Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-30-300-017 Inner Combustion Chamber Liner - Size or Roll To Restore The Rear Inside Diameter, Repair-017 (VRS3628)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-401 | 2A0549-01 |

01-401 | 2A1374 |

01-401 | 2A1398 |

01-401 | 2A1617 |

01-401 | 2A2034 |

01-401 | 2A2034-001 |

01-401 | 2A2722-01 |

01-401 | 2A2838-01 |

01-401 | 2A3344-01 |

01-401 | 2A3344-001 |

01-401 | 2A3344-002 |

01-401 | 2A3344-003 |

01-401 | 2A3344-004 |

01-401 | 2A3344-005 |

01-401 | 2A3344-006 |

01-401 | 2A3344-007 |

01-401 | 2A3351-01 |

01-401 | 2A3351-003 |

01-401 | 2A3351-004 |

01-401 | 2A4283-01 |

01-401 | 2A4311-01 |

01-401 | 2A4313-01 |

01-401 | 2A4315-01 |

01-401 | 2A4315-001 |

01-420 | 2A2718-01 |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Combustion chamber inner liner | - | Wrought non-hardenable nickel base alloy |

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK number are in SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Pneumatic or electric nut splitter | LOCAL | Pneumatic or electric nut splitter | ||

| IAE 3P16238 Angle box wrench | 0AM53 | IAE 3P16238 | ||

| IAE 3P16239 Ratchet wrench | 0AM53 | IAE 3P16239 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER | 53012 | CoMat 07-175 | ||

| CoMat 10-049 MOLYBDENUM DISULFIDE | 71984 | CoMat 10-049 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Nut | LOCAL | 4W0001 | As required | |

| Gang nut channel | 2A1009-01 | As required |

Safety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-44-30-350-089 Remove the Liner Segments from the Combustion Chamber Inner Liner

Refer to Repair 003, VRS3264 V2500-A0-72-44-3001-00A-920A-C.

Remove the gang nut channels.

SUBTASK 72-44-30-350-090 Remove the Gang Nut Channels from the Inner Liner

Refer to Figure

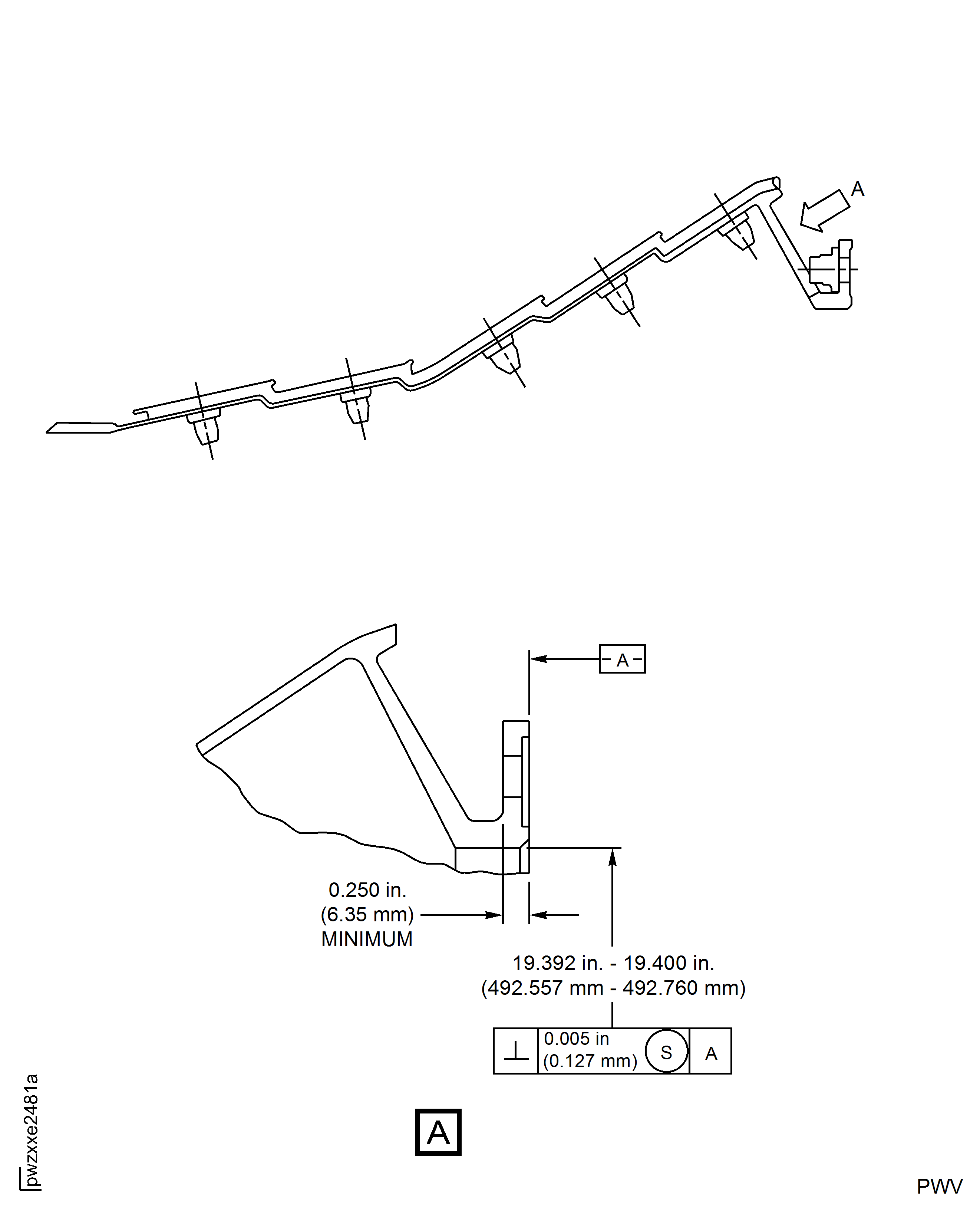

SUBTASK 72-44-30-350-091-002 Roll to Restore the Rear Inside Diameter Seal Diameter of the Combustion Chamber Inner Liner

Refer to Figure

SUBTASK 72-44-30-230-056 Examine the Shell after Sizing or Rolling

Refer to TASK 72-44-30-200-000 (INSPECTION/CHECK-000).

Examine rear inside diameter seal for coating after sizing or rolling.

SUBTASK 72-44-30-220-087 Examine the Rear Inside Diameter Seal of the Combustion Chamber Inner Liner

Refer to Repair 003, VRS3264 V2500-A0-72-44-3001-00A-920A-C.

Install gang nut channels.

SUBTASK 72-44-30-350-092 Replace the Gang Nut Channels in the Inner Liner

Install oval-shaped washers with dimple facing to the liner shell and seated in slot.

If engine oil is preferred on Rows 2 thru 5 liner segments, apply engine oil on the stud threads. Do not use engine oil on Row 1 liner segment stud threads.

Install the nuts with IAE 3P16238 Angle box wrench (angle box wrench) 1 off.

Torque the segment's center stud first followed by the two adjacent studs then the segment's two outer-most studs. Tighten nuts down on the stud between 40 to 50 lbfin (4.519 to 5.649 Nm) of torque and make sure that the washer is not free to move. Back the nut off one-half turn, then use IAE 3P16239 Ratchet wrench (ratchet wrench) 1 off to torque the nut to 25 to 35 lbfin (2.824 to 3.954 Nm).

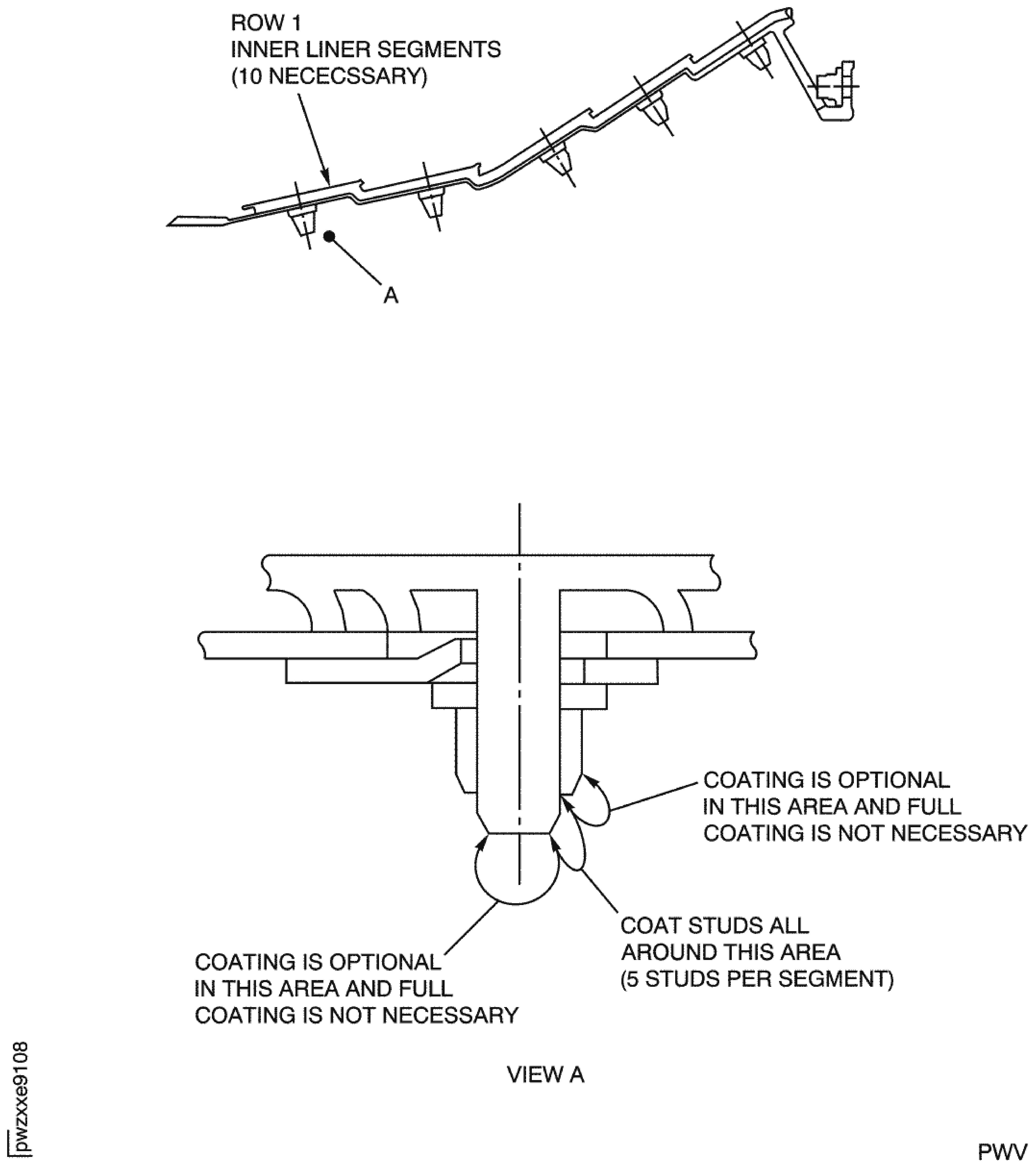

Apply CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER coating compound on the threaded studs of the Row 1 liner segments, use a small artists brush. Full coverage is necessary, but there is no thickness limit. Refer to Figure for coating application.

If engine oil was not used on liner segments Row 2 thru 5, apply CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER on the threaded studs using a small artist's brush. Complete coverage is necessary but there is no thickness requirement. Refer to Figure as a reference for coating application.

CAUTION

DO NOT USE CoMat 10-049 MOLYBDENUM DISULFIDE TO LUBRICATE THE NUT THREADS. MOLYBDENUM DISULFIDE CAN CAUSE CORROSION.

CAUTION

DO NOT USE ENGINE OIL AND COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER ON THE SAME STUDS.

CAUTION

IT IS REQUIRED TO USE COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER ON ROW 1 LINER SEGMENTS AFTER FINAL TORQUE THE NUTS. DO NOT USE COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER ON ALL THE STUD THREADS DURING INSTALLATION.

CAUTION

COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER IS OPTIONAL ON OTHER LINER SEGMENTS (ROWS 2 THRU 5). HOWEVER, DO NOT USE COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER IF ENGINE OIL WAS ALREADY APPLIED ON THE STUD THREADS.

CAUTION

IF COATING CoMat 07-175 COATING COMPOUND - ALUMINUM, INORGANIC BINDER WAS USED IN LINER SEGMENTS, LIGHTLY USE A STAINLESS STEEL WIRE BRUSH TO REMOVE LOOSE DEBRIS BEFORE NEW COATING.Install liner segments that you removed from back to front with washers and new nuts.

SUBTASK 72-44-30-350-093 Install the Liner Segments

Figure: Repair Details and Dimensions

Repair Details and Dimensions

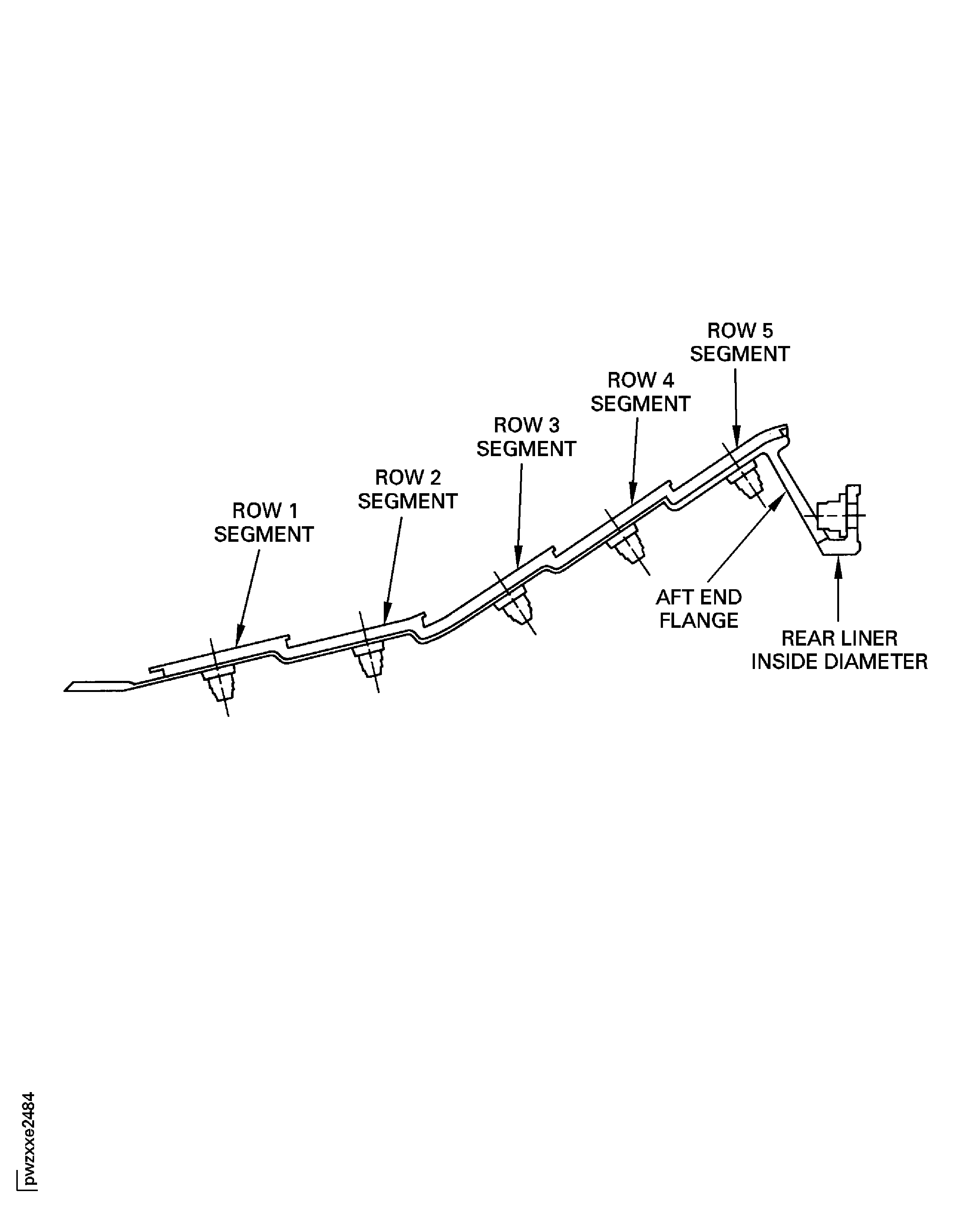

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions