Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 72-42-00-990-501 Description and Operation of the Diffuser and Combustion Group

Description

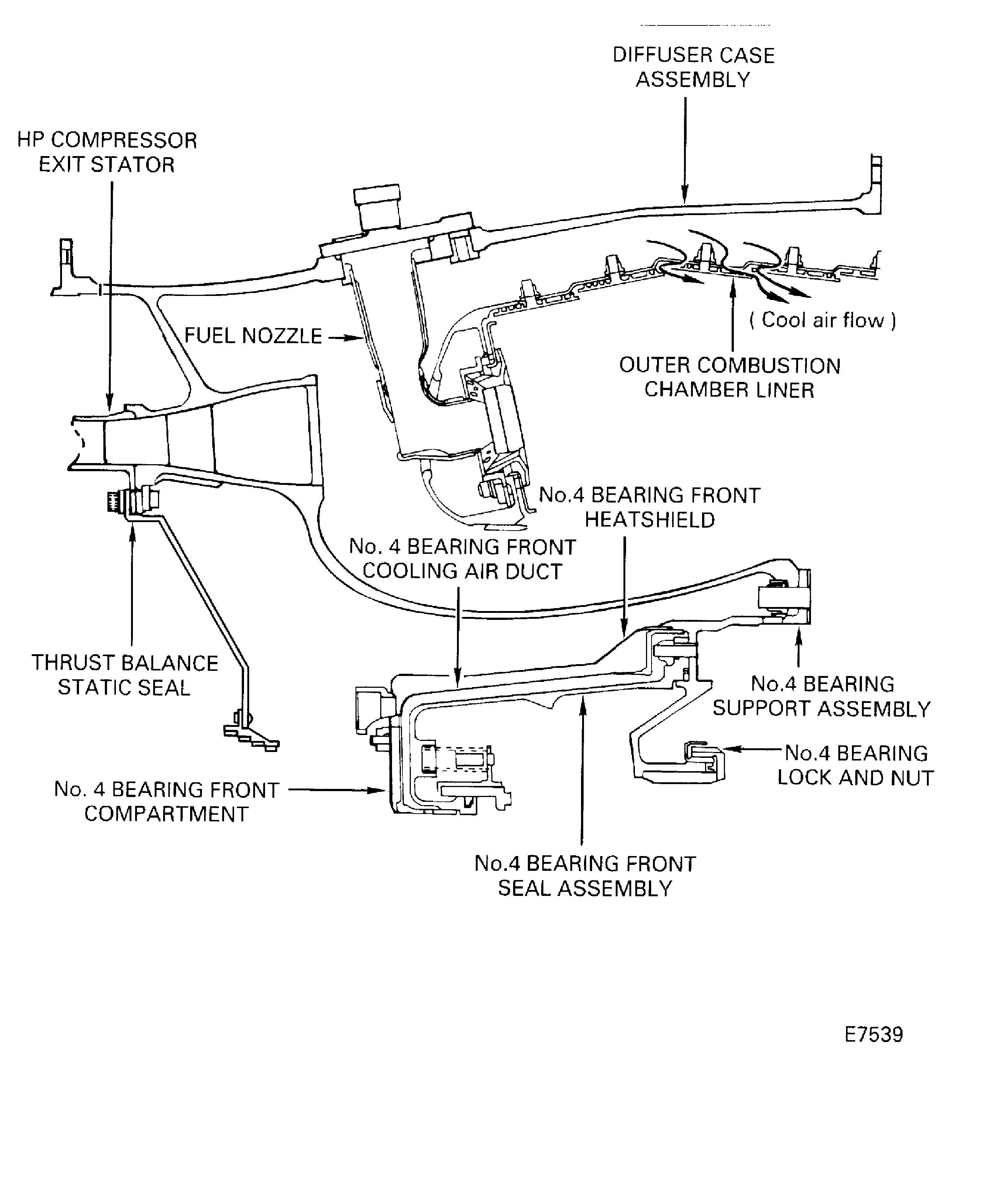

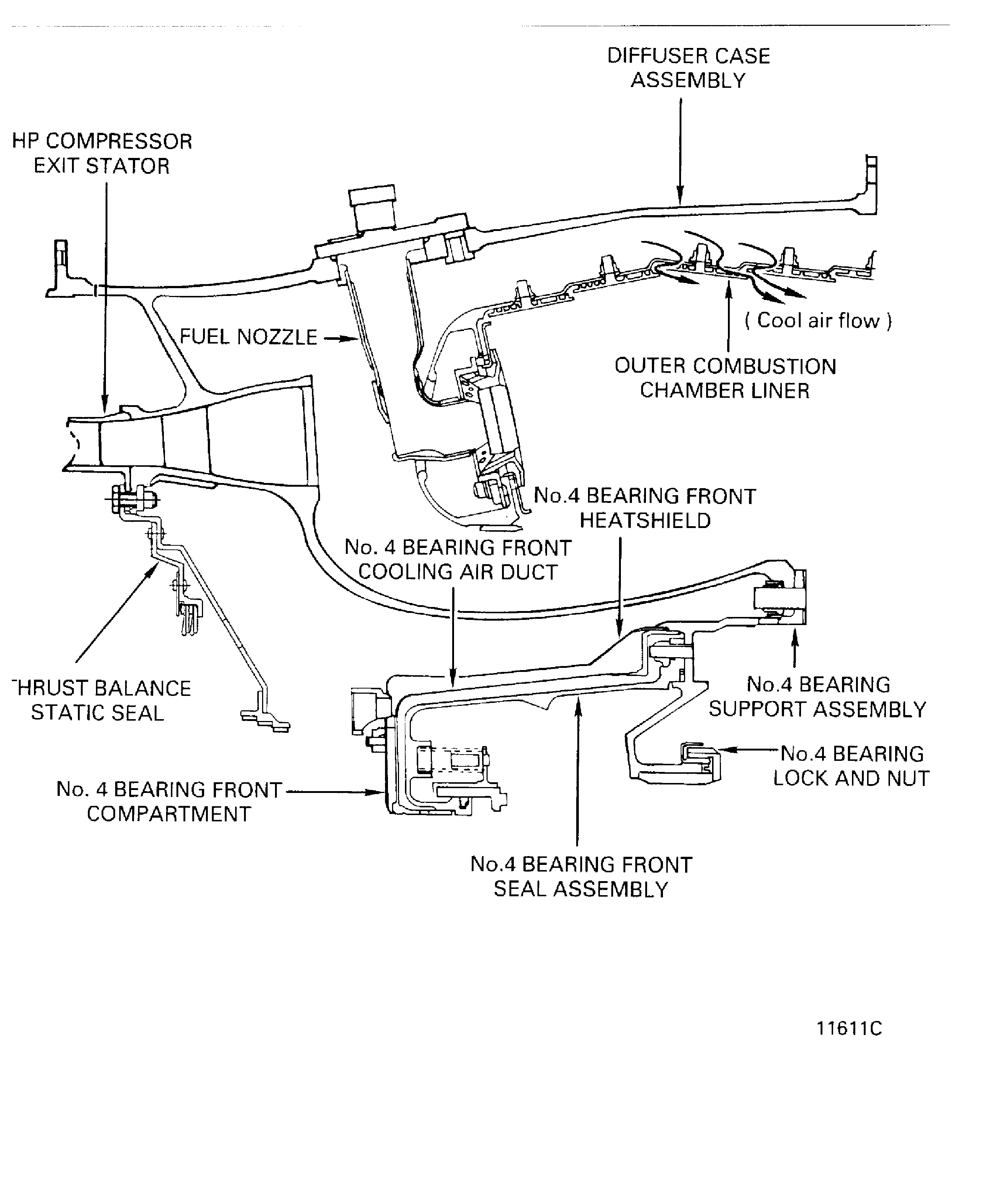

The diffuser case assembly is the primary structural part of the group. The diffuser case assembly extends from the rear flange of the rear HPC case to the front flange of the HPT case.

The diffuser case has 20 mounting pads where the fuel nozzles are installed, two mounting pads where the ignitor plugs are installed, and give borescope bosses located around the case.

The combustion chamber assembly includes the combustion chamber outer liner and five combustion chamber retaining bolts. When assembled with the combustion chamber inner liner assembly, which is attached to the turbine nozzle assembly, the two combustion chamber liner assemblies make a chamber for burning the mixture of fuel and air.

The front of the combustion chamber outer liner assembly has an aerodynamic contour with 20 fuel nozzle guides. The fuel nozzles install through the guides and into the combustion chamber.

The combustion chamber outer liner is a sheet-metal shell with 50 separate segment liners attached to the internal surface. If any segments become damaged, each one can be removed and replaced.

The No.4 bearing front compartment when assembled with the No.4 bearing and rear compartment, forms an insulated sealed area for bearing lubrication, support and protection from high temperatures.

The internal tubes include the tubes which carry oil and cooling air for the No.4 bearing and cooling air for the HP turbine.

The fuel distribution valve is installed at the front flange of the diffuser case.

Operation

The diffuser and combustion group has four primary functions.

Straighten the flow of air from the HP compressor.

Change the flow of air to get the best speed and pressure for combustion.

Mix fuel with the air and supply ignition to make the fuel burn.

Hold the No.4 bearing in position.

The diameter of the diffuser case is larger at the rear than at the front. This diametral difference decreases the speed of the air and changes the energy of the speed into pressure.

Fuel is mixed with the air in the combustion chamber and burned. The hot gases which result are directed back toward the turbine nozzle assembly. Cool air goes through the sheet-metal shell of the combustion chamber liners. This flow of air between the shell and segments helps prevent damage caused by high temperatures.

The fuel distribution valve receives fuel through a fuel line from the fuel metering unit. The fuel goes through a 200 micron strainer, into 10 internal discharge ports and then through the fuel manifolds to the fuel nozzles.

The fuel nozzles carry the fuel through a single orifice. The fuel is atomized by high-velocity air as it enters the combustion chamber. The fuel nozzle mixes the atomized mixture of fuel and air into the correct pattern for satisfactory combustion.

Module Sub-Assemblies

Listed below are the module build groups with the associated work groups (marked *). The work group level is where piece parts are cleaned, inspected and repaired/reworked:

SNS

Part

Location

Diffuser And Combustion Group Nomenclature

72-42-10

Diffuser case assembly and fittings

72-42-11

*

Diffuser case

72-42-20

*

No.4 bearing compartment tubes

72-42-30

No.4 bearing front compartment assembly

72-42-31

*

No.4 bearing support assembly

72-42-32

*

No.4 bearing lock and nut

72-42-33

*

No.4 bearing front seal assembly

72-42-34

*

No.4 bearing oil nozzle assembly

72-42-35

*

No.4 bearing front cooling duct

72-42-36

*

No.4 bearing front heatshield

72-42-40

HPC exit stator

72-42-50

HPC static air seal

72-42-60

Outer combustion chamber assembly

72-42-61

*

Combustion chamber outer liner

72-42-62

*

Combustion chamber retaining bolt

Figure: V2500 A1: Diffuser and combustion group

V2500 A1: Diffuser and combustion group

Figure: V2500 A5: Diffuser and combustion group

V2500 A5: Diffuser and combustion group