Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-33-300-033 LPT Stage 3 Rotating Airseal - Rebalance, Repair-033 (VRS4244)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

For more equipment and materials necessary to this repair refer to the SPM TASK 70-23-05-230-501.

Equivalent materials or equipment may be used.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Grinding machine | LOCAL | Grinding machine | ||

| Horizontal rotating table | LOCAL | Horizontal rotating table | ||

| Vertical balancing machine | LOCAL | Vertical balancing machine | ||

| Radius gage set | LOCAL | Radius gage set | ||

| Roughness microtester | LOCAL | Roughness microtester | ||

| Vernier caliper | LOCAL | Vernier caliper | ||

| IAE 1M14234 Balancing fixture | 0AM53 | IAE 1M14234 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

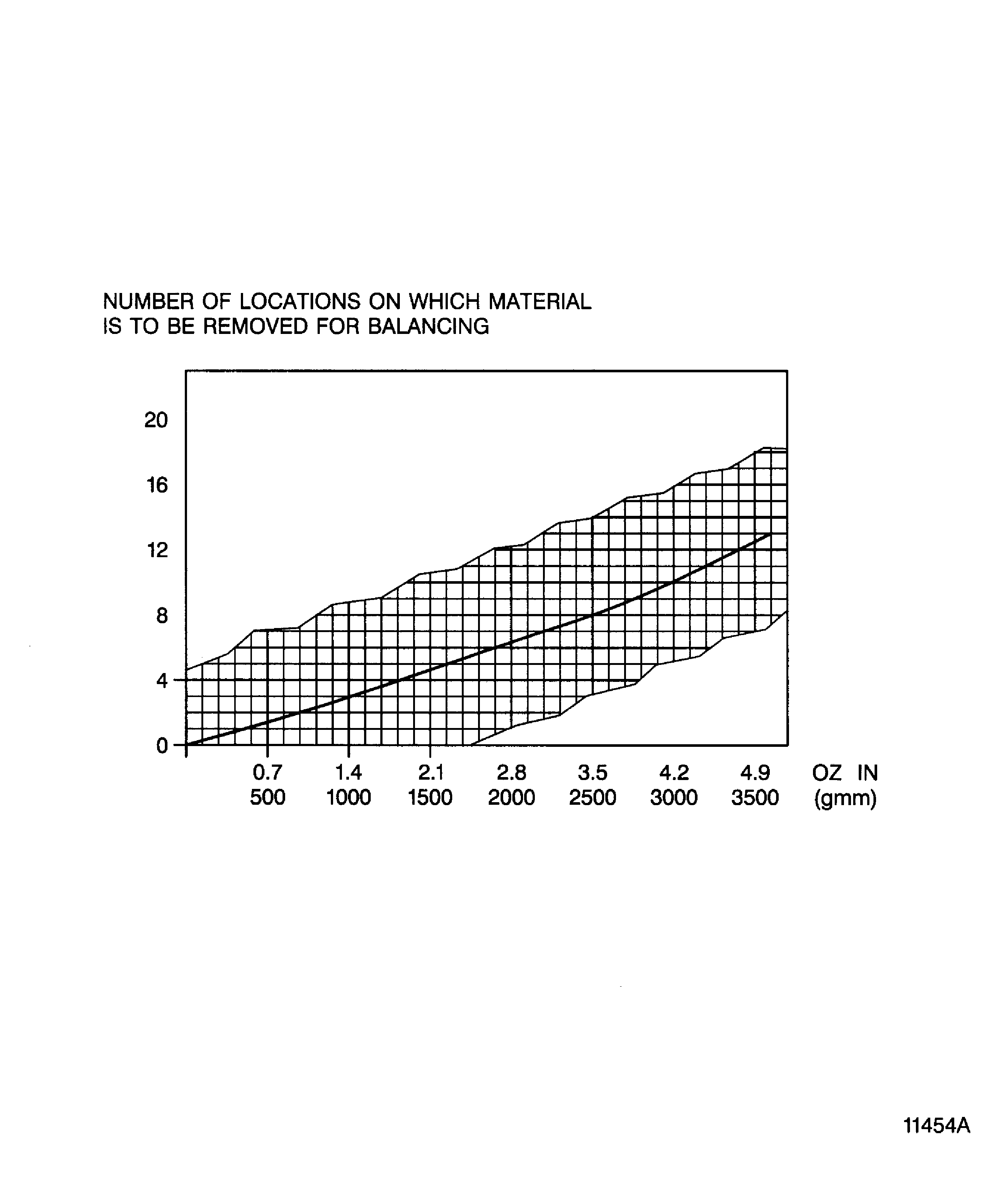

Keep material removal to the minimum to get balace within limits.

Do not remove material from a small number of areas. Remove material over a larger number, with less removal, to permit more rebalancing procedure.

Refer to: Figure

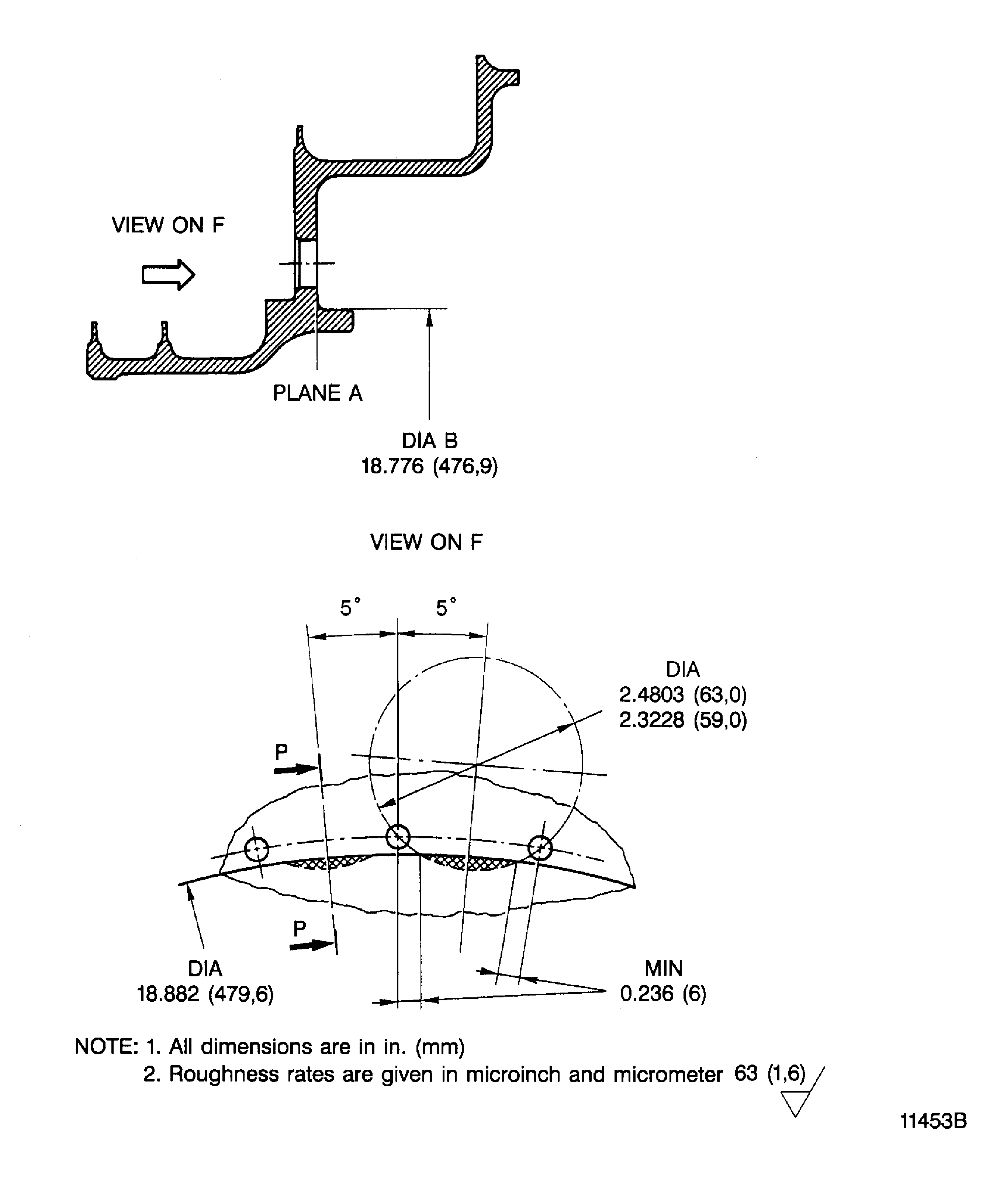

Initial unbalance must not be more than a maximum of 5 ozin (3600 gmm) when attached on diameter B and plane A.

Remaining unbalance must not be more than a maximum of 0.50 ozin (360 gmm).

The direction of turn on the vertical balancing machine can be set in two directions, clockwise or counterclockwise.

Do the check for actual static unbalance of the stage 3 turbine air seal at 900 RPM minimum.

SUBTASK 72-50-33-350-075 Rebalance the Stage 3 Turbine Air Seal

NOTE

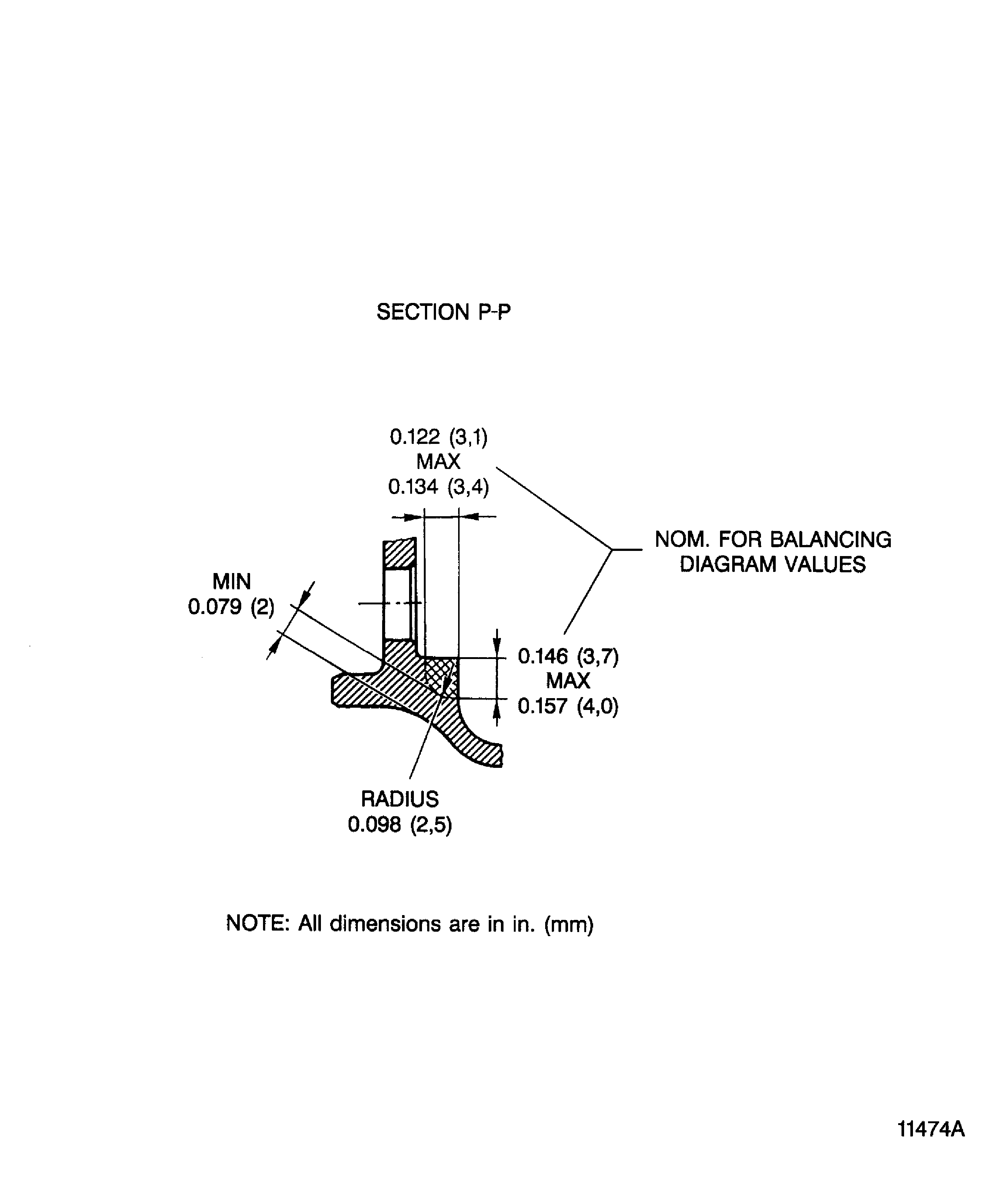

Make sure, that dimensions are within the limits, given in Figure.

Use the horizontal rotating table, vernier caliper and radius gage.

Dimensionally examine the machined areas.

SUBTASK 72-50-33-220-099 Do the Post Repair Inspection of the Turbine Air Seal

Figure: Rebalance the stage 3 turbine air seal

Rebalance the stage 3 turbine air seal

Figure: Rebalance the stage 3 turbine air seal

Rebalance the stage 3 turbine air seal

Figure: Balancing diagram of the stage 3 turbine air seal

Balancing diagram of the stage 3 turbine air seal