Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-31-300-009 HPT Stage 2 Hub - Machine Repair The Axial Length, Repair-009 (VRS3510)

General

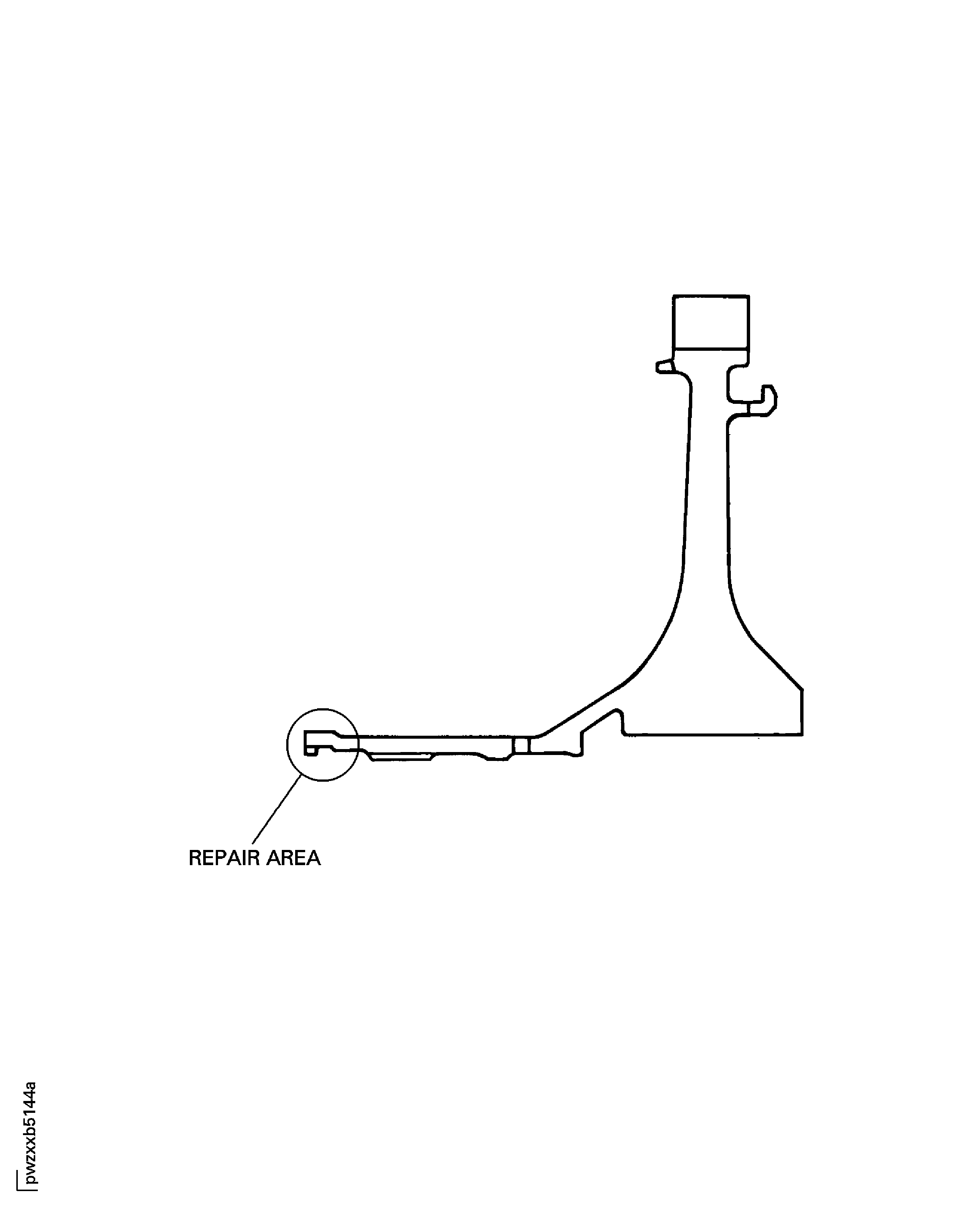

Refer to Figurefor the areas that are to be repaired.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

CAUTION

Procedure

The Source Demonstration requirements of this repair mean that any facility not authorized to accomplish this repair either utilize the Authorized Repair Vendors listed below or contact IAE Manager Maintenance Operations to determine if a qualification program can be initiated at their facility.

IAE - INTERNATIONAL AERO ENGINES AG

400 Main Street M/S 121-10

East Hartford

CT 06108 USA

ATTN: Manager Maintenance Operations

Authorized Repair Vendors for the Machine section of Repair VRS3510 are listed below:

PRATT AND WHITNEY EAGLE SERVICES

East Hartford Engine and Component Center

400 Main Street

East Hartford, CT 06108 - 0969

USA

Well No.14

Turbine Component Repair

Caval Tool Division

655 New Britain Ave.

Newington, CT 06131 USA

MTU - Maintenance GmbH

Airport Hannover

Munchner Strasse 31

30855 Langenhagen Germany

Ishikawajima - Harima Heavy Industries Co., Ltd.

Mizuho - Machi

Nishitama - Gun

Tokyo 190 - 12,

JAPAN

Attn: Program Manager, V2500

The designation by IAE of an authorized repair vendor indicates that the repair vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the repair vendors to carry out the repair work, and accepts no responsibility whatsoever for any work that may be carried out by a repair vendor, other than when IAE is listed as the repair vendor. Authorized repair vendors do not act as agents or representatives of IAE.

Repair Facilities

Figure: Stage 2 turbine hub machine repair areas

Stage 2 turbine hub machine repair areas