Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-50-560-003 LPT Module - Turn The LPC/Intermediate Case Module, HP System, And LPT Modules From Horizontal To Vertical (Front End Down) - Maintenance Requirement B1-0923, Installation-013

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10028 Support Pedestal | 0AM53 | IAE 1F10028 | 2 | |

| IAE 1F10051 Two cable sling | 0AM53 | IAE 1F10051 | 1 | |

| IAE 1F10108 Lifting turn adapter | 0AM53 | IAE 1F10108 | 1 | |

| IAE 1J12000 Lift bracket | 0AM53 | IAE 1J12000 | 2 | |

| IAE 1J12008 Trunnion | 0AM53 | IAE 1J12008 | 2 | |

| IAE 1J12010 Storage stand | 0AM53 | IAE 1J12010 | 1 | |

| IAE 1J12210 Vertical build stand | 0AM53 | IAE 1J12210 | 1 | |

| IAE 1P16002 Cradle pedestal | 0AM53 | IAE 1P16002 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

If necessary set IAE 1F10051 Two cable sling 1 off in to the outer position.

SUBTASK 72-00-40-560-079 Install the Lift Sling to the LP Compressor/Intermediate Case Module, HP System and LP Turbine Modules to be Turned

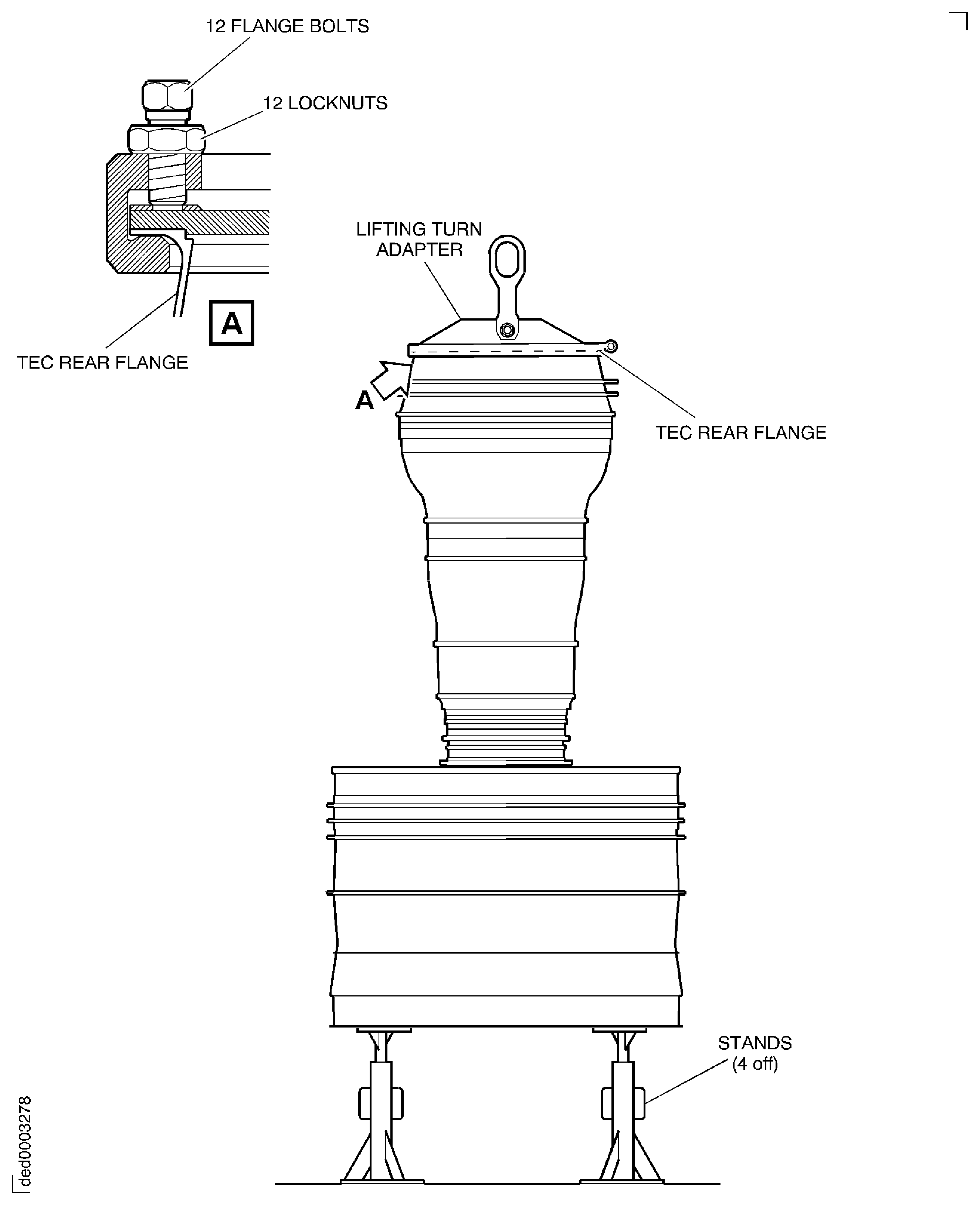

Attach the hoist equipment to the lifting eye hook of the IAE 1F10108 Lifting turn adapter 1 off. Make sure the eye hook of the adapter is installed at TDC (12 0'clock position) relative to the engine center line.

CAUTION

YOU MUST NOT LET THE LIFTING TURN ADAPTER HIT THE TEC REAR FLANGE OR OTHER PARTS OF THE ENGINE.Install the adapter to the TEC rear flange, tighten the 12 tool flange bolts and the 12 tool lock nuts. Refer to view at A, Figure.

SUBTASK 72-00-50-560-063 Install the Lifting Turn Adapter to the TEC Rear Flange

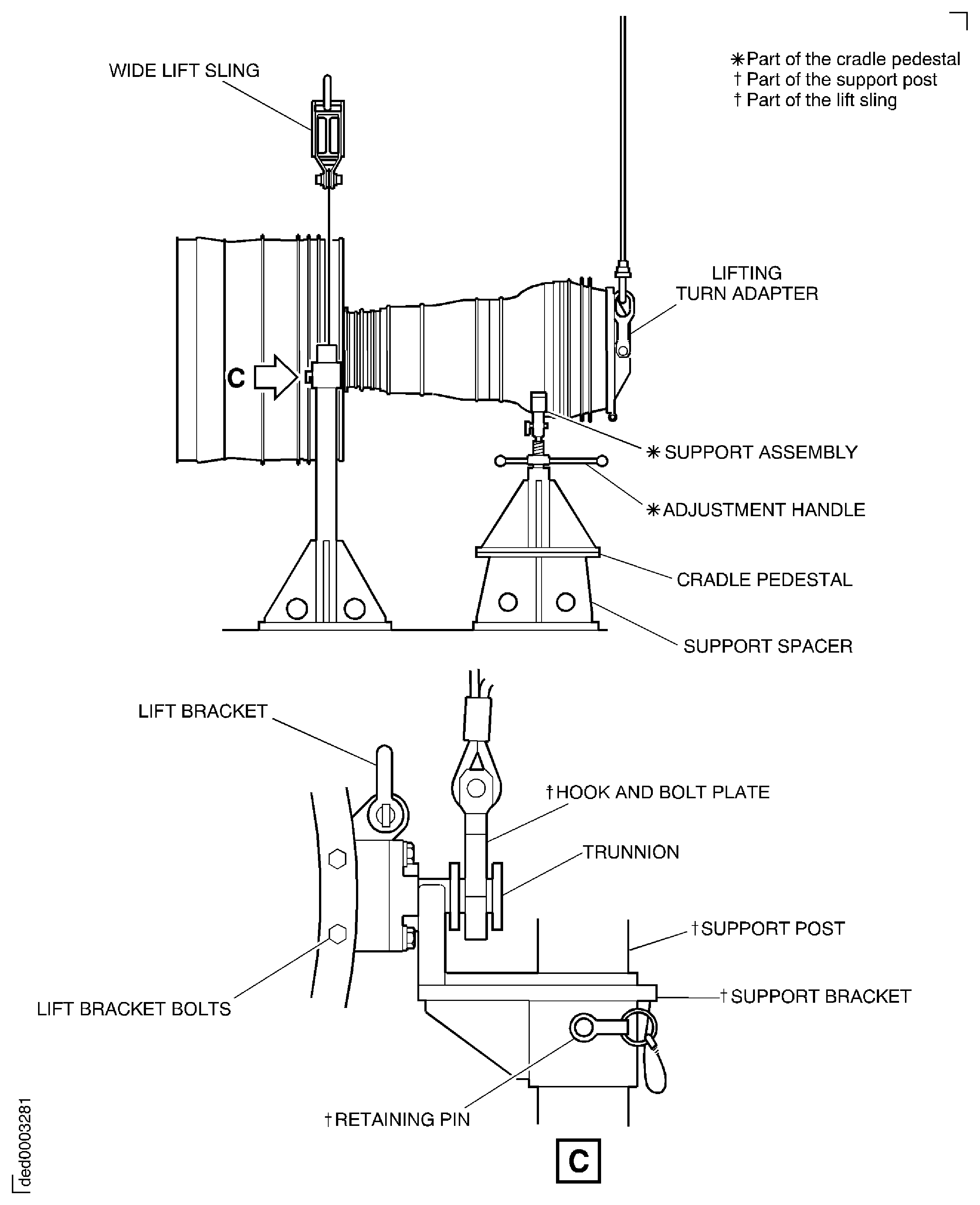

Remove the forward lift sling hook and bolt plate from the trunnions on the LP compressor/intermediate case module. Refer to Figure.

SUBTASK 72-00-50-560-064 Lift and Turn the LP Compressor/Intermediate Case Module, the HP System and LP Turbine Modules

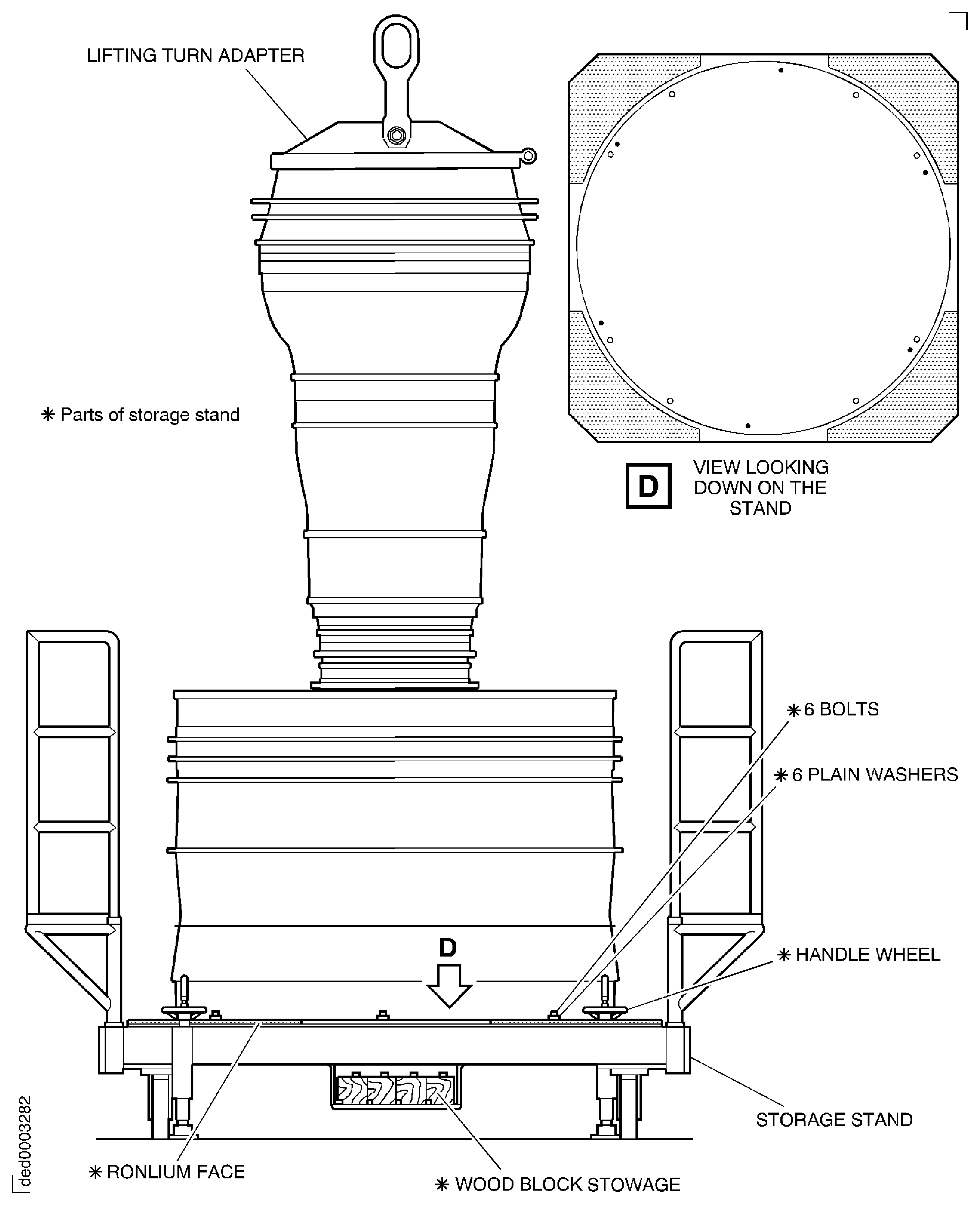

Refer to Figure.

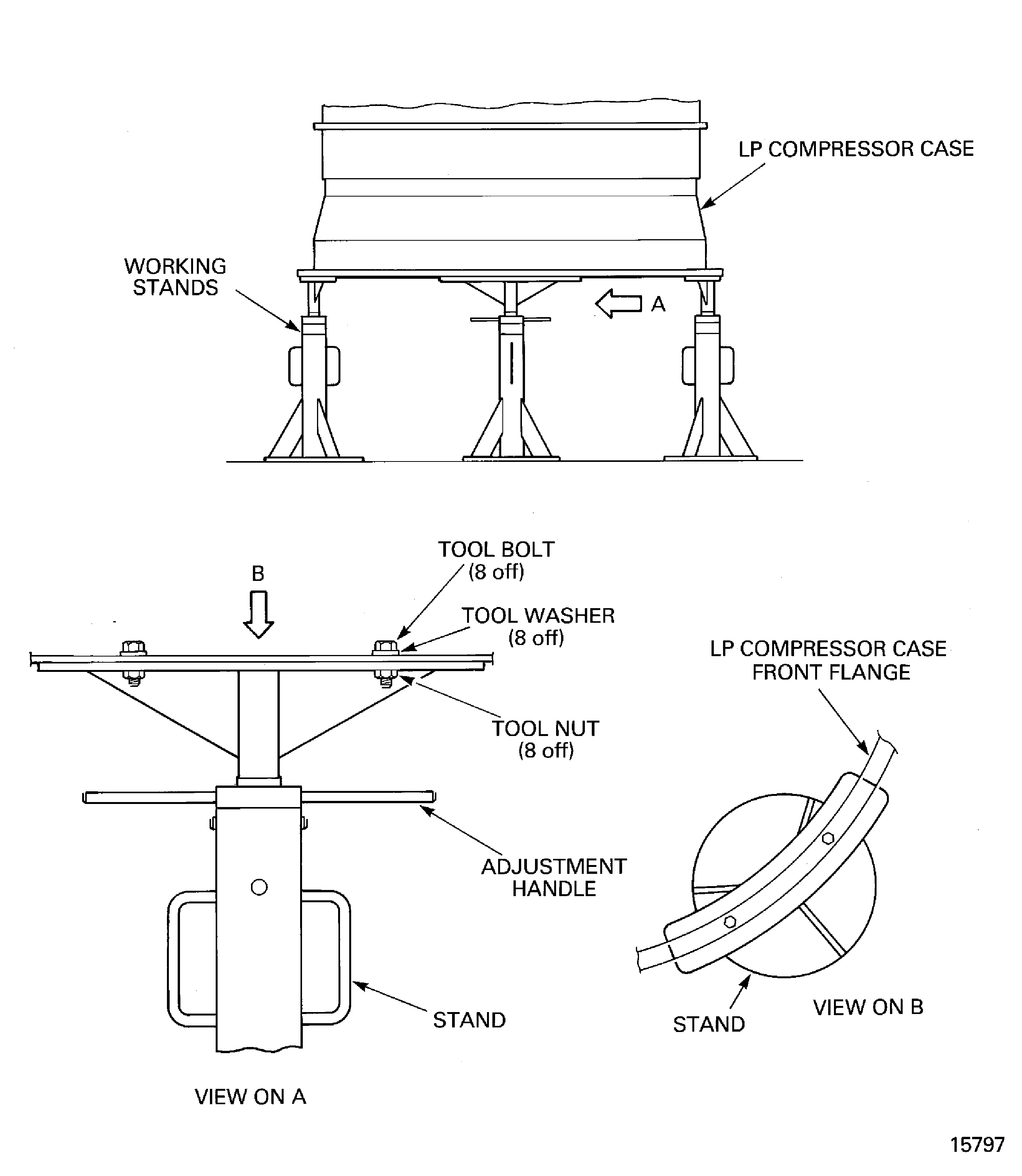

Put the 4 stands (part of IAE 1J12210 Vertical build stand 1 off) in a circular position. The four stands must be equally spaced. The diameter of the circle should be equal to the diameter of the LP compressor and intermediate case module front flange.

NOTE

It can be necessary to make small adjustments of the four stand positions to align the holes in the support brackets.Turn the adjustment handles on the build stand until the brackets touch the LP compressor/intermediate case module front flange. At the same time align the holes in the support brackets with holes in the front flange. Make sure the front flange is level.

SUBTASK 72-00-50-560-065-001 Install the LP Compressor/Intermediate Case Module, the HP System and LP Turbine Module Assembly on to the Vertical Build Stand (Alternative Procedure to SUBTASK 72-00-50-560-065-002 )

Refer to Figure.

Turn the 4 handle wheels on the IAE IAE 1J12010 Storage stand 1 off to secure the stand to the floor. The wooden blocks supplied with the stand are not required for this procedure, store the blocks in the stand stowage.

Remove the lift and turn adapter. Refer to Step.

SUBTASK 72-00-50-560-065-002 Install the LP Compressor/Intermediate Case Module, the HP System and LP Turbine Modules in the Storage Stand (Alternative Procedure to SUBTASK 72-00-50-560-065-001 )

Remove the trunnions from the LP compressor/intermediate case module. Figure.

SUBTASK 72-00-50-560-066 Remove the Tools from the LP Compressor/Intermediate Case Module the HP System and LP Turbine Modules

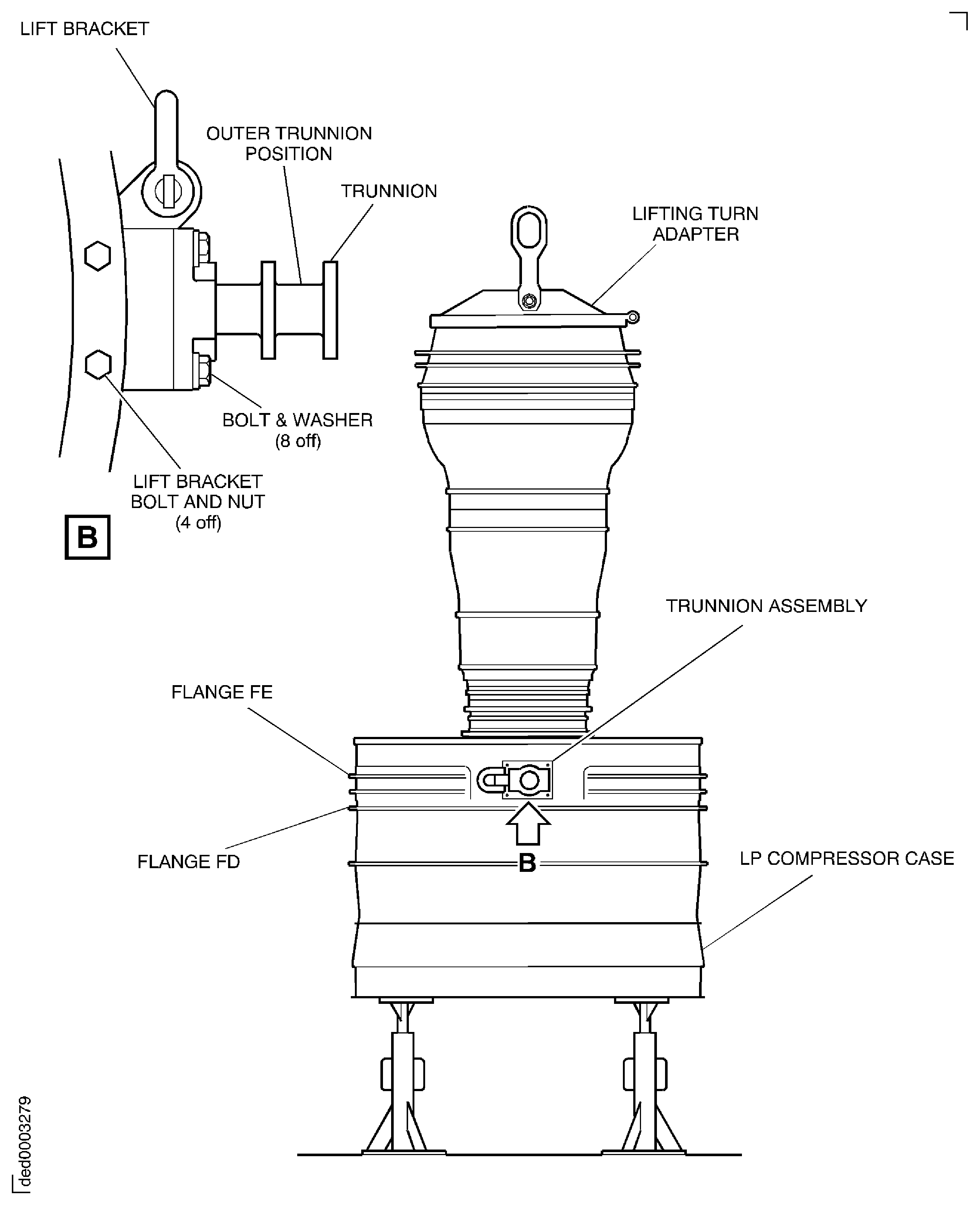

Figure: Remove the LP compressor/intermediate case module, HP system and LP modules from the support posts and cradle pedestal

Remove the LP compressor/intermediate case module, HP system and LP modules from the support posts and cradle pedestal

Figure: Install the LP compressor/intermediate case module, HP system and LP modules to the working stand

Sheet 1

Figure: Install the LP compressor/intermediate case module, HP system and LP modules to the working stand

Sheet 2

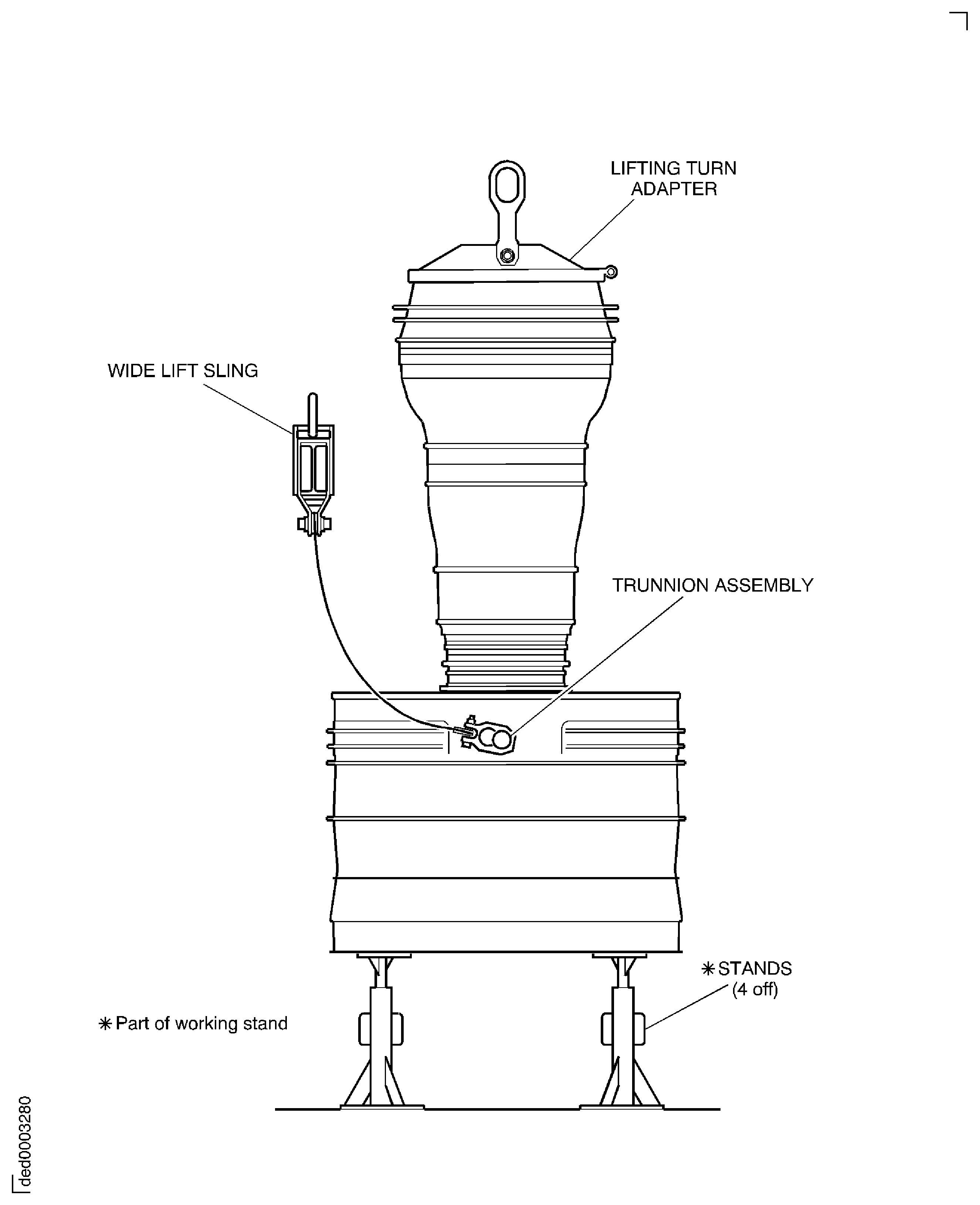

Figure: Install the LP compressor/intermediate case module, HP system and LP modules to the storage stand

Install the LP compressor/intermediate case module, HP system and LP modules to the storage stand

Figure: Remove/install the lifting turn adapter from/to the TEC rear flange

Remove/install the lifting turn adapter from/to the TEC rear flange

Figure: Remove the trunnions from the LP compressor/intermediate case module

Remove the trunnions from the LP compressor/intermediate case module