Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-007 Turbine Exhaust Case (TEC) - Replace The No. 5 Bearing Scavenge Oil Tube, Repair-007 (VRS5391)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Turbine exhaust case | Corrosion and heat resistant steel | |

Tubes | Corrosion and heat resistant steel |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Hand tools | LOCAL | Tools, hand | ||

| TIG welding equipment | LOCAL | TIG welding equipment | ||

| Brazing equipment | LOCAL | Brazing equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| IAE 2F10331 Plug | 0AM53 | IAE 2F10331 | 1 | |

| IAE 2F10332 Bracket | 0AM53 | IAE 2F10332 | 1 | |

| IAE 2F10411 Adapter | 0AM53 | IAE 2F10411 | 1 | |

| IAE 6F10029 Air flow test cart | 0AM53 | IAE 6F10029 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-004 INTERM. TEMP. BRAZINGWIRE, 24% Ag | LOCAL | CoMat 03-004 | ||

| CoMat 03-005 BRAZING FLUX | LOCAL | CoMat 03-005 | ||

| CoMat 03-286 WELDING WIRE | LOCAL | CoMat 03-286 |

Safety Requirements

NONEProcedure

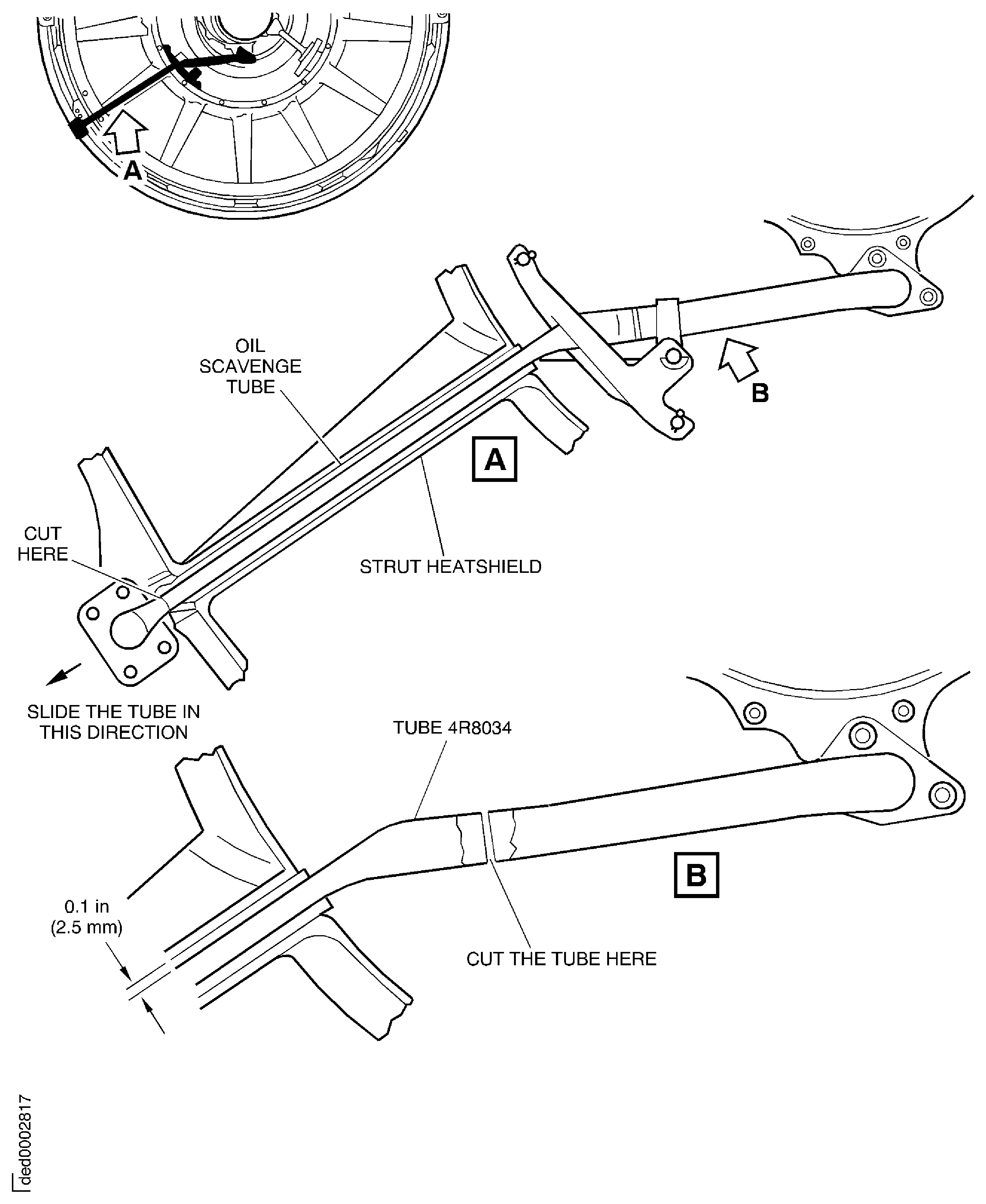

Refer to: Figure

SUBTASK 72-50-53-350-123 Cut the Scavenge Oil Tube

Refer to the SPM TASK 70-31-02-310-501.

Use CoMat 03-286 WELDING WIRE dia 0.05in. (1.2 mm).

Welding data:

Current intensity

45 to 50 A

Torch type

HW20

Torch nozzle

No. 6

Argon flow

8 1/m

Electrode

2% thoriated tungsten

Electrode dia

0.095in. (2.4 mm)

Complete weld the components.

SUBTASK 72-50-53-310-068 Weld the New Tubes

Inspect the weld for a good penetration.

Refer to the SPM TASK 70-23-05-230-501.

Weld again the areas where the weld condition is not satisfactory.

Inspect the weld.

SUBTASK 72-50-53-220-207 Inspect the Welding Area

Refer to the SPM TASK 70-31-01-310-501.

Braze the new tube p/n 4B8047 to the tube p/n 4B8034.

SUBTASK 72-50-53-310-069 Braze the New Tubes

Inspect the brazed joint.

Refer to the SPM TASK 70-23-05-230-501.

Do again the brazing if defects have occurred during brazing.

Inspect the brazing.

SUBTASK 72-50-53-220-208 Inspect the Brazed Area

Install the IAE 2F10331 Plug into the scavenge oil tube hole in bearing compartment flange.

Install the IAE 2F10332 Bracket to the bearing compartment flange.

Install the IAE 2F10411 Adapter to the scavenge oil tube outer flange.

Connect the IAE 6F10029 Air flow test cart to the adapter.

SUBTASK 72-50-53-780-051 Pressure Leak Check the Assembled Tube

Figure: Repair details

Repair details