Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 72-41-00-990-501 Description and Operation of the HP Compressor Assembly

Description

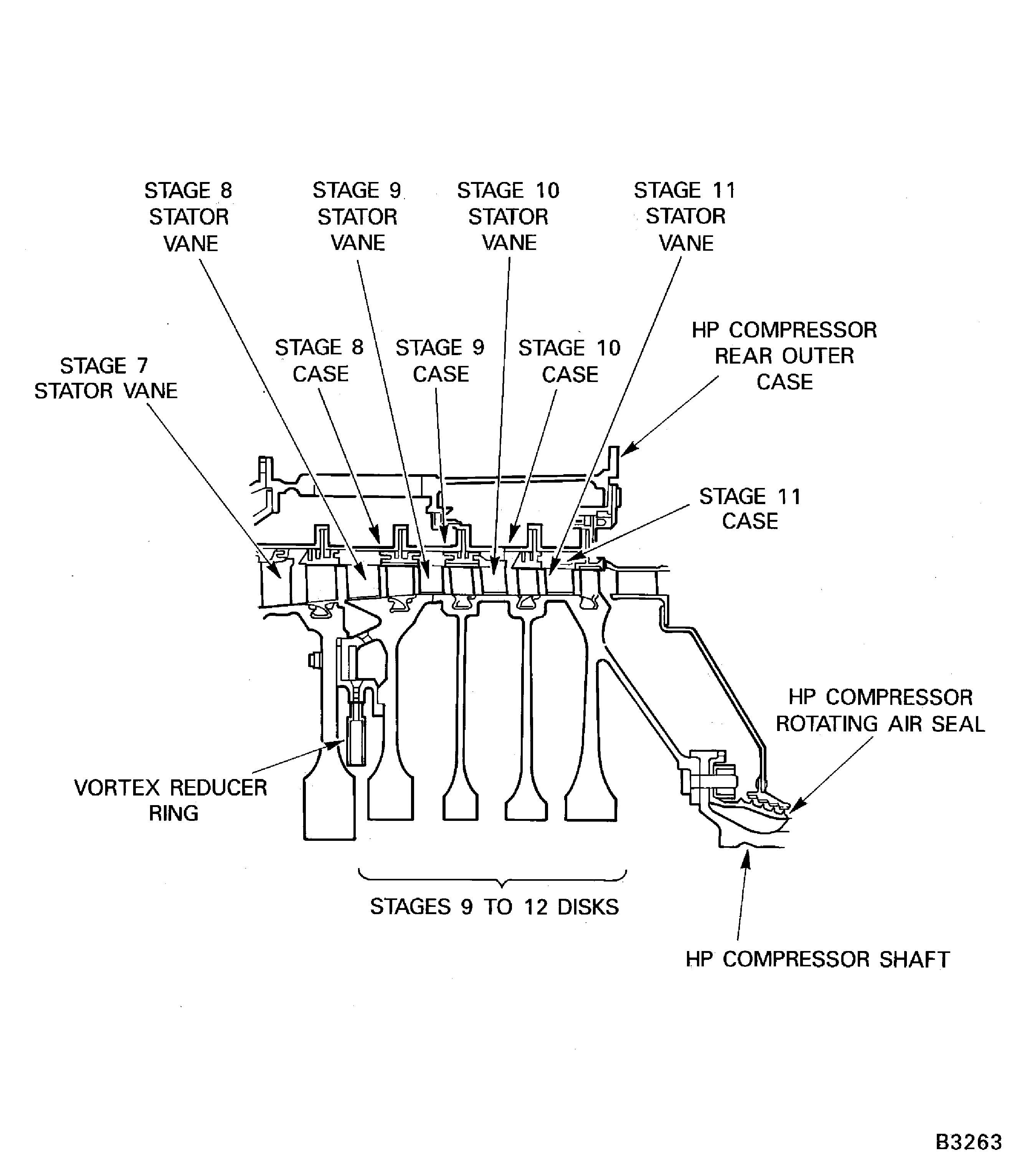

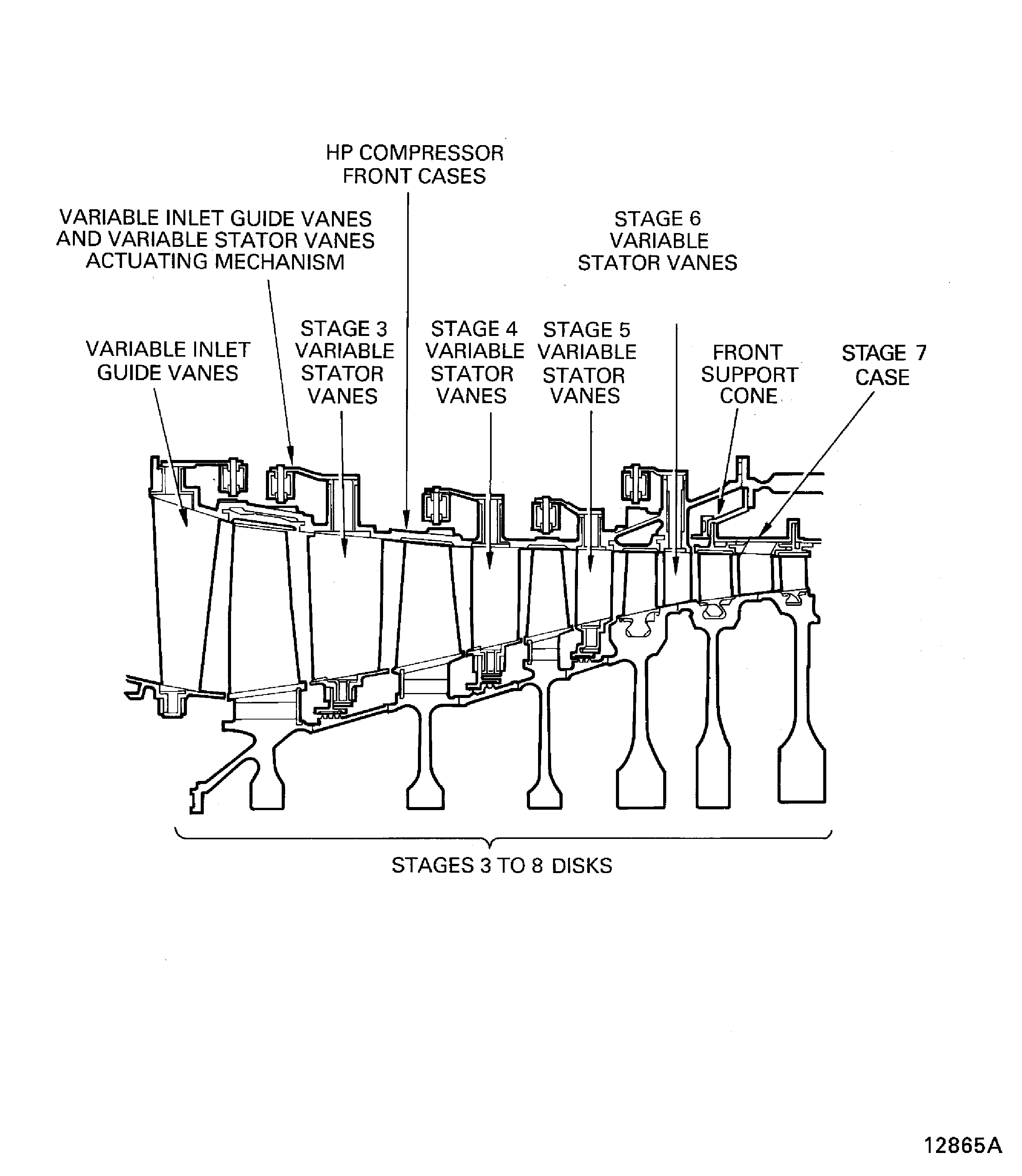

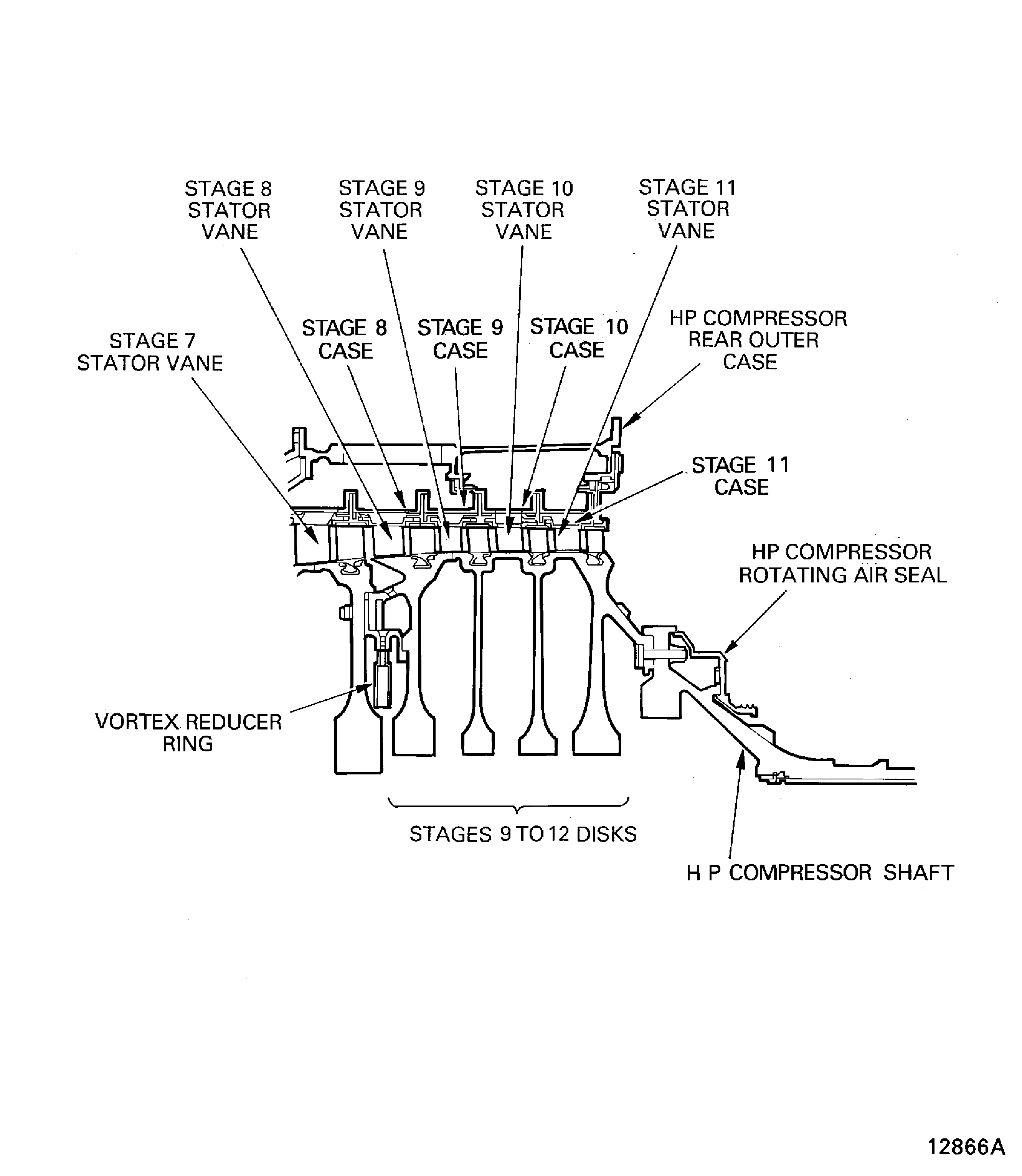

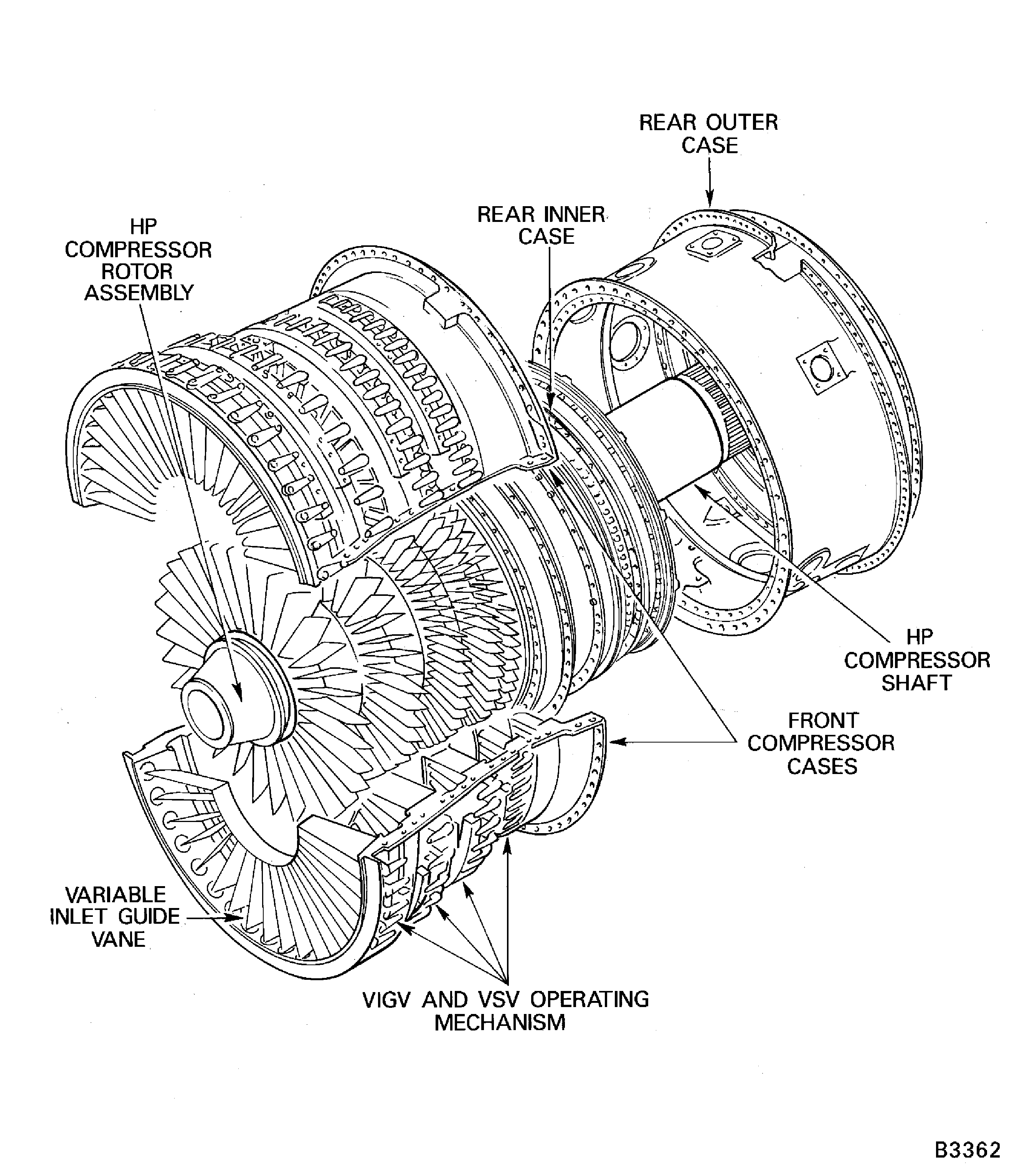

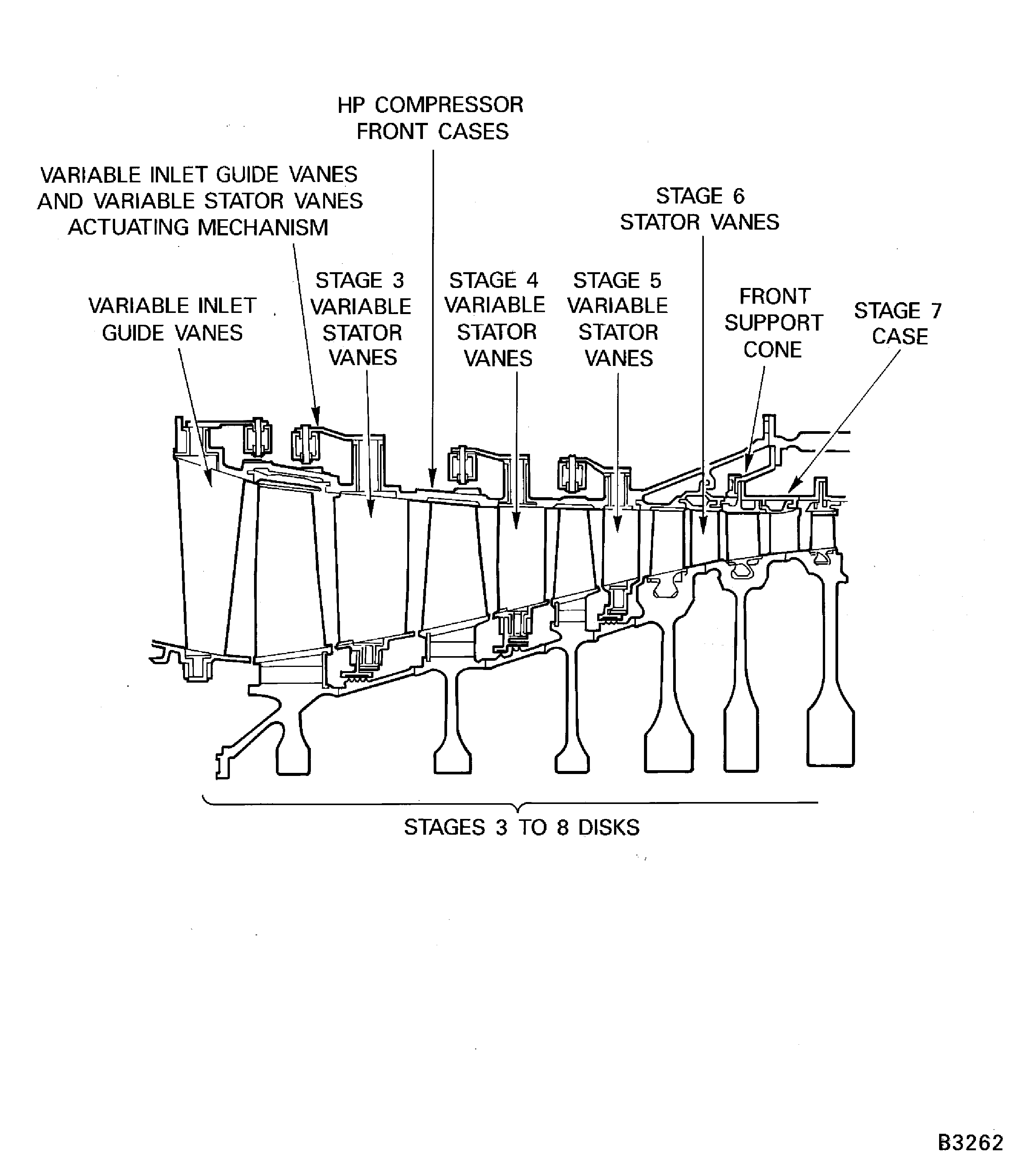

The HP (HPC) compressor assembly (Module 40), refer to Figure and Figure, is a 10 stage axial flow compressor. It has a rotor assembly and stator cases. The compressor stages are numbered from the front, the first stage is stage 3. Air flow through the compressor is controlled by variable inlet guide vanes (VIGV), variable stator vanes (VSV) and bleed valves.

The rotor assembly has five sub-assemblies

HPC Stage 3 to 8 disks

Vortex reducer ring

HPC Stage 9 to 12 disks

HPC rear shaft

HPC rotating air seal

The five sub-assemblies are bolted together to make the rotor. The compressor blades in stages 3 to 5 are attached to the compressor disks in axial dovetail slots and secured by lockplates. The stages 6 to 12 compressor blades are installed in slots around the circumference of the disks through an axial loading slot, lock blades, lock nuts and jack screws hold the blades in position.

The HPC stator case has two primary sub-assemblies, the HPC front and rear cases.

V2500-A1: The HPC front case assembly has two split cases bolted together along the engine horizontal center line. The front case assembly contains the VIGVs and the stages 3 to 6 VSVs. The lower case provides a mounting for the VIGV and VSV actuator. The front case assembly is bolted to the intermediate case and to the rear outer case.

V2500-A5: The HPC front case assembly has two split cases bolted together along the engine horizontal center line. The front case assembly contains the VIGVs, the stages 3 to 5 VSVs and the stage 6 stator vanes. The lower case provides a mounting for the VIGV and VSV actuator. The front case assembly is bolted to the intermediate case and to the rear outer case.

The HPC rear case assembly has five inner ring cases and an outer case. Flanges on the inner cases form annular manifolds which provide stages 7 and 10 air offtakes. The five inner cases are bolted together, with the front support cone bolted at the stage 7 case and the stage 11 case bolted to the rear outer case. The five inner cases contain the stages 7 to 11 fixed stator vanes. The rear outer case is bolted to the diffuser case and to the rear flange of the HPC front case.

Access is provided in the compressor cases for borescope inspection of the compressor blades and stator vanes.

Operation

The compressed air from the LP compressor (LPC) goes into the HPC through the VIGVs.

The angular position of the VIGVs and the VSVs is automatically adjusted to give the air flow the correct direction through the compressor. The angular position of the VIGVs and the VSVs is controlled by a variable stator vane actuator, hydraulically operated by the HP fuel system.

As the air goes through the compressor each stage compresses it more. The compressed air goes into the combustion chamber.

The HPC shaft is connected to the HP turbine which supplies the power to turn the HPC rotor.

The vortex reducer ring straightens the stage 8 airflow and supplies air to the center of the engine for internal sealing and cooling.

Air is ducted from the HPC stages 7 and 10 to supply air for the aircraft services. More air is bled off at stages 7 and 10 to improve engine starting and to prevent surge at some conditions.

Module Sub-Assemblies

Listed below are the module build groups with the associated work groups (marked *). The work group level is where piece parts are cleaned, inspected and repaired/reworked:

SNS

Part

Location

HPC Module Nomenclature

72-41-10

HPC rotor assembly

72-41-11

*

HPC stage 3 to 8 disk

72-41-12

*

HPC stage 9 to 12 disk

72-41-13

*

HPC rear shaft

72-41-14

*

HPC rotating air seals

72-41-15

*

HPC blades

72-41-20

HPC rear cases and vanes assembly

72-41-21

*

HPC ring cases

72-41-22

*

HPC fixed stator vanes

72-41-23

*

HPC rear outer case

72-41-30

HPC front case and vanes assembly

72-41-31

*

HPC split case and ring segments

72-41-32

*

HPC variable vanes

72-41-33

*

HPC variable vane inner shrouds

72-41-34

*

HPC variable vane actuating mechanism

Figure: V2500-A1: HP compressor sub-assemblies

V2500-A1: HP compressor sub-assemblies

V2500-A1: HP compressor sub-assemblies

V2500-A1: HP compressor sub-assemblies

Figure: V2500-A5: HP compressor sub-assemblies

V2500-A5: HP compressor sub-assemblies

V2500-A5: HP compressor sub-assemblies

V2500-A5: HP compressor sub-assemblies