Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-41-300-004 HPC Assembly - HPC Stage 3 To 5 And Stage 7 To 12 Rotor Blade(s) - Blend Repair The Leading Or Trailing Edge, Repair-004 (VRS6524)

General

This repair must only be done when the instruction to do so is given in the related Inspection/Check.

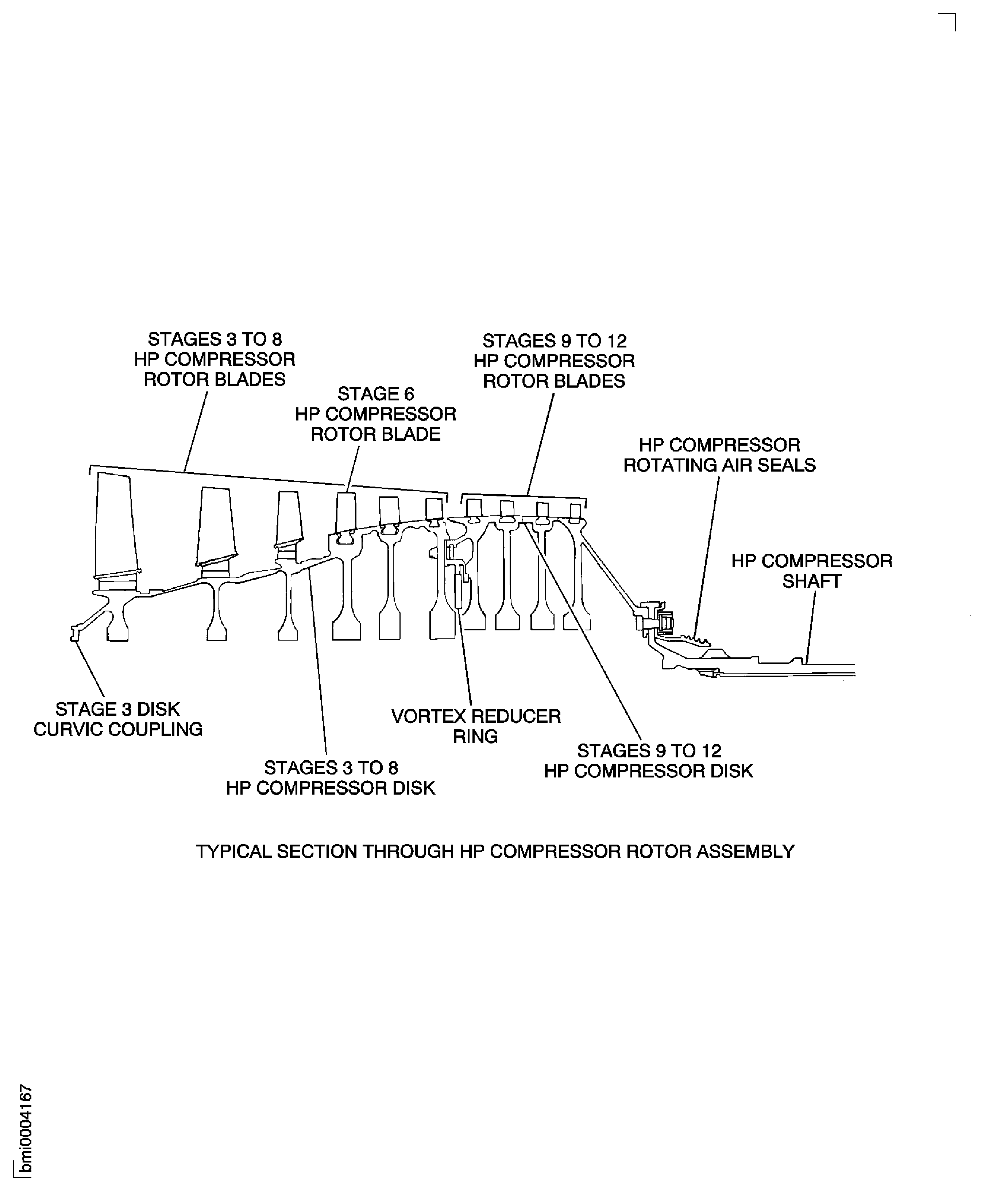

This TASK gives the procedure to repair leading or trailing edge damage only on HP compressor stage 3 to stage 5 and stage 7 to stage 12 rotor blade(s), by material removal while installed on the rotor drum.

Material removal from the HP compressor rotor blade aerofoil suction and pressure faces/platform fillet radius is not permitted.

Material of Components

PART IDENT | MATERIAL | |

HP compressor rotor blade(s) stage 3 to stage 8 | Titanium alloy | |

HP compressor rotor blade(s) stage 9 to stage 12 | Nickel alloy |

TASKS identified by SPM TASK are in the Standard Practices and Processes Manual (SPM).

Price and Availability: Refer to International Aero Engines

Related Repairs: None

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical Cleaning Equipment | LOCAL | Chemical Cleaning Equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant Crack Test Equipment | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Vacuum cleaning equipment | LOCAL | Vacuum cleaning equipment | ||

| Workshop Inspection Equipment | LOCAL | Workshop Inspection Equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-459 AQUEOUS WIPE CLEANER | 71410 | CoMat 01-459 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-005 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-005 | ||

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 | ||

| CoMat 05-076 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-076 | ||

| CoMat 05-077 WATERPROOF SILICON CARBIDE | K6835 | CoMat 05-077 | ||

| CoMat 05-079 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-079 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-082 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

NOTE

The adjacent components that can prevent the access during the repair or the components that can be damaged during the repair must be removed using related disassembly TASKs.When you estimate whether the blade is applicable for repair, make sure that the total material to be removed from the stage (cumulative blend limit) is not more than the limits. This includes all the blades that have been blended.When you do this repair on a rotor stage, make sure that all damaged blades are blended. This includes damage that has been accepted, refer to the applicable inspection TASK.Only one blend on the leading or trailing edge is permitted for each blade. This includes all the blends.If the area to be blended is near to the blade tip, make sure that the blend will not produce hook feature.The HP compressor stage 6 blade is not to be blended using this repair.

SUBTASK 72-00-41-220-056 Examine the Assembly

Refer to the SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-003.

Locally degrease the repair area.

SUBTASK 72-00-41-110-011 Chemically Clean

WARNING

WHEN USING DANGEROUS MATERIALS, MAKE SURE THAT THE SPM MANUAL AND MANUFACTURER'S MATERIAL SAFETY DATA SHEET SAFETY PRECAUTIONS ARE FOLLOWED.

CAUTION

MAKE SURE THAT THE ETCH SOLUTION DOES NOT TOUCH THE AREAS OTHER THAN THE INTENDED REPAIR AREA. MAKE SURE THAT ALL THE ETCH SOLUTION IS REMOVED AFTER OPERATION.

CAUTION

IF ETCHING SOLUTION DOES TOUCH THE UNINTENDED AREAS, MAKE SURE THAT THE ETCHING SOLUTION IS FULLY REMOVED, DISASSEMBLE THE ASSEMBLY IF NECESSARY.Refer to Figure.

For stage 3 to 8 blades (titanium alloy parts), refer to the SPM TASK 70-11-08-300-503.

For stage 9 to 12 blades (nickel alloy), refer to the SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001

Use Chemical Cleaning Equipment 1 off.

Swab etch the repaired area.

SUBTASK 72-00-41-110-012 Do a Swab Etch

Refer to the SPM TASK 70-23-05-230-501.

Use Penetrant Crack Test Equipment 1 off.

Cracks are not permitted.

Do a local penetrant crack test.

SUBTASK 72-00-41-230-006 Do a Crack Test

CAUTION

USE GLOVES AND SAFETY EQUIPMENT OR MASKING DURING REPAIR. SHARP EDGES OF BLADES AND VANES CAN CAUSE PERSONAL INJURY.

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE TYPE ABRASIVE WHEELS, STONES AND PAPERS TO DRESS BLEND AND POLISH THIS COMPONENT.

CAUTION

TITANIUM COMPONENT - PREVENT BUILD UP OF HEAT BY CAREFULLY APPLYING THE PRESSURE AND KEEPING THE TOOL SPEED AS LOW AS POSSIBLE.

CAUTION

TITANIUM COMPONENT - MAXIMUM SPEED FOR MECHANICAL TOOLS MUST NOT BE MORE THAN 1000 REVOLUTIONS PER MINUTE.

CAUTION

TITANIUM COMPONENT - YOU MUST MAKE SURE THAT WHEN YOU DRESS MATERIAL, BLEND AND POLISH, TO MAKE SMOOTH, NO SPARKS ARE PRODUCED.

CAUTION

TITANIUM COMPONENT - IF THE MATERIAL SHOWS A CHANGE IN COLOR, TO DARKER THAN A LIGHT STRAW COLOR, THE COMPONENT IS TO BE REJECTED.

CAUTION

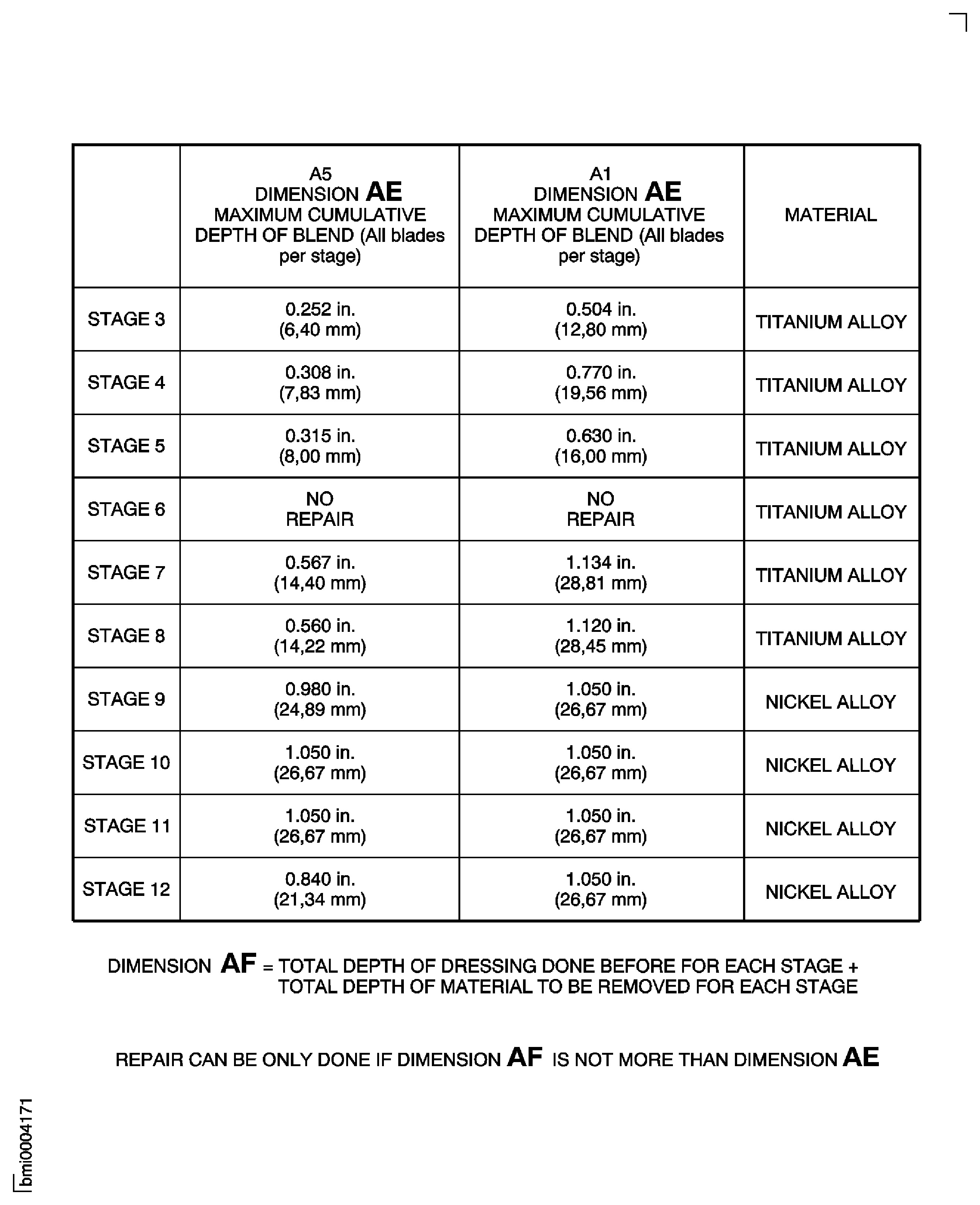

MAKE SURE THAT THE REPAIR AREA IS NOT NEAR THE EXCLUSION ZONE (ZONE B).The maximum depth of removed material must not be more than specified.

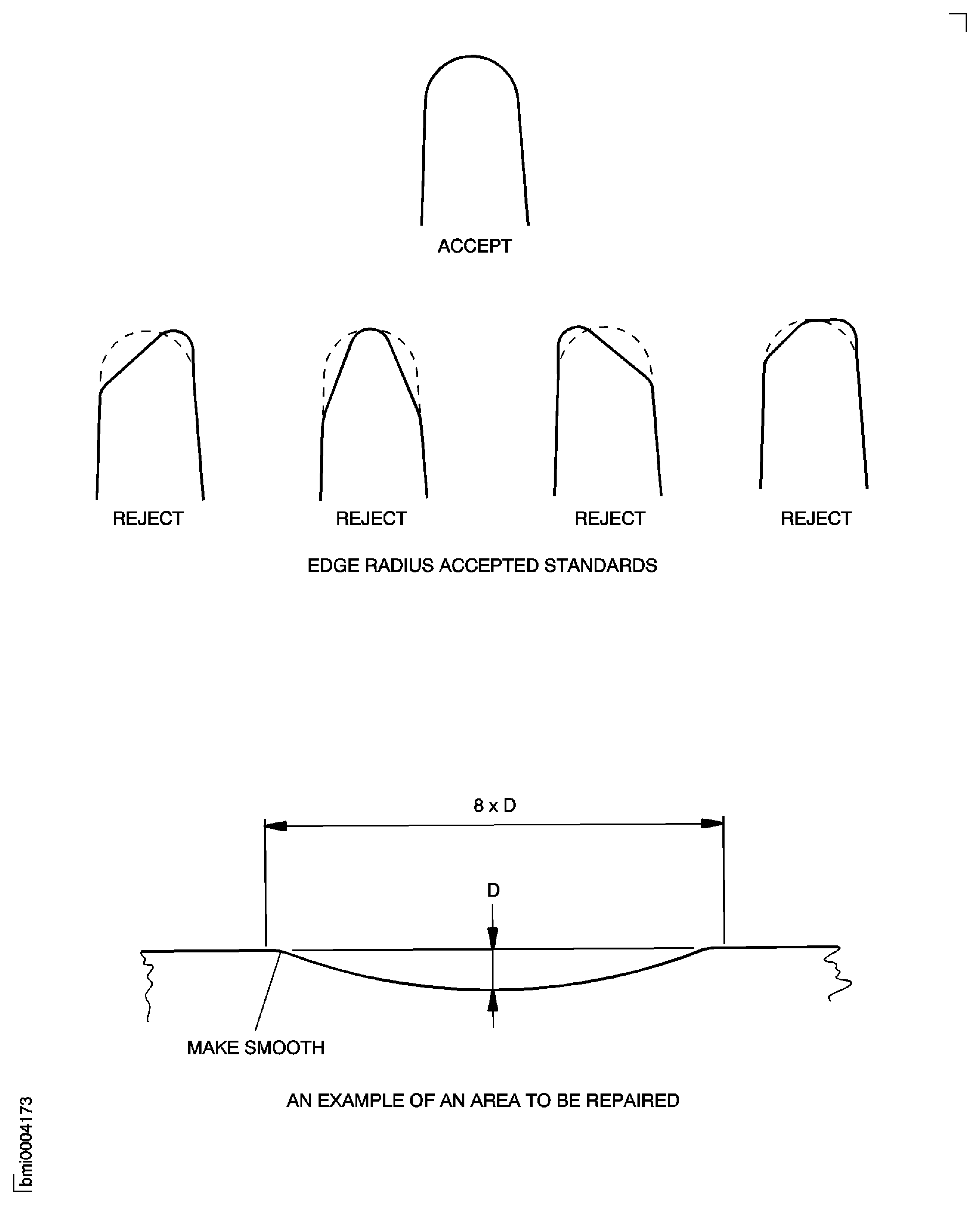

The repaired area diameter must be 8X the depth of the material removed.

Use Portablegrinding equipment 1 off.

NOTE

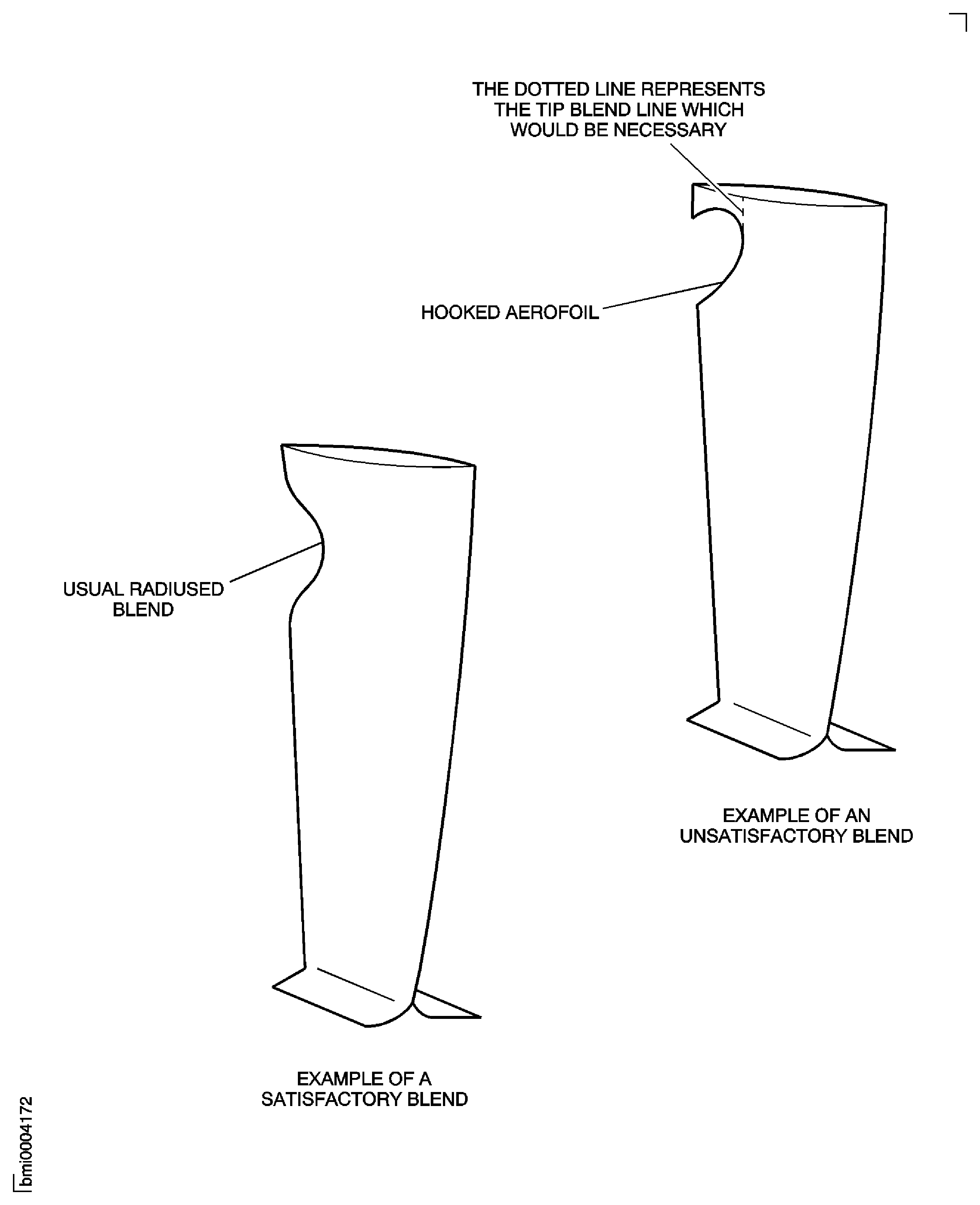

While doing this repair on a compressor stage, make sure that all damaged blades in the compressor stage are blended. This includes damage that has been accepted as applicable in the related inspection TASK.Only one blend on the leading or trailing edge is permitted for each blade. This includes all the blends.If the area to be blended is near to the blade tip, make sure that the blend will not produce hook feature.The HP compressor stage 6 blade is not to be blended using this repair.Remove damage on the leading or trailing edges by material removal.

Make sure all the damage marks are completely removed and the area is made smooth into the adjacent material.

Use CoMat 05-082 WATERPROOF SILICON CARBIDE and/or CoMat 05-079 WATERPROOF SILICON CARBIDE, as necessary.

CAUTION

THE USE OF TOO MUCH FORCE WHILE REMOVING THE MATERIAL IS NOT ALLOWED. APPLY THE PRESSURE CAREFULLY AND SUFFICIENT SUPPORT OF THE BLADE AEROFOIL MUST BE USED TO PREVENT THE BLADE ROOT BEING SUBJECTED TO ADDITIONAL STRESSES.Make smooth the repair area.

SUBTASK 72-00-41-350-005 Remove the Damage from HPC Rotor Blades(s)

Refer to the SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-003.

Locally degrease the repair area.

SUBTASK 72-00-41-110-014 Chemically Clean

WARNING

WHEN USING DANGEROUS MATERIALS, MAKE SURE THAT THE SPM MANUAL AND MANUFACTURER'S MATERIAL SAFETY DATA SHEET SAFETY PRECAUTIONS ARE FOLLOWED.

CAUTION

MAKE SURE THAT THE ETCH SOLUTION DOES NOT TOUCH THE AREAS OTHER THAN THE INTENDED REPAIR AREA. MAKE SURE THAT ALL THE ETCH SOLUTION IS REMOVED AFTER OPERATION.

CAUTION

IF ETCHING SOLUTION DOES TOUCH THE UNINTENDED AREAS, MAKE SURE THAT THE ETCHING SOLUTION IS FULLY REMOVED, DISASSEMBLE THE ASSEMBLY IF NECESSARY.Refer to Figure.

For stage 3 to 8 blades (titanium alloy parts), refer to the SPM TASK 70-11-39-300-503, SUBTASK 70-11-39-300-001.

For stage 9 to 12 blades (nickel alloy), refer to the SPM TASK 70-11-08-300-503.

Use Chemical Cleaning Equipment 1 off.

Swab etch the repaired area.

SUBTASK 72-00-41-110-015 Do a Swab Etch

Refer to the SPM TASK 70-23-05-230-501.

Use Penetrant Crack Test Equipment 1 off.

Cracks are not permitted.

Do a local penetrant crack test.

SUBTASK 72-00-41-230-008 Do a Crack Test

NOTE

While doing this repair on a rotor stage, make sure that all damaged blades on the rotor stage are blended. This includes damage that has been accepted, refer to the applicable inspection TASK.

When you estimate whether a blade is acceptable after repair, make sure that the total material removed from the stage (cumulative blend limit) is not more than the limit given. This includes all the blades that were blended before.

Make sure that the damage is removed completely and there is no undressed damage on the blades in the stage.

Make sure that all the debris are removed.

Use Workshop Inspection Equipment 1 off.

Visually examine the repair area.

Make sure that the blended area is in the repair limits. If not, reject the blade.

Use Workshop Inspection Equipment 1 off.

Dimensionally examine the repair area.

SUBTASK 72-00-41-220-059 Examine the Repair Area

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions