Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-41-300-004 LPT Shaft - Apply Chromium Plating, Repair-004 (VRS1498)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil | ||

| Chromium Plate equipment | LOCAL | Chromium Plate equipment | ||

| Magnetic particle inspection equipment | LOCAL | Magnetic particle inspection equipment | ||

| Grinding Machine | LOCAL | Grinding Machine |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-019 WATERPROOF SILICON CARBIDE | 1E1X8 | CoMat 05-019 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 |

Spares

NONESafety Requirements

NONEProcedure

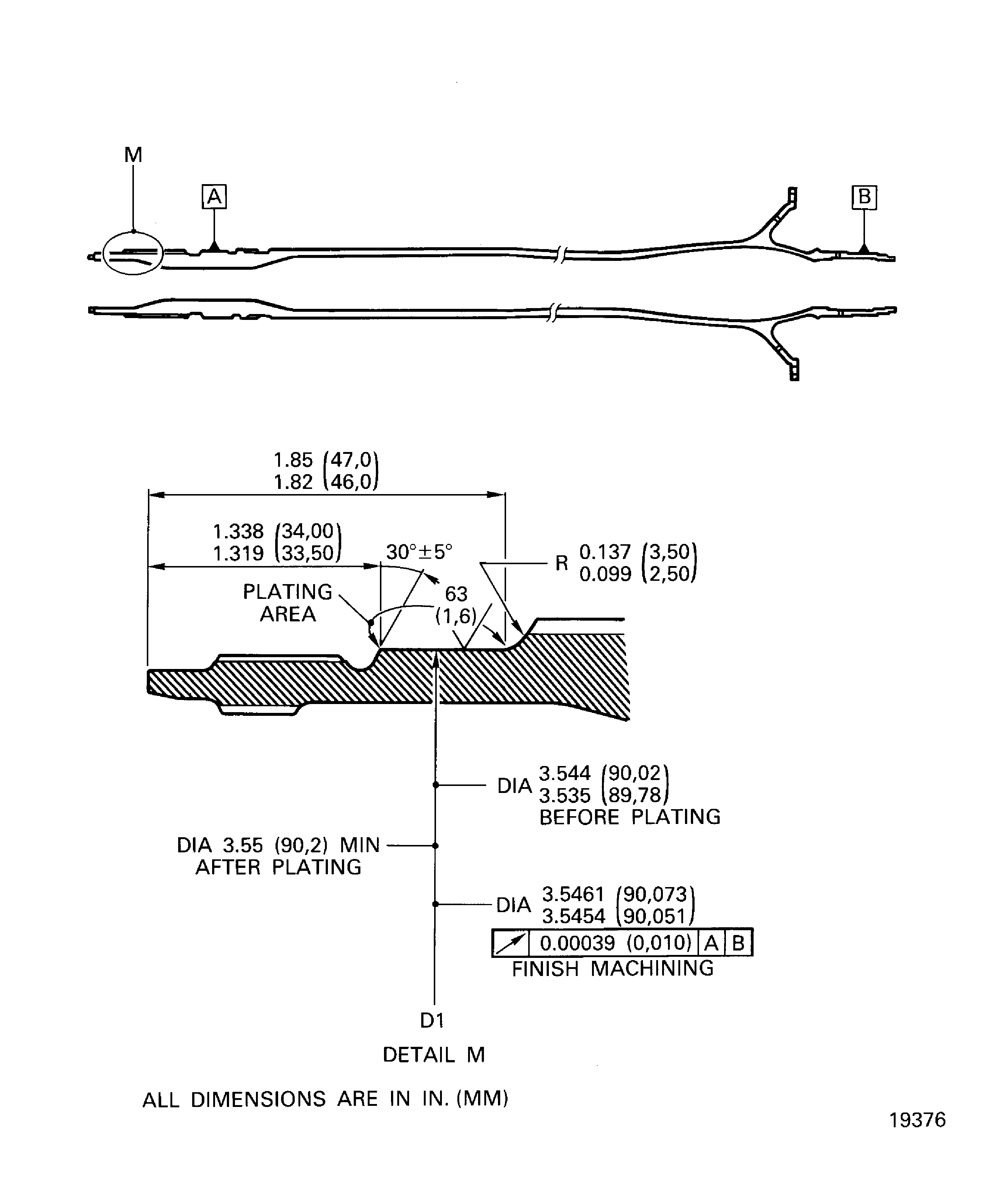

Refer to: Figure

Use portable grinding equipment, abrasive stones, fine file, CoMat 05-019 WATERPROOF SILICON CARBIDE and/or CoMat 05-020 WATERPROOF SILICON CARBIDE.

Maximum depth to remove the remaining damages must not be more than 0.023 in. (0.60 mm).

Width of the blended area is to be more than 10 times the depth.

Total circumferential length of the blended area is not more than 10 percent of circumferential of the snap diameter.

Remove minimum quantity of material necessary to remove the damages.

Surface finish of the repair must be the same as the adjacent area.

Refer to the SPM TASK 70-35-03-300-501.

Make smooth and/or polish to remove all the remaining damages if the damages can't be removed by grinding in Step.

SUBTASK 72-50-41-330-061 Machine Worn Diameter D1

NOTE

If the surface has been previously repaired using chromium plate, remove the old plating completely.Refer to the SPM TASK 70-33-02-300-503.

Heat treat the part for one hour at 374 to 410 deg F (190 to 210 deg C).

SUBTASK 72-50-41-370-057 Stress Relieve the LP Turbine Shaft after Plate Stripping

Refer to the SPM TASK 70-33-02-300-503.

Clean the part.

Refer to the SPM TASK 70-38-24-300-503.

Mask all the surface except the plating area.

SUBTASK 72-50-41-330-062 Prepare the LP Turbine Shaft for Plating

Refer to the SPM TASK 70-33-02-300-503.

Alkali clear the part.

SUBTASK 72-50-41-380-059 Alkali Clear the LP Turbine Shaft

Refer to the SPM TASK 70-33-02-300-503.

Immerse the part in a standard chromium plating solution for sufficient time to achieve the diameter 3.55 in. (90.20 mm) minimum.

Refer to the SPM TASK 70-33-02-300-503.

Treatment after plating.

SUBTASK 72-50-41-330-063 Chromium Plate the LP Turbine Shaft

Refer to: Figure

Refer to TASK 72-50-41-200-000 (INSPECTION-000).

The dimples which are caused by the blended area in Step are acceptable.

Visually examine the chromium deposit for pits, visible cracks, burns and excessive build-up of a corner.

Refer to TASK 72-50-41-200-000 (INSPECTION-000).

Dimensional check the plated area for diameter 3.55 in. (90.20 mm) minimum.

SUBTASK 72-50-41-220-087 Examine the LP Turbine Shaft after Plating

Refer to Figure.

Refer to the SPM TASK 70-35-03-300-501.

Make smooth and polish the dimples which are caused by the blended area in step 4.B.

Refer to the SPM TASK 70-35-03-300-501.

Remove loose materials or burrs from the edge of chamfer fully.

SUBTASK 72-50-41-324-054 Grind the LP Turbine Shaft after Plating

Refer to Figure.

Refer to TASK 72-50-41-200-000 (INSPECTION-000).

The dimples which are caused by the blended area in Step are acceptable.

Visually examine the ground area for pits or cracks after grinding.

SUBTASK 72-50-41-220-091 Examine the LP Turbine Shaft after Grinding

Figure: Repair Details and Dimensions

Repair Details and Dimensions