Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-64-02-640-501 Identification, Lubrication And Installation Of Rubber Seal Rings

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 | ||

| CoMat 10-087 SEALING RING LUBRICANT | 56385 | CoMat 10-087 |

Spares

NONESafety Requirements

WARNING

Procedure

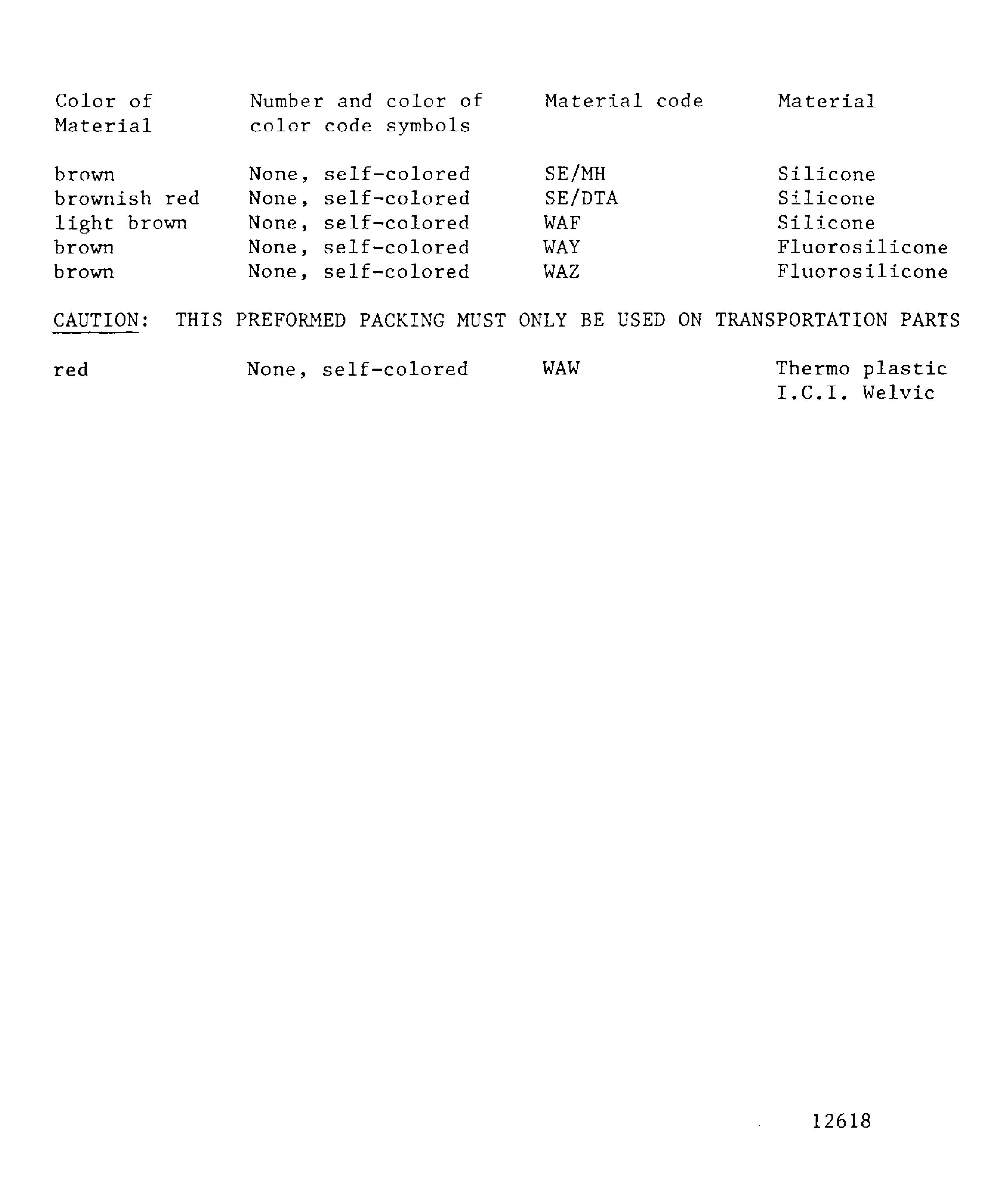

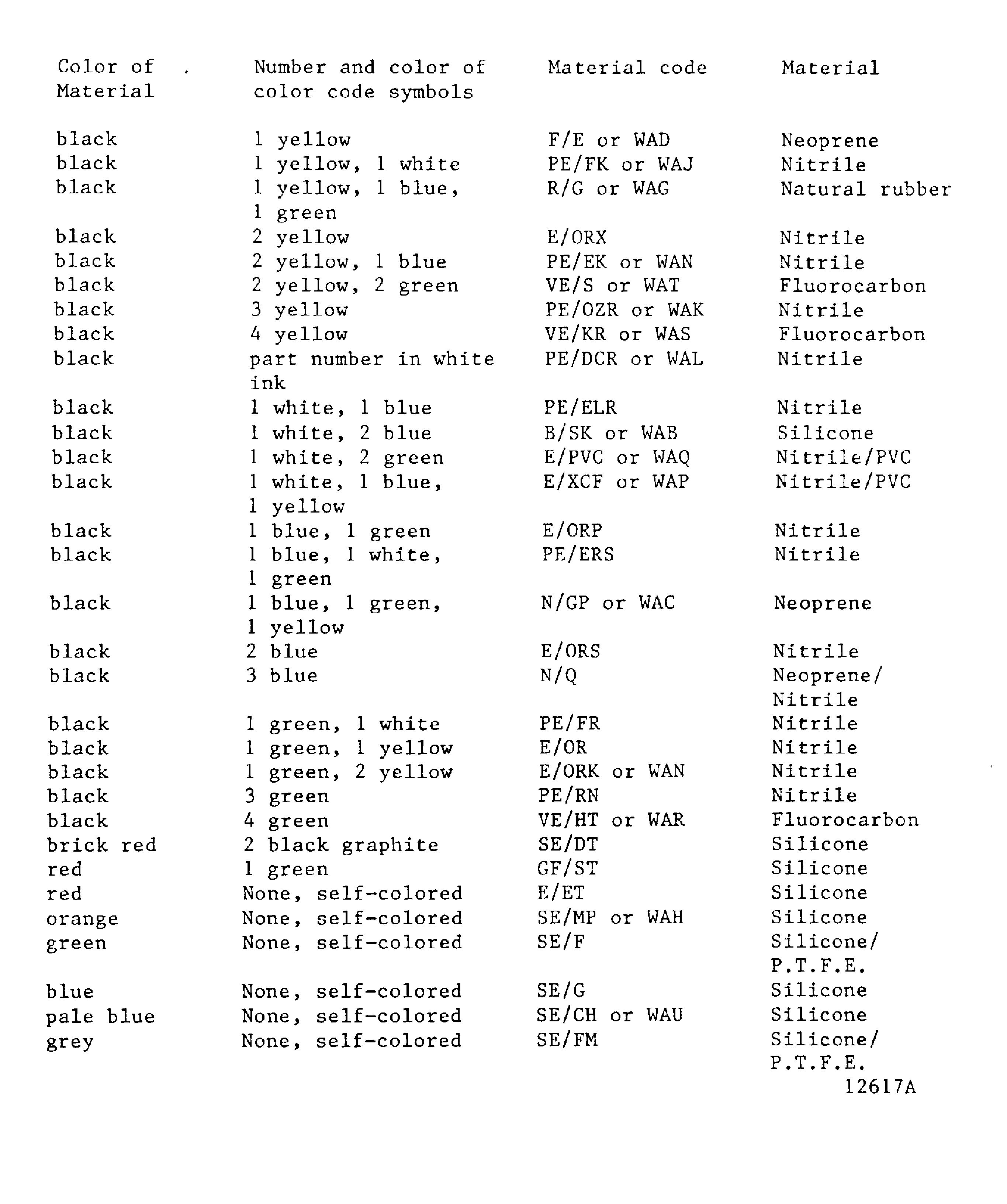

The seal ring material is identified by the color of the ring material, or by the color code marks on the outer diameter of the ring. A seal ring identification table of color codes in relation to material codes and materials is given in Figure.

SUBTASK 70-64-02-640-001 Identification

Seal rings in oil systems - CoMat 10-077 APPROVED ENGINE OILS.

Seal rings in fuel systems - CoMat 10-077 APPROVED ENGINE OILS or CoMat 10-087 SEALING RING LUBRICANT.

NOTE

To prevent damage to rigid air system seals (Made from SE/DTA or WAF code materials) light lubrication with CoMat 10-077 APPROVED ENGINE OILS.Fluorocarbon seals in air systems - CoMat 10-077 APPROVED ENGINE OILS.

The lubricants to be used for seal ring lubrication are as follows:

The recommended lubricant must be applied to the seal in small quantities immediately before you install the unit or part. This makes sure that the ring can not become soaked with lubricant and thus become too large. If the ring does become soaked with lubricant it can be damaged when you install the unit or part.

SUBTASK 70-64-02-640-002 Lubrication

Make sure that the life and condition of the seal ring is satisfactory, refer to Step.

SUBTASK 70-64-02-640-003 Installation of the Flexible Seal Rings

Figure: Seal ring identification table

Seal ring identification table

Figure: Seal ring identification table

Seal ring identification table