Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-32-300-017 HPC Inlet Variable Stator Vane - Replace The Stud, Repair-017 (VRS6259)

Effectivity

FIG/ITEM PART NO. | |

|---|---|

01-500 | 6A3690 |

01-500 | 6A4201 |

01-500 | 6A5653 |

01-600 | 6A3692 |

01-600 | 6A4203 |

01-600 | 6A5655 |

Material of component

RR | ||

|---|---|---|

DESCRIPTION SYMBOL MATERIAL | ||

HP compressor VIGV assembly | TAF | Titanium alloy |

Stud | EAL | Corrosion resistant steel |

General

This repair must only be done when the instruction to do so is given in 72-41-32 Inspection/Check.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and Availability

Refer to International Aero Engines

NOTE

Equivalent materials or equipment can be used.

More equipment and materials necessary to do this Repair are in the SPM TASKS given below

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Extractor | LOCAL | Extractor | ||

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Standard stud driver | LOCAL | Standard stud driver | ||

| Torque wrench | LOCAL | Wrench, torque |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | 0AM53 | CoMat 01-001 | ||

| CoMat 04-004 JOINTING COMPOUND, LIGHT GRADE | LOCAL | CoMat 04-004 |

Safety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-01-300-503.

Use CoMat 01-001 SOLVENT, DELETED, with chemical cleaning equipment.

Chemically clean the vanes.

SUBTASK 72-41-32-110-062 Clean the HP Compressor VIGV

Refer to the SPM TASK 70-23-01-230-501.

Use penetrant crack test equipment.

Discard any cracked vanes.

Do a penetrant crack test.

SUBTASK 72-41-32-230-061 Do a Crack Test

Refer to the SPM TASK 70-11-03-300-503.

Use CoMat 01-001 SOLVENT, DELETED, with chemical cleaning equipment.

Chemically clean the repair parts and vanes.

SUBTASK 72-41-32-110-063 Clean the Repair Parts and the HP Compressor VIGV

Use UP11066 1 off.

Refer to the SPM TASK 70-41-02-410-501, SUBTASK 70-41-02-410-004.

Test the jointing compound air dry for ten minutes.

Apply jointing compound to the thread of the stud.

Use UP11066 1 off with a standard stud driver with a 0.250-28 UNJF thread size.

Install the stud.

SUBTASK 72-41-32-350-066-A00 Install the Stud to the HP Compressor VIGV, Assembly A

Use UP11066 1 off.

Refer to the SPM TASK 70-41-02-410-501, SUBTASK 70-41-02-410-004.

Use CoMat 04-004 JOINTING COMPOUND, LIGHT GRADEjointing compound. est the jointing compound air dry for ten minutes.

Apply jointing compound to the thread of the stud.

Use UP11066 1 off with a standard stud driver with a 0.250-28 UNJF thread size.

Install the stud.

SUBTASK 72-41-32-350-113-B00 Install the Stud to the HP Compressor VIGV, Assembly B

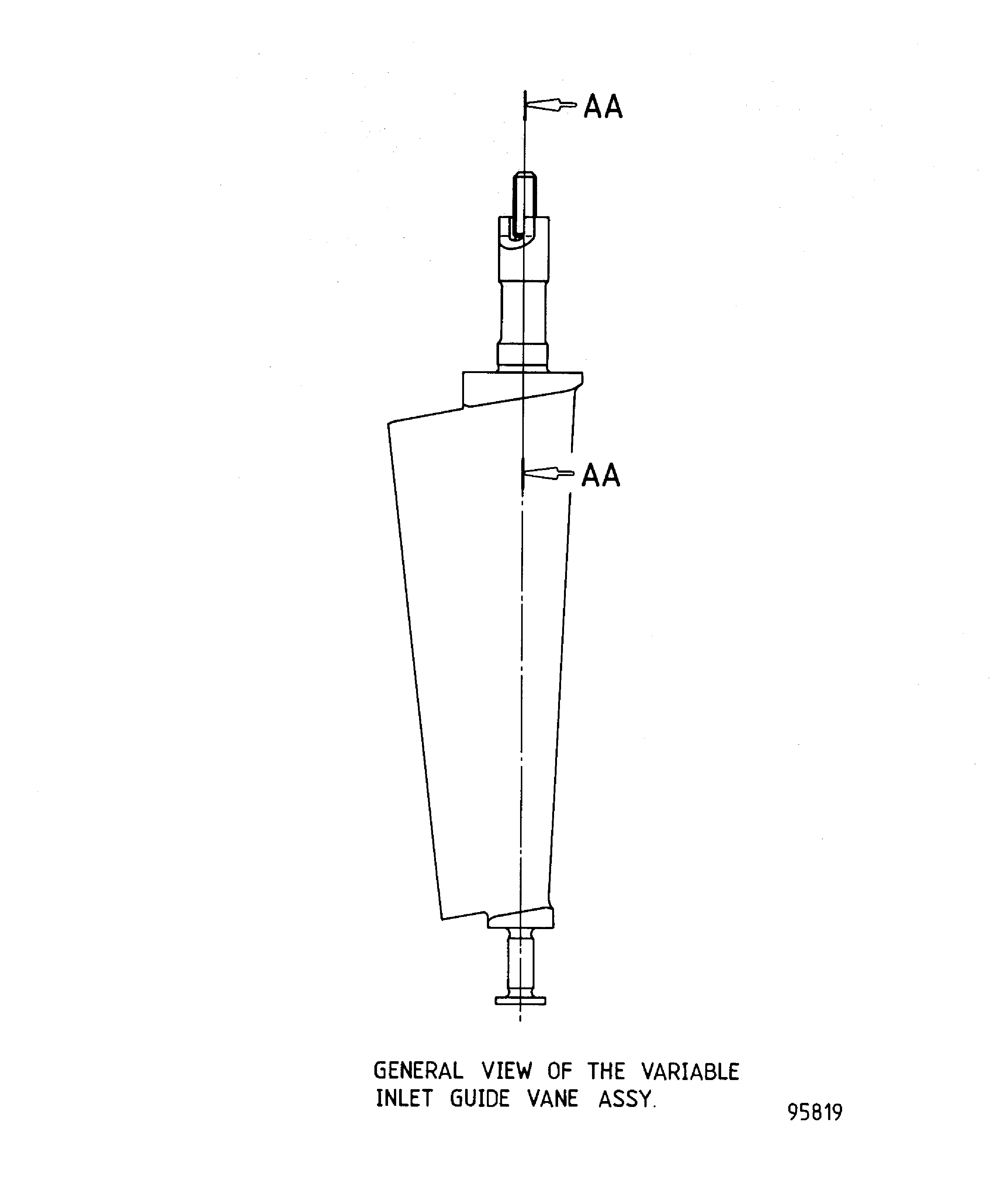

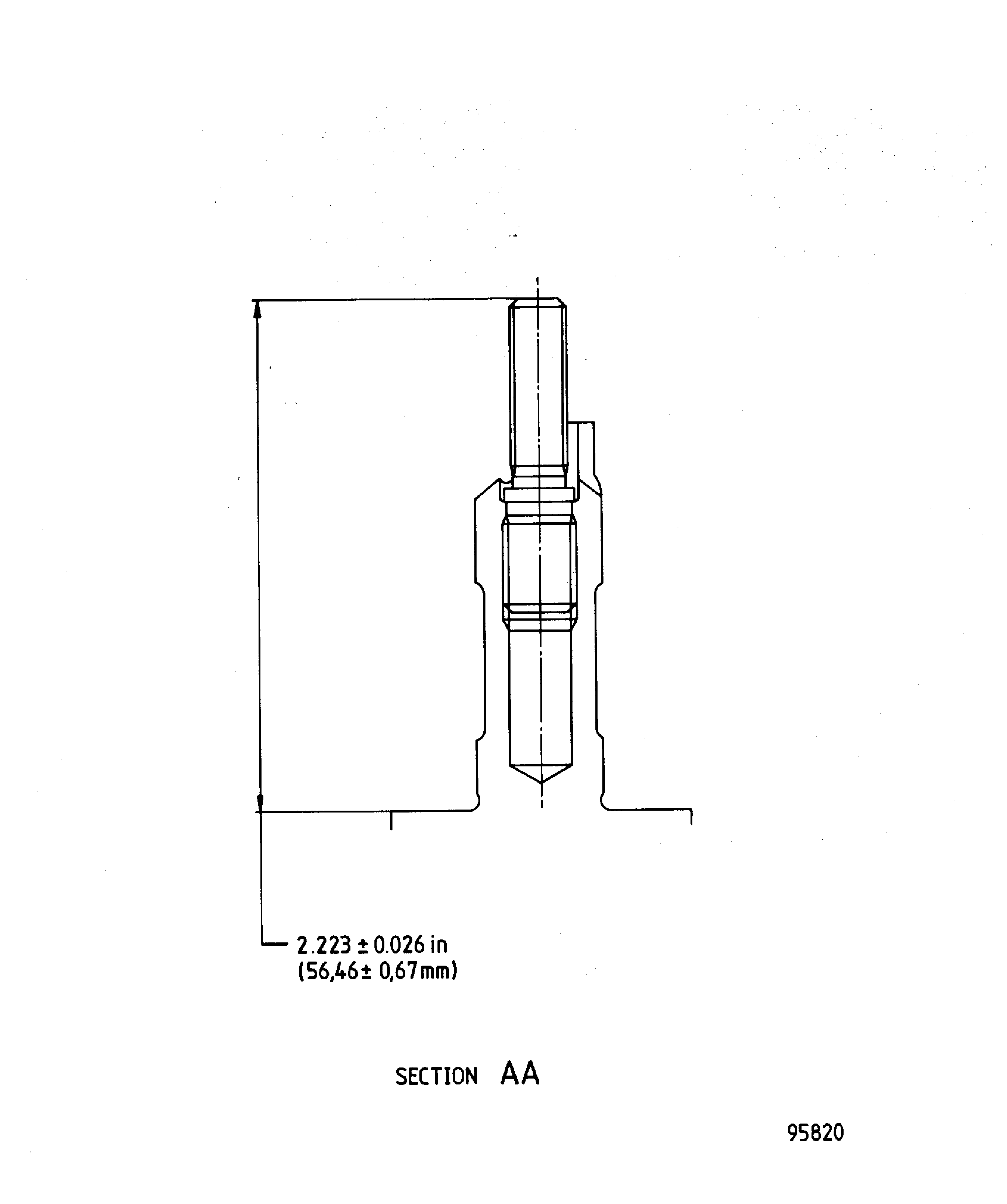

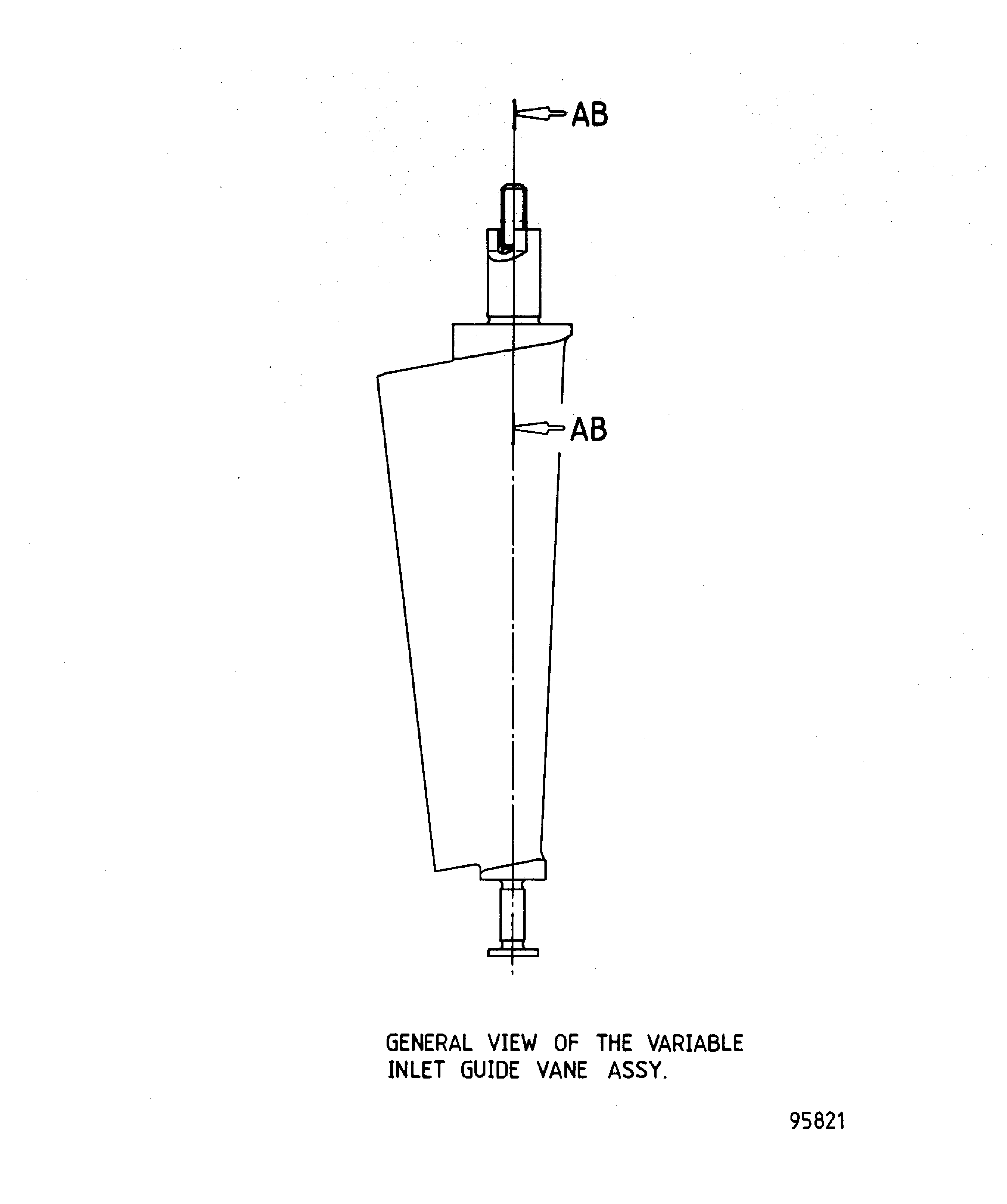

Refer to Figure.

SUBTASK 72-41-32-220-113-A00 Examine the Stud Length, Assembly A

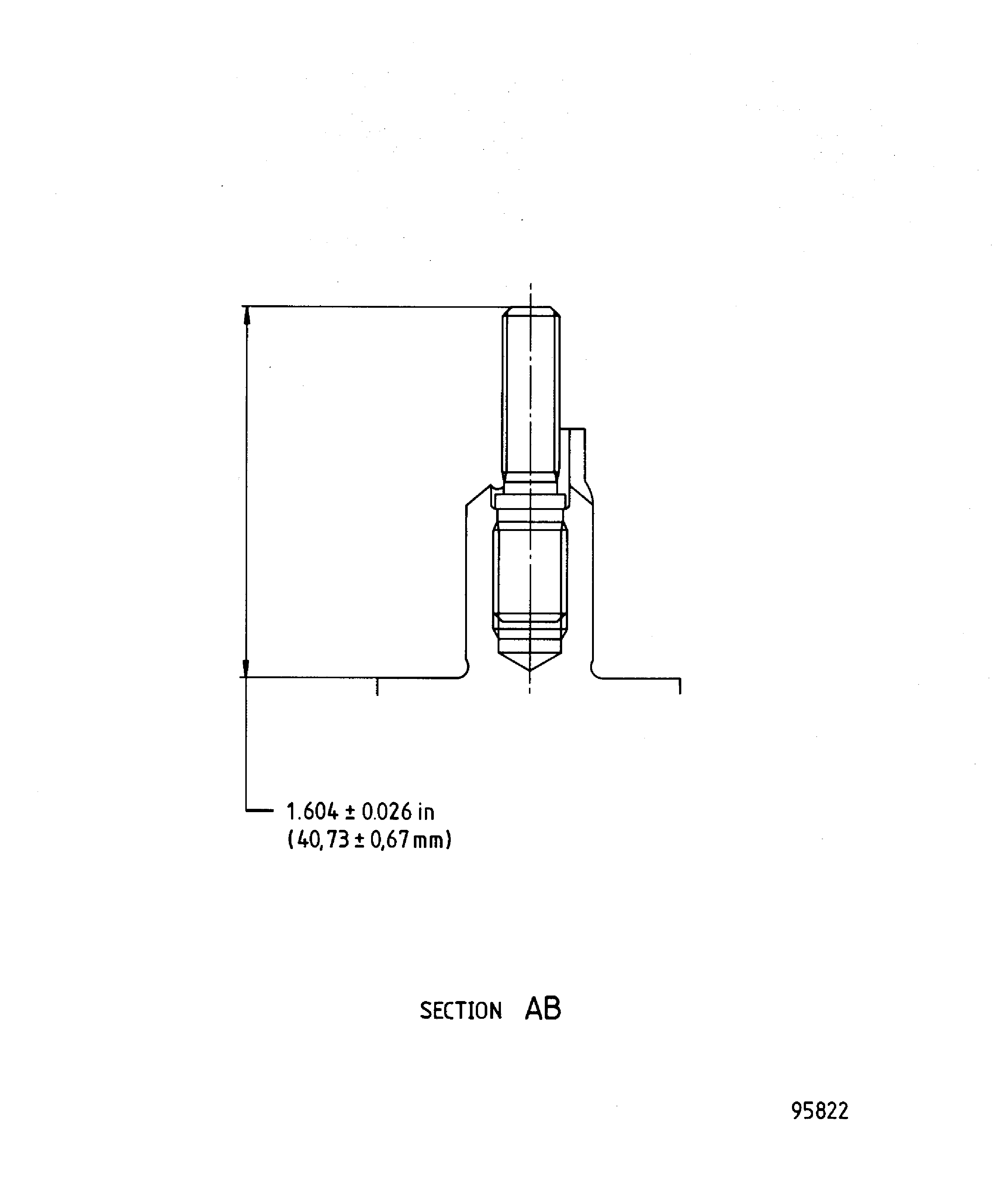

Refer to Figure.

SUBTASK 72-41-32-220-113-B00 Examine the Stud Length, Assembly B

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy B

Repair details and dimensions - Assy B

Figure: Repair details and dimensions - Assy B

Repair details and dimensions - Assy B