DMC:V2500-A0-72-50-2203-08A-609A-CIssue No:002.00Issue Date:2013-11-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-22-300-059 LPT Stage 3 Vane - Touch-Up Coating After Blend, Repair-059 (VRS4325)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

A ** following any repair reference in this procedure indicates that the repair is not yet published in the current revision of this manual.

NOTE

Equivalent equipment may be used

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Furnace | LOCAL | Furnace | ||

| Illuminated comparator magnifier | LOCAL | Illuminated comparator magnifier | ||

| Vapor blast equipment | LOCAL | Vapor blast equipment |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-38-14-380-501.

Do the touch-up coating.

SUBTASK 72-50-22-380-064 Touch-Up Coating after Blend Repair of the Stage 3 Turbine Vane

NOTE

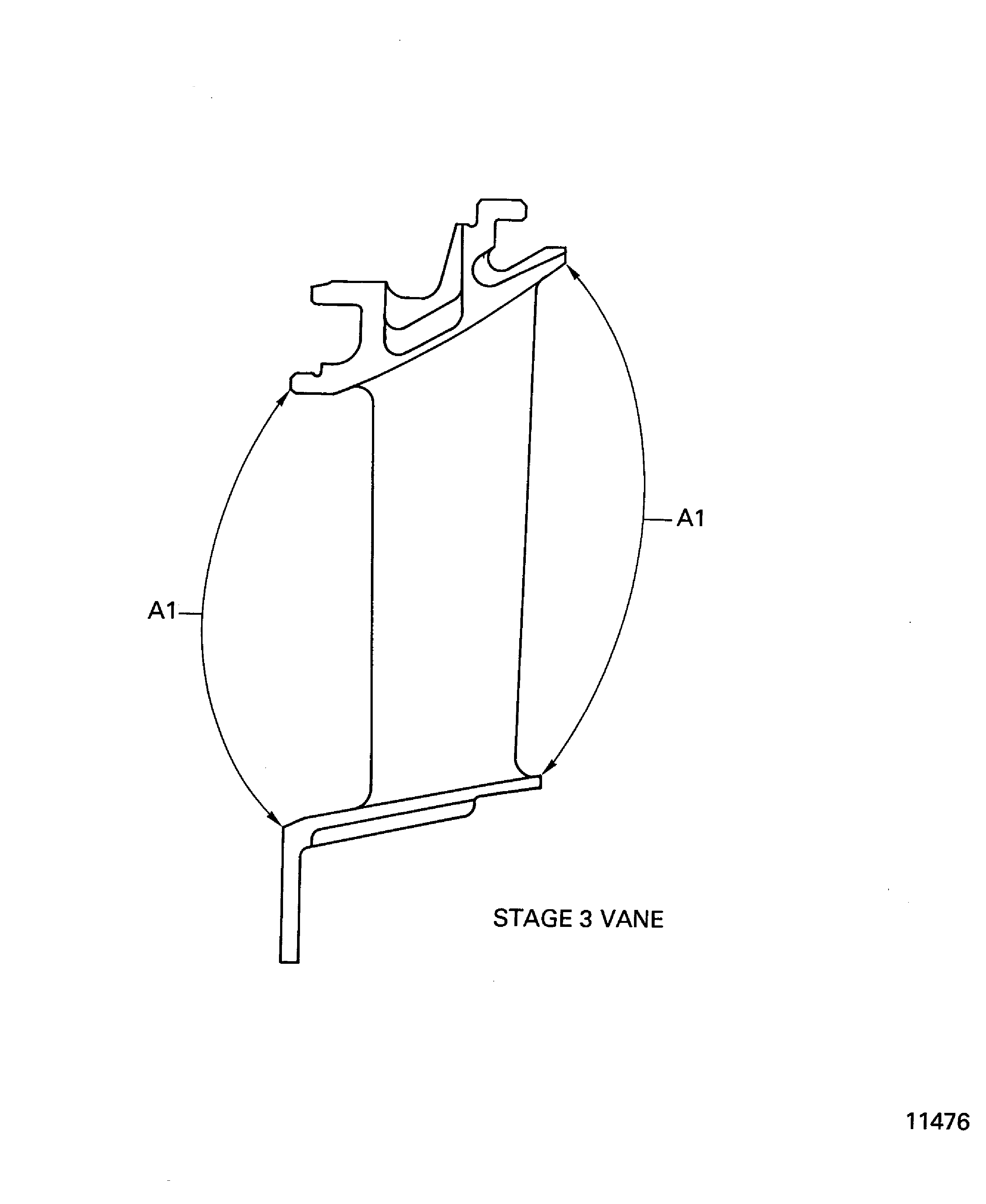

This repair is only permitted in conjunction with repair instruction VRS 4328. Refer to TASK 72-50-22-300-069 (REPAIR-069)**.If coating is badly damaged, then refer to VRS 4326, TASK 72-50-22-300-067 (REPAIR-067)** or VRS 4327, TASK 72-50-22-300-068 (REPAIR-068)**.Touch up is only permitted in area A1, refer to Figure.Optional standard diffusion heat treatment of 1950 to 2000 deg F (1066 to 1094 deg C) for 4 hours can be used. This diffusion heat treatment gives slightly more corrosion protection. The vanes then have to be placed in an oven for 8 hours at 1652 deg F (900 deg C) for precipitation heat treatment.Refer to the SPM TASK 70-38-14-380-501.

Heat treat for 2 hours at 1575 to 1625 deg F (857 to 885 deg C).

Use furnace.

Heat treat the stage 3 turbine vanes to diffuse the coating.

SUBTASK 72-50-22-370-058 Diffusion Heat Treatment of the Coated Stage 3 Turbine Vane

Figure: Touch-up coating of the stage 3 turbine vane

Touch-up coating of the stage 3 turbine vane