Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-034 HPC Rotor Blades - (Stages 7 And 8) Replace The Flame Deposition Material, Repair-034 (VRS6153)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-270 | 6A3246 |

02-270 | 6A5588 |

02-270 | 6A4905 |

02-285 | 6A3247 |

02-285 | 6A5589 |

02-285 | 6A4906 |

02-300 | 6A3245C01 |

02-300 | 6A5584C01 |

02-300 | 6A4907C01 |

02-315 | 6A3245C01 |

02-315 | 6A5584C01 |

02-315 | 6A4907C01 |

02-317 | 6A3245C02 |

02-317 | 6A5584C02 |

02-317 | 6A4907C02 |

02-370 | 6A3249 |

02-370 | 6A5590 |

02-370 | 6A4908 |

02-385 | 6A3250 |

02-385 | 6A5591 |

02-385 | 6A4909 |

02-400 | 6A3248C01 |

02-400 | 6A5585C01 |

02-400 | 6A4910C01 |

02-415 | 6A3248C01 |

02-415 | 6A5585C01 |

02-415 | 6A4910C01 |

02-417 | 6A3248C02 |

02-417 | 6A5585C02 |

02-417 | 6A4910C02 |

General

This repair must only be done when the instruction to do so is given in 72-41-15 Inspection.

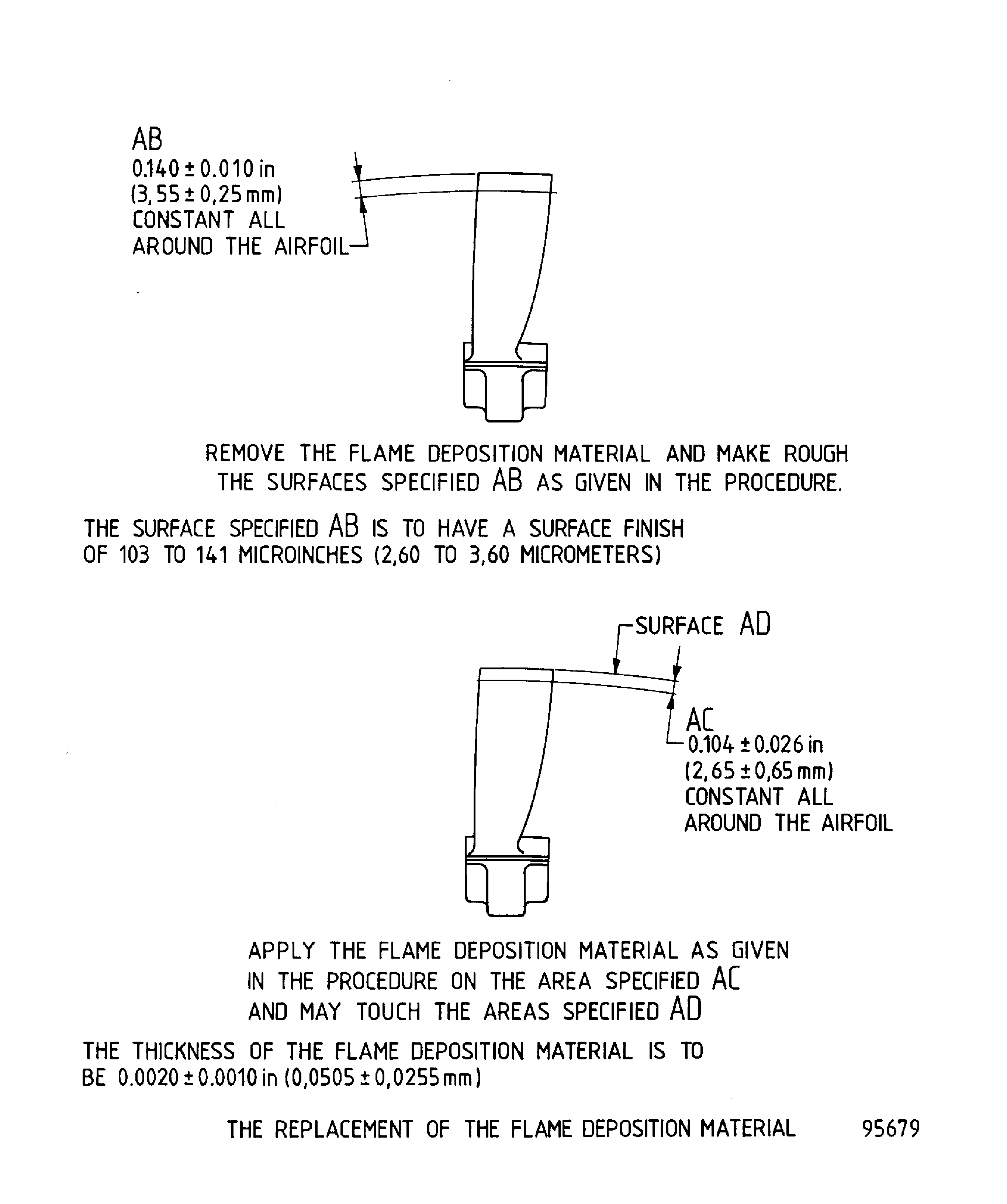

This repair is to replace the aluminium oxide coating on the tips of Stage 7 and 8 HP compressor blades by the flame deposition method.

This is a source controlled repair which can only be done by approved vendors. The vendor is self provisioning for the coating material.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Price and availability

Refer to IAE

Repair facilities

The Proprietary nature of this repair requires that any facility not authorized to accomplish this repair either, utilize the Authorized Repair Vendors listed below or contact the IAE Repair Services Group to determine if a qualification program can be initiated at their facility.

IAE - INTERNATIONAL AERO ENGINES AG

400 Main Sreet

East Hartford CT 06108

U.S.A.

ATTN: Manager Repair Services

Authorized repair vendors for Repair VRS6153 are listed below:

PRAXAIR SURFACE TECHNOLOGIES LTD

Southam Industrial Estate

Westfield Road

Southam

Leamington Spa

Warwickshire

CV33 0JH

Praxair Surface Technologies GmbH

Robert - Zapp - Strasse 7

4030 RATINGEN

West Germany

Praxair Surface Technologies Ltd

1234 Atlantic Street

NORTH KANSAS CITY

Missouri

M064116

U.S.A.

The designation by IAE of an authorized repair vendor indicates that the repair vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the repair vendors to carry out the repair work, and accepts no responsibility whatsoever for any work that may be carried out by a repair vendor other than when IAE is listed as the repair vendor. Authorized repair vendors do not act as agents or representatives of IAE.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Degreasing equipment | LOCAL | Degreasing equipment | ||

| Dry blast equipment | LOCAL | Dry blast equipment | ||

| Detonation flame deposition equipment | LOCAL | Detonation flame deposition equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL | K0993 | CoMat 02-006 | ||

| CoMat 05-002 ABRASIVE MEDIUM, ALUMINUM OXIDE | LOCAL | CoMat 05-002 | ||

| Aluminium oxide coating | LOCAL | Aluminium oxide coating | Union Carbide LA-2 (proprietory item) |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-01-300-503.

Remove the grease.

SUBTASK 72-41-15-110-081 Clean the Stage 7 and 8 Compressor Blades

Refer to Figure.

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or locally manufactured fixture.

Mask the areas not to be blasted.

SUBTASK 72-41-15-350-088 Apply Mask to the Stage 7 and 8 Compressor Blades

Refer to the SPM TASK 70-12-02-120-501.

Make sure that the minimum amount of the blade material is removed.

Remove masks when blasting is completed.

Abrasive blast.

SUBTASK 72-41-15-120-053 Abrasive Blast the Stage 7 and 8 Compressor Blades

Refer to Figure.

Use CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or locally manufactured fixture.

Mask the areas not to be sprayed.

SUBTASK 72-41-15-350-089 Apply Mask to the Stage 7 and 8 Compressor Blades

Refer to Figure.

SUBTASK 72-41-15-340-051 Apply the Flame Deposition Material

Refer to Figure.

SUBTASK 72-41-15-220-193 Examine the Repair

Figure: HP compressor stage 7 and 8 compressor blades repair data

HP compressor stage 7 and 8 compressor blades repair data