Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-15-300-049 HPC Stage 6 Rotor Blade - Restore The Anti-Fret Treatment - Repair-049 (VRS6495)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-170 | 6A3338 |

02-170 | 6A4902 |

02-170 | 6A5586 |

02-170 | 6A7406 |

02-170 | 6A7508 |

02-170 | 6A8322 |

02-170 | 6A8463 |

02-170 | 6A8797 |

02-185 | 6A3339 |

02-185 | 6A4903 |

02-185 | 6A5587 |

02-185 | 6A7407 |

02-185 | 6A7509 |

02-185 | 6A8323 |

02-185 | 6A8464 |

02-185 | 6A8798 |

02-200 | 6A3340C01 |

02-200 | 6A4904C01 |

02-200 | 6A5583C01 |

02-200 | 6A7405C01 |

02-200 | 6A7510C01 |

02-200 | 6A8320 |

02-200 | 6A8461 |

02-200 | 6A8732 |

02-215 | 6A3340C01 |

02-215 | 6A4904C01 |

02-215 | 6A5583C01 |

02-215 | 6A7405C01 |

02-215 | 6A7510C01 |

02-215 | 6A8320 |

02-215 | 6A8461 |

02-215 | 6A8732 |

02-216 | 6B1494 |

02-217 | 6A3340C02 |

02-217 | 6A4904C02 |

02-217 | 6A5583C02 |

02-217 | 6A7405C02 |

02-217 | 6A7510C02 |

02-217 | 6A8321 |

02-217 | 6A8462 |

02-217 | 6A8733 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

HP Compressor Stage 6 Rotor Blade | TAF or TDY or TTX | Titanium Alloy |

General

This TASK gives the procedure to restore the anti-fret treatment on the HP Compressor Stage 6 Rotor Blade.

The repair must only be done when the instruction to do so is given in the relevant inspection procedures (identified by the applicable part number) located in section 72-41-15.

Where reference is made to a SUBTASK within a TASK in the form "TASK, SUBTASK" the operator must read and apply the complete TASK. The SUBTASK is listed only when the TASK gives options for the processing of the component. The specified SUBT ASK instructs what option must be used during application of the TASK for the successful completion of the Repair Scheme VRS6495.

TASKS identified by SPM TASK are in the Standard Practices Manual (SPM).

This repair restores the dry film lubricant to the HP Compressor Blades, Stage 6.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and availability

Refer to International Aero Engines.

Related repairs - none

NOTE

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Oven | LOCAL | Oven | ||

| Brush | LOCAL | Brush | ||

| Paint spray equipment | LOCAL | Paint spray equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-009 THINNER | LOCAL | CoMat 07-009 | ||

| CoMat 10-002 DRY FILM LUBRICANT | LOCAL | CoMat 10-002 | Graphite |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

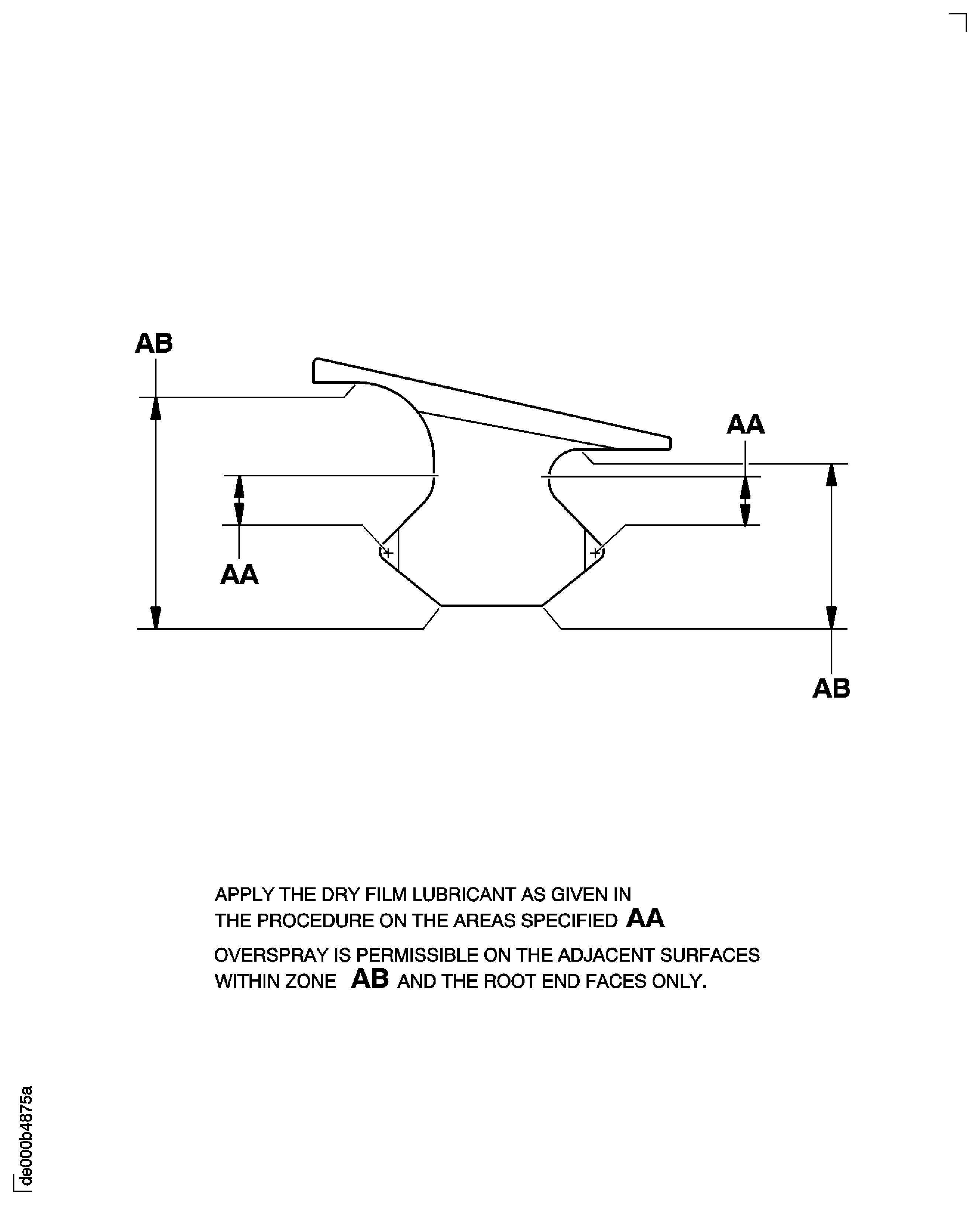

DO NOT ABRASIVE BLAST THE DOVETAIL ROOT PRIOR TO THE APPLICATION OF THE DRY FILM LUBRICANT. THIS IS A SHOT PEENED AREA.Refer to Figure.

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-004.

Apply DFL to a total thickness of 0.00031 in. (0.008 mm) to 0.00118 in. (0.030 mm).

Use Paint spray equipment or a Brush.

Apply DFL to the identified locations of the HP Compressor Stage 6 Rotor Blade.

Refer to SPM TASK 70-38-03-380-501, SUBTASK 70-38-03-380-005.

Use an Oven.

Stove the HP Compressor Stage 6 Rotor Blade.

SUBTASK 72-41-15-380-116 Apply the Dry Film Lubricant (DFL)

Figure: HP Compressor Stage 6 Rotor Blade - DFL Locations

HP Compressor Stage 6 Rotor Blade - DFL Locations