Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 72-43-00-990-501 Description and Operation of the No. 4 Bearing and Rear Compartment

Description

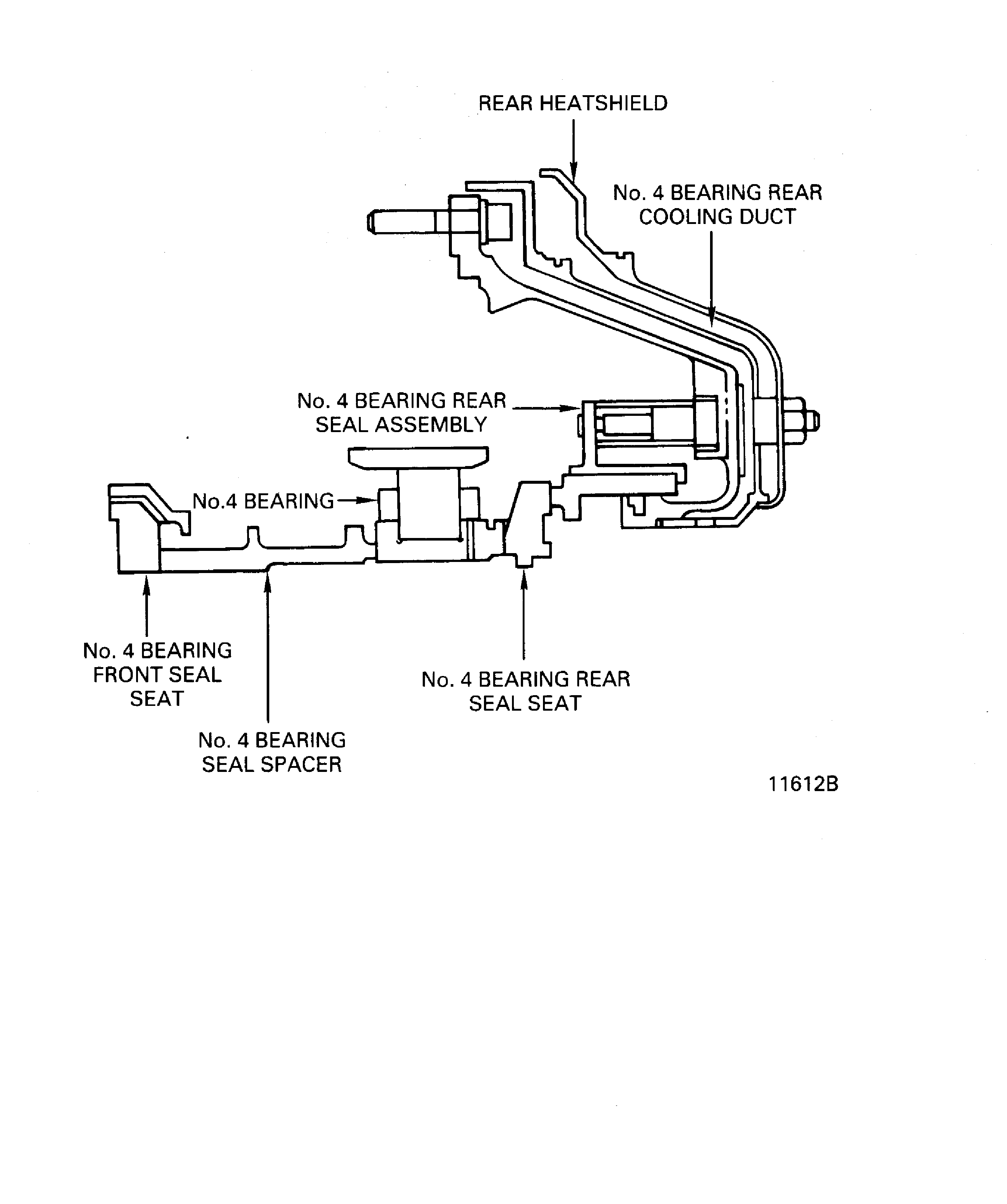

The primary parts of the No. 4 bearing and rear compartment assembly, refer to Figure, are:

No. 4 Bearing

No. 4 Bearing Seal Spacer

No. 4 Bearing Front and Rear Seal Seats

Rear Bearing Compartment

No. 4 Bearing Rear Seal Assembly

The related parts of the No. 4 Bearing Front Compartment are:

No. 4 Bearing Support Assembly

No. 4 Bearing Front Compartment

No. 4 Bearing Front Seal Assembly

The No. 4 bearing and rear compartment, when assembled with the No. 4 bearing front compartment, completes the assembly of the No. 4 bearing within an insulated and sealed area.

The No. 4 bearing is a cylindrical roller bearing. The inner race has shoulders which guide the rollers in the race. The outer race, installed in the No. 4 bearing support assembly, is machined elliptical so that the bearing rollers cannot skid. The outer race is held in the No. 4 bearing support assembly by a nut and key washer.

The front and rear bearing compartments are made of three separate walls. The walls form insulation chambers. The inner wall of each compartment forms a chamber with the middle wall, and carries cool air around the bearing area.

Oil for lubrication of the No. 4 bearing and the front and rear seals is supplied through a diffuser case internal tube which is attached to the No. 4 bearing front compartment.

Operation

Cool air comes from the HP compressor, and is carried into the No. 4 bearing front compartment through three diffuser case internal tubes. The outer wall of each bearing compartment, separated from the middle wall by an air space, forms a heatshield around each bearing compartment.

The cool air, carried to the No. 4 bearing front and rear compartment, also causes higher pressure in the compartment to keep out hot combustion chamber gases.

Passages in the compartment send oil into the bearing compartment. The oil is then sent to the No. 4 bearing and the carbon seal faces. Scavenge oil is carried away through another diffuser case internal tube.

The front and rear seal seats have oil-wetted surfaces for the front and rear carbon seals to seat against. The seal assemblies make a low-friction seal against the rotating seal seats. The seal effect is maintained by the pressure differential and the spring-loaded carbon seals.

The bearing forces are carried to the diffuser case through the No. 4 bearing support assembly.

The No. 4 bearing seal spacer holds the bearing in the correct axial location when installed on the HPC drive shaft.

In this way, the No. 4 bearing is provided with lubrication, support and protection from high temperatures.

Module Sub-Assemblies

Listed below is the breakdown of sub-assemblies within the module:

SNS

Part

Location

No. 4 Bearing And Rear Compartment Assembly Nomenclature

72-43-11

No. 4 bearing front seal seat

72-43-12

No. 4 bearing seal spacer

72-43-13

No. 4 bearing

72-43-14

No. 4 bearing rear seal seat

72-43-20

No. 4 bearing rear seal assembly

72-43-30

No. 4 bearing rear cooling duct and heatshield

Figure: No. 4 bearing and rear compartment

No. 4 bearing and rear compartment