Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 71-00-00-990-502 Description and Operation of Power Plant Components

Power Plant - Chapter 71

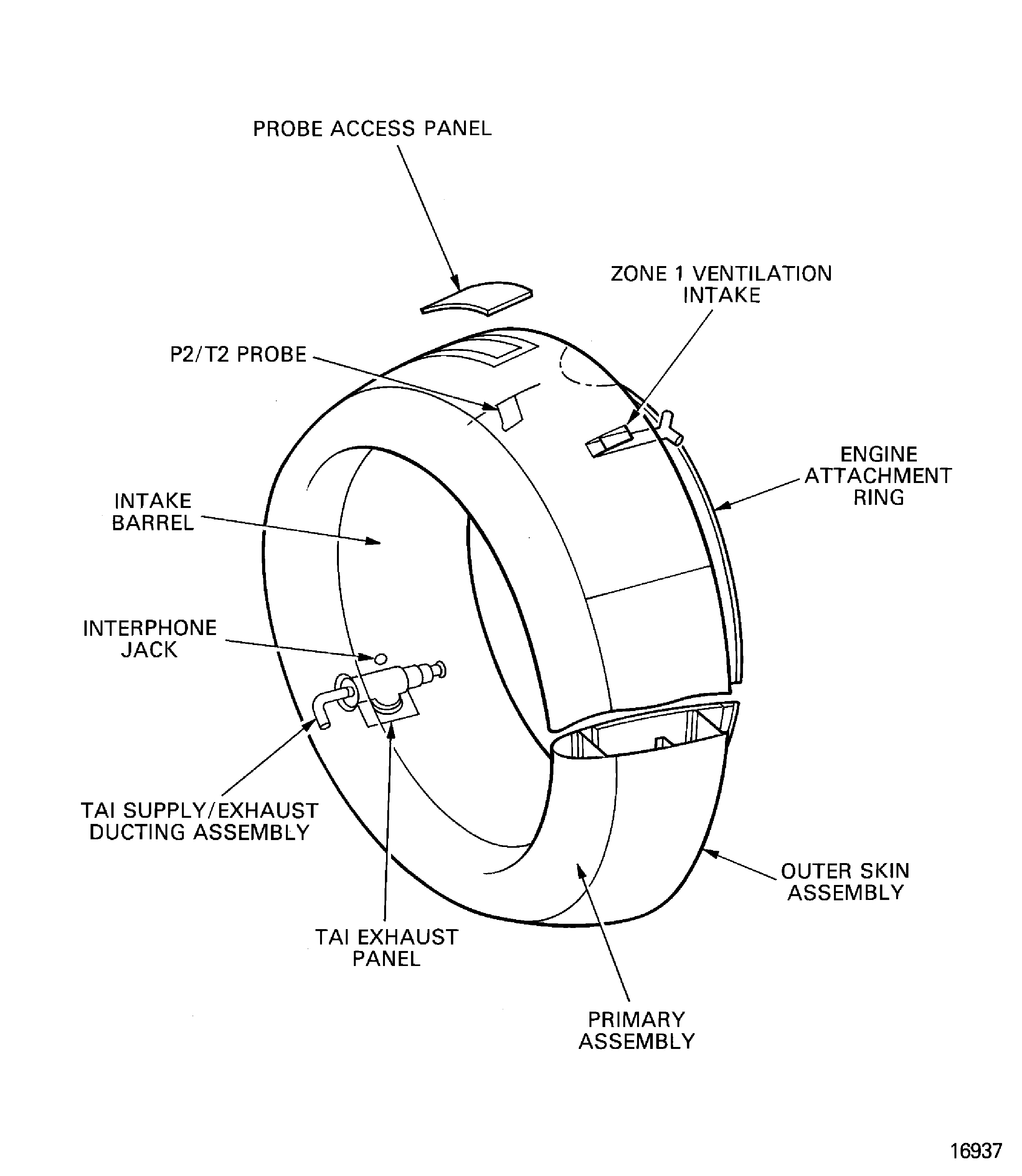

Intake cowl (71-11-00), Figure

The intake cowl is bolted to the front of the LP compressor/intermediate case. It is of a hollow, composite construction with an aluminum leading edge and titanium rear bulkhead.

Its purpose is the minimize nacelle drag and supply all the air required by the engine with minimum pressure losses and with an even pressure face to the fan.

The intake cowl contains the anti-icing supply and exhaust ducting and the P2/T2 probe.

Engine front mount (71-20-00), Figure

The engine front mount transfers vertical, lateral and thrust loads. It locates to the LP compressor/intermediate case at three places with two mount support brackets and a monoball mount. It is attached to the aircraft pylon with four bolts aligned by two shear pins.

Engine rear mount (71-20-00), Figure

The engine rear mount transfers vertical, lateral and torque loads. It is located to the LP turbine exhaust case and is attached to the aircraft pylon with four bolts aligned by two shear pins.

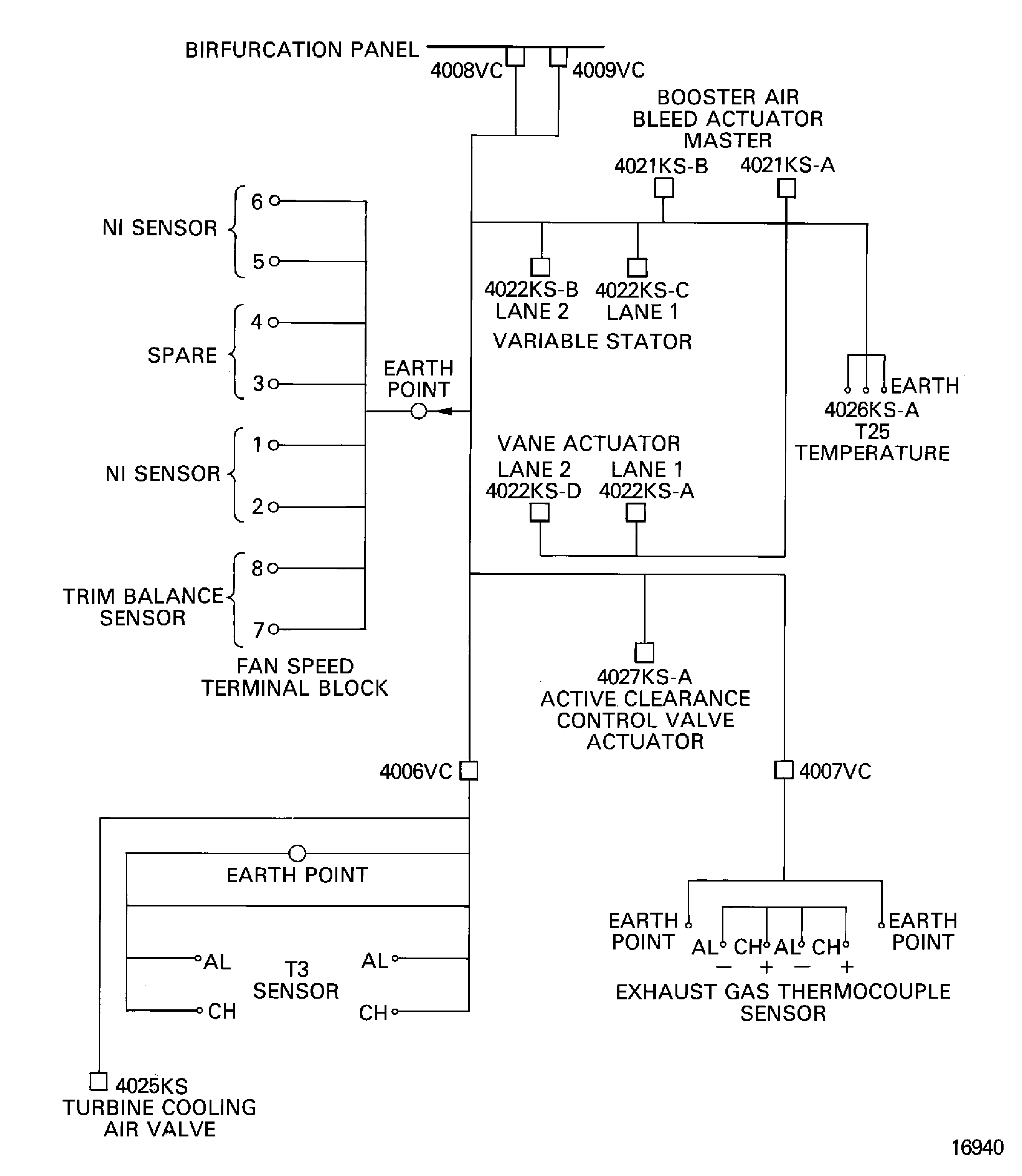

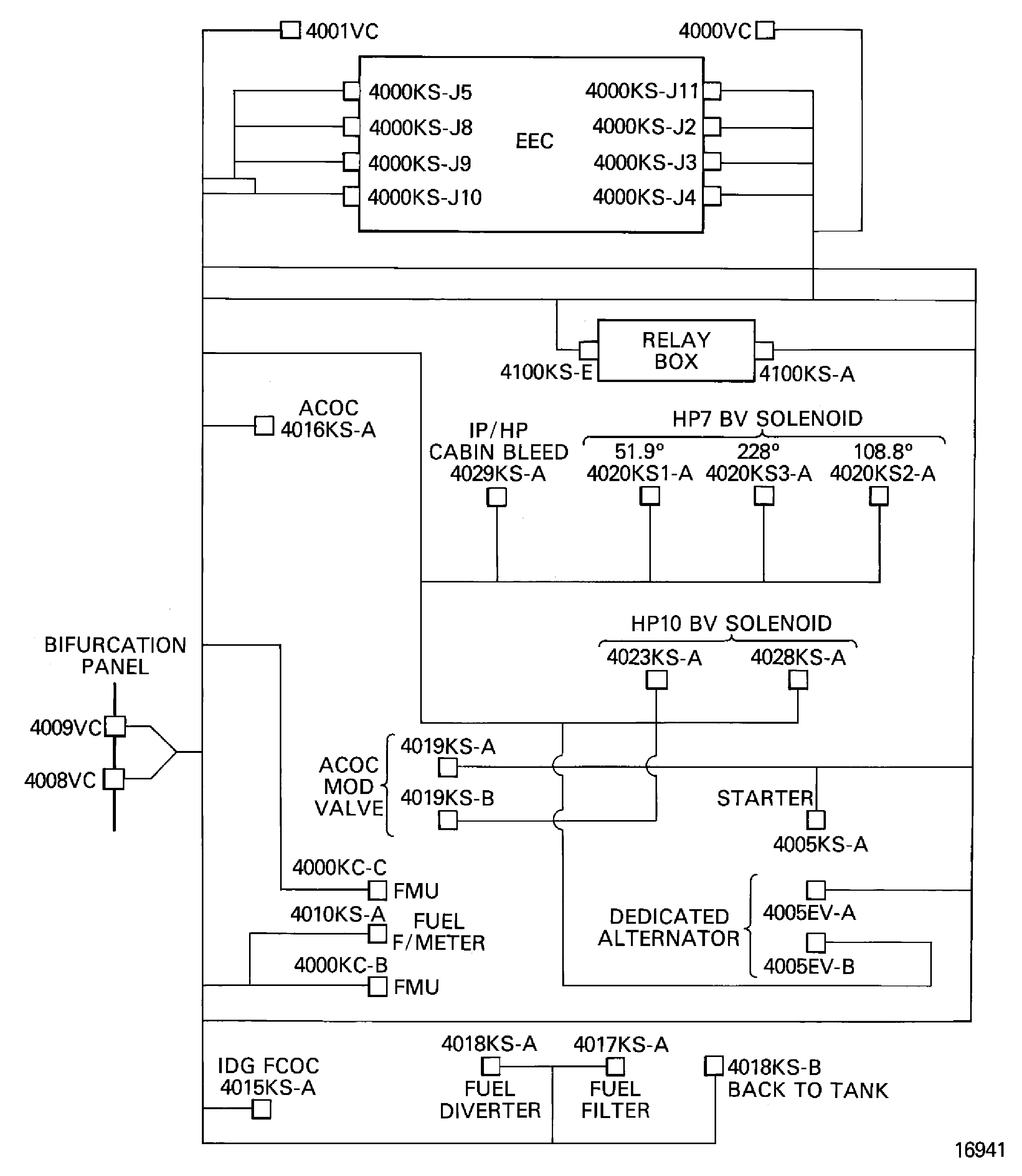

There are four main groups of electrical harness:

The EEC harness (71-51-41, 71-52-43, 71-52-44 and 71-52-45).

The general services harness (71-51-43).

The ignition supply harness (71-51-44).

The EEC and ignition supply harness (71-51-42).

Combined drains (71-71-00), Figure

This provides a combined overboard drain through a drains mast at the base of the LP compressor/intermediate case. The drains are for fuel and oil from the core module components, the LP compressor/intermediate case components and the external gearbox.

Figure: Intake cowl

Intake cowl

Figure: Engine front mount

Engine front mount

Figure: Engine rear mount

Engine rear mount

Figure: EEC harness

EEC harness

EEC harness

Figure: General services harness

General services harness

Figure: Ignition supply harness

Ignition supply harness

Figure: Combined drains

Combined drains