DMC:V2500-A0-72-00-4300-00A-364A-BIssue No:001.00Issue Date:2014-05-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

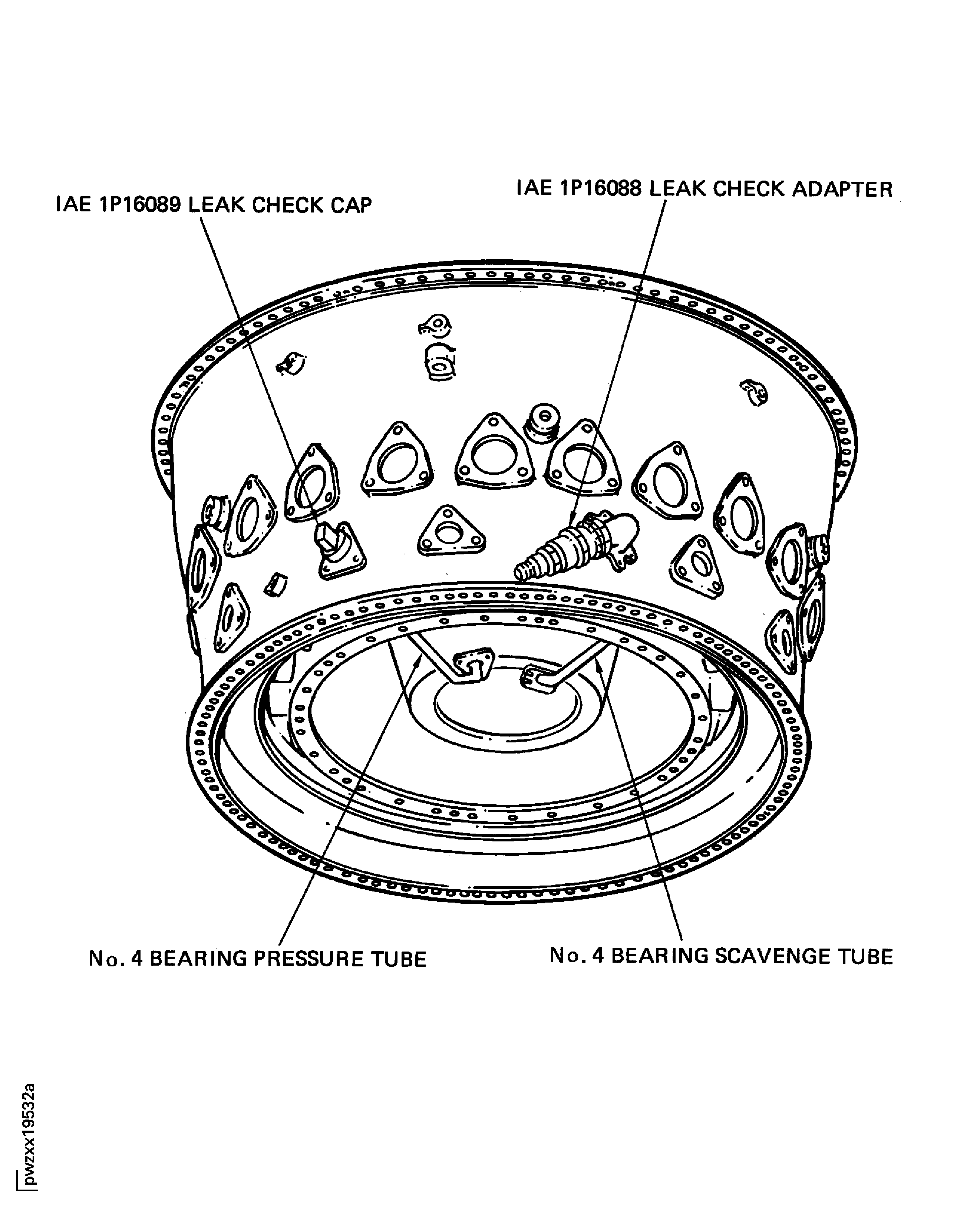

TASK 72-00-43-220-003 No. 4 Bearing And Rear Compartment Assembly - Examine The No. 4 Bearing And Rear Compartment For Leaks, Inspection-003

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1P16088 Leak check adapter | 0AM53 | IAE 1P16088 | 1 | |

| IAE 1P16089 Leak check cap | 0AM53 | IAE 1P16089 | 1 | |

| IAE 6F10030 Vacuum test cart | 0AM53 | IAE 6F10030 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure

Install the IAE 1P16089 Leak check cap 1 off in the coupling nut of the pressure tube.

Install the IAE 1P16088 Leak check adapter 1 off in the scavenge tube.

Connect the IAE 6F10030 Vacuum test cart 1 off to the adapter.

Adjust the vacuum on the cart to 20 in. Hg and evacuate the bearing compartment. Based on the ambient pressure, refer to the table below for the vacuum pressure in psia.

Ambient Pressure of the Day (psia)

Vacuum Pressure (psia)

14.7

4.9

14.5

4.7

14.3

4.5

14.1

4.3

13.9

4.1

13.7

3.9

13.5

3.7

13.3

3.5

13.1

3.3

Vacuum pressure (psia) = Ambient pressure of the day (psia) - 9.8 psia

SUBTASK 72-00-43-720-001 Do a Check of the No. 4 Front and Rear Bearing Compartments for Leaks

Figure: Check the No. 4 Front and Rear Bearing Compartment for Leaks

Check the No. 4 Front and Rear Bearing Compartment for Leaks