Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 23-44-41-700-301 Do a Test of the Maintenance Interphone Jack Harness

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 740-3215-501 |

01-010 | 740-3215-503 |

01-010 | 740-3215-505 |

01-010 | 740-3215-507 |

01-010 | 740-3215-509 |

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Digital Milliohmeter Test Set BT51 or equivalent | LOCAL | Digital Milliohmeter Test Set BT51 or equivalent | ||

| Insulation Resistance Meter - 250 volts DC | LOCAL | Insulation Resistance Meter | ||

| Multimeter | LOCAL | Multimeter |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

NOTE

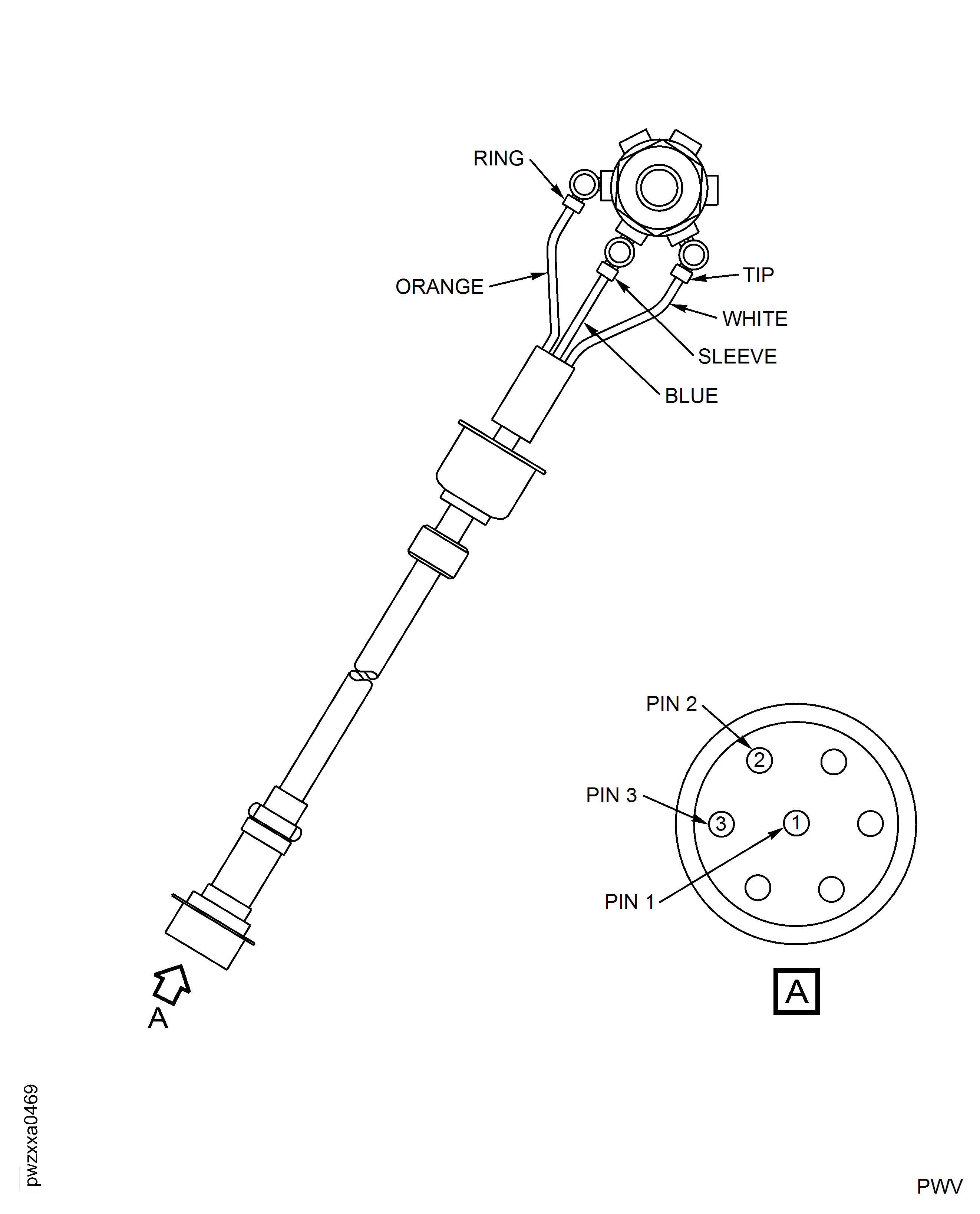

Make sure you use the negative contact on the connector shell and the positive contact on the pins.Refer to Figure.

Set the supply voltage, on the Insulation Resistance Tester, to 250 volts.

Contact to Contact - The insulation resistance must be more than or equal to 20 megohms minimum.

Contact to Connector Shell - The insulation resistance must be more than or equal to 20 megohms minimum.

If the Insulation Resistance Tester shows an incorrect value, reject the harness.

Connect the insulation resistance test leads, between the connector body and each contact of the connector.

SUBTASK 23-44-41-750-054 Do the Test to Check the Insulation Resistance on the Maintenance Interphone Jack Harness (Refer to Table 1)

NOTE

Different methods can be used for continuity testing but in all cases the maximum voltage allowed is 24 volts DC.Refer to Figure.

Set the Multimeter to the continuity position.

Connect the Multimeter test leads to the contacts at the ends of each wire.

Make sure that the Multimeter shows continuity. If the Multimeter shows no continuity, reject the harness.

SUBTASK 23-44-41-750-055 Do the Test for Continuity of the Maintenance Interphone Jack Harness (Refer to Table 1)

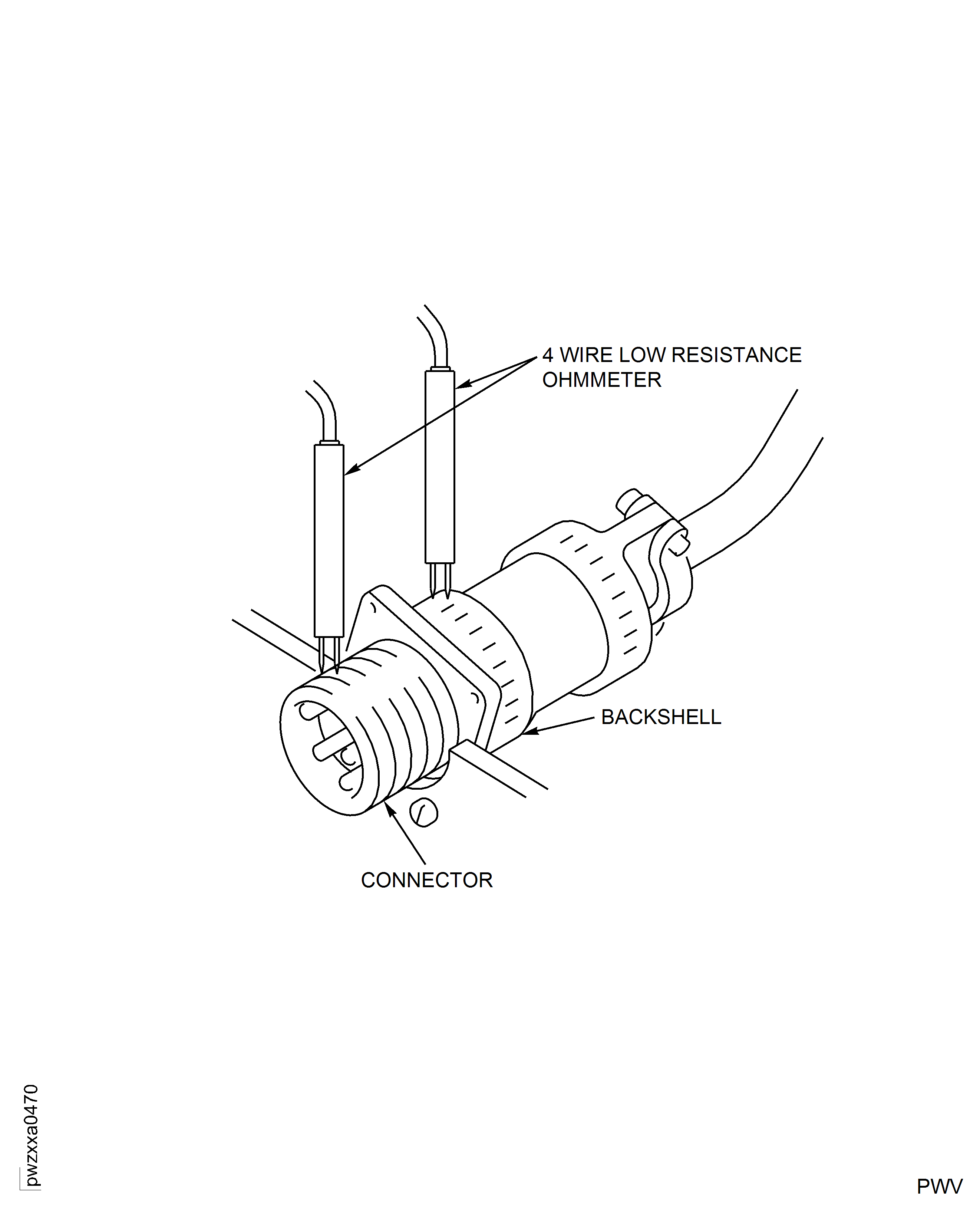

Refer to Figure.

Connect the ohmmeter leads between the connector and backshell. The resistance must be less than or equal to 5 milliohms.

If the ohmmeter shows an incorrect value, reject the harness.

SUBTASK 23-44-41-750-056 Do a 4 Wire Low Resistance Ohmmeter Test (BT51)

Figure: Maintenance Interphone Jack Harness

Maintenance Interphone Jack Harness

Figure: 4 Wire Low Resistance Ohmmeter Test

4 Wire Low Resistance Ohmmeter Test