Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

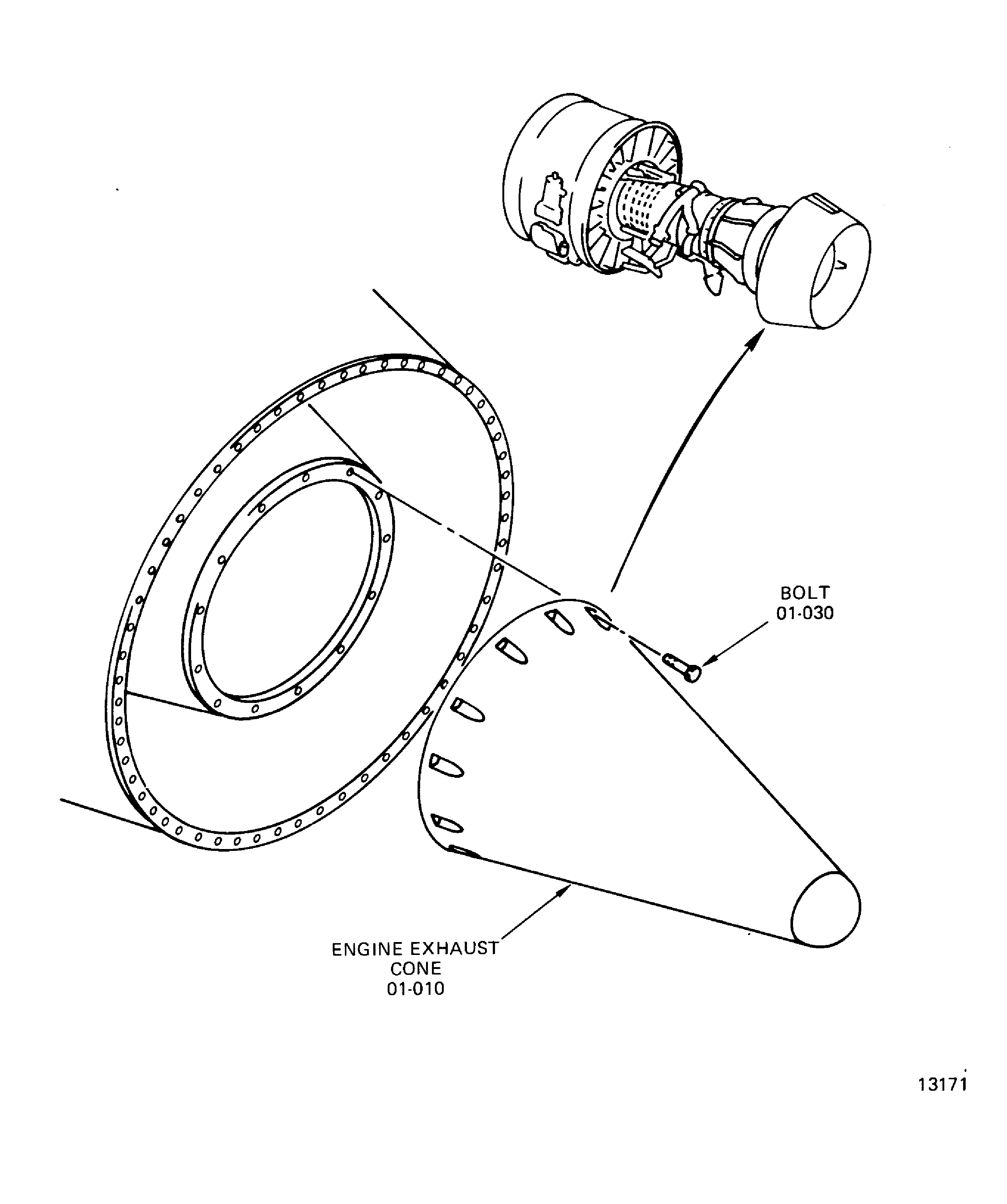

TASK 71-00-02-400-024 (A1/A5-PPBU) - Install The Engine Exhaust Cone, Installation-024

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-38-21-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Transportation covers/blanks must be removed immediately before installation of the components.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL | LOCAL | CoMat 10-094 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Position the engine exhaust cone Engine Exhaust Cone And Plug (78-11-12, 01-010) against the engine flange.

WARNING

WEAR PROTECTIVE GLOVES WHEN YOU USE DEGREASERS.

WARNING

USE DEGREASER ONLY IN AREAS WITH GOOD VENTILATION.

WARNING

DEGREASERS ARE VERY FLAMMABLE, KEEP AWAY FROM IGNITION SOURCES.Clean the engine exhaust cone attaching bolts Engine Exhaust Cone And Plug (78-11-12, 01-030) with CoMat 01-076 METHYL ETHYL KETONE. Wipe dry with a lint-free cloth before the MEK evaporates.

Apply CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL to the engine exhaust cone attaching bolts Engine Exhaust Cone And Plug (78-11-12, 01-030).

Attach the engine exhaust cone to the engine flange with the 13 bolts Engine Exhaust Cone And Plug (78-11-12, 01-030). Do not fully torque the bolts until all are installed.

Torque the bolts Engine Exhaust Cone And Plug (78-11-12, 01-030) to between 120 and 130 lbf.in (13.56 and 14.69 Nm) in opposite pairs sequence.

SUBTASK 71-00-02-420-001 Install the Engine Exhaust Cone

Figure: Engine Exhaust Cone

Engine Exhaust Cone