Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 72-50-00-990-501 Description and Operation of the LP Turbine Module

Description

The LP turbine (LPT) has a five stage rotor which supplies power to the LP compressor (LPC) through the LPT shaft. The LPT rotor is installed in the LPT case where it is in alignment with the LPT stators. The LPT case is made from high-heat resistant nickel alloy and is a one part, welded assembly. To identify the LPT module, an identification plate is attached to the LPT case at the 136 degrees position.

The LPT case has two borescope inspection ports at 125.27 and 237.10 degrees. The ports are used to internally examine the adjacent engine sections:

Trailing Edge (TE), HPT Stage 2 Blades

Leading Edge (LE), LPT Stage 3Blades

Trailing Edge (TE), LPT Stage 3 Blades

NOTE

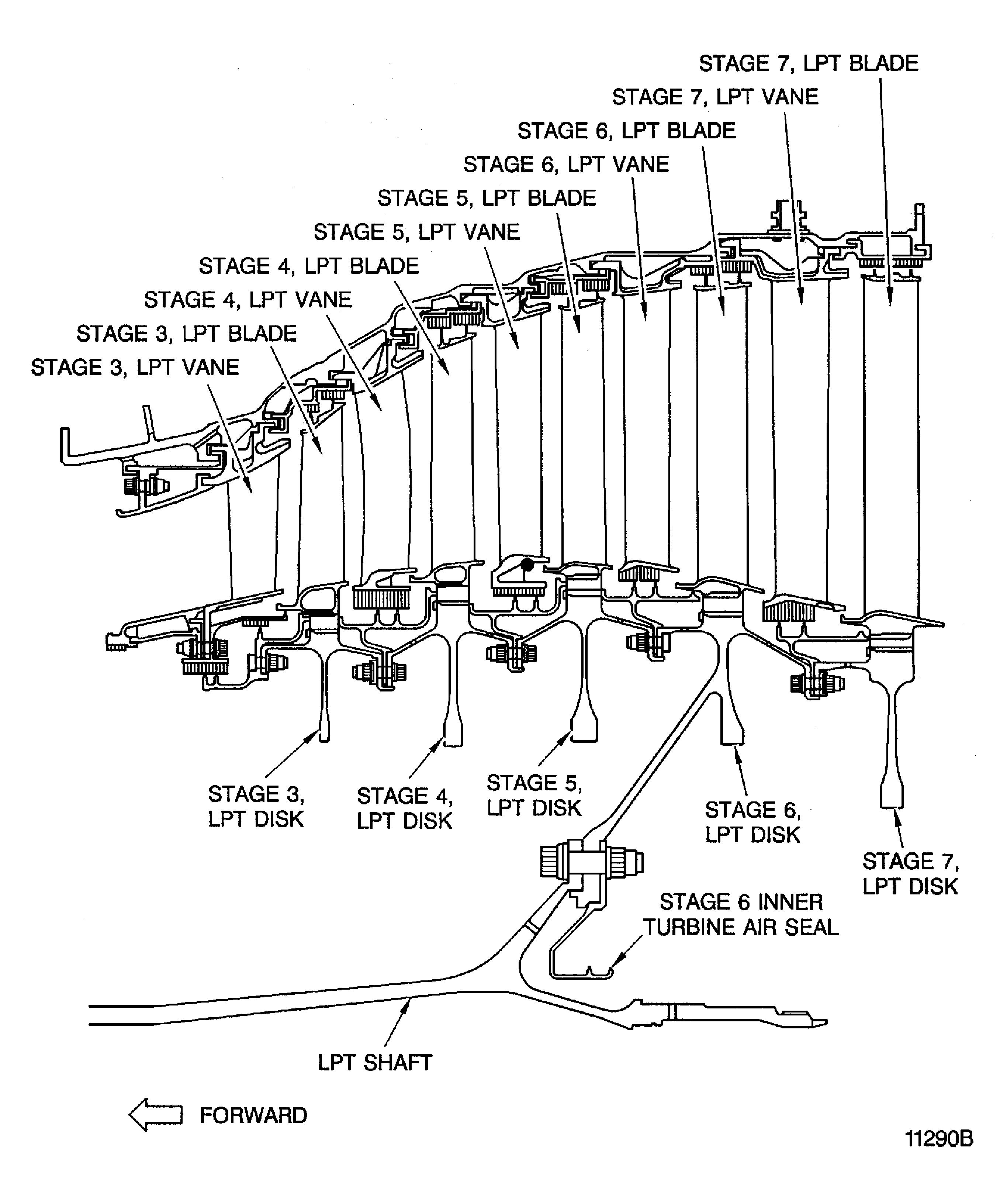

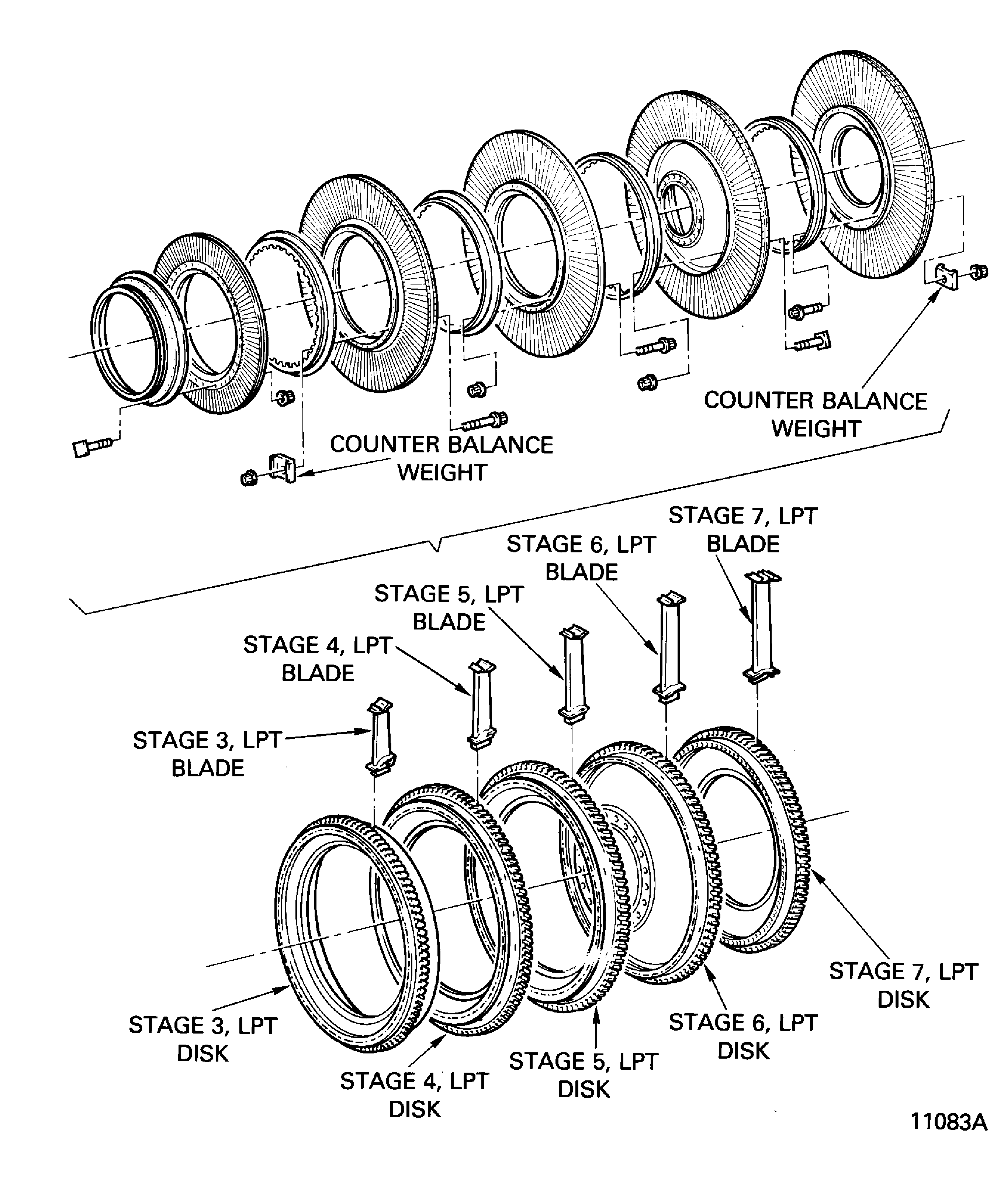

For technical data of the LPT module, refer to Figure.The five LPT disks, refer to Fig 72-50-00-990-004, are made from high heat resistant nickel alloy. The LPT blades are also made from nickel alloy and are attached to the disks by fir-tree roots. The blades are held in axial position on the disk by the rotating air seals (knife edge).

The five LPT disks are axially installed and are assembled together with bolts and nuts. The stage 6 disk is attached with twenty bolts and nuts to the outside diameter flange of the LPT shaft. With the same bolts and nuts, the stage 6 inner airseal is attached to the rear flange of the stage 6 disk. The rotating air seals are located between the adjacent disks. These seals are in line with abradable seals, which are installed on the inner diameter of the LPT stator vanes. The stage 3 air seal is attached with bolts to the front face of the LPT stage 3 disk.

V2500-A1: The turbine blades are installed in axial, dovetail slots of the fir-tree root type. The blades are held in position on the disks by the rear edges of the air seals. The LPT blades are solid and have inner platforms. These are extended axially to provide effective gas-path sealing. Stage 3 turbine blades have an aluminized coating, the remaining turbine blades are uncoated. The outer shroud seals of the turbine blades have interlocking hard faced notches which prevent vibration. The airfoils are made for a minimum weight.

V2500-A5: The turbine blades are installed in axial, dovetail slots of the fir-tree root type. The blades are held in position on the disks by the rear edges of the air seals. The LPT blades are solid and have inner platforms. These are extended axially to provide effective gas-path sealing. Stage 3 and 4 turbine blades have an aluminized coating, the remaining turbine blades are uncoated. The outer shroud seals of the turbine blades have interlocking hard faced notches which prevent vibration. The airfoils are made for a minimum weight.

The parts of the LPT rotor are pre-balanced when installed to the LPT. The balance procedures applied to the parts of the LPT rotor before installation are specified below:

Disks, stages 3 to 7 are balanced by the removal of material.

Rotating air seals are balanced by the removal of material.

All rotor blades are moment weighted.

Assembled disks are balanced by blade selection.

The complete LPT rotor is balanced after assembly of the LPT case and rotor with counterweights (installed on stages 3/4 and 6/7).

After assembly of the LPT, the LP shaft and the stage 6 inner airseal, no balance action is necessary.

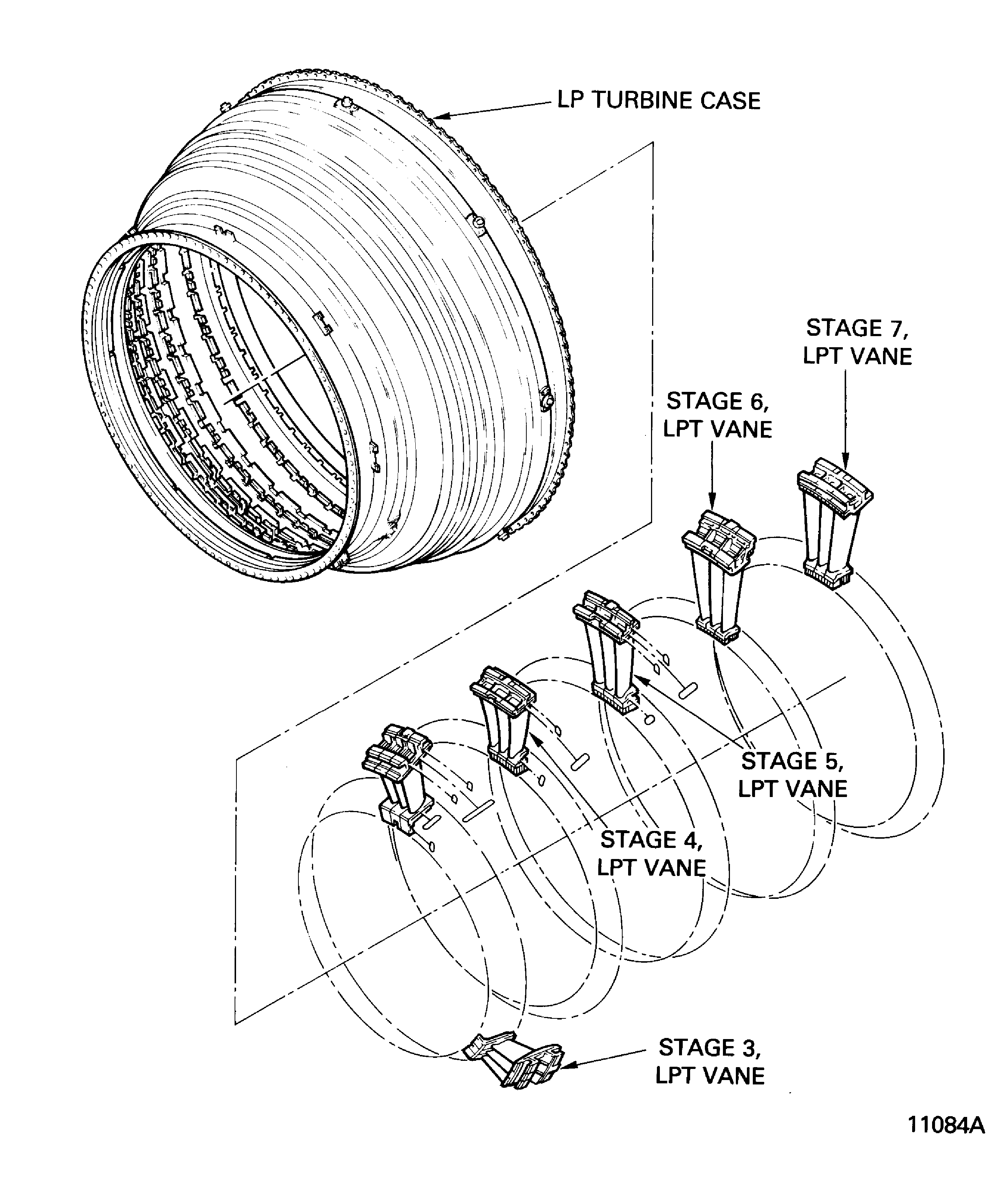

The LPT stator vanes are made of nickel alloy and are assembled in clusters of three vanes. They are installed on internal flanges in the LPT case. They are held in position on the flanges by the outside diameter shroud seal segments which are located between the stator stages.

The clusters of vanes are assembled between the front and rear buttress flanges. The rear vane roots have hooks which engage into the LPT case slots. The inner vane diameter has brazed-in shroud seal segments which will tolerate the rubbing of the rotating air seals. Each vane segment of the stages 3, 4 and 5 has slots at the roots ends, into which the seal strips are placed.

The LPT module has air seals. The air seals have a static part and a rotating part. The outer shroud seal segments form the static part. The fin edges form the rotating part.

The outer shroud seals (static seals) are installed in the LPT case between the stages 3, 4, 5 and 7 turbine vanes. The seals between stages 6 and 7 are brazed at the inner diameter to the stages 6 and 7 stator vanes.

The inner vane segment seals are brazed to the inner vane diameter of the LPT vane segments.

All LPT blade stages have double knife-edge seals on the outer diameter. They cause a ringseal to be made around the outer diameter of LPT blades.

Rotating air seals are attached to the forward flange of the LPT disk and make a seal ring between each rotor and stator stage.

A thin metal sheet is brazed into the inner segment of the LPT case and inner duct. It decreases the leakage of hot gas between the HP turbine and the LP turbine. The temperature of the turbine stage 3 vanes is decreased by a braid seal installed between the stage 3 heatshield and the LPT case.

The LPT case is assembled from six nickel alloy roll forged rings welded around the circumference. The internal flanges are slotted to attach the turbine vane segments.

Operation

The LP turbine turns the LP compressor and the LP compressor fan. Hot gas goes into the LP turbine at the stage 3 and goes through the five stages. Heatshields are installed between the vane stages 3, 4, 5 and LPT case to seal the LPT case from the gas-path heat.

Module Sub-Assemblies

Listed below are the module build groups with the associated work groups (marked *). The work group level is where piece parts are cleaned, inspected and repaired/reworked.

SNS | Part | |

|---|---|---|

Location | LP Turbine (LPT) And Exhaust Module Nomenclature | |

72-50-10 | LPT case and rotor assembly | |

72-50-21 | LPT case | |

72-50-22 | LPT nozzle vanes | |

72-50-23 | LPT shroud seal segments | |

72-50-24 | LPT inner duct segments, supports, and rings | |

72-50-25 | LPT diffuser support and duct segments | |

72-50-30 | LPT rotor assembly | |

72-50-31 | * | LPT disks |

72-50-32 | * | LPT blades |

72-50-33 | * | LPT air rotating seals |

72-50-41 | LPT shaft | |

72-50-42 | No.5 bearing assembly and seal |

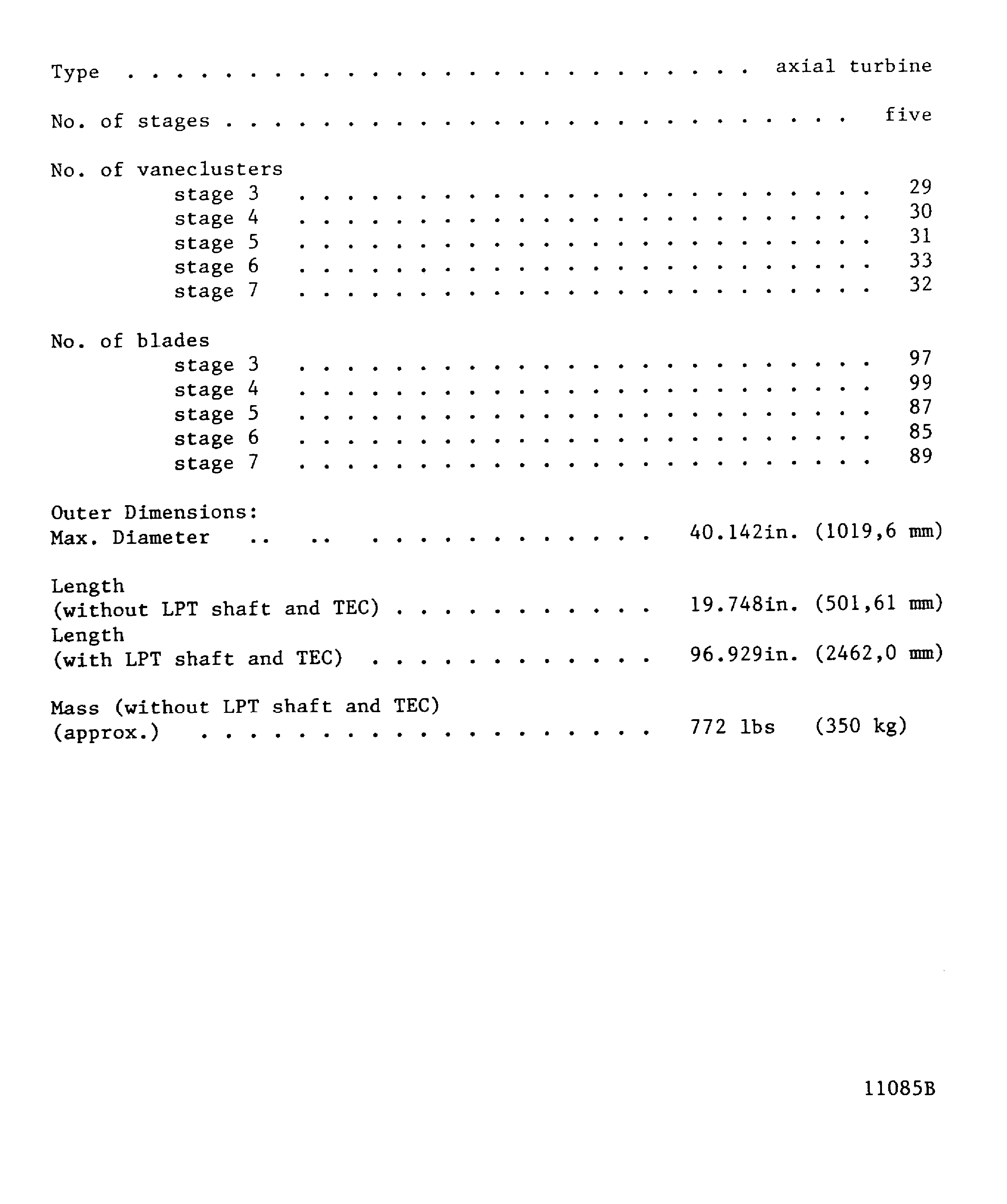

Figure: Table of technical data, LPT module

Table of technical data, LPT module

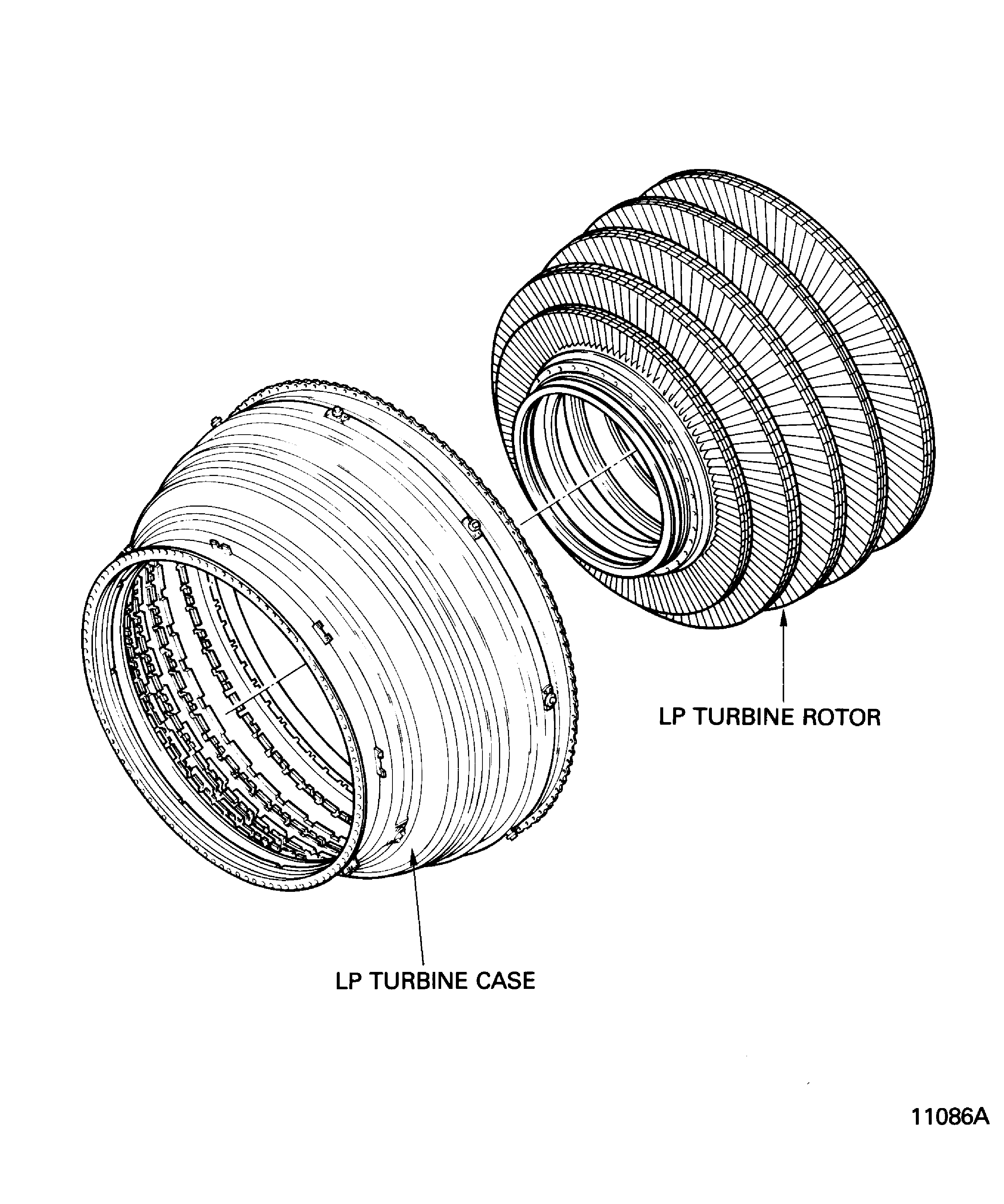

Figure: LPT module

LPT module

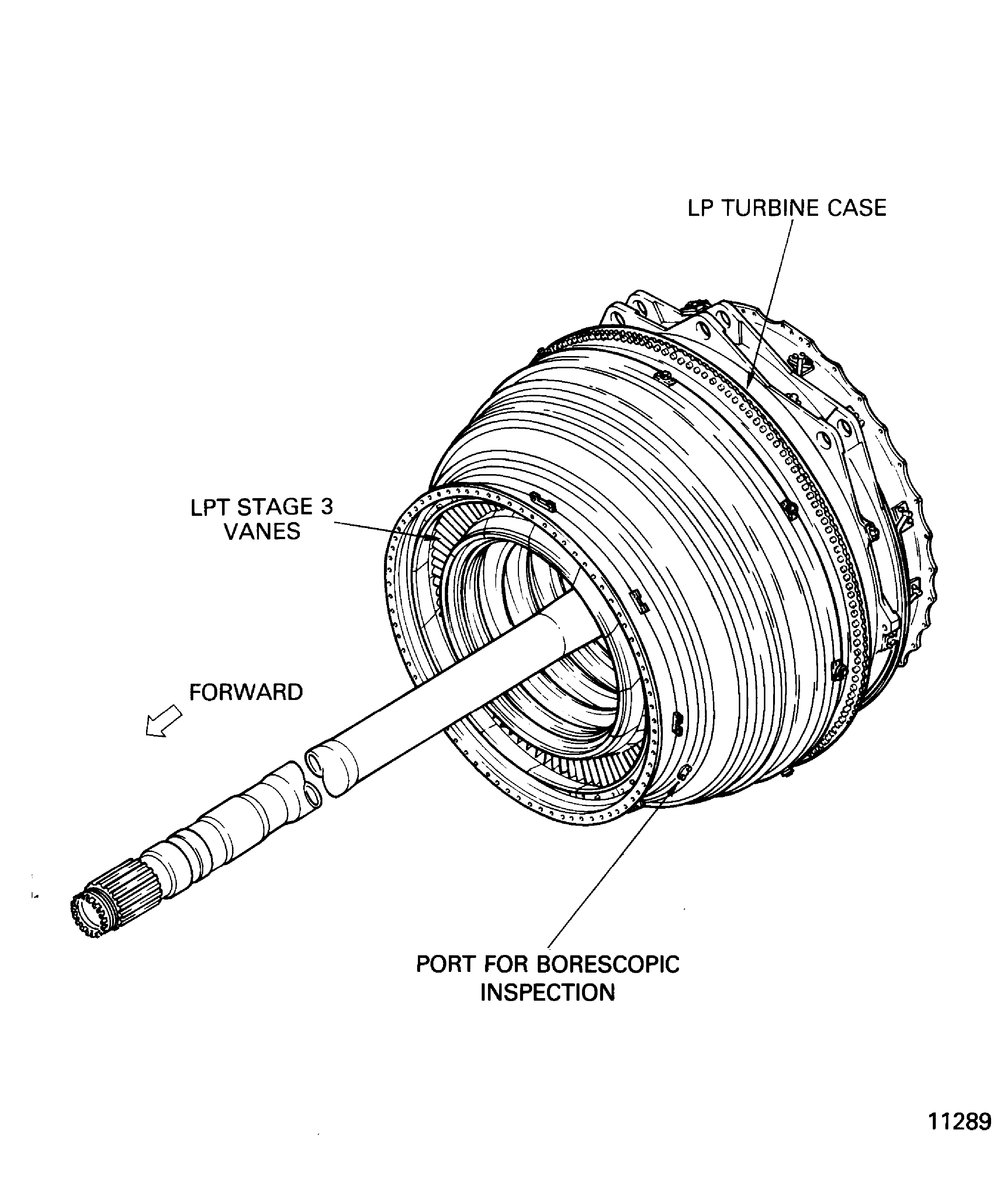

Figure: LPT module (TEC not installed)

LPT module (TEC not installed)

Figure: LPT rotor

LPT rotor

Figure: LPT stator

LPT stator

Figure: LPT case and rotor

LPT case and rotor