Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-51-43-300-003 General Services Harness - Replace The Connectors, Repair-003 (VRS2981)

Effectivity

FIG/ITEM | PART NO |

|---|---|

01-005 | 740-5966-503 |

01-005 | 740-5966-505 |

01-005 | 740-5966-507 |

01-005 | 740-5966-511 |

01-005 | 740-5966-513 |

01-005 | 740-5966-515 |

01-005 | 740-5966-517 |

01-005 | 740-5966-519 |

01-005 | 740-5966-521 |

01-005 | 740-5966-523 |

01-005 | 740-5966-525 |

01-005 | 740-5966-527 |

01-005 | 740-5966-529 |

General

This repair can be done on the harnesses during overhaul, or while they are installed on the engine. Replace only the parts of the connectors which are unserviceable.

To identify the consumable materials, refer to the PCI.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Extractor/inserter tool | LOCAL | 16g | ||

| Extractor/inserter tool | LOCAL | 20g | ||

| Strap Wrench | LOCAL | BT-BS-611 | ||

| Strap Wrench | LOCAL | TG-70 | ||

| Torque Wrench - 0 to 1000 lbf.in range | LOCAL | Torque Wrench |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-127 LOCKWIRE | LOCAL | CoMat 02-127 | ||

| CoMat 02-138 LOCKWIRE | LOCAL | CoMat 02-138 | ||

| CoMat 02-141 LOCKWIRE | LOCAL | CoMat 02-141 | ||

| CoMat 06-131 MARKING PEN | LOCAL | CoMat 06-131 | ||

| CoMat 08-026 THREADLOCKING MATERIAL | LOCAL | CoMat 08-026 |

Spares

NONESafety Requirements

NONEProcedure

WARNING

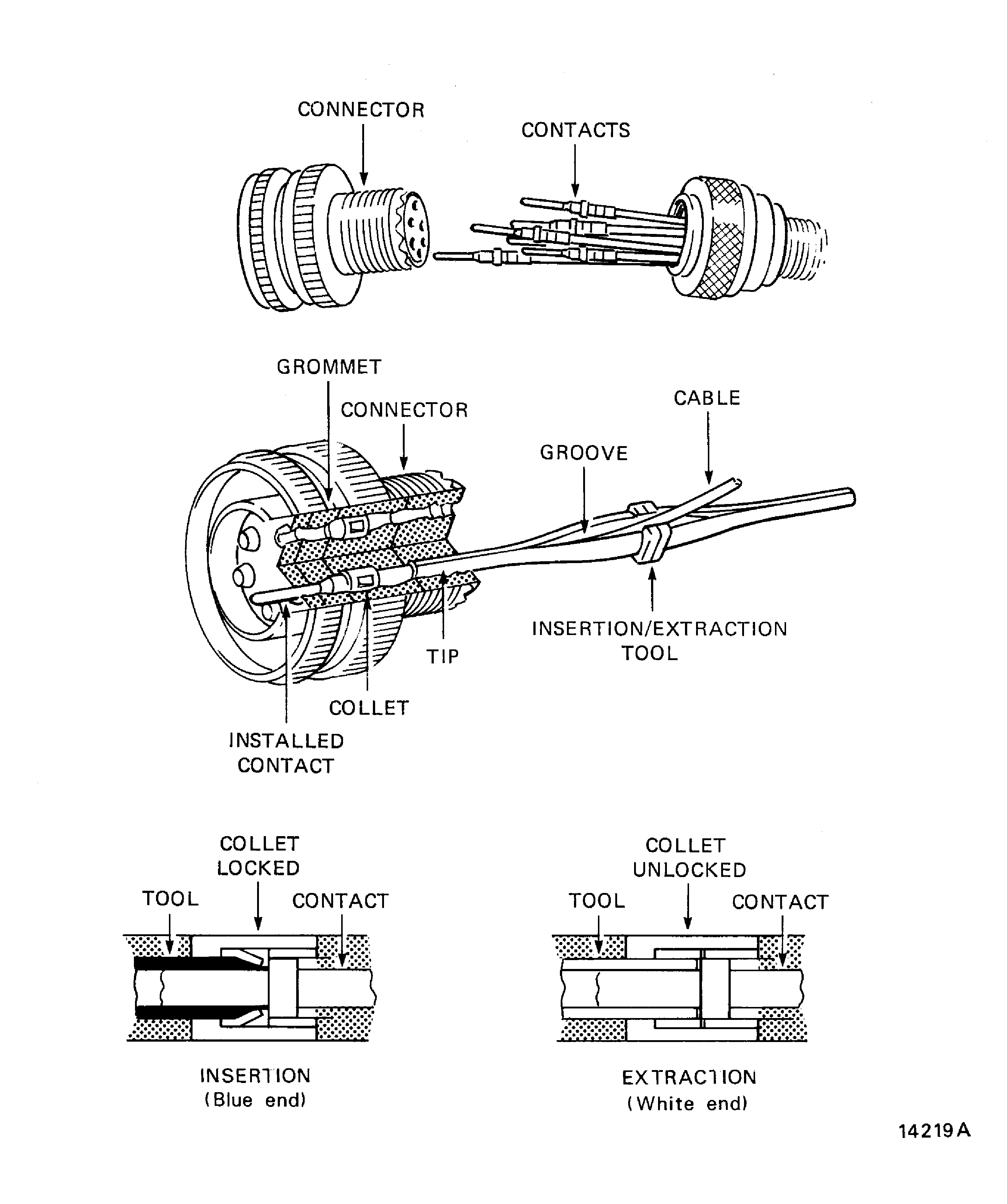

PUT ON PROTECTIVE GOGGLES WHEN YOU CUT THE LOCKWIRE. PIECES OF THE LOCKWIRE CAN CAUSE DAMAGE TO YOUR EYES.Refer to Figure.

Be careful not to cause damage to the lockwire holes.

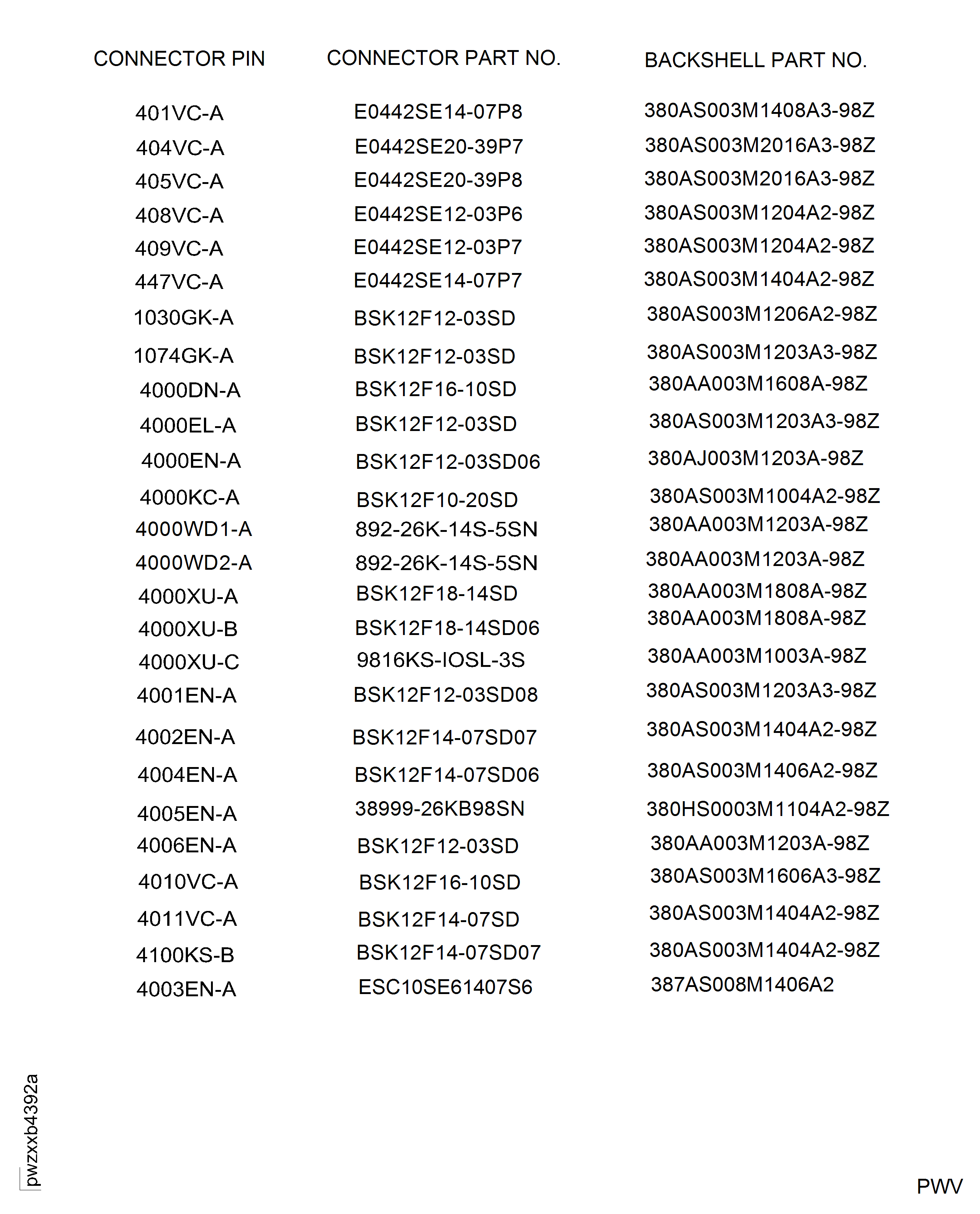

Cut and remove the lockwire from the screws, the coupling nut and the shell.

Use the CoMat 06-131 MARKING PEN.

If the backshell is not a straight type, make a mark on the shell which aligns with the master keyway.

Remove the screws and the strain-relief clamp from the coupling nut.

Use the applicable Strap Wrench (BT-BS- 611 or TG-70).

Move the coupling nut and the grounding ferrule away from the shell.

Be careful not to cause damage to the ground-shields of the cables.

Remove the coupling nut from the shell.

Use the applicable Strap Wrench (BT-BS- 611 or TG-70).

Move the shell away from the connector.

Be careful not to cause damage to the ground-shields of the cables.

Remove the shell from the connector.

SUBTASK 71-51-43-350-053 Disassemble the Connector Assembly

Refer to Figure.

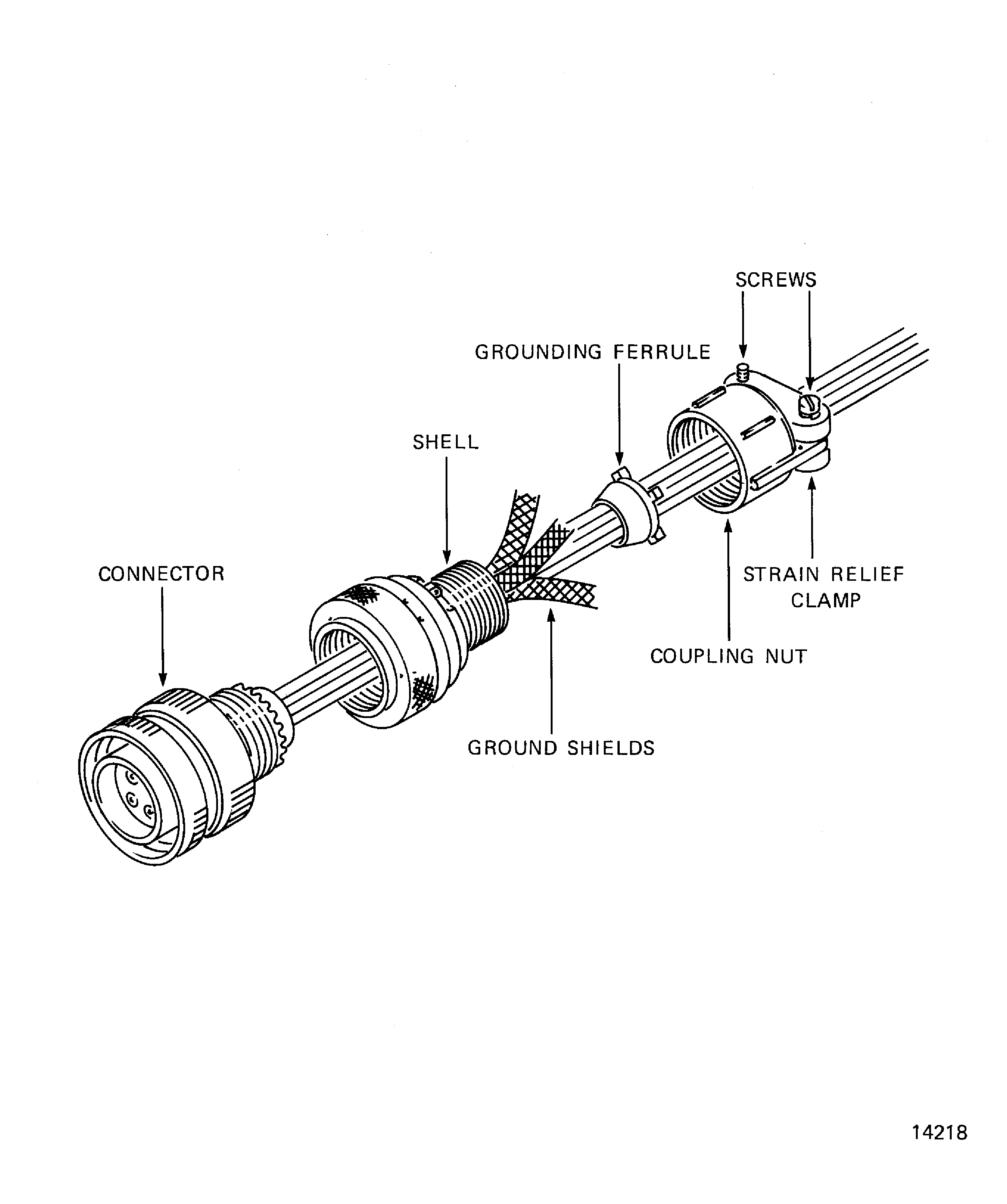

Write on the tag the number of the connector hole from which the cable came.

Attach a temporary identification tag to each of the cables in the connector.

Use the applicable Extractor/inserter tool (16g or 20g).

Put the cable in the groove of the tool.

Push the tool along the cable and into the rear of the connector, until it touches the contact (the tool will open the collet).

Hold the cable and the tool together and remove the contact, from the rear of the connector.

Remove a contact from the connector.

Do Step again for the remaining contacts.

Remove the remaining contacts from the connector.

SUBTASK 71-51-43-350-054 Remove the Contacts from the Connector.

Be careful not to cause damage to the contacts or the ground-shields.

Remove the shell, the grounding ferrule and the coupling nut, from the harness.

SUBTASK 71-51-43-350-055 Remove the Components of the Connector Assembly

Refer to Inspection-001 TASK 71-51-43-200-301. Reject the parts which are unserviceable.

Examine the connector, the contacts, the coupling nut, the grounding ferrule, the screws and the shell.

SUBTASK 71-51-43-220-056 Examine the Components

CAUTION

THE REPLACEMENT COMPONENTS MUST HAVE THE SAME PART NUMBERS AS THE COMPONENTS WHICH WERE REMOVED. INCORRECT COMPONENTS CAN CAUSE DAMAGE TO THE SYSTEM.Refer to Figure.

Install the components in the sequence that follows: the coupling nut, the grounding ferrule and the shell.

Be careful not to cause damage to the contacts or the ground-shields.

Install the new, or serviceable, components to the harness.

SUBTASK 71-51-43-350-056 Install the Replacement Components of the Connector Assembly

CAUTION

THE CONTACTS MUST BE INSTALLED IN THEIR CORRECT POSITIONS IN THE CONNECTOR. IF THEY ARE INSTALLED IN THE INCORRECT POSITIONS, THE SYSTEM CAN BE DAMAGED.Refer to Figure.

You must install the contacts at the center of the connector first and work out.

Find the contact which must be installed in the center hole of the connector.

Use the applicable Extractor/inserter tool (16g or 20g).

Put the cable in the groove of the tool.

Push the tool along the cable, until it touches the flange of the contact.

Hold the cable and the tool together and use the tool to push the contact in to the connector hole.

When the contact is in the correct position, in the connector hole, release the cable and remove the tool.

Lightly pull the cable to make sure that the contact is engaged correctly in the connector.

Install the center contact to the connector.

Do Step again for the remaining contacts.

Make sure the contacts are installed in the positions noted during their removal.

Install the contacts nearest to the center first.

Install the remaining contacts to the connector.

Remove the temporary tags, which were installed in Step.

Remove the identification tags from the cables.

SUBTASK 71-51-43-350-057 Install the Contacts to the Connector

Refer to Figure.

Use the applicable Strap Wrench (BT-BS-611 or TG-70) to tighten the shell.

If the backshell is not a straight type, align the mark (made in Step ) with the master keyway.

Install the shell to the connector.

Put the ground-shields an equal distance apart around the shell.

Push the ground ferrule along the harness, until it touches the ground-shields.

Put the ground-shields through the coupling nut.

Put two drops of the CoMat 08-026 THREADLOCKING MATERIAL opposite to each other, on the threads of the shell.

Install the coupling nut to the shell.

Use the Torque Wrench - 0 to 1000 lbf.in range and the applicable Strap Wrench (BT-BS-611 or TG-70), to torque the coupling nut to 10 lbfin. (1.13 Nm).

Install the coupling nut to the shell.

Make sure that all of the twists and bends are out of the cables.

Attach the clamp to the coupling nut, with the two screws.

Use the torque wrench to torque the screws to between 10 lbfin. and 20 lbfin. (1.13 Nm and 2.26 Nm).

Install the strain-relief clamp to the coupling nut.

SUBTASK 71-51-43-350-058 Assemble the Connector Assembly

Refer to Testing-001 TASK 71-51-43-700-301.

Do the test for continuity and insulation.

SUBTASK 71-51-43-750-051 Do a Continuity and Insulation Test on the Connector Assembly

Refer to Figure.

Make sure that the shell, the coupling nut and the screws, are all safetied.

Safety the connector assembly.

SUBTASK 71-51-43-350-059 Safety the Connector Assembly

Use the CoMat 06-131 MARKING PEN.

Put the repair scheme number VRS2981 on the identification sleeve, of the harness, adjacent to the part number.

SUBTASK 71-51-43-850-055 Put the Repair Scheme Number on the Harness

Figure: Connector Assembly Details

Connector Assembly Details

Figure: Contact Removal and Installation Details

Contact Removal and Installation Details

Figure: Connector Assembly Lockwire Details

Connector Assembly Lockwire Details

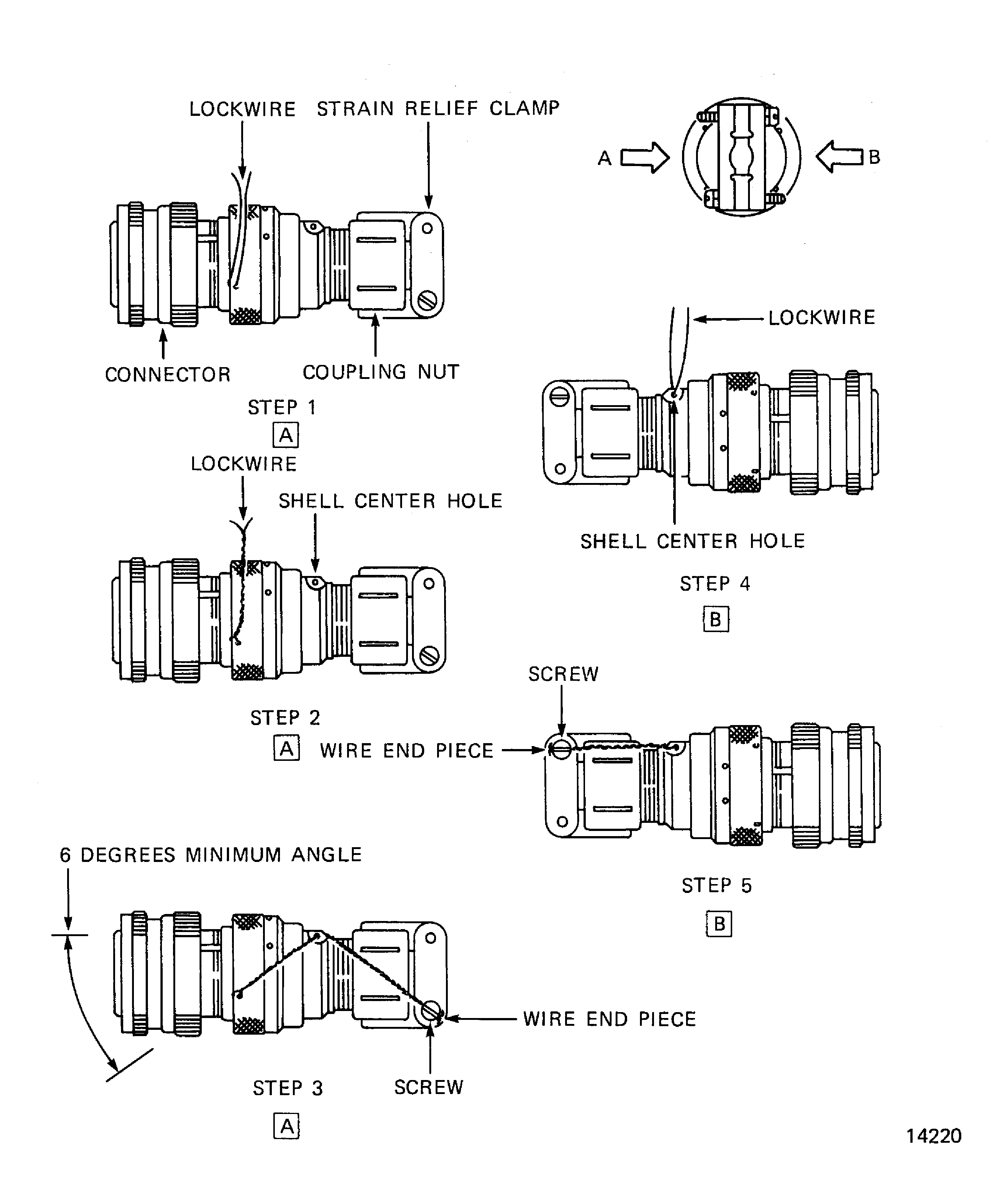

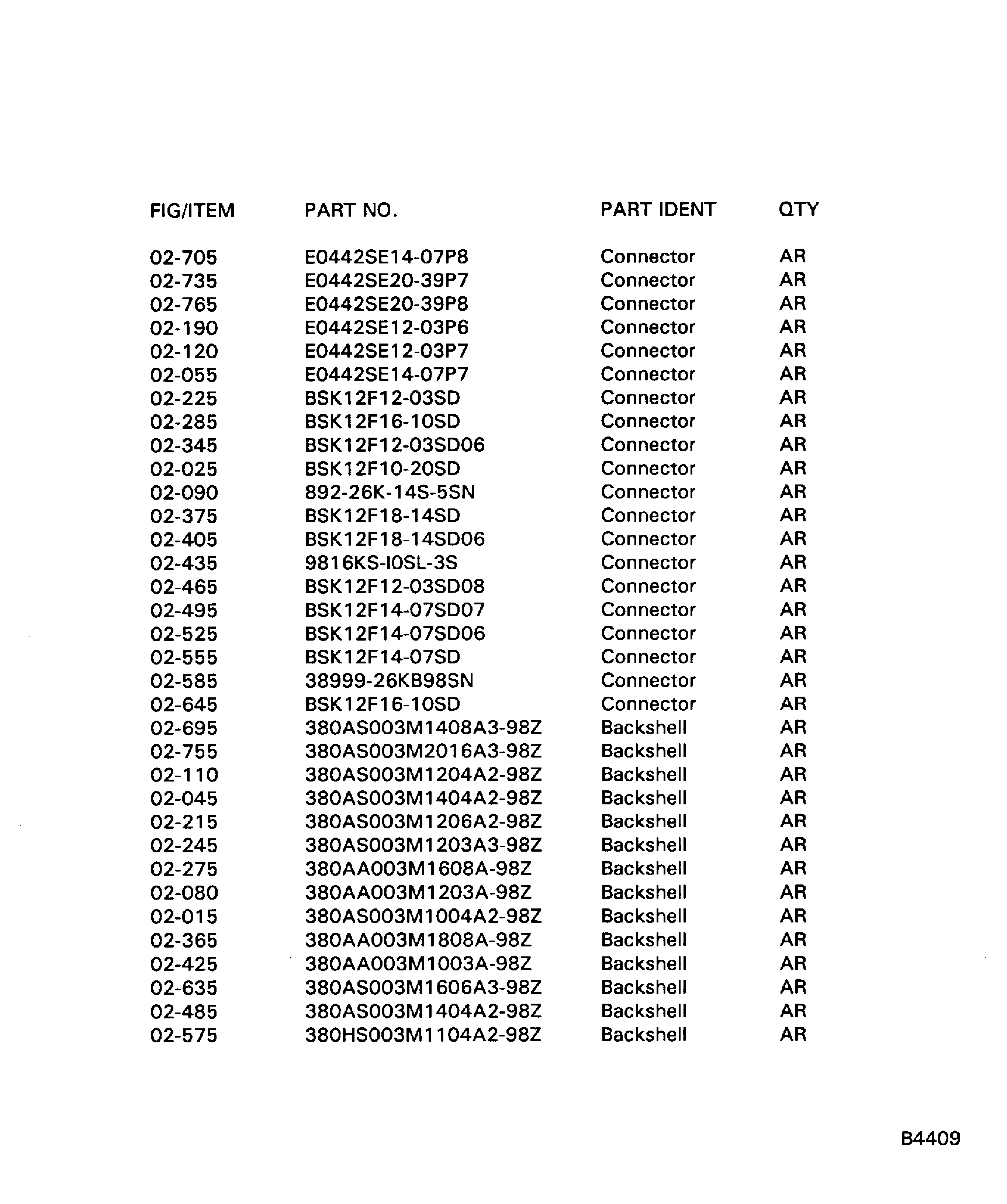

Figure: Repair Part Identification

Repair Part Identification

Figure: Repair Part Location

Repair Part Location