Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-71-300-011 LPC Bleed Valve Power Arm - Replace The Spherical Bearing, Repair-011 (VRS1325)

General

Price and availability - not applicable

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Arbor Press | LOCAL | Arbor press | ||

| IAE 3J12745 Swaging tool | 0AM53 | IAE 3J12745 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Bearing, spherical | MS14104-4 | 1 | ||

| Bearing, spherical | 5A3653 | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

Inspect and identify defective spherical bearing.

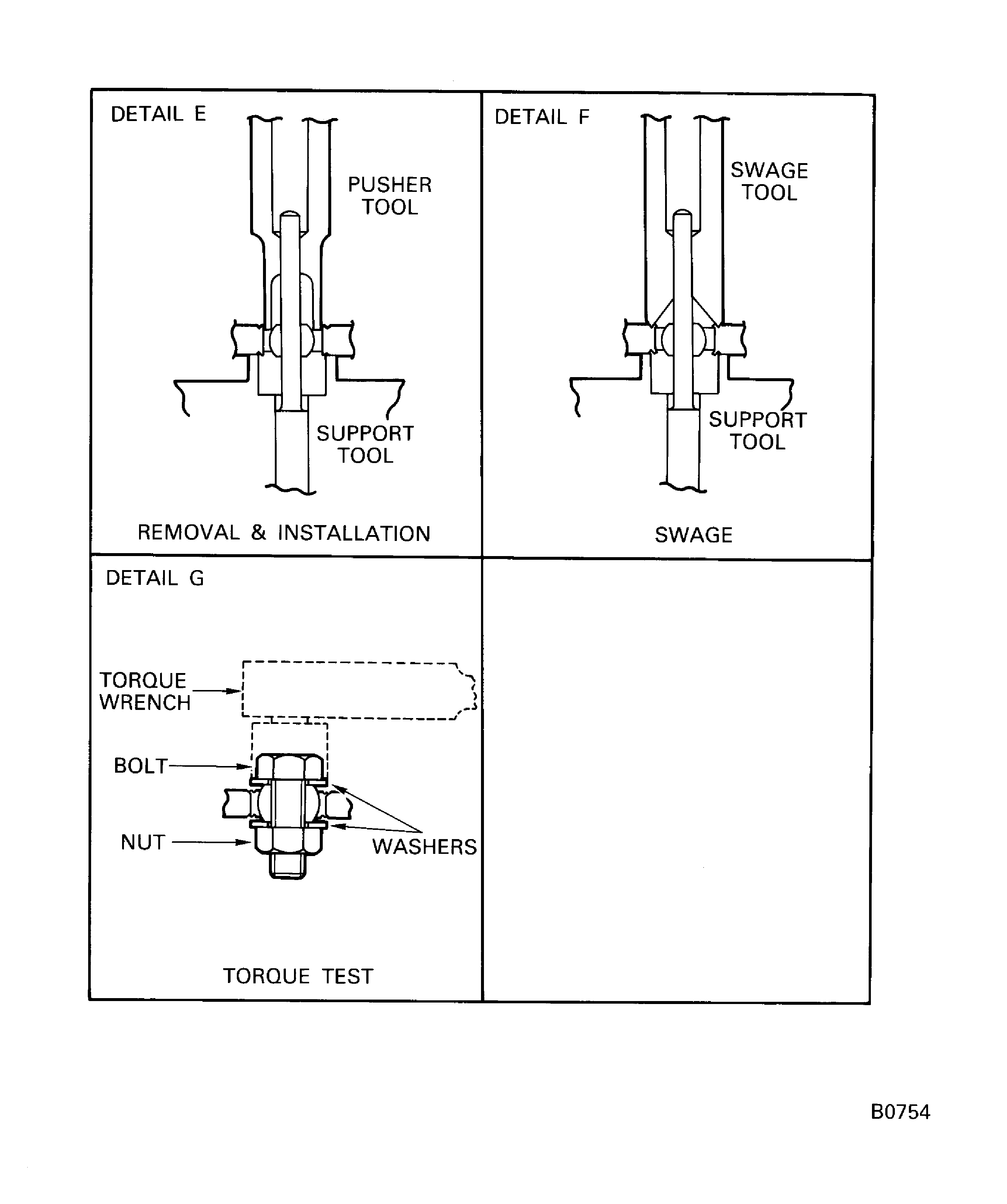

Refer to Figure DETAIL E.

Use an Arbor Press and IAE IAE 3J12745 Swaging tool 1 off.

Press out defective spherical bearing.

Refer to the SPM TASK 70-35-03-300-501.

Scratches are permitted by remove the burrs.

Check damage in bore.

SUBTASK 72-32-71-350-063 Remove the Defective Spherical Bearing from the Power Arm Assembly

Refer to the SPM TASK 70-23-05-230-501.

Make sure there is no cracks in the hole.

Fluorescent penetrant examine the spherical bearing hole.

SUBTASK 72-32-71-230-064 Examine the Power Arm Assembly for Cracks

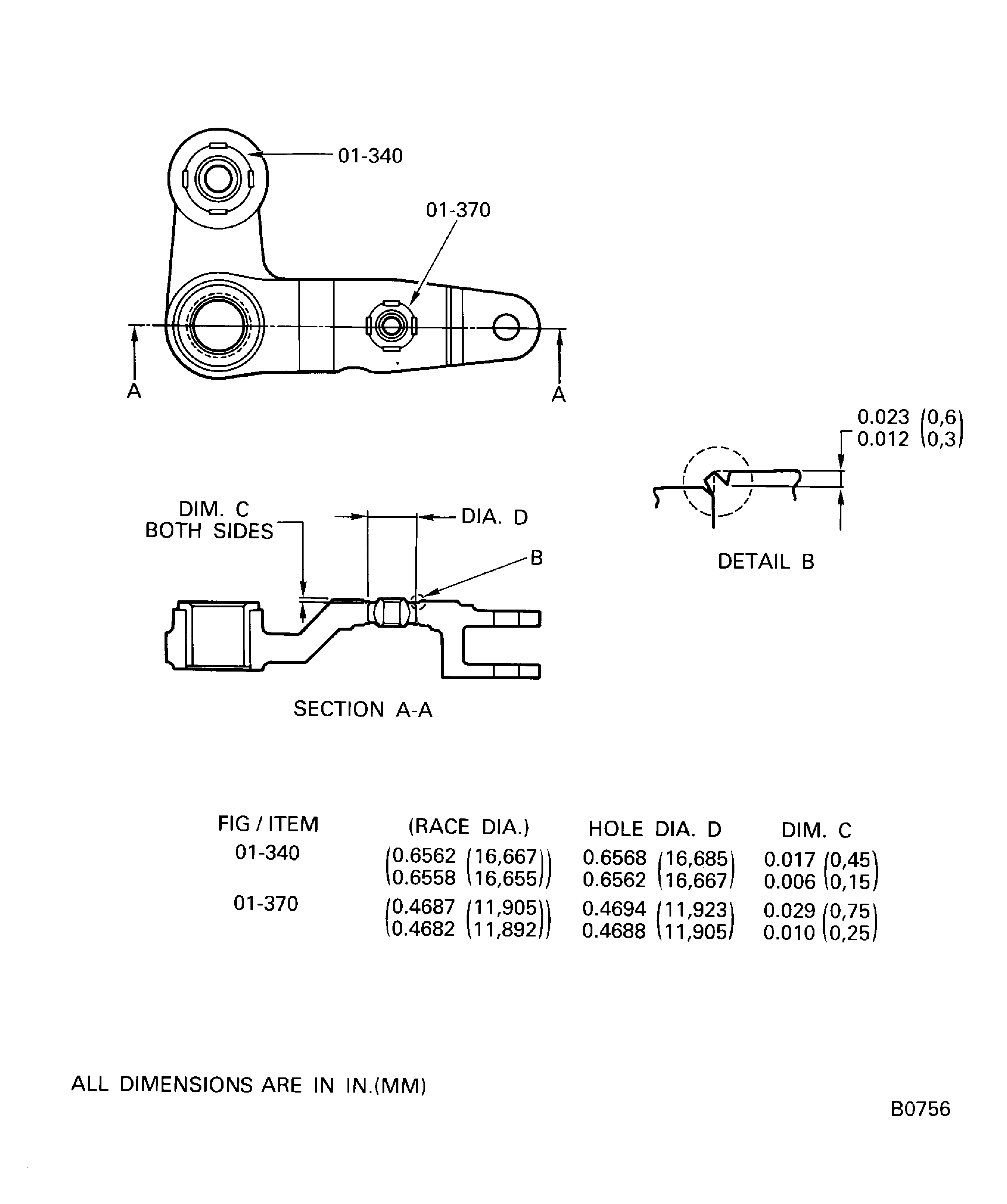

Refer to Figure.

Ensure the correct diamter.

Dimensionally inspect the hole of the power arm.

SUBTASK 72-32-71-220-092 Inspect the Power Arm Assembly

Use clean dry air blast or CoMat 02-099 LINT-FREE CLOTH.

Clean the new spherical bearing and the hole of the power arm.

Position bearing race slightly below the surface of arm.

Use an arbor press and IAE IAE 3J12745 Swaging tool 1 off.

Install the bearing.

Apply swaging force to the 45 degrees circumferential position from the existing swage point up to the depth of the swage.

Invert the arm and re-apply swaging force.

Use an Arbor Press and IAE 3J12745 Swaging tool 1 off.

Swage the arm to fix the bearing.

Refer to Figure DETAIL G.

NOTE

If the torque exceeds the limits as follows:Fig/Item 01-340, torque limit 6.0 lbfin (69 kgmm).Fig/Item 01-370, torque limit 2.6 lbfin (30 kgmm).Replace the bearing using lower staking load.If movement is not free, install screw, nut and washers and measure torque required to rotate the ball.

Inspect the ball for free movement in the race.

SUBTASK 72-32-71-350-064 Install the New Spherical Bearing

Refer to Figure.

Race of bearing must be located just below the arm face.

Visually examine the spherical bearing seating.

SUBTASK 72-32-71-220-093 Examine the Spherical Bearing Seating

Figure: Replacement of the spherical bearing

Replacement of the spherical bearing

Figure: Replacement of the spherical bearing

Replacement of the spherical bearing