Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-00-00-700-070 Functional Test Of The P4.9 (P5) Sensor System, Testing-070

General

Use this procedure to leak check and flow check the P4.9 (P5) system for leaks and obstructions.

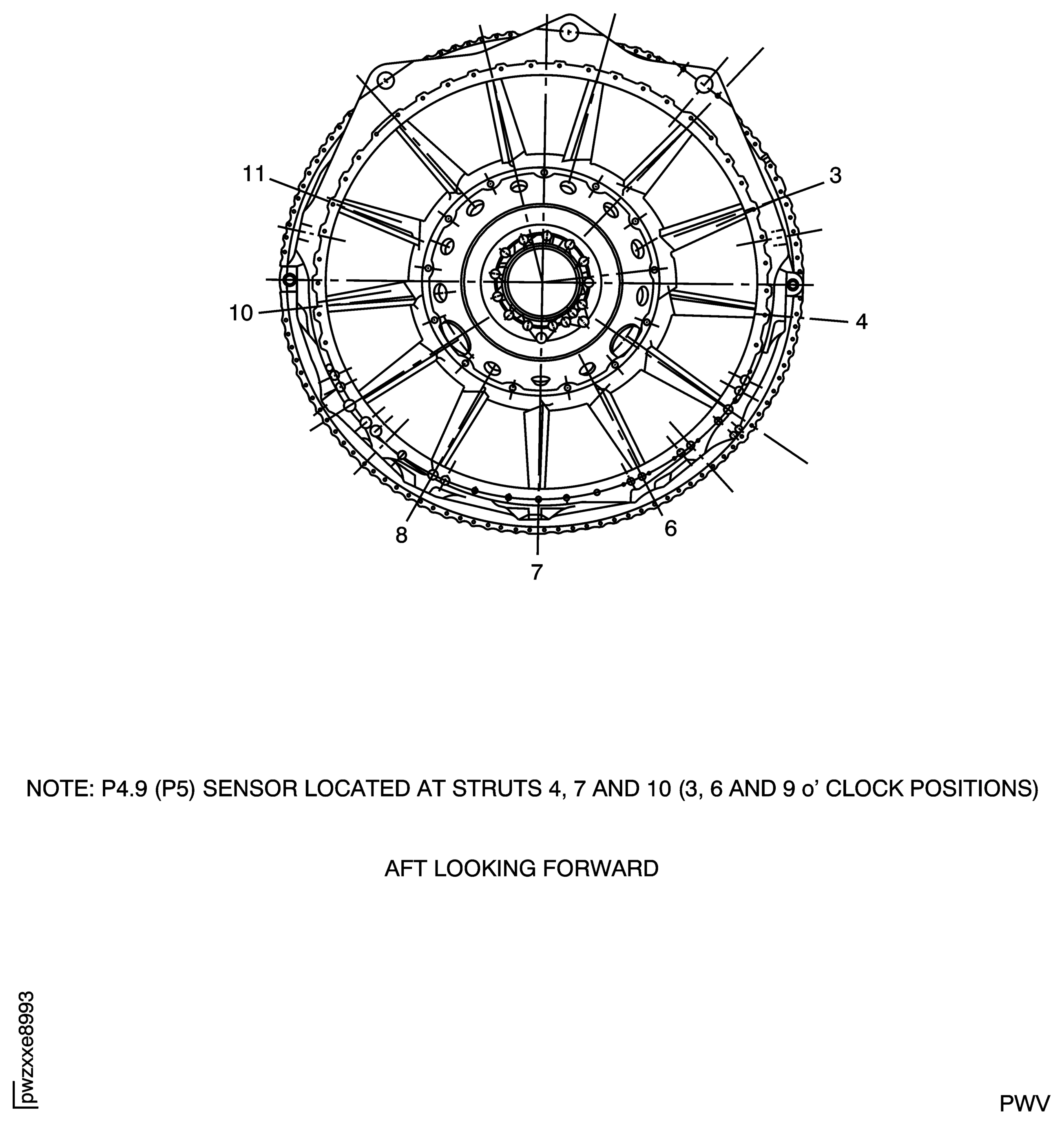

There are three P4.9 (P5) pressure sensing systems located in the turbine exhaust case (TEC) struts numbers 4, 7 and 10 (located at the 3, 6 and 9 o'clock) respectively, aft looking forward. Refer to Figure.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Reducer fitting: AN6-AN4 | LOCAL | Reducer fitting: AN6-AN4 | (commercially available hardware) | |

| Portable gas source | LOCAL | Portable gas source | Regulated Air or Nitrogen gas, 0 to 30 psi (0 to 308.1 KPa) IF AIR IS USED, THE AIR MUST BE CLEAN AND DRY IN ORDER NOT TO INTRODUCE FOD OR OTHER DEBRIS WHICH CAN OBSTRUCT THE NORMAL FUNCTIONING OF THE P4.9 (P5) SYSTEM, INCLUDING ALL PLUMBING LINES. | |

| Torque wrench | LOCAL | Torque wrench |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPE | 03530 | CoMat 10-045 |

Spares

NONESafety Requirements

CAUTION

Procedure

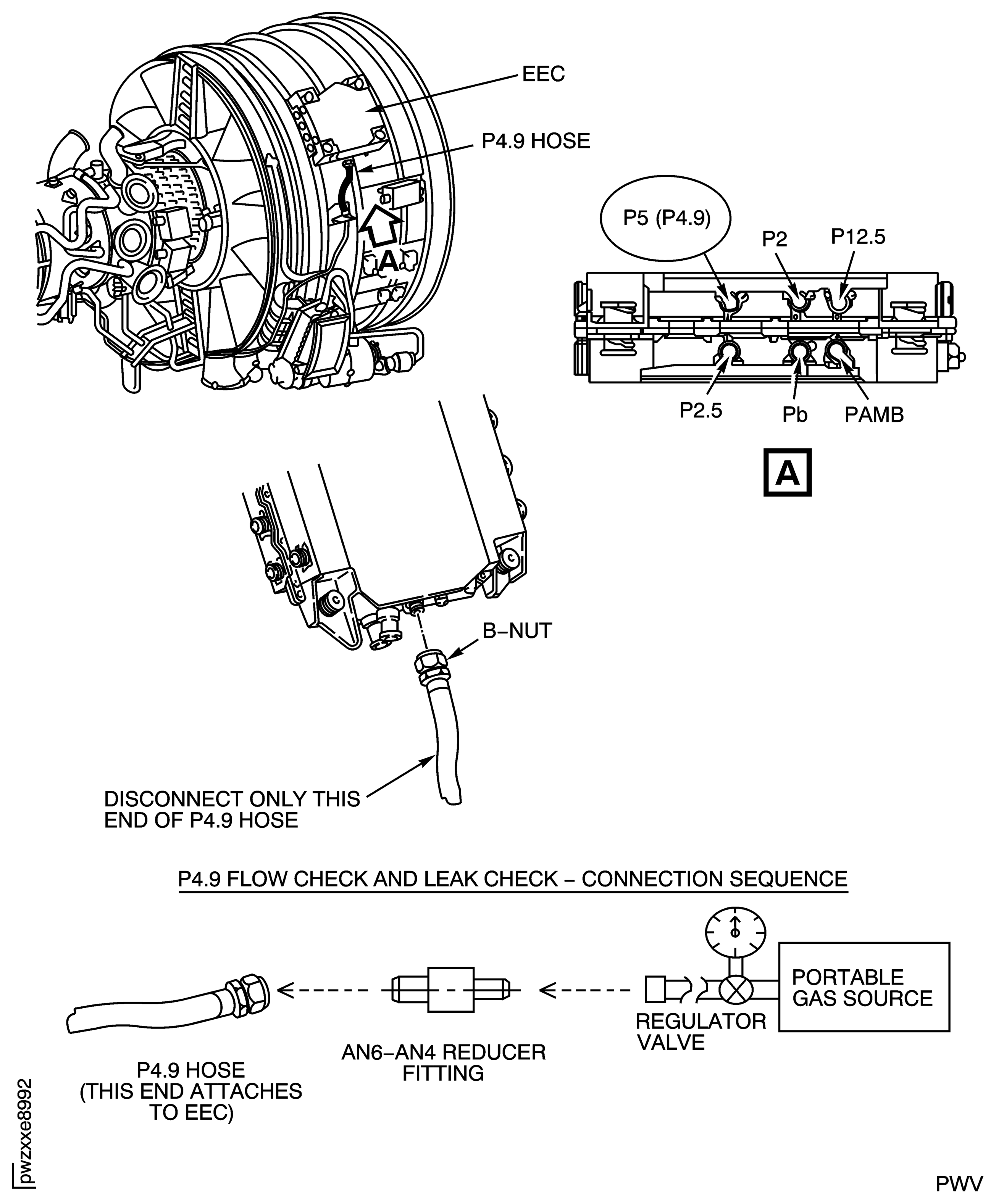

Connect the portable gas source as follows. Refer to Figure.

Perform flow check of the P4.9 (P5) system as follows: (Refer to Figure).

With 30 psig (308.1 KPa) applied, utilize leak check fluid (CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPE) by applying to all interfacing locations on external plumbing between the portable gas source at the P4.9 (P5) flexible line and the inlet of the P4.9 (P5) sense line at the TEC.

Perform leak check of the P4.9 (P5) system as follows:

NOTE

Leak check fluid (CoMat 10-045 LEAK CHECK FLUID, BUBBLES-TYPE) should be applied all around periphery of flange.

SUBTASK 71-00-00-790-001 Perform EPR P4.9 (P5) System Leak/Flow Check

Figure: P4.9 Flow Check and Leak Check-Connection Sequence

P4.9 Flow Check and Leak Check-Connection Sequence

Figure: P4.9 (P5) Sensor Strut Locations

P4.9 (P5) Sensor Strut Locations