Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 71-52-45-700-302 Exhaust Gas Temperature (EGT) Wiring Harness - Test, Testing-002 (Post SBE 77-0015)

General

Fig/Item numbers in parentheses in the procedure agree with those used in the IPC.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Megohmmeter - model 1620-C | LOCAL | Megohmmeter - model 1620-C | ||

| Multimeter keithley model 177 | LOCAL | Multimeter keithley model 177 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

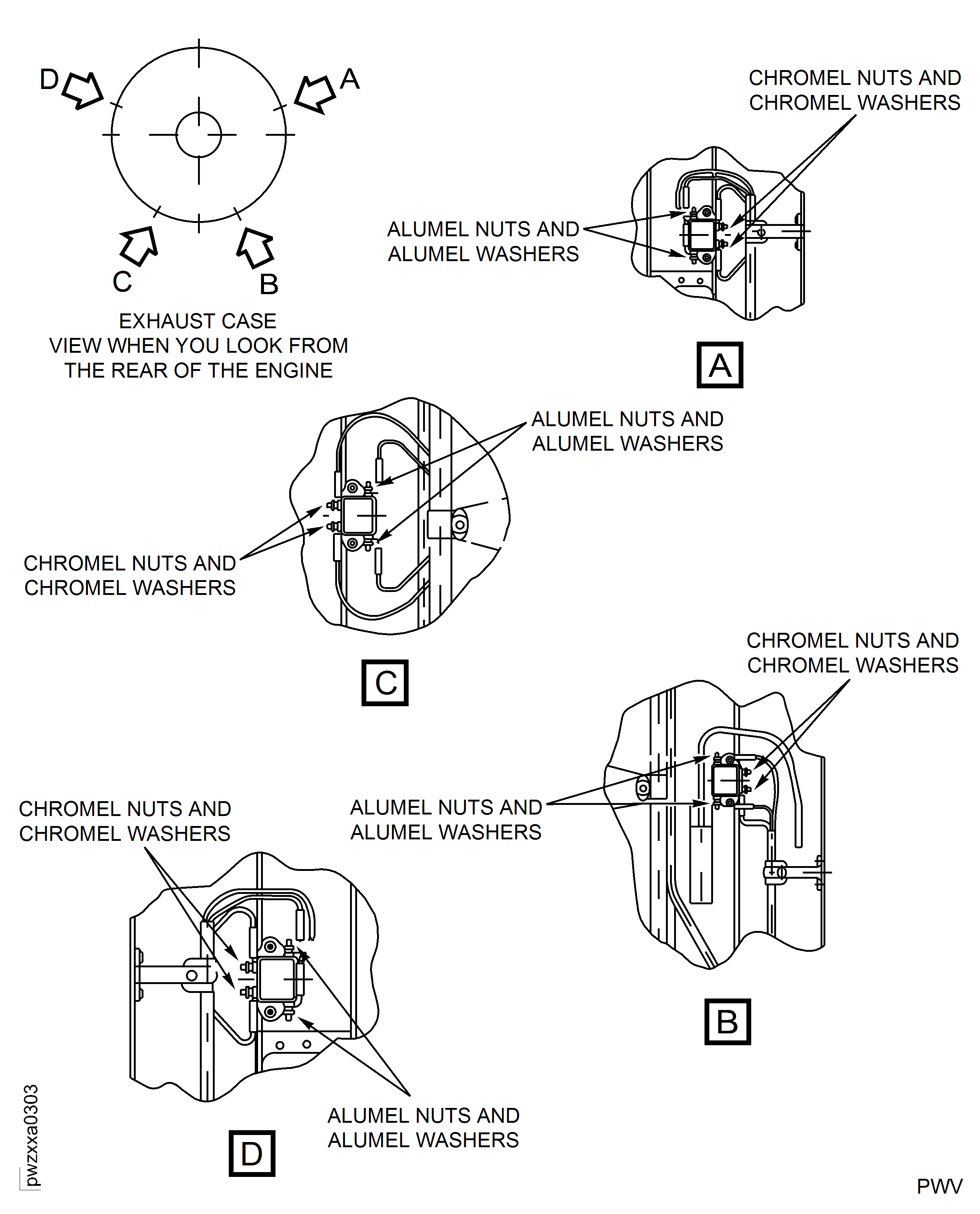

Remove the two alumel (larger) nuts and washers and the two chromel (smaller) nuts and washers which attach the harness lugs to the thermocouple terminals.

Remove the harness lugs from the thermocouple terminals.

Install the washers and nuts back on the thermocouple terminals.

Do these steps at the four thermocouple locations.

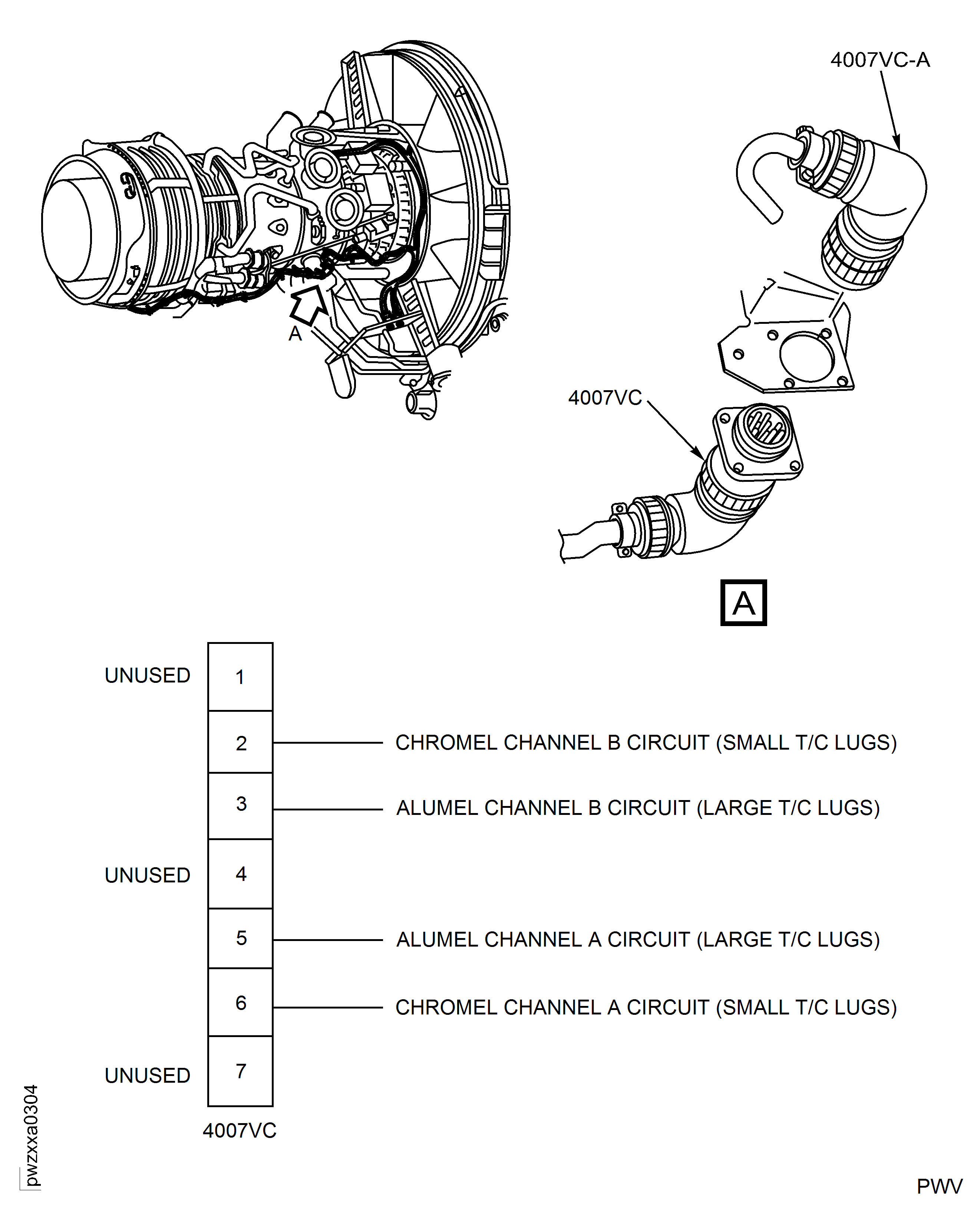

Disconnect 4007VC-A from 4007VC.

SUBTASK 71-52-45-750-056 Disconnect the EGT Wiring Harness from Thermocouple and 4007VC-A

Refer to Figure.

NOTE

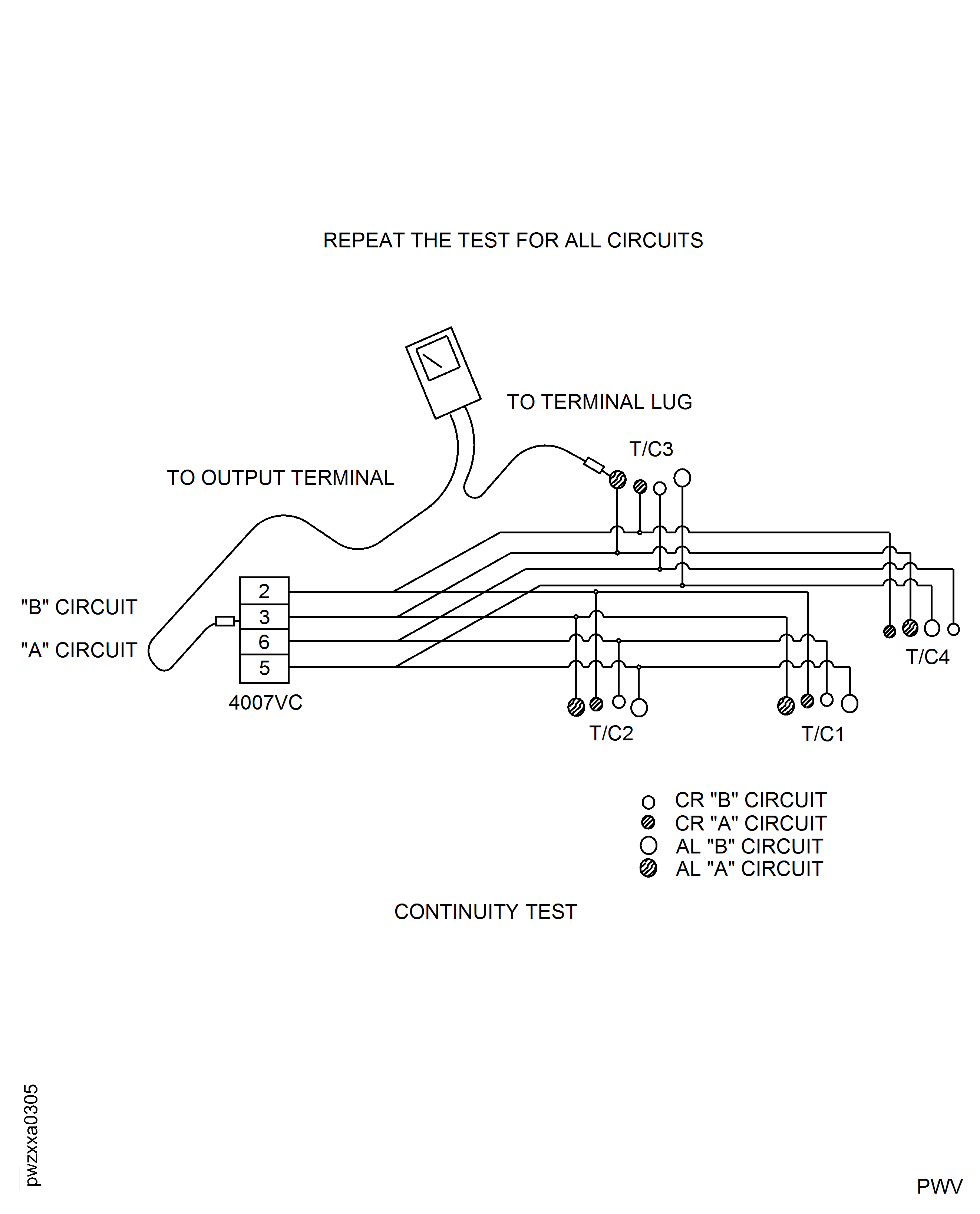

The Multimeter keithley model 177 and the test leads must be in good condition. The dry cells must be in a condition to give full scale movement for all the positions of the range switch. Make sure that the pin jacks are tight.ACTION

RESULT

1. Set the Multimeter keithley model 177 or equivalent to the range that has a center scale value of approximately 10 ohms.

2. Do the continuity test of the EGT harness from each thermocouples to the connector 4007VC. If when you bend the wire, the resistance value changes, reject the harness.

The resistance value must be between 0 ohms and 10 ohms.

NOTE

There are four thermocouple locations with four leads at each location, which means that sixteen measurements are necessary.3. If the meter shows a high resistance value, reject the harness.

Resistance value above 10 ohms.

NOTE

Small movements of the harness during the test must not cause the needle to change. This can be a sign of broken wires.

SUBTASK 71-52-45-750-057 Continuity Test of EGT Wiring Harness

Refer to Figure.

ACTION

RESULT

1. Set the Megohmmeter - model 1620-C or equivalent to the 100 volts DC scale.

2. Put one lead of the meter in contact with the chromel harness lug by the A circuit. Put the second lead in contact with the alumel harness lug of the A circuit.

A resistance value of more than one megohm must show.

3. Put the second lead in contact with the chromel harness lug of the B circuit.

A resistance value of more than one megohm must show.

4. Put the second lead in contact with the alumel harness lug of the B circuit.

A resistance value of more than one megohm must show.

5. Put one lead of the meter in contact with the alumel harness lug of the A circuit. Put the second lead in contact with the chromel harness lug of the B circuit.

A resistance value of more than one megohm must show.

6. Put the second lead of the meter in contact with the alumel harness lug for the B circuit.

A resistance value of more than one megohm must show.

7. Put one lead of the meter in contact with the chromel harness lug of the B circuit. Put the second lead in contact with the alumel harness lug of the B circuit.

A resistance value of more than one megohm must show.

8. lf the resistance value shown is less than one megohm or 0 ohm in one of these tests, reject the harness.

NOTE

Small movements of the harness during the tests must not cause the meter to move to below one megohm. This can be a sign of a defect and you must reject the harness.

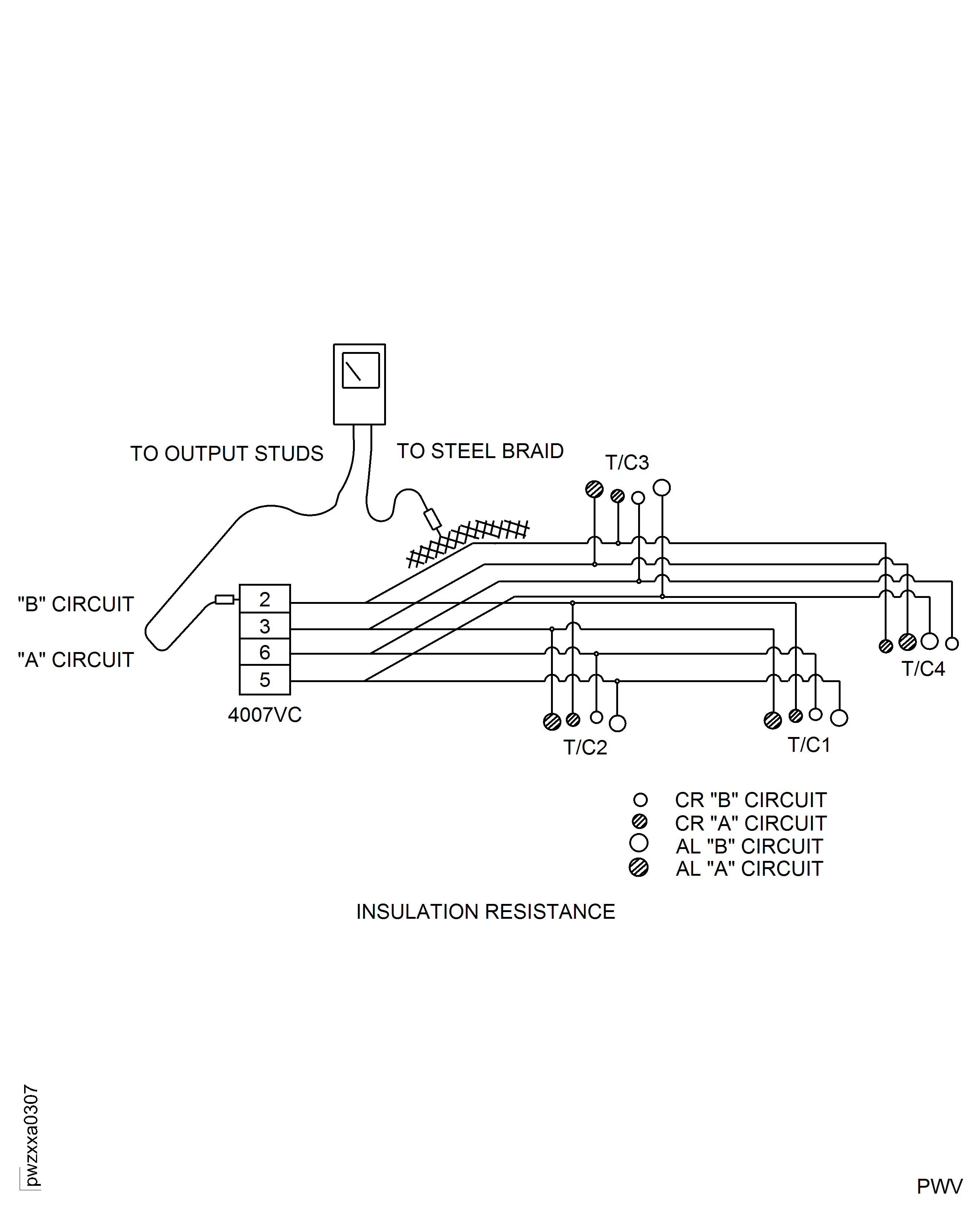

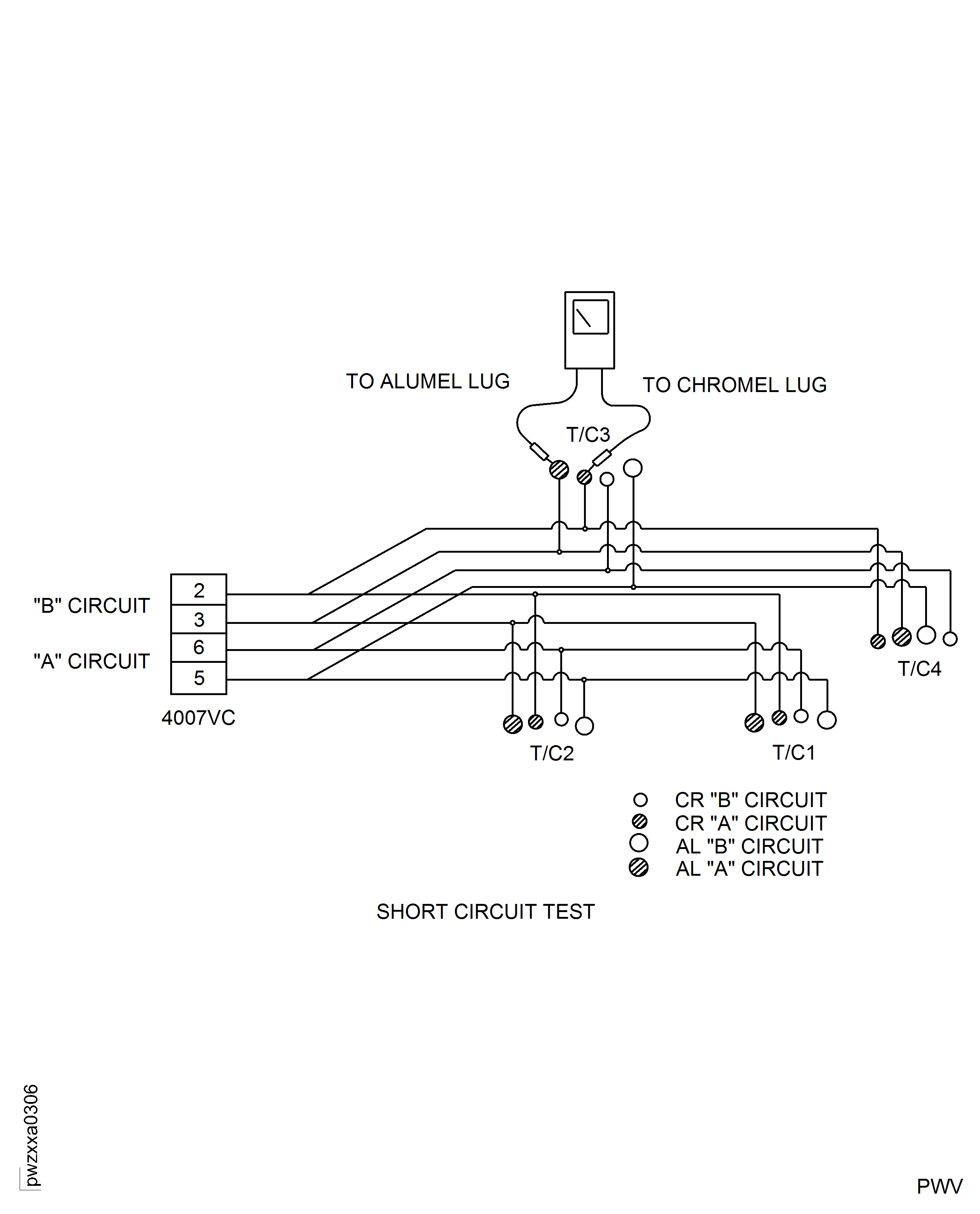

SUBTASK 71-52-45-750-058 Test of the EGT Harness for Short Circuits

Refer to Figure.

ACTION

RESULT

1. Set the Megohmmeter - model 1620-C or equivalent to the 100 VDC scale.

2. Put one lead of the meter in contact with the external steel braid of the harness lead. Put the other lead in contact with each of the alumel and chromel pins (2, 3, 5 and 6: silver in color) in connector 4007VC.

A resistance value of more than one megohm must show.

3. If the resistance value shown is less than one megohm, correct or repair the harness.

NOTE

The harness can absorb or trap moisture after water wash or an overnight in wet/humid conditions. High humidity can cause insulation resistance to read low. If insulation resistance reads low, you can apply air to correct this condition.4. Do the test of the resistance between each separate or band and the external steel braid of each circuit.

A resistance value of more than one megohm must show.

NOTE

There are four thermocouple locations with four leads at each location, which means that sixteen measurements are necessary.5. If the resistance value is less than one megohm correct or repair the harness.

NOTE

The harness can absorb or trap moisture after water wash or an overnight in wet/humid conditions. High humidity can cause insulation resistance to read low. If insulation resistance reads low, you can apply air to correct this condition.6. Do the test of the resistance between the lug and the band separator of each circuit.

A resistance value of more than one megohm must show.

7. If the resistance value shown is less than one megohm, correct or repair the harness.

NOTE

The harness can absorb or trap moisture after water wash or an overnight in wet/humid conditions. High humidity can cause insulation resistance to read low. If insulation resistance reads low, you can apply air to correct this condition.

SUBTASK 71-52-45-750-059 Insulation Resistance Test for EGT Wiring Harness

CAUTION

DO NOT ACCIDENTLY TOUCH THE INSULATION WITH THE INSTRUMENT PROBE.

Figure: Thermocouple Locations

Thermocouple Locations

Figure: 4007VC/4007VC-A Location and Pin Identification

4007VC/4007VC-A Location and Pin Identification

Figure: EGT Wiring Harness Continuity Test

EGT Wiring Harness Continuity Test

Figure: EGT Wiring Harness Short Circuit Test

EGT Wiring Harness Short Circuit Test

Figure: EGT Wiring Harness Insulation Resistance Test

EGT Wiring Harness Insulation Resistance Test