Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 72-45-00-990-501 HP Turbine (HPT) Stage 1 Rotor And Stator Assembly

Description

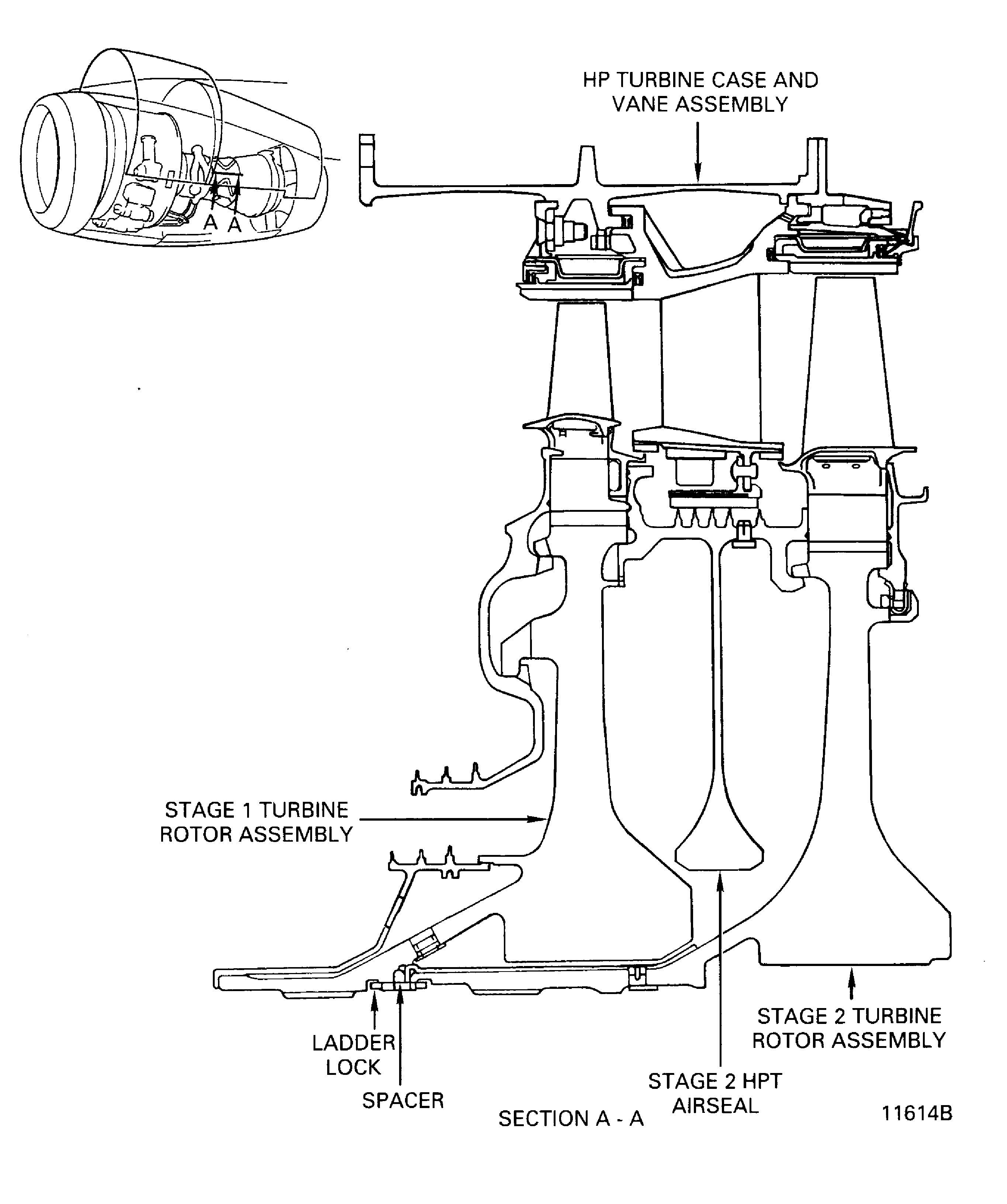

The primary parts of the HP turbine (HPT) rotor and stator assembly, refer to Figure, are:

HPT Rotor Assemblies (Stage 1 and Stage 2)

HPT Case and Vane Assembly

The HPT rotor assemblies are two stages of turbine hubs with single-crystal, nickel-alloy blades. The two-hub configuration removes a bolt flange between hubs. This decreases weight and make assembly faster. The blades have airfoils with high strength and resistance to creep. Satisfactory blade tip clearances are supplied by active clearance control (ACC) to cool the case with compressor air.

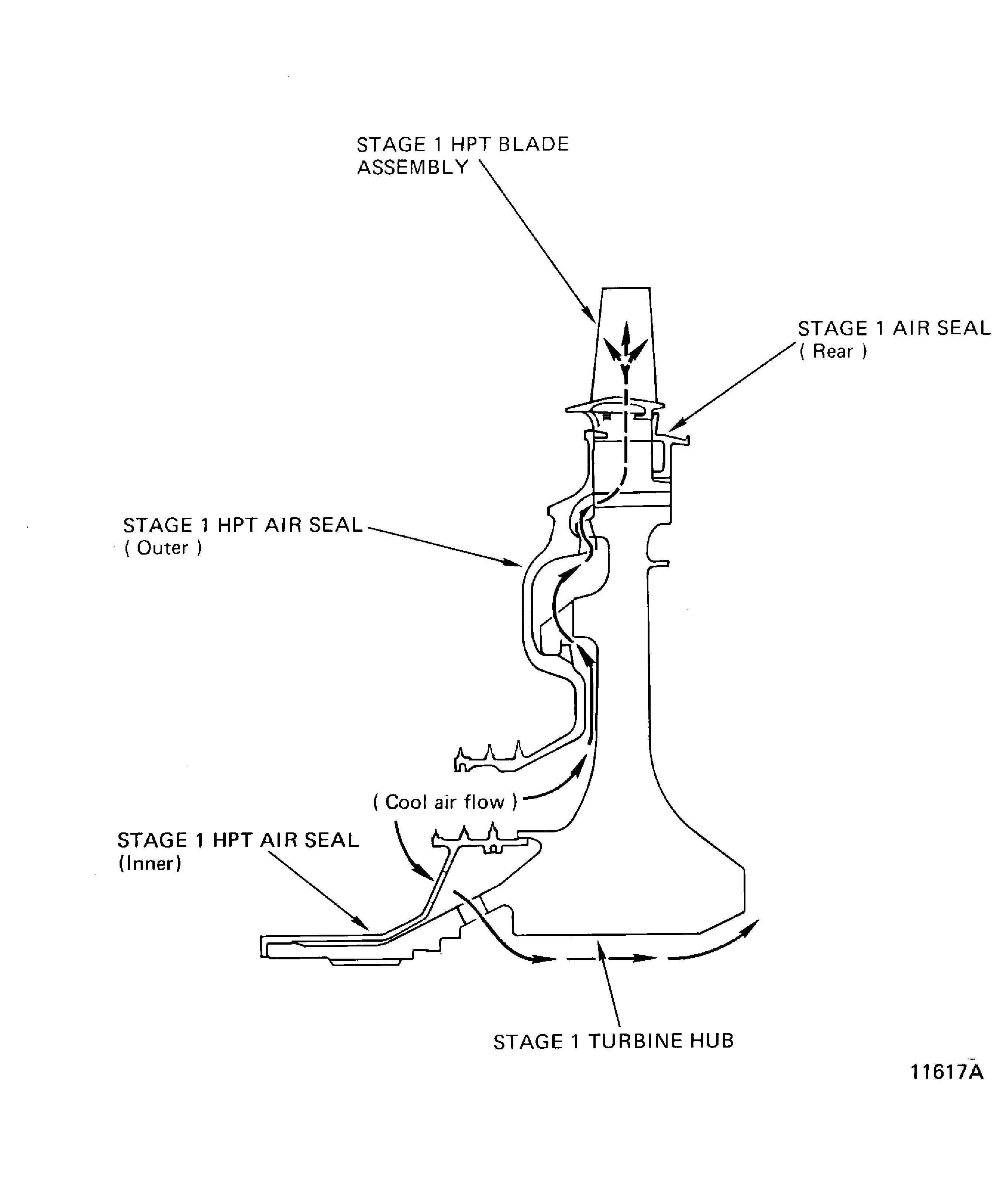

The primary parts of the HPT stage 1 rotor assembly, refer to Figure, are:

HPT Stage 1 Turbine Hub

HPT Inner and Outer Air Seals

68 HPT Stage 1 Blades

HPT Rear Air Seal

The primary parts of the HPT stage 2 rotor assembly, refer to Figure, are:

HPT Stage 2 Turbine Hub

72 HPT Stage 2 Blades

HPT Stage 2 Blade Retaining Plate

The inner and outer HPT air seals are installed on the front of the stage 1 hub. The stage 1 blades are installed in slots on the hub. The blades are held on the forward side by the outer HPT air seal. The stage 2 HPT air seal is installed on the rear of the stage 1 hub. This air seal holds the stage 1 blades on the rear side.

The stage 2 turbine hub is installed behind the stage 1 hub and the stage 2 HPT air seal. Stage 2 blades are installed in slots in the hub. The blades are held on the forward side by the stage 2 HPT air seal. The blades are held on the rear side by the stage 2 blade retaining plate.

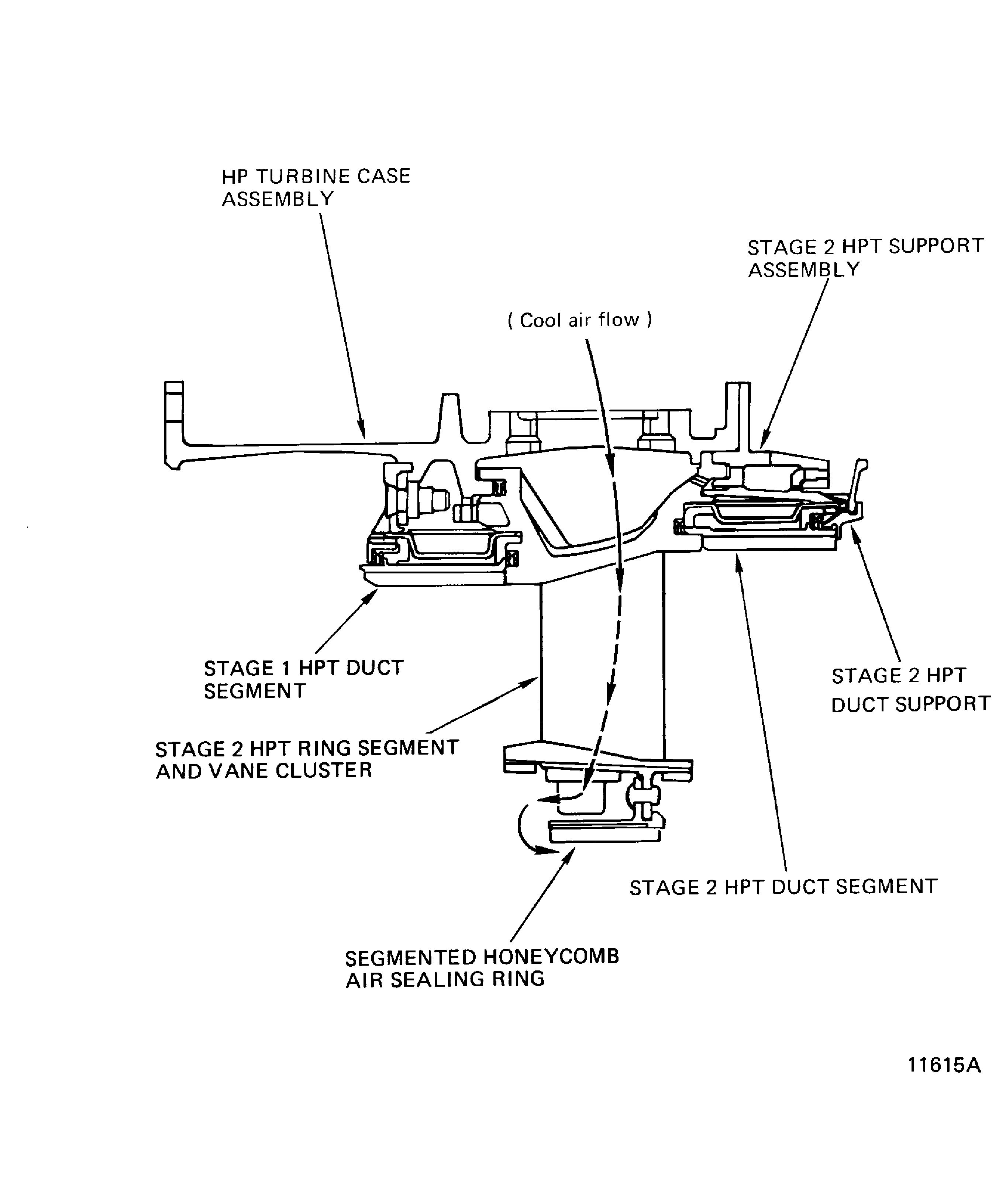

The primary parts of the HP turbine case and vane assembly, refer to Figure, are:

HPT Case Assembly

HPT Duct Support Set (Stage 1)

Stage 1 and 2 HPT Duct Segments

Stage 2 HPT Ring Segment and Vane Cluster

Stage 2 HPT Duct Support

Stage 2 HPT Support Assembly

The turbine case has internal flanges to hold the vane clusters and the HPT stage 1 duct support set.

The HPT stage 1 duct support set holds the HPT stage 1 duct segments in position at the front side. The rear side of the duct segments are held by the vane clusters.

The HPT stage 2 duct segments are held in position at the front side by the vanes. Two supports hold the vanes and duct segments at the rear.

The HPT stage 1 and 2 duct segments have an abradable ceramic coating. They are assembled in sets for each stage. Sheet-metal seals are installed between the segments.

The stage 2 air-cooled vanes are assembled in clusters of two vanes. Segmented honeycomb air sealing rings on the vane inner shrouds are in alignment with knife-edges of the HPT stage 2 air seal. The vanes are installed into flanges inside the case. Segmented sheet-metal seals are installed between adjacent clusters.

Operation

The HPT rotor and stator assembly uses the energy of the combustion gases to supply movement to the HP compressor (HPC).

Honeycomb seals on the ID end of the vane platform, along with knife-edge seals on the HPT stage 1 (rear) air seal and HPT stage 2 blades, prevent gas-path leakage. The sheet-metal seals installed between duct segments and vane clusters also prevent gas leakage.

All of the HPT airfoils are cooled by air flow.

The HPT stage 1 blades are cooled by the HPC discharge air which flows through the HPT stage 1 cooling duct assembly.

The HPT stage 2 vane clusters are cooled by HPC stage 10 air. Air flows into the case, through the center of each vane, and then outward into the turbine area and the gas-path. Some of this air is used to cool the HPT stage 2 air seal.

HPT stage 2 blade cooling air is a mixture of HPC discharge air and HPC stage 10 compressor air. This air moves through holes in the HPT stage 1 (front inner) air seal and the HPT stage 1 hub into the area between the hubs. The air then goes into the HPT stage 2 blade root and out the trailing-edge cooling holes.

The abradable duct segments and abrasive blade tips, along with active clearance control (ACC), refer to Figure, keep tight blade tip clearances for better performance. The abrasive/abradable system makes tight clearances because the parts are permitted to rub. The abrasive decreases blade tip wear during rub.

Active clearance control (ACC) tubes around the turbine case supply fan discharge air to cool the surface of the case during climb and cruise-power operation. This results in shrinkage of the case and decreased blade tip clearances.

Module Sub-Assemble

Listed below is the breakdown of sub-assemblies within the module:

SNS | Part | |

|---|---|---|

Location | HP Turbine (HPT) Stage 1 Rotor And Stator Assembly Nomenclature | |

72-45-10 | HPT stage 1 rotor assembly | |

72-45-11 | HPT stage 1 hub | |

72-45-12 | HPT stage 1 outer air seal | |

72-45-13 | HPT stage 1 inner air seal | |

72-45-14 | HPT stage 1 blade | |

72-45-15 | HPT stage 1 rear air seal | |

72-45-20 | HPT case and vane assembly | |

72-45-21 | HPT case | |

72-45-22 | HPT stage 1 duct support set | |

72-45-23 | HPT stage 1 duct segment | |

72-45-24 | HPT stage 2 ring segment and vane cluster | |

72-45-25 | HPT stage 2 duct segment | |

72-45-26 | HPT stage 2 duct support | |

72-45-27 | HPT stage 2 support assembly | |

72-45-30 | HPT stage 2 rotor assembly | |

72-45-31 | HPT stage 2 hub | |

72-45-32 | HPT stage 2 blade | |

72-45-33 | HPT stage 2 blade retaining plate |

Figure: HP turbine rotor and stator assembly

HP turbine rotor and stator assembly

Figure: Stage 1 HP turbine rotor assembly

Stage 1 HP turbine rotor assembly

Figure: Stage 2 HP turbine rotor assembly

Stage 2 HP turbine rotor assembly

Figure: HP turbine case and vane assembly

HP turbine case and vane assembly

Figure: HP turbine blade tip clearance control

HP turbine blade tip clearance control