Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 71-00-00-990-503 Description and Operation of the Modules

Engine - Chapter 72

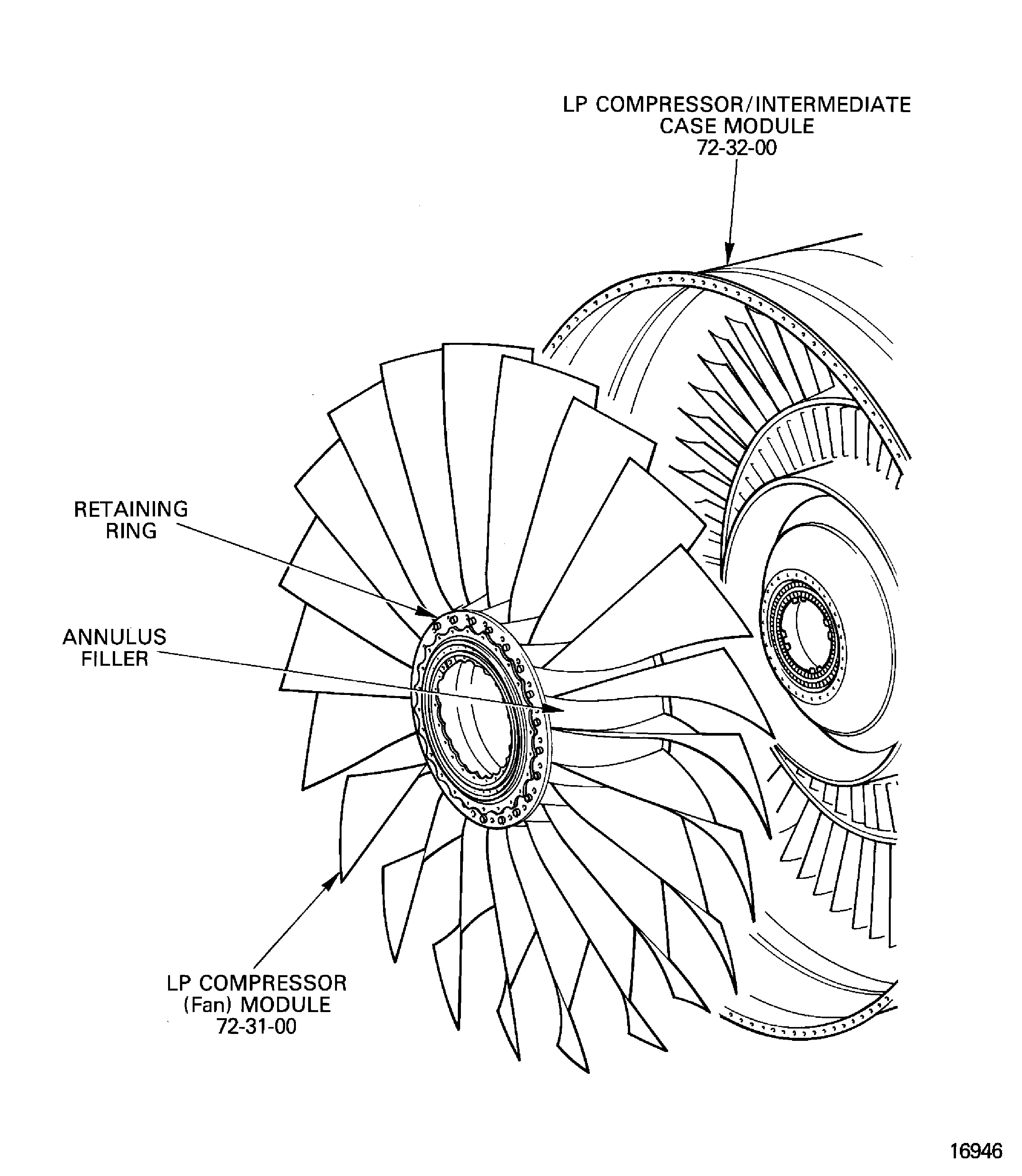

The LP Compressor (LPC) Fan Module (72-31-00), Figure

The LPC fan module is a single stage fan rotor assembly. The rotor assembly includes 22 fan blades and a disk. The fan blades are of a wide-chord type without shrouds and they are installed to the disk by a dovetail root.

22 annulus fillers are installed between adjacent blades as a platform between each two blades. This is because each blade has no structural platform. A rubber seal is bonded to each side of the annulus fillers to prevent air leakage between each blade and filler.

The blades and fillers are attached to the disk by a front blade retaining ring and a rear blade retaining ring with bolts.

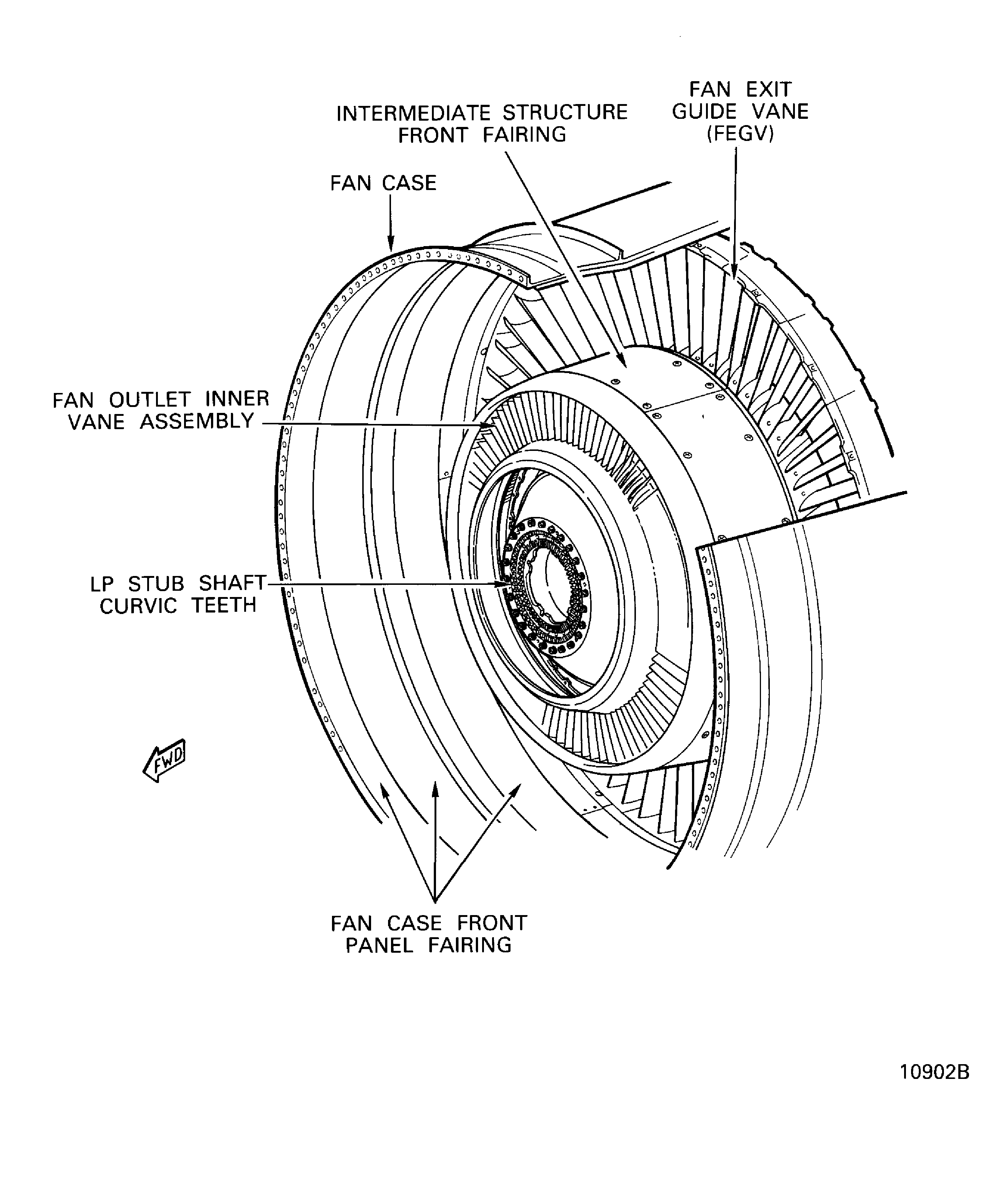

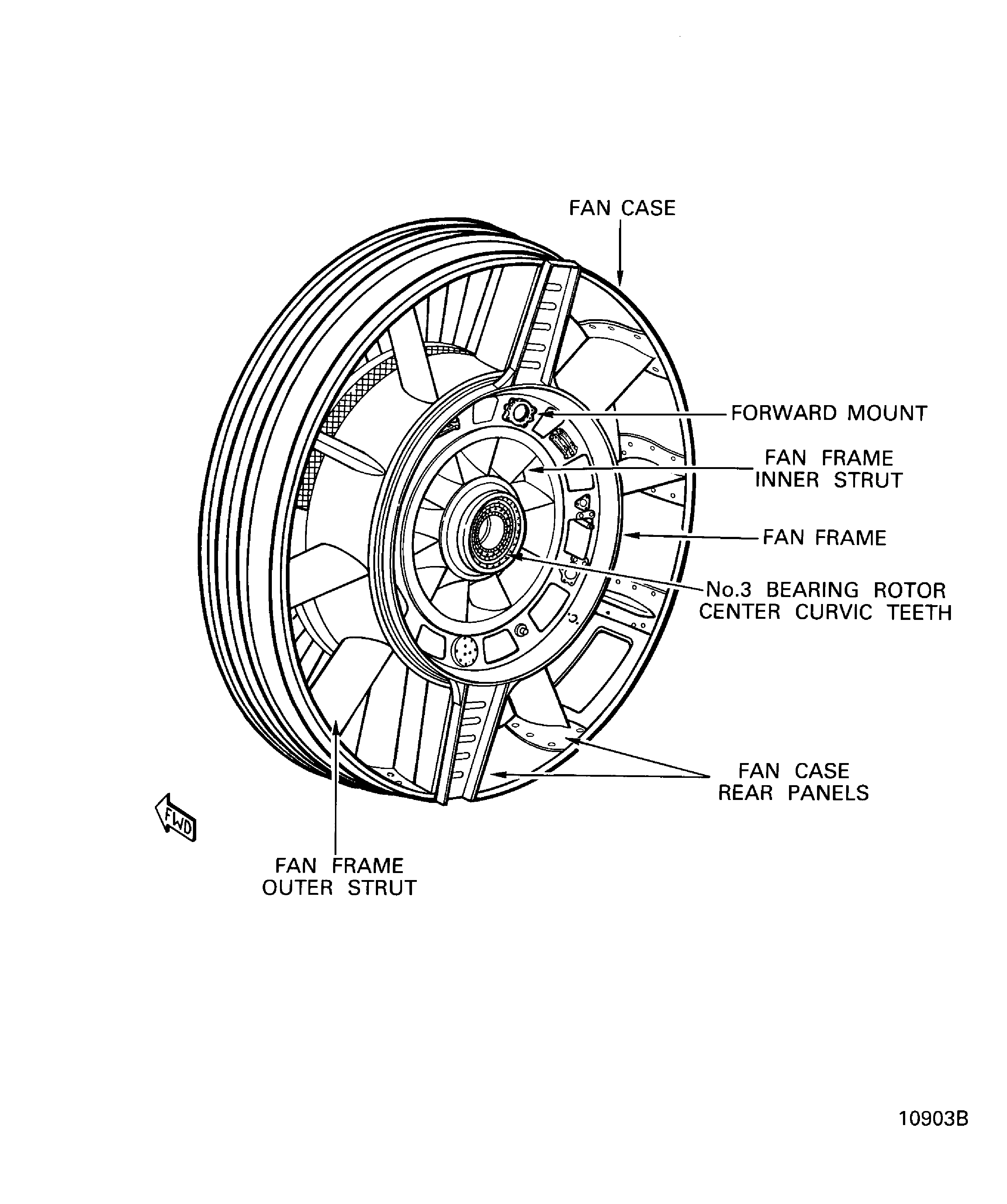

The LPC/intermediate case module includes the fan case and the intermediate structure fan frame. The two components are primary components to make the case module.

The intermediate structure is a one-piece welded structure with 10 inner and outer struts. The inner struts hold the LP compressor assembly (LPC) and the components to make the front bearing compartment.

V2500-A1 engine: The LPC is a three stage axial compressor to which the fan is attached. The assembly is driven by a five stage low pressure turbine (LPT).

V2500-A5 engine: The LPC is a four stage axial compressor to which the LP fan is attached. The assembly is driven by a five stage low pressure turbine (LPT).

The fan case is a one-piece welded structure. It is installed on to the mounting pads on each outer strut end of the intermediate structure with bolts.

The case module includes a front bearing compartment where No.1, No.2 and No.3 bearing are installed. The fan/LPC rotor is held in position by the No.1 and No.2 bearings. The No.3 bearing holds the front part of the HP compressor (HPC) rotor from which the power is supplied to the Power Take Off (PTO) system. These rotors and the bearing compartment are held by an intermediate structure of the case module.

The case module also includes an internal gearbox. Torque is transmitted from the HPC through a bevel gear of the internal gearbox and a PTO shaft. The PTO shaft power output is then transmitted through an external gearbox to the engine accessories installed on the gearbox.

A bleed valve mechanism is included in the case module to bleed air from the rear of the LP compressor (LPC). The mechanism operates to make the engine more stable during engine start and transient operation.

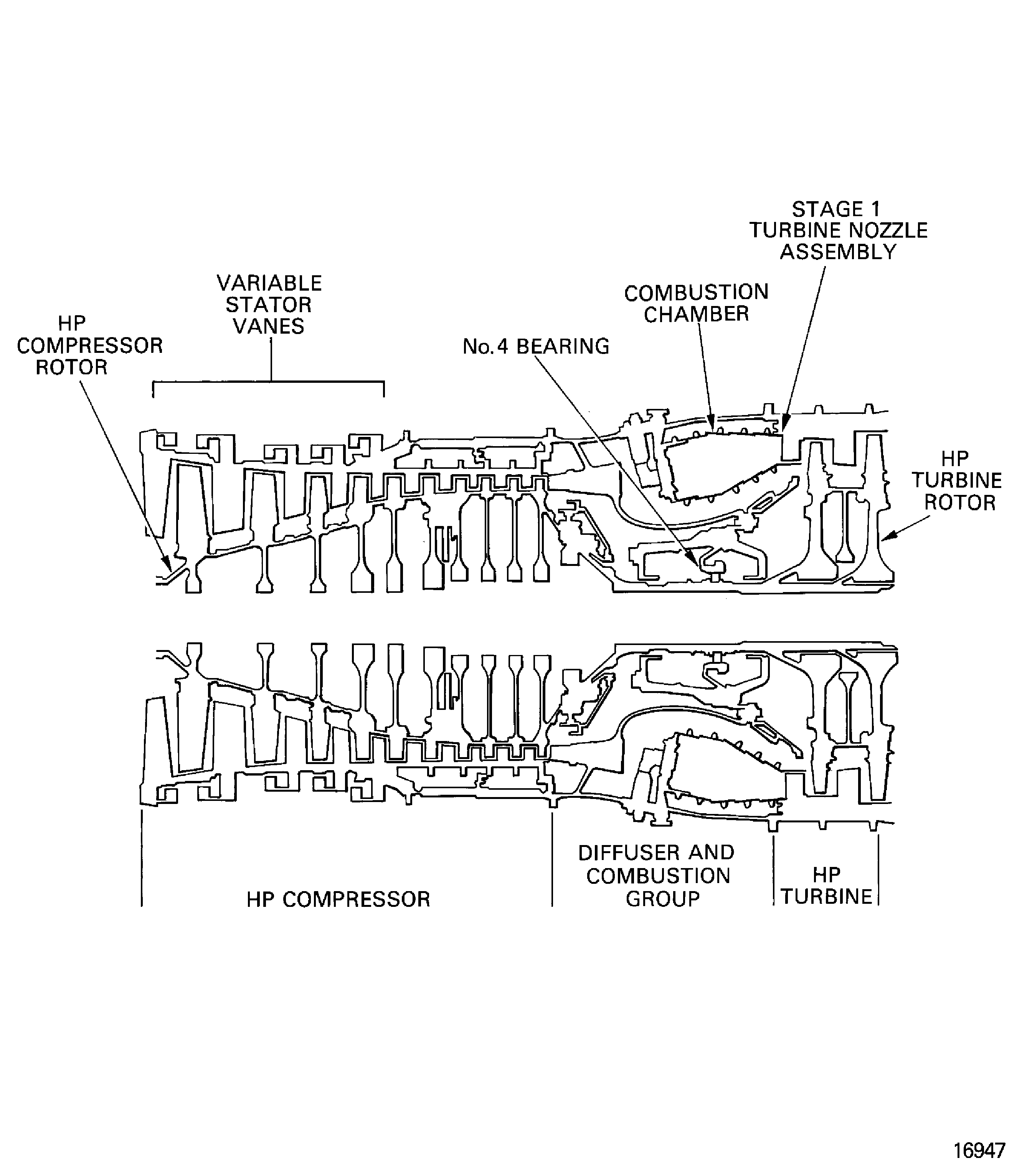

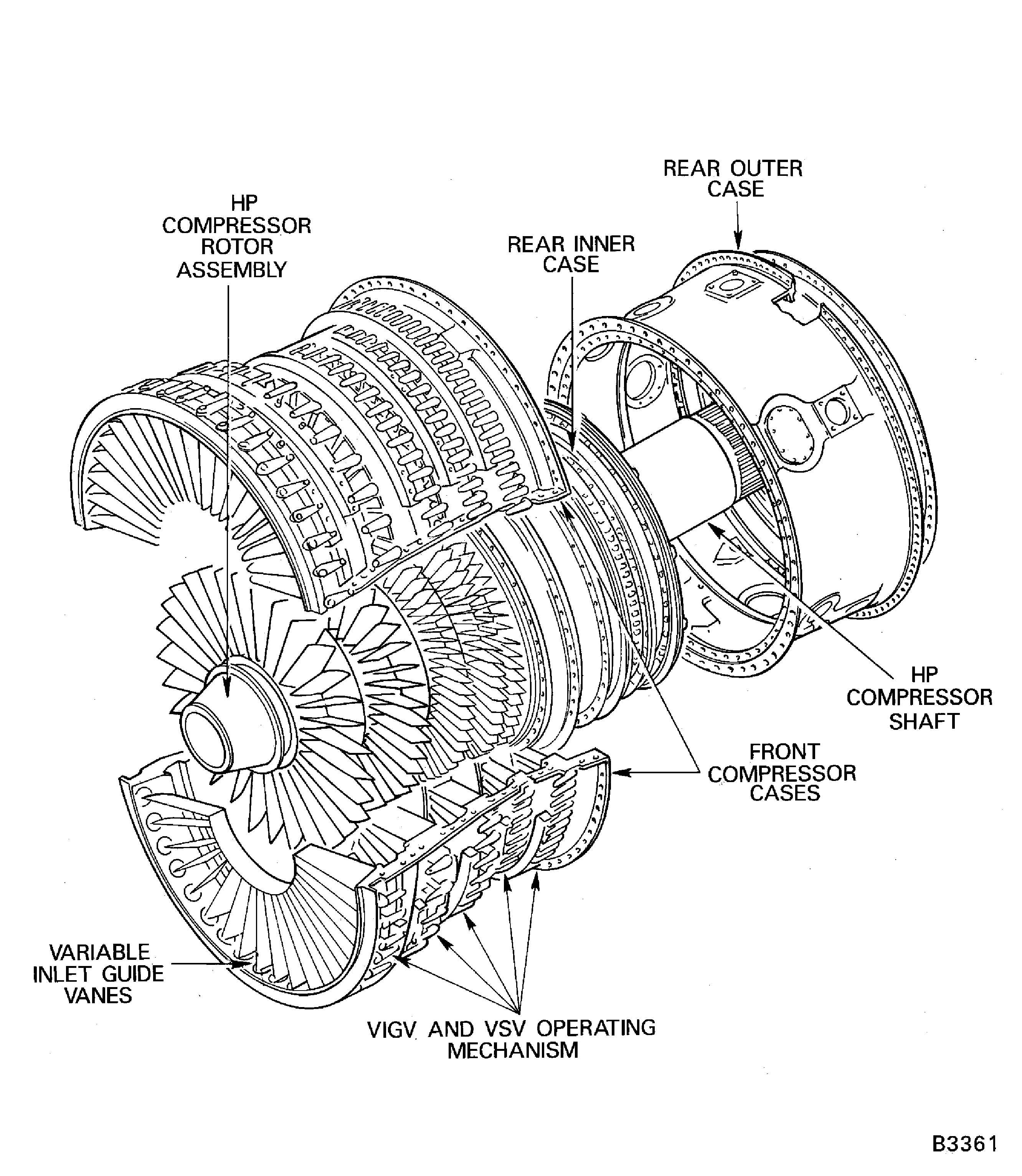

The HPC assembly is a 10 stage axial flow compressor. It has a rotor assembly and stator cases. As the compressor stages are numbered from the front of the engine, the first stage of the HPC is stage 3.

The HPC rotor has five sub-assemblies - stage 3 to 8 HPC disk, a vortex reducer ring, stage 9 to 12 HPC disks, HPC rear shaft, and the HPC rotating air seal. The five sub-assemblies are bolted together to make the HPC rotor. The HPC shaft supplies the power from the HP turbine (HPT).

The HPC blades are held in to the HPC disks as follows; stages 3 to 5 by axial dovetail locations and stages 6 to 12 by radial dovetail locations.

V2500-A1: The HPC stator case has two primary sub-assemblies. The first sub-assembly is the HPC front cases, which has two split cases. The second sub-assembly is the HPC rear cases which has five ring cases. The HPC front cases include the variable inlet guide vanes and the stage 3 to 6 variable stator vanes. The HPC rear cases include the stage 7 to 11 fixed stator vanes. The HPC split cases are bolted together along the engine horizontal center line. The five HPC ring cases are bolted together, with the front support cone bolted at the stage 7 case.

V2500-A5: The HPC stator case has two primary sub-assemblies. The first sub-assembly is the HPC front cases, which has two split cases. The second sub-assembly is the HP compressor rear cases which has five ring cases. The HP compressor front cases include the variable inlet guide vanes, the stage 3 to 5 variable stator vanes, and the stage 6 fixed stator vanes. The HPC rear cases include the stage 7 to 11 fixed stator vanes. The HPC split cases are bolted together along the engine horizontal center line. The five HPC ring cases are bolted together, with the front support cone bolted at the stage 7 case.

The HPC rear outer case locates on the cross-key ring at the rear of the ring cases. It is also bolted to the front support cone and the rear flange of the HPC front cases.

The variable inlet guide vanes and variable stator vanes actuating mechanism is attached to the HPC front cases.

The Diffuser and Combustion Group (72-42-00), Figure

The primary parts of the diffuser and combustion group are the:

Diffuser case assembly

Combustion chamber assembly

No.4 bearing front compartment

Internal tubes

Fuel distribution valve

Fuel nozzles

The diffuser case assembly is the primary structural part of the group. The diffuser case assembly extends from the rear flange of the HP compressor case, to the front flange of the HP turbine case.

The diffuser case has 20 mounting pads, where the fuel nozzles are installed, two mounting pads where the ignitor plugs are installed, and five borescope bosses located around the case.

The combustion chamber assembly includes the combustion chamber outer liner, and the five combustion chamber retaining bolts. When assembled with the combustion chamber inner liner assembly, which is attached to the turbine nozzle assembly, the two combustion chamber liner assemblies make a chamber for burning the mixture of fuel and air.

The front of the combustion chamber outer liner assembly has an aerodynamic contour, with 20 fuel nozzle guides. The fuel nozzles install through the guides, and into the combustion chamber.

The combustion chamber outer liner is a sheet-metal shell with 50 separate segment liners attached to the internal surface. If any segments become damaged, each one can be removed and replaced.

The No.4 bearing front compartment, when assembled with the No.4 bearing and rear compartment, forms an insulated, sealed area for bearing lubrication, support, and protection from high temperatures.

The internal tubes include the tubes which carry oil and cooling air for the No.4 bearing, and cooling air for the HP turbine.

There are 20 fuel nozzles equally spaced around the diffuser case assembly. The fuel nozzles are installed through the wall of the case and each nozzle is held in position by three bolts.

The fuel distribution valve is installed at the front flange of the diffuser case.

The No.4 Bearing and Rear Compartment (72-43-00), Figure

The primary parts of the No.4 bearing and rear compartment are the:

No.4 bearing

No.4 bearing seal spacer

No.4 bearing front and rear seal seats

Rear bearing compartment

No.4 bearing rear seal assembly

Related parts of the No.4 bearing front compartment are the:

No.4 bearing support assembly

No.4 bearing front compartment

No.4 bearing front seal assembly

The No.4 bearing and rear compartment, when assembled with the No.4 bearing front compartment, completes assembly of the No.4 bearing within an insulated, sealed area.

The No.4 bearing is a cylindrical roller bearing. The inner race has shoulders which guide the rollers in the race. The outer race, installed in the No.4 bearing support assembly, is machined elliptical so the bearing rollers cannot skid. The outer race is held in the No.4 bearing support assembly by a nut and lock.

The front and rear bearing compartments are made of three separate walls. The walls form insulation chambers. The inner wall of each compartment forms a chamber with the middle wall, and carries cool air around the bearing area.

Oil for lubrication of the No.4 bearing, and the front and rear seals is supplied through a diffuser case internal tube attached to the No.4 bearing front compartment.

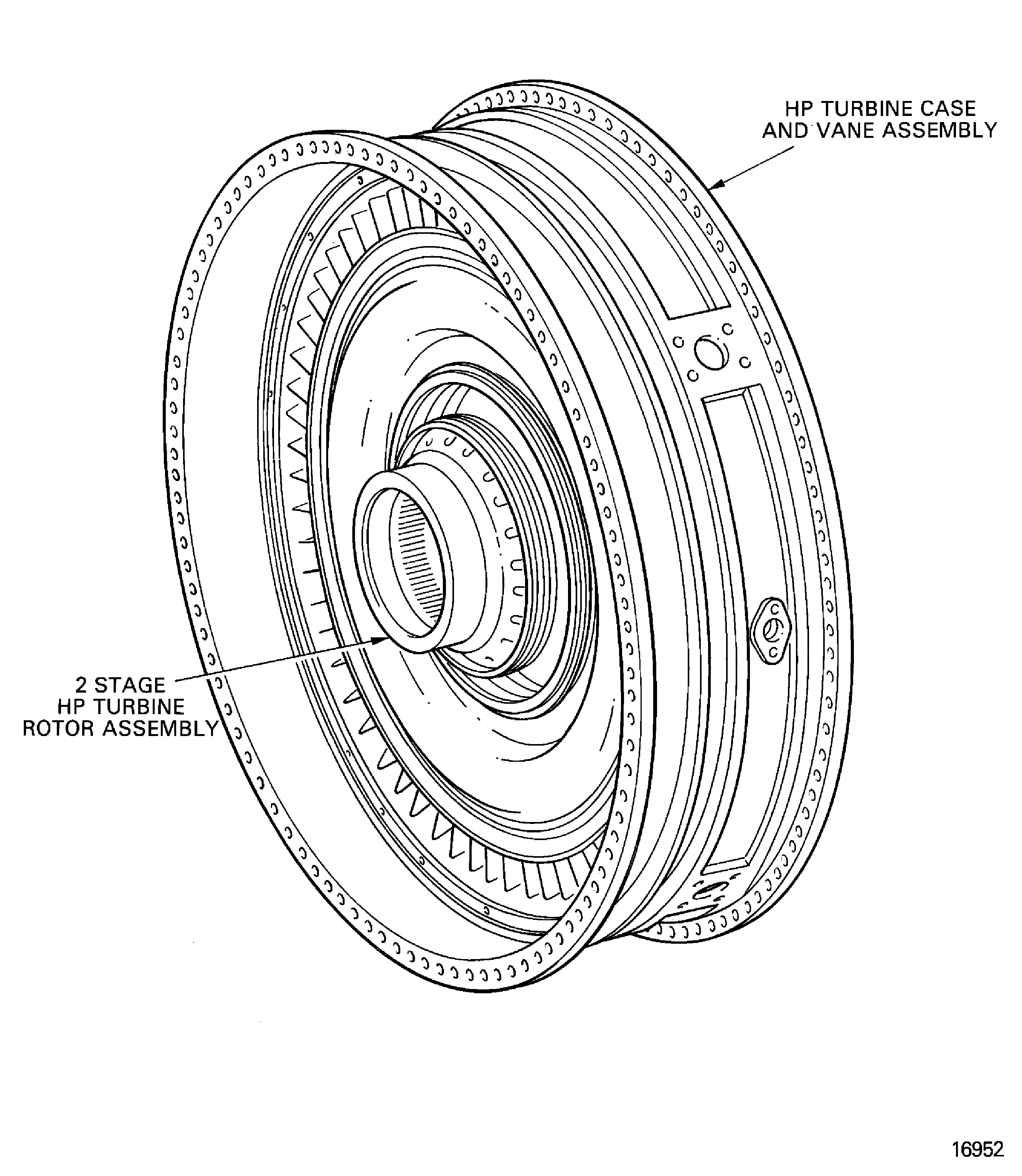

The HP Turbine (HPT) Rotor and Stator Assembly (72-45-00), Figure

The primary parts of the HP turbine rotor and stator assembly are the:

HPT rotor assemblies (stage 1 and stage 2)

HPT case and vane assembly

The HP turbine rotor assemblies are two stages of turbine hubs with single-crystal, nickel-alloy blades. The two-hub configuration removes a bolt flange between hubs. This decreases weight, and makes assembly faster. The blades have airfoils with high strength and resistance to creep. Satisfactory blade tip clearances are supplied by active clearance control (ACC) to cool the case with compressor air.

The stage 1 rotor assembly has the following parts:

HPT stage 1 hub

HPT inner and outer air seals

68 HPT stage 1 blades

HPT rear air seal

The stage 2 rotor assembly has the following parts:

HPT stage 2 hub

72 HPT stage 2 blades

HPT stage 2 blade retaining plate

The inner and outer HPT air seals are installed on the front of the stage 1 hub. The stage 1 blades are installed in slots on the hub. The blades are held on the forward side by the outer HPT air seal. The stage 2 HPT air seal is installed on the rear of the stage 1 hub. This air seal holds the stage 1 blades on the rear side.

The stage 2 turbine hub is installed behind the stage 1 hub and the stage 2 HPT air seal. Stage 2 blades are installed in slots in the hub. The blades are held on the forward side by the stage 2 HPT air seal. The blades are held on the rear side by the stage 2 blade retaining plate.

The HP turbine (HPT) case and vane assembly has the following parts:

HPT case assembly

HPT duct support set (stage 1)

HPT stage 1 and 2 duct segments

HPT stage 2 ring segment and vane clusters

HPT stage 2 duct support

HPT stage 2 support assembly

The HPT case has internal flanges to hold the vane clusters and the HPT stage 1 duct support set.

The HPT stage 1 duct support set holds the HPT stage 1 duct segments in position at the front side. The rear side of the duct segments are held by the vane clusters.

The HPT stage 2 duct segments are held in position at the front by the vanes. Two supports hold the vanes and duct segments at the rear.

The HPT stage 1 and 2 duct segments have an abradable ceramic coating. They are assembled in sets for each stage. Sheet-metal seals are installed between the segments.

The HPT stage 2 air-cooled vanes are assembled in clusters of two vanes. Segmented honeycomb airsealing rings on the vane inner shrouds are in alignment with knife-edges of the HPT stage 2 air seal. The vanes are installed into flanges inside the case. Segmented sheet-metal seals are installed between adjacent clusters.

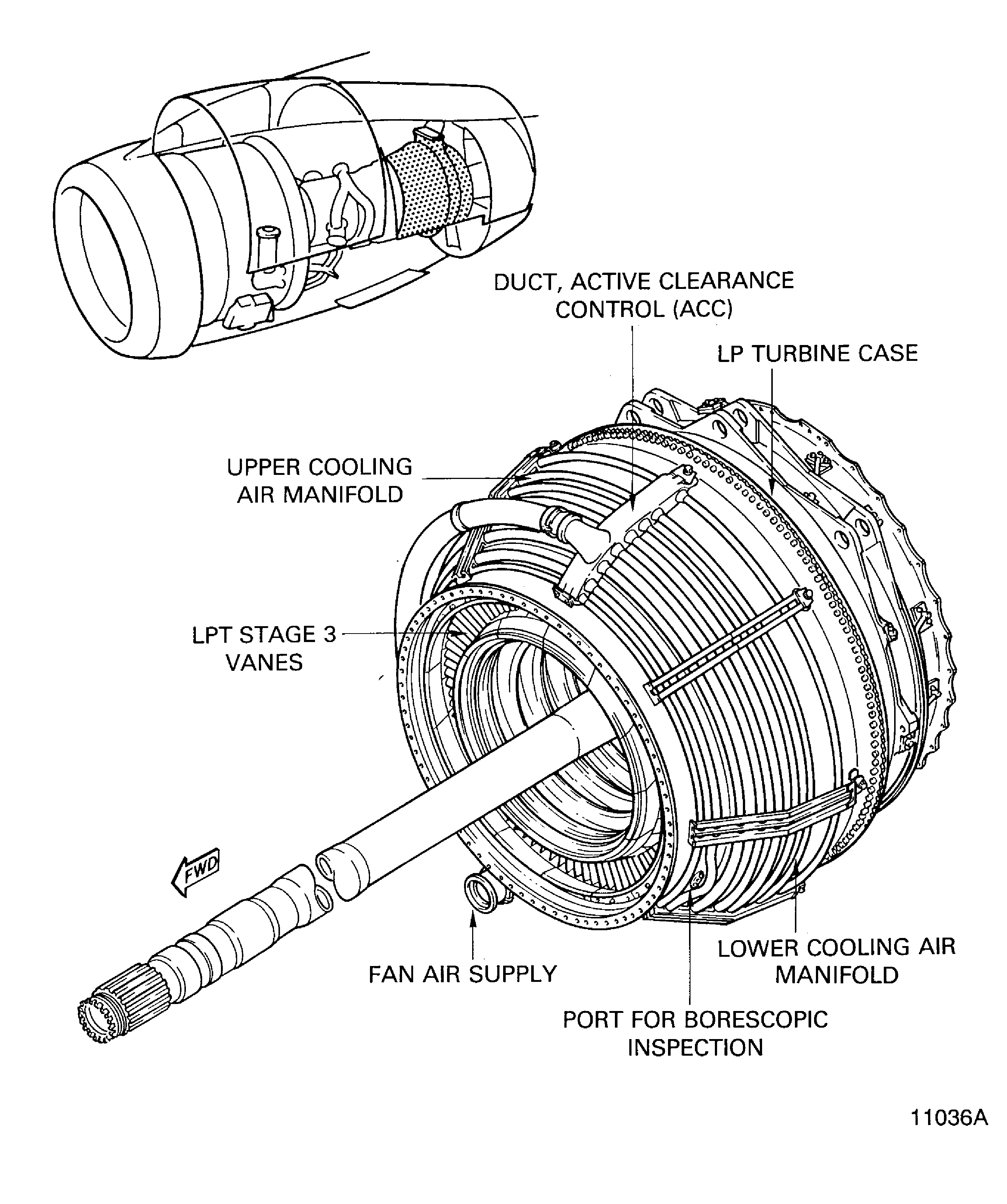

The LP Turbine (LPT) Module (72-50-00), Figure

The low pressure turbine (LPT) module has the following parts:

LPT five stage rotor

LPT five stage stator vanes

LPT air seals

LPT case

LPT inner and outer duct

LPT Active clearance control system (ACCS)

LPT shaft

Turbine exhaust case (TEC)

The LPT has a five stage rotor which supplies power to the LP compressor (LPC) through the LPT shaft. The LPT rotor is installed in the LPT case where it is in alignment with the LPT stators. The LPT case is made from high-heat resistant nickel alloy and is a one part, welded assembly.

The five LPT disks are made from high heat resistant nickel alloy. The LPT blades are also made from nickel alloy and are attached to the disks by fir tree roots. The blades are held in axial position on the disk by the rotating air seals (knife edge).

The LPT stator vanes are made of nickel alloy and are assembled in clusters of three vanes. They are installed on internal flanges in the LPT case. They are held in position on the flanges by the outside diameter shroud seal segments located between the stator stages.

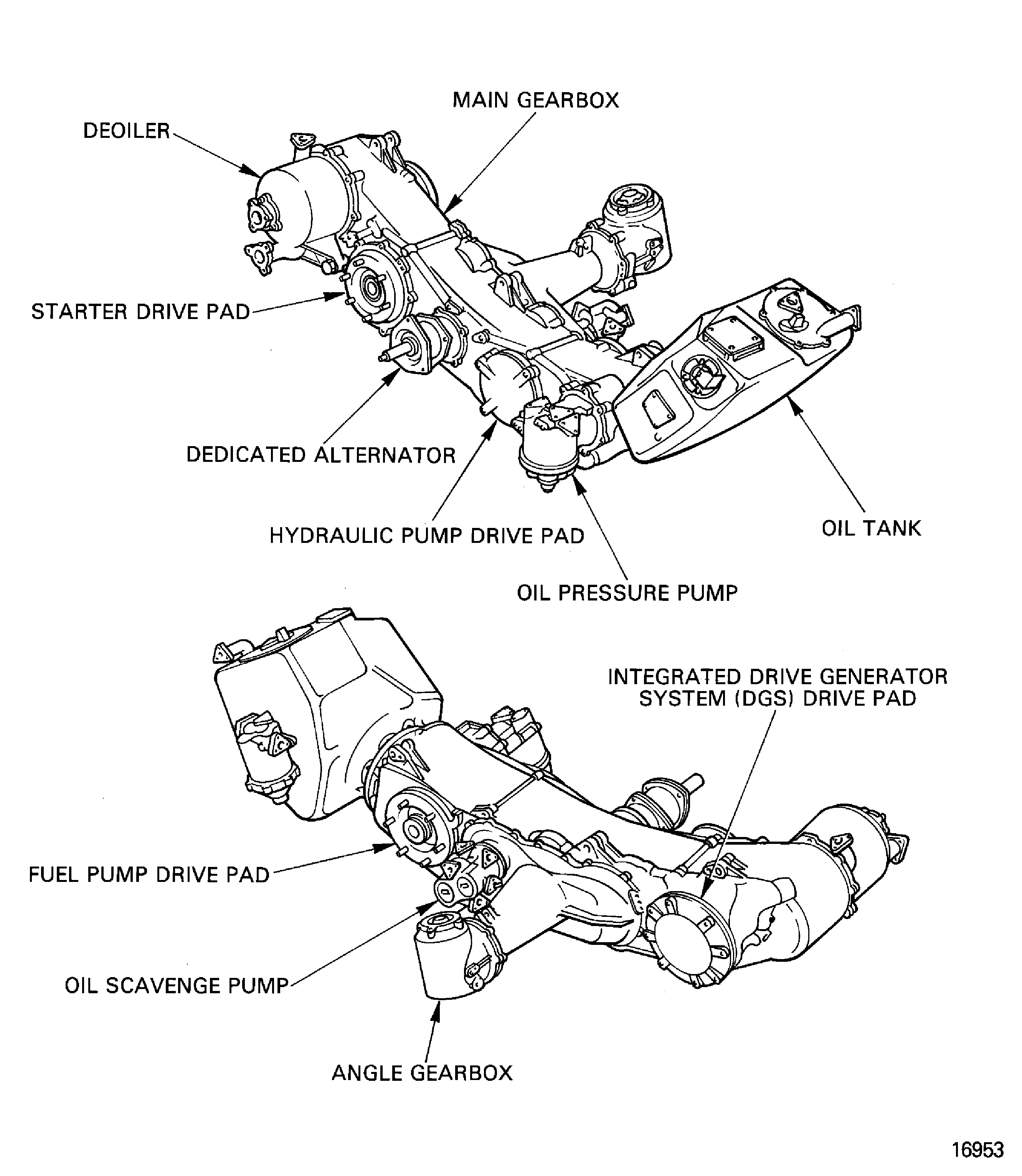

The External Gearbox (72-60-00), Figure

External Gearbox

The external gearbox is a modular unit. It has two primary sub-assemblies:

Main gearbox

Angle gearbox

The external gearbox is installed at the bottom of the intermediate case module. Four flexible support links, three on the main gearbox and one on the angle gearbox support, attach the external gearbox to the intermediate case flanges. The links have spherical bearings at each end to permit any necessary mount flexibility.

Main gearbox

The main gearbox is installed forward of the angle gearbox. It is attached to the angle gearbox by an angle gearbox support and to the intermediate case flange by three joint links.

The angle gearbox support is a casting, housing the layshaft and is rigidly connects the angle gearbox to the main gearbox. A pad on the support is used for the installation of the oil scavenge pump.

The main gearbox has a cast aluminum housing. It incorporates a gear train, carbon seals and mounting pads for the airframe and engine accessories. An external deoiler is installed on the front face of the main gearbox. Each of the accessories drive gear train sections is individually replaceable.

The metered oil nozzles are installed on a gearbox housing and supply pressure oil to the bearings and gears in the gearbox.

An external oil tank is attached at the left-hand flange of the main gearbox.

Drive pads on the forward face of the gearbox are used for installation of the following:

Hydraulic pump

Starter

Oil pressure pump

Dedicated alternator (PMA)

Provision for remote cranking of the HP rotor is also located on the front face.

Drive pads on the rear face of the gearbox are used for installation of the following:

Integrated drive generator (IDG)

Fuel pump

Oil scavenge pump (on the angle gearbox support)

NOTE

Direction of gearshaft rotation is the direction that you look at when facing the mounting pad being described.Hydraulic pump drive gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the adjacent idler gearshaft. If the hydraulic pump is not installed, the ID gearshaft is sealed and the pad cover is installed.

Starter drive gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the adjacent crank gearshaft.

Oil pressure pump

The oil pressure pump is a removable assembly installed on the front flange of the gearbox. The pump has a separate housing that has two bush-mounted drive gear assemblies and the seat of the oil pressure filter. Direction of drive rotation is counterclockwise. The oil pressure pump receives the motion through the fuel pump drive gearshaft. The pump supplies oil under pressure to the engine bearings and accessory drives.

Dedicated alternator (PMA) gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the adjacent input gearshaft.

IDG gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the starter gearshaft. When the IDG is not installed, the ID gearshaft is sealed and the mount pad is installed.

Fuel pump drive gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the hydraulic pump drive gearshaft.

Oil scavenge pump

The oil scavenge pump is a removable assembly installed on the flange of the support angle gearbox. The pump has a separable housing that has a bush-mounted drive gear assembly, which moves two pump gear stages. The pump receives the motion through the idler gearshaft. The direction of drive rotation is counterclockwise. The oil scavenge pump increases the scavenge capacity of the oil pump module and sends the scavenge oil to the oil tank.

External deoiler

Direction of drive rotation is counterclockwise. The deoiler receives the motion through the IDG gearshaft. The oil/air mixture flows through the deoiler, that, with the centrifugal action removes the air from the oil. The deaerated oil goes back to the oil system and the clean air is bled overboard.

Angle gearbox

The angle gearbox is installed on the rear of the main gearbox and engages with the towershaft on the engine.

The angle gearbox has a bevel gearset. A cast aluminum housing holds a bevel gearset. The bevel gearset transmits the power to and from the engine through a powershaft engaged to the HP rotor. The bevel gearset has a spiral gear mesh which drives a horizontal input gearshaft in the main gearbox.

Two metered jets supply pressure oil to the bearings and gears in the angle gearbox.

Figure: LP compressor (fan) module

LP compressor (fan) module

Figure: LP compressor/intermediate case module

LP compressor/intermediate case module

LP compressor/intermediate case module

LP compressor/intermediate case module

Figure: V2500-A1: HP system module

V2500-A1: HP system module

V2500-A1: HP system module

Figure: V2500-A1: HP compressor assembly

V2500-A1: HP compressor assembly

V2500-A1: HP compressor assembly

Figure: Diffuser and combustion group

Diffuser and combustion group

Figure: No. 4 bearing and rear compartment

No. 4 bearing and rear compartment

Figure: Stage 1 turbine nozzle assembly

Stage 1 turbine nozzle assembly

Figure: HP turbine rotor and stator assembly

HP turbine rotor and stator assembly

Figure: LP turbine module

LP turbine module

Figure: External gearbox

External gearbox