Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

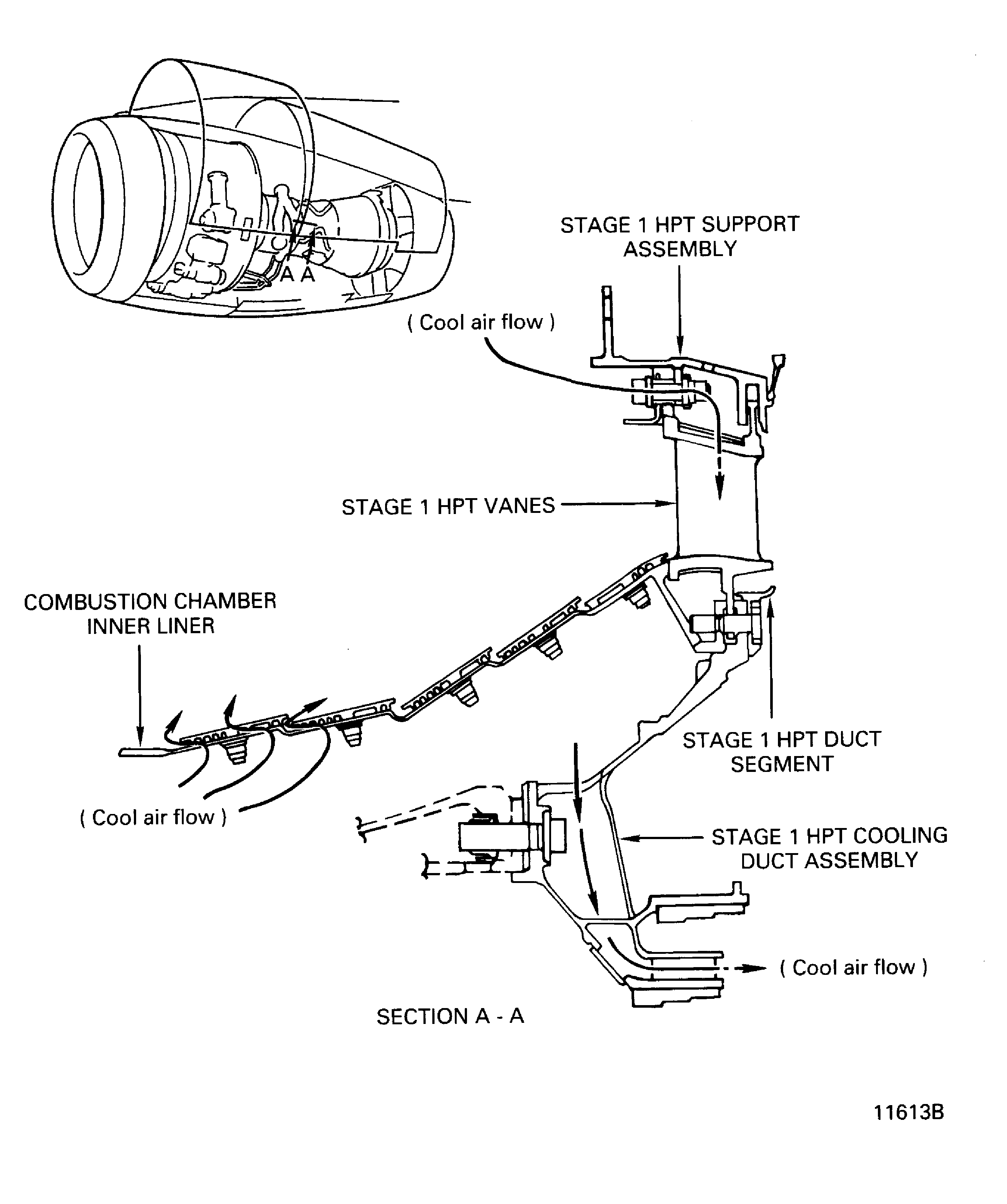

TASK 72-44-00-990-501 Description and Operation of the Stage 1 Turbine Nozzle Assembly

Description - Refer to Figure.

Stage 1 HPT Vane Cluster Assemblies

Stage 1 HPT Cooling Duct Assembly

Combustion Chamber Inner Liner

The stage 1 turbine nozzle assembly has 40 air-cooled vanes, made of cobalt alloy. The vanes are attached to the stage 1 HPT cooling duct assembly with bolts.

V2500-A1: The stage 1 vanes are assembled in 20 clusters of vane pairs. The pairs are bonded at the ID and OD buttresses. Each hollow vane has internal baffles, and cooling holes in the airfoil. Vane airfoils also have a heat-resistant coating.

V2500-A5: The stage 1 has 40 vanes, each hollow vane has internal baffles and cooling holes in the airfoil. Vane airfoils also have a heat-resistant coating.

The stage 1 vanes are held in position by the stage 1 HPT cooling duct assembly. The duct is installed on the rear-inner flange of the diffuser case.

The combustion chamber inner liner, when assembled with the outer combustion chamber liner assembly, makes a chamber for burning the mixture of fuel and air. It is a sheet metal shell with 50 separate liner segments attached to the internal surface. If any segments become damaged, each one can be removed and replaced.

Operation

The ring of vanes makes a series of nozzles which increases the velocity of the gases from the combustion chamber. The vanes point the gases at the correct angle onto the stage 1 turbine blades.

The internal vane baffles and airfoil cooling holes permit cool air from the diffuser case to go through the vane and over the external airfoil to decrease metal temperature. Sheet-metal seals between adjacent vane platforms decrease leakage of the cool air.

The stage 1 HPT cooling duct assembly carries the cool air from the diffuser case, and sends it through metered nozzles toward the stage 1 turbine rotor.

Cool air goes through the shell of the combustion chamber inner liner. The flow of air between the shell and segments helps prevent damage caused by high temperatures.

Module Sub - Assemblies

Listed below are the module build groups with the associated work groups (marked *). The work group level is where piece parts are cleaned, inspected and repaired/reworked.

SNS | Part | |

|---|---|---|

Location | HP Turbine (HPT) Stage 1 Nozzle Nomenclature | |

72-44-10 | HPT stage 1 support assembly | |

72-44-20 | HPT stage 1 vane cluster assembly | |

72-44-30 | Inner combustion chamber assembly and liner | |

72-44-40 | HPT stage 1 outer seal | |

72-44-50 | * | HPT stage 1 cooling duct |

72-44-60 | * | HPT stage 1 duct segment |

Figure: HP Turbine (HPT) Stage 1 Nozzle

HP Turbine (HPT) Stage 1 Nozzle