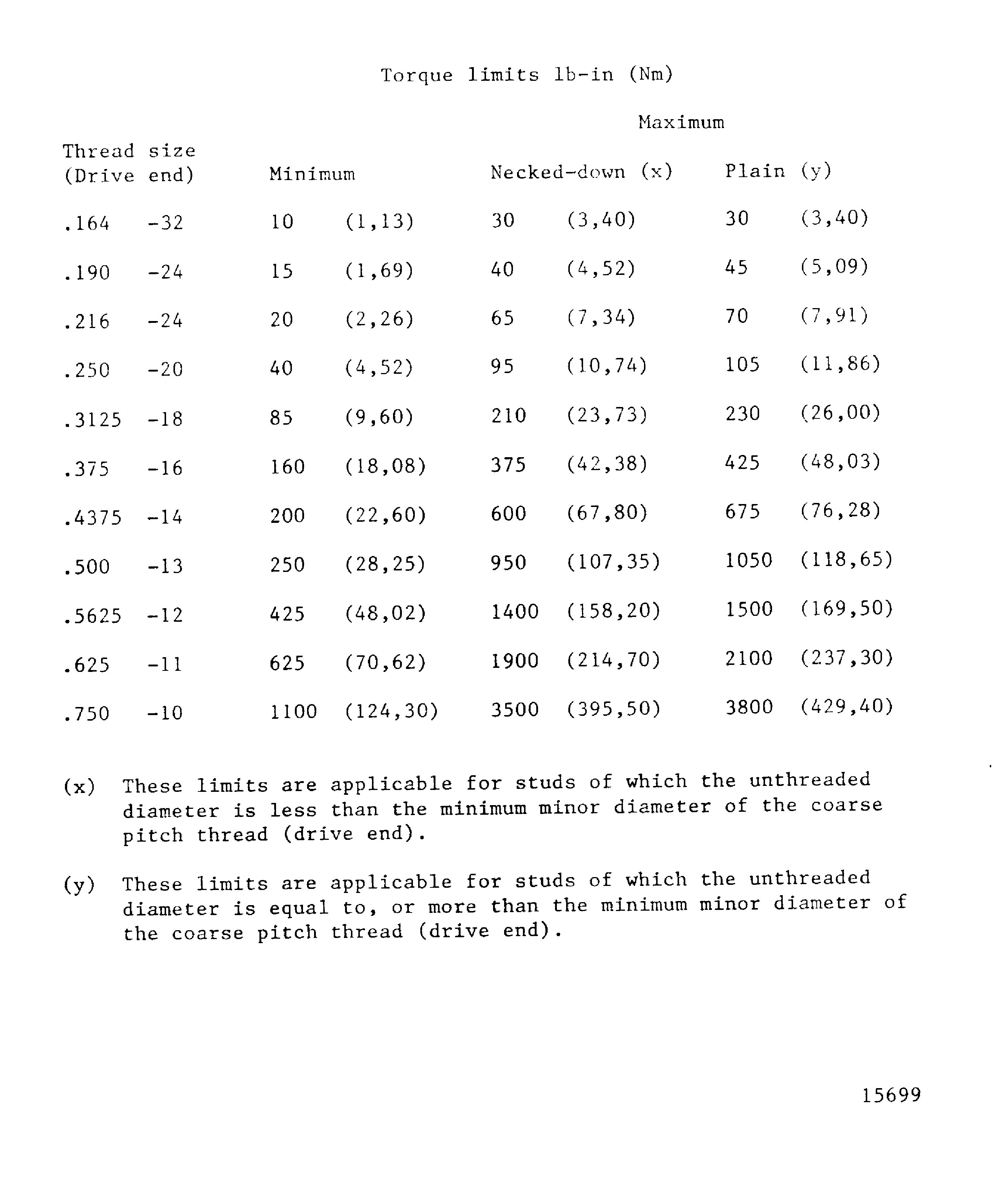

Standard interference fit studs.

Use the torque limits given in Figure for driving studs where the thread size of the nut end is smaller than the thread size of the driven end.

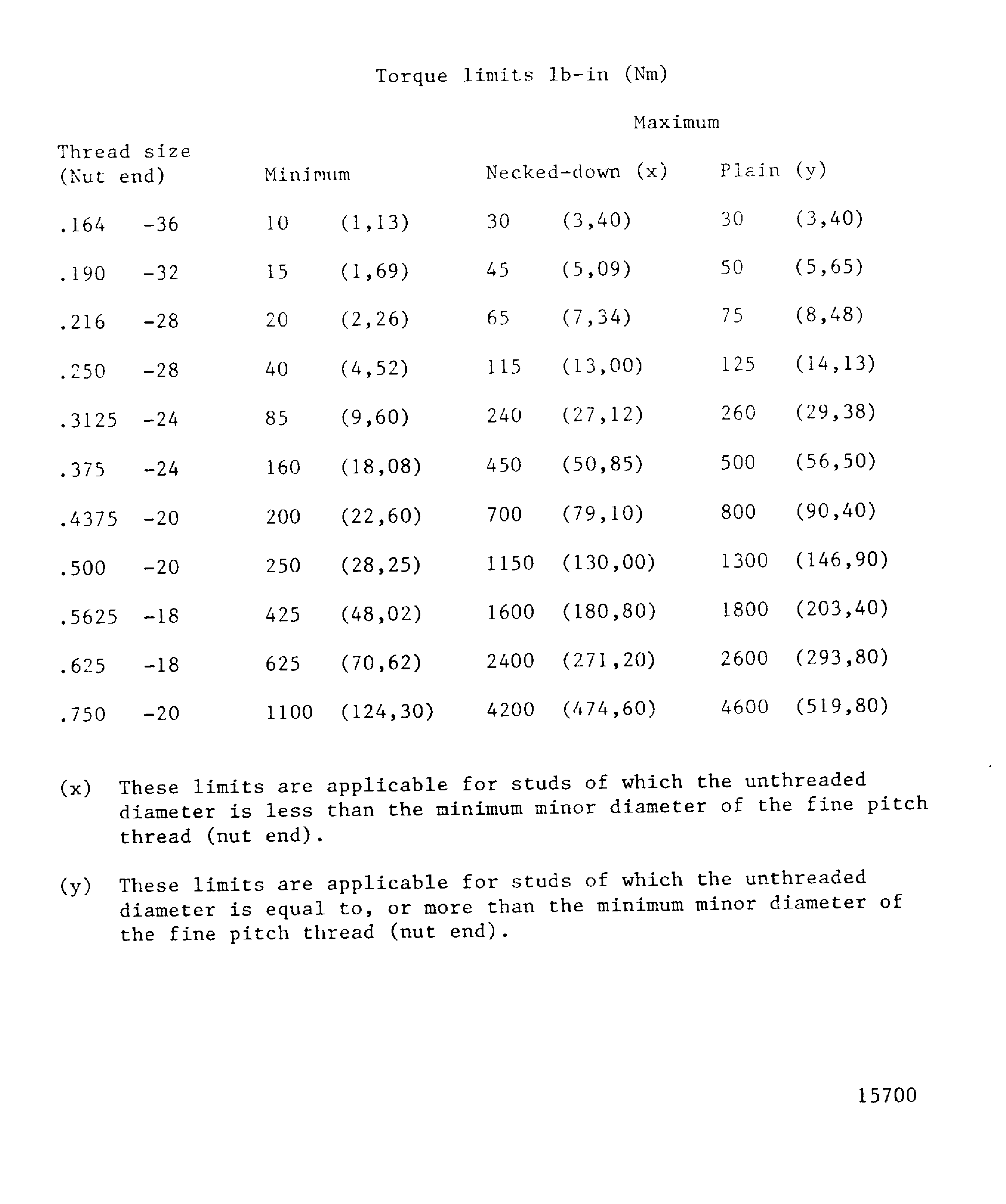

Stepped interference fit studs.

Studs installed directly in to bosses.

Use the torque limits given in Figure for driving studs in to self locking helical coil inserts. These limits are for studs where the nominal thread size on each end of the studs are equal. Also they are for studs where the thread size of the nut end is smaller than the thread size of the driven end.

Studs installed in to self-locking helical coil inserts.

Use the torque limits given in Figure for driving interference fit studs in to nonlocking helical coil inserts.

Studs installed in to nonlocking helical coil inserts.

SUBTASK 70-46-01-400-001 Stud Torques

Interference fit titanium studs or any stud driven directly in to titanium to the torque limits given in Figure and Figure must be lubricated with wet CoMat 06-081 COMPOUND, ANTIGALLING. Oil is not permitted.

If lubrication is used, use CoMat 10-077 APPROVED ENGINE OILS or CoMat 10-129 ANTI-SEIZE PASTE. Refer to the SPM TASK 70-38-38-380-501. The minimum and maximum torque limits in Figure must be used.

Studs can be installed with or without lubrication.

Studs in self-locking helical coil inserts.

SUBTASK 70-46-01-400-002 Stud Lubrication

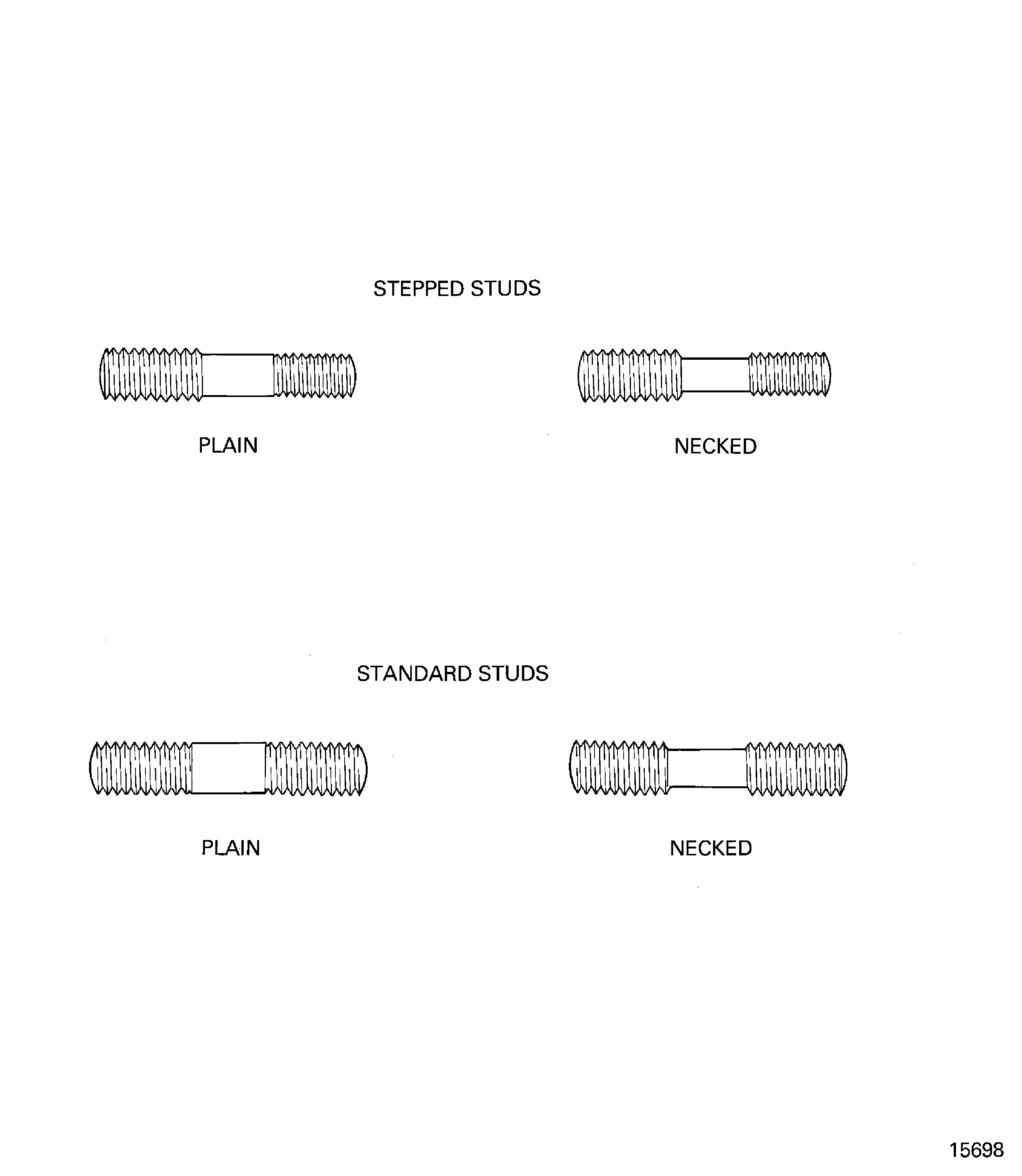

Figure: Replacement stud types

Replacement stud types

Figure: Standard interference fit stud torque limits

Standard interference fit stud torque limits

Figure: Stepped interference fit stud torque limits

Stepped interference fit stud torque limits

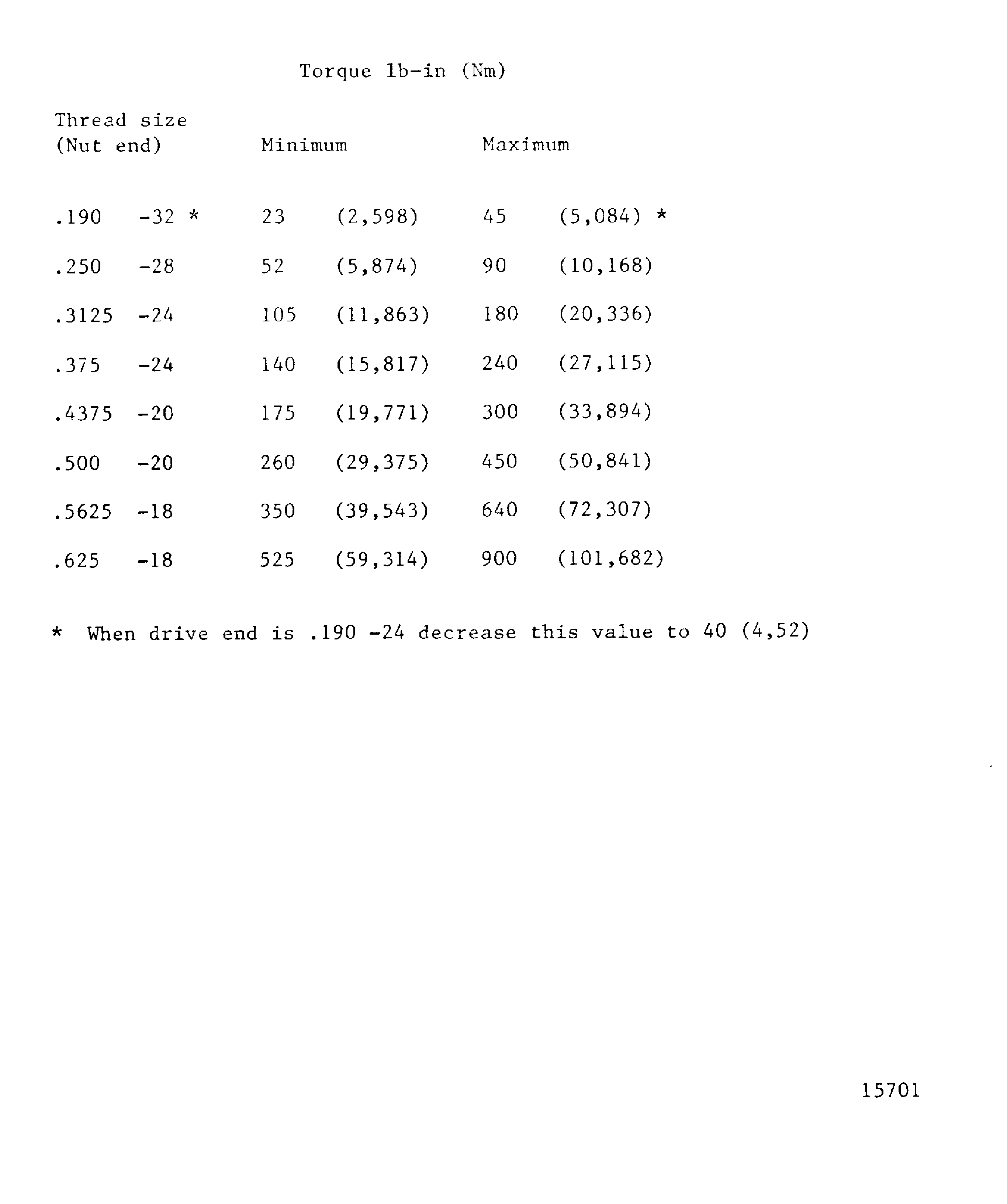

Figure: Standard and stepped studs installed in self-locking helical coil inserts

Standard and stepped studs installed in self-locking helical coil inserts