Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-20-200-001-C00 HPT Case And Vane Assembly - Examine, Inspection-001 - SBE 72-0522

General

The word "reject" is used after an interface inspection statement to show that a higher level inspection and possible repair to the damaged part is necessary.

Do the higher level inspection procedure as found in the applicable Chapter/Section/Subject of this manual on the damaged part(s). It is not necessary to do the higher level inspection on parts that are serviceable to the interface inspection standard.

All parts must be visually examined for damage, corrosion and wear. All defects (distress, missing hardware etc.) that are not identified in the procedure must be documented and referred to IAE Technical Services.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

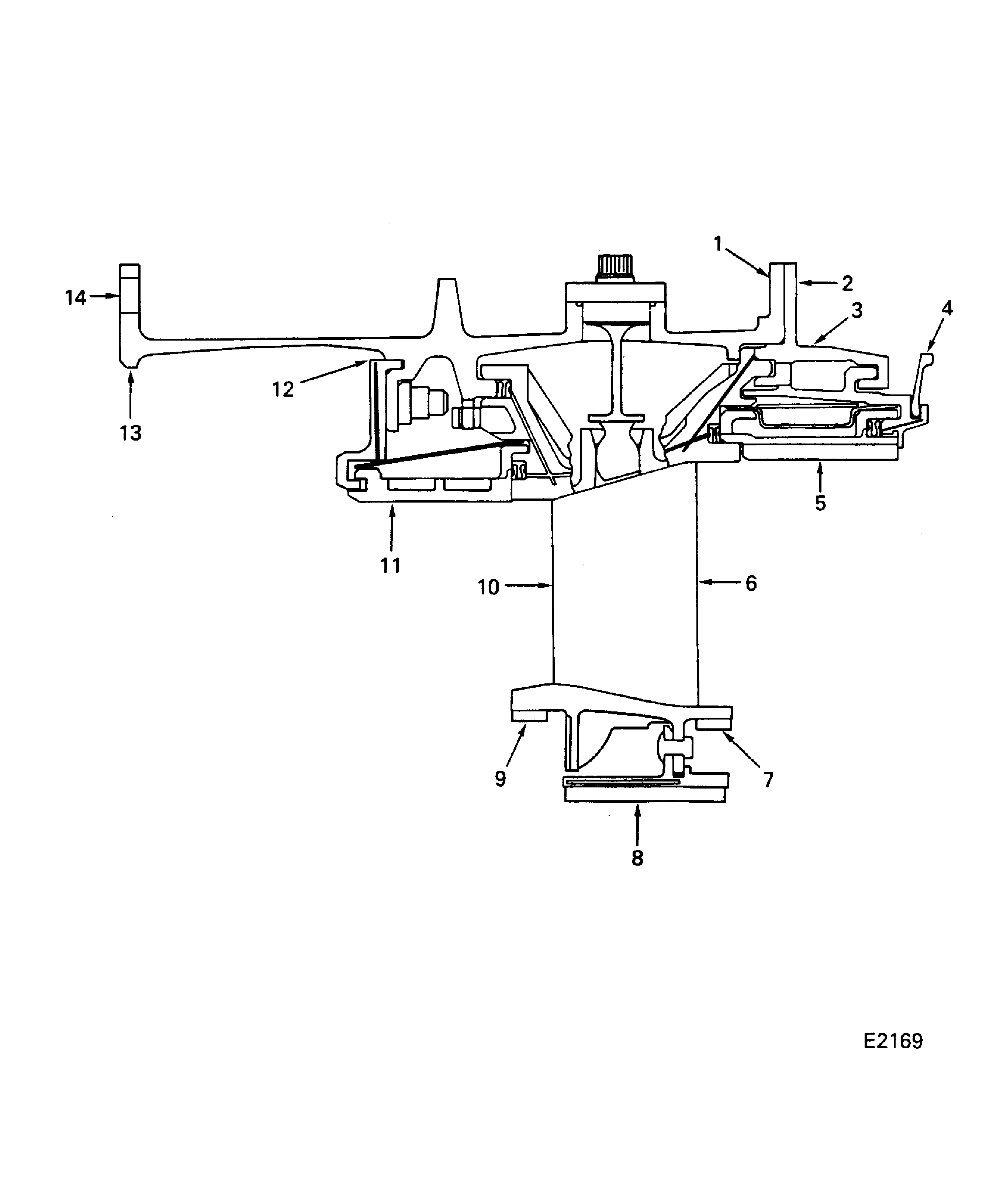

Refer to Figure.

SUBTASK 72-45-20-220-109 Visually Examine the Outer Flange at Location 1

Refer to Figure.

SUBTASK 72-45-20-220-110 Visually Examine the Support Assembly Outer Flange Bolt Holes at Location 2

Refer to Figure.

SUBTASK 72-45-20-220-111 Visually Examine the Support Assembly Outer Flange at Location 3

Refer to Figure.

SUBTASK 72-45-20-220-112 Visually Examine the Rear Turbine Seal of the Stage 2 Turbine Nozzle Assembly at Location 4

Refer to Figure.

SUBTASK 72-45-20-220-113 Visually Examine the Stage 2 Ceramic Outer Airseals at Location 5

Refer to Figure.

SUBTASK 72-45-20-220-114 Measure the Diameter of the Stage 2 Ceramic Outer Airseals at Location 5

One or more cracks not more than 0.500 in. (12.7 mm) in length on the airfoil and platforms. Cracks not more than 0.750 in. (19.05 mm) in length are permitted on vanes that are not adjacent. Cracks on the airfoil must be less than 0.050 in. (1.27 mm) wide. Platform cracks must be tight with no burning. The cracks do not make a closed loop and do not look like they will make a closed loop.

SUBTASK 72-45-20-220-115 Visually Examine the Stage 2 Turbine Vane at Locations 6 and 10

Refer to Figure.

SUBTASK 72-45-20-220-116 Visually Examine the Honeycomb Seal Land at Location 7

Refer to Figure.

SUBTASK 72-45-20-220-117 Visually Examine the Honeycomb Seal Lands at Location 9

Refer to Figure.

SUBTASK 72-45-20-220-118 Visually Examine the Honeycomb Seal Lands at Location 8

Refer to Figure.

SUBTASK 72-45-20-220-119 Visually Examine the Stage 1 Ceramic Outer Airseals at Location 11

Refer to Figure.

SUBTASK 72-45-20-220-120 Measure the Diameter of the Stage 1 Ceramic Outer Airseals at Location 11

Refer to Figure.

SUBTASK 72-45-20-220-121 Visually Examine the Hardface on the Outer Airseal Supports at Location 12

Refer to Figure.

SUBTASK 72-45-20-220-122 Visually Examine the Surface of the Case at Location 13

Refer to Figure.

SUBTASK 72-45-20-220-123 Visually Examine the Case Outer Flange and the Flange Bolt Holes at Location 14

Refer to Figure.

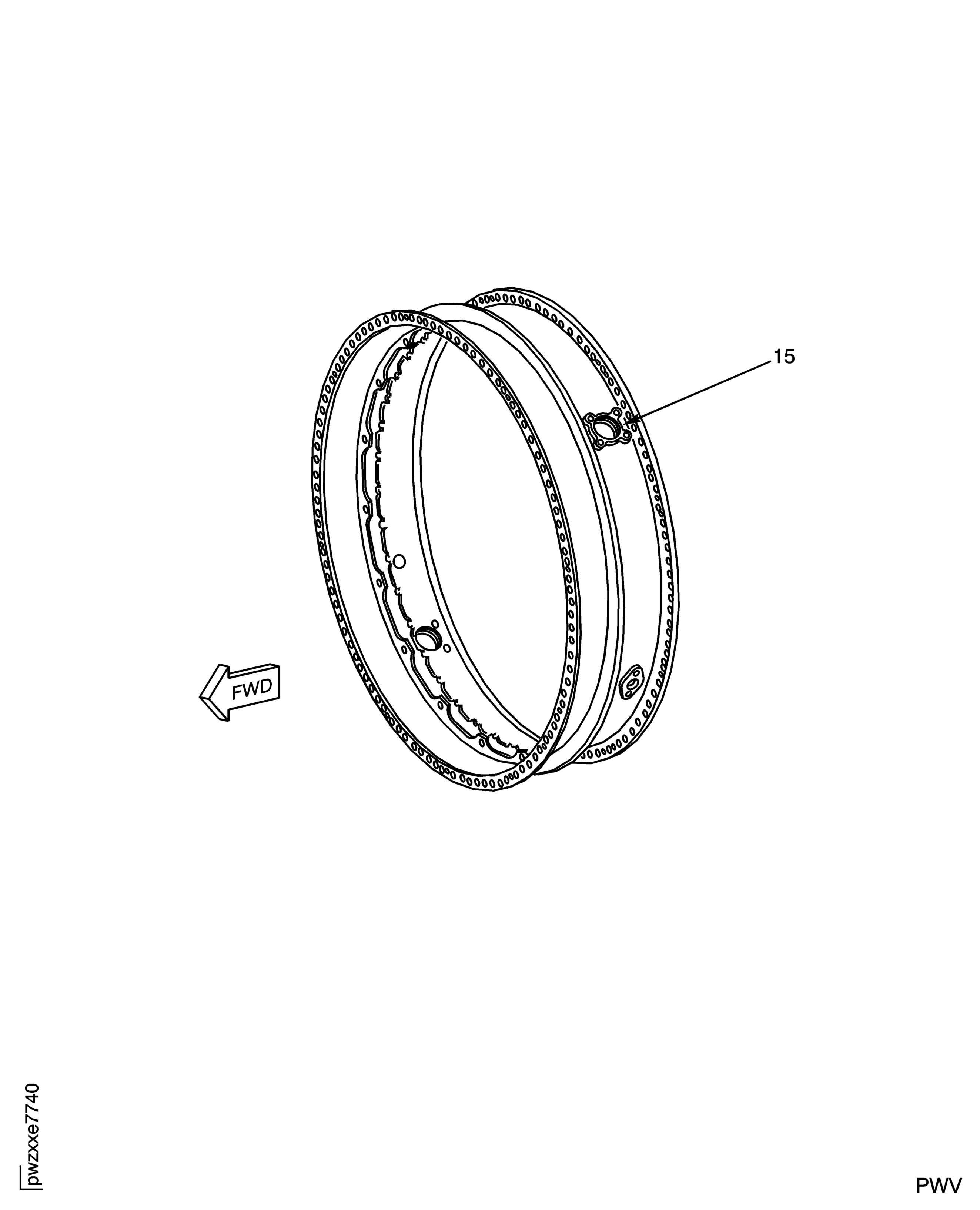

SUBTASK 72-45-20-220-124 Measure the Diameter of the Orifice Plates in the Turbine Cooling Air Bosses at Location 15

Figure: HP Turbine Case and Vane Assembly Inspection Locations

Sheet 1

Figure: HP Turbine Case and Vane Assembly Inspection Locations

Sheet 2