Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-52-44-300-001 EEC Link Core Harness - Replace The Connectors, Repair-001 (VRS1082)

General

The practices and processes referred to in the procedure by the TASK number are in the SPM.

For the method to clean the parts, refer to Cleaning-000 TASK 71-52-44-100-300.

Repair parts

FIG/ITEM | PART NO. | PART IDENT | QTY |

04-010 | BSK17E161OPD | Receptacle | 1 |

03-010 | G9312S16BNF-D3 | Backshell | 1 |

04-027 | BA-4016-1OP | Chromel pin | 2 |

04-028 | BA-4016-1OR | Alumel pin | 2 |

04-030 | T3K-1211- 98SN | Plug | 1 |

03-030 | G9311A11BNF-D | Backshell | 1 |

04-015 | BA4016-36LD | Pin | 6 |

04-035 | T3-4120-36LD | Socket | 6 |

03-760 | 20-90970-2 | Tube, heat shrinkable, PTFE | 1 |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Removal/insertion tool | LOCAL | Removal/insertion tool | ||

| Crimping tool | LOCAL | Crimping tool |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-146 LOCKWIRE | LOCAL | CoMat 02-146 |

Spares

NONESafety Requirements

NONEProcedure

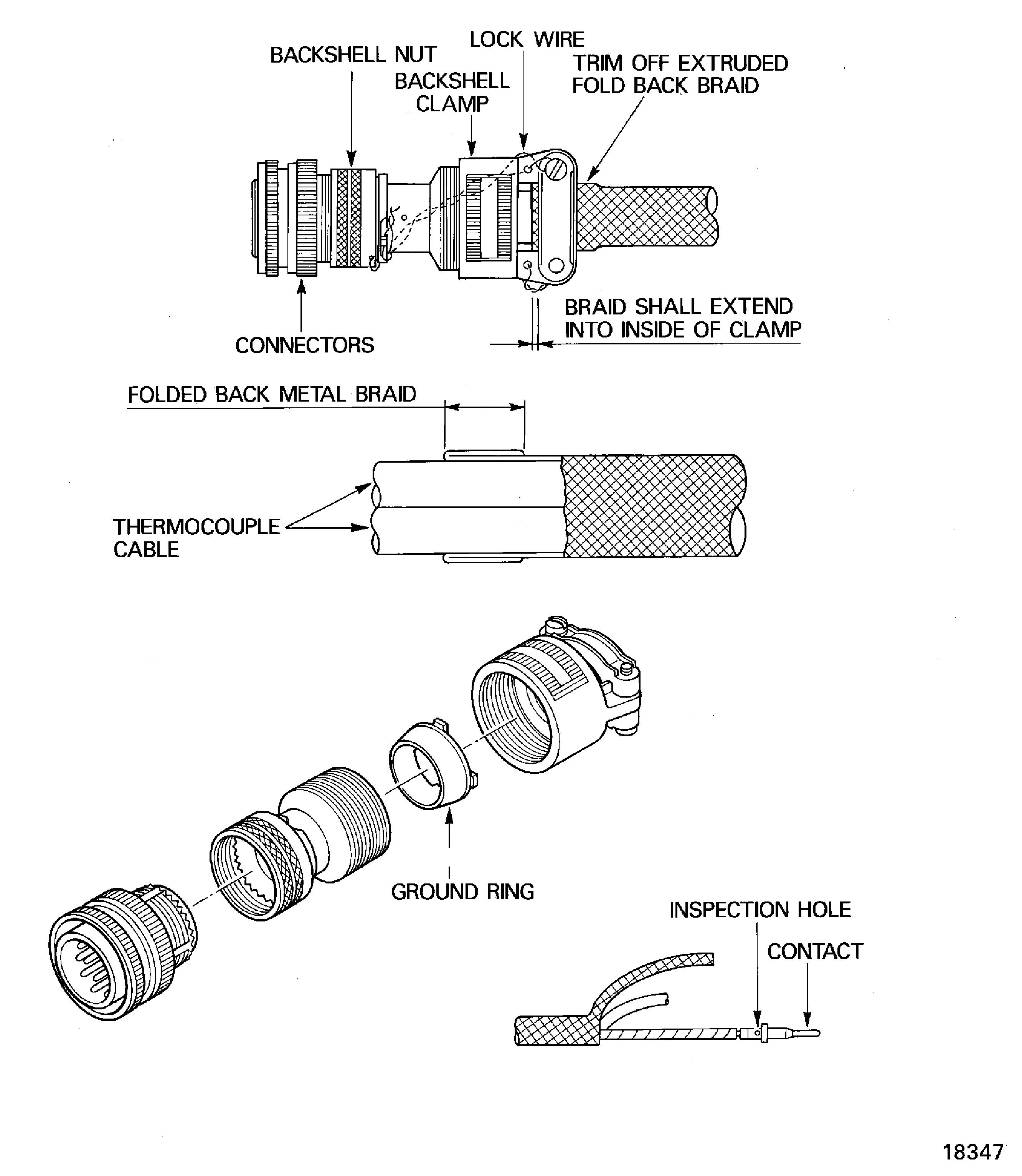

Refer to Figure.

Remove the locking wire from the backshells

Loosen the screws on the backshell clamp

Loosen the backshell clamp

CAUTION

DO NOT CUT THE INDIVIDUAL SHIELDRemove the ground ring

Use Glenair TG69 pliers

Loosen the backshell nut

SUBTASK 71-52-44-350-054 Disassemble the Backshells

Use a Removal/insertion tool.

Remove the contacts (pin and socket) from the connectors

SUBTASK 71-52-44-350-055 Remove the Pin and Socket from Connectors

Cut off the bent contacts from the cable

SUBTASK 71-52-44-350-056 Remove the Bent Contacts from the Cables

Use a cable stripper.

Remove the cable insulation to expose 0.25 in. (6.4 mm) for contact size 16 and 0.19 in. (4.8 mm) for contact size 20

Remove the cable insulation

Use a Crimping tool.

Install the conductor into the contact bucket until it bottoms or is visible in the inspection hole

Install contact bucket

SUBTASK 71-52-44-350-057 Install the Contacts to the Cables

Use a Removal/insertion tool.

Install the contacts into the connectors

Use a Removal/insertion tool.

Install unused contacts into spare holes in the connectors

Install sealing plugs to spare holes containing unused contacts

SUBTASK 71-52-44-350-058 Install the Contacts into the Connectors

Refer to Figure.

Screw the backshell nut onto the connector

Use Glenair TG69 pliers.

Turn a quater rotation from above position

Tighten the backshell nut

Install the ground ring on the backshell sleeve

Use Glenair TG69 pliers.

Turn a half rotation from above position

Tighten the backshell clamp

Metal braiding shall be twisted up and folded up two times

Folded back metal braid

Tighten the screws on the backshell clamp

SUBTASK 71-52-44-350-059 Assembly Backshells

Install locking wire on the backshell

SUBTASK 71-52-44-350-060 Install Locking Wire

Figure: Replacement Of The Connector

Replacement Of The Connector