Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Description

TASK 72-60-00-990-501 Description And Operation Of The External Gearbox Module

External gearbox

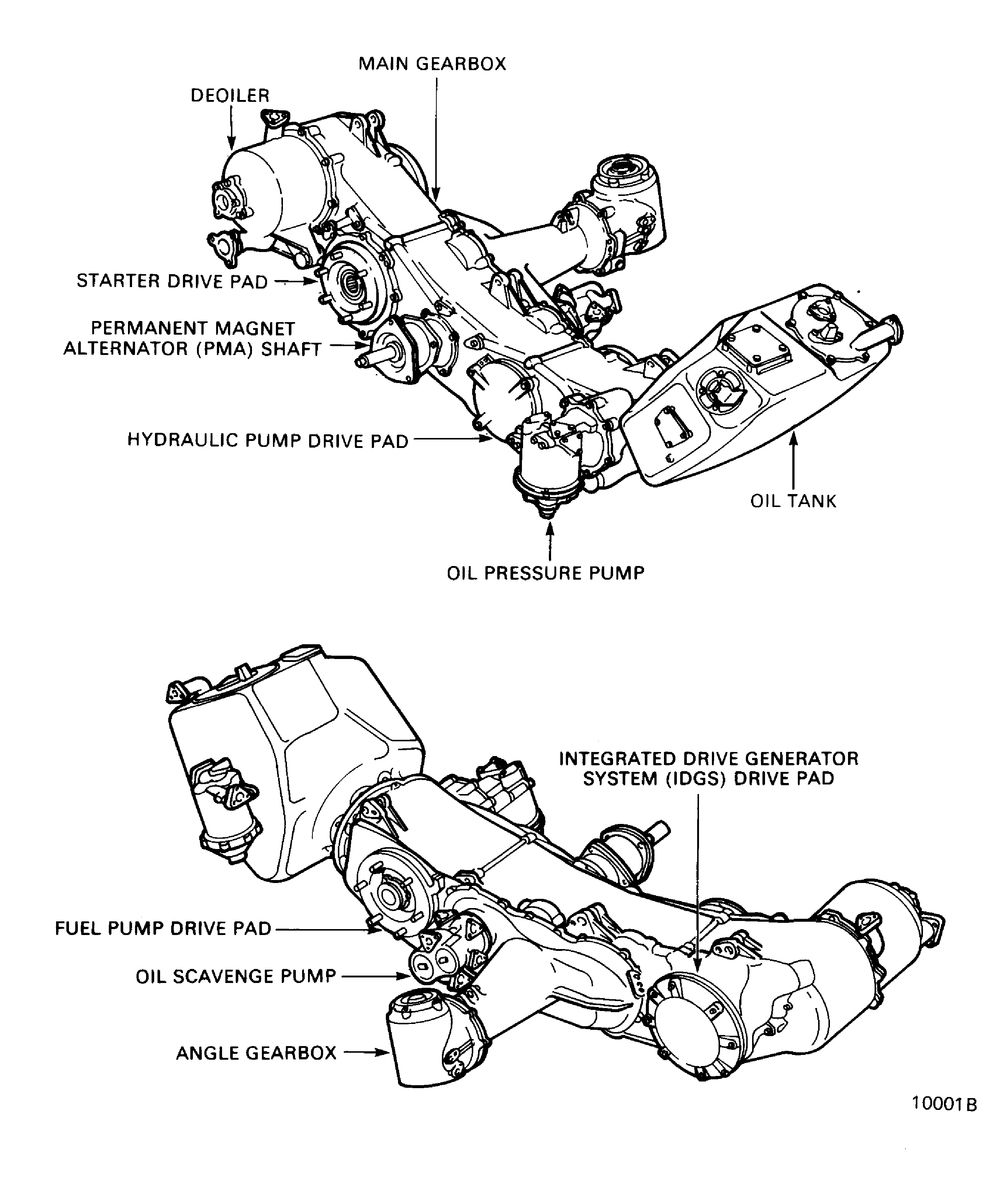

The primary parts of the external gearbox module (Figure) are:

Main gearbox

Angle gearbox

The external gearbox is installed at the bottom of the intermediate case module. Four flexible support links, three on the main gearbox and one on the angle gearbox support, attach the external gearbox to the intermediate case flanges. The links have spherical bearings at each end to permit any necessary mount flexibility.

Main gearbox

The main gearbox is installed forward of the angle gearbox and is attached to the angle gearbox by an angle gearbox support and to the intermediate case flange by three joint links.

The angle gearbox support is a casting which houses the layshaft and rigidly connects the angle gearbox with the main gearbox. A pad on the support is used for the installation of the oil scavenge pump.

The main gearbox has a cast aluminum housing that has a gear train, carbon seals and mounting pads for the airframe and engine accessories. An external deoiler is installed on the front face of the main gearbox. Each of the accessory drive gear train sections is individually replaceable.

The metered oil nozzles are installed on a gearbox housing and supply pressure oil to the bearings and gears in the gearbox.

An external oil tank is attached at the left-hand flange of the main gearbox.

Drive pads on the forward face of the gearbox are used to install these that follow:

Hydraulic pump

Starter

Oil pressure pump

Permanent magnet alternator (PMA)

Provision for remote cranking of the HPC rotor is also located on the front face.

Drive pads on the rear face of the gearbox are used to install these that follow:

Integrated drive generator system (IDGS)

Fuel pump

Oil scavenge pump (on the angle gearbox support)

Drive gearshaft rotation

NOTE

The direction of gearshaft rotation is when you face the mounting pad being described.Hydraulic pump drive gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the adjacent idler gearshaft. If the hydraulic pump is not installed, the ID gearshaft is sealed and the pad cover is installed.

Starter drive gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the adjacent crank gearshaft.

Oil pressure pump

The oil pressure pump is a removable assembly installed on the front flange of the gearbox. The pump has a separate housing that has two bush-mounted drive gear assemblies and the seat for the oil pressure filter.

Direction of drive rotation is counterclockwise. The oil pressure pump receives the motion through the fuel pump drive gearshaft.

The pump supplies oil under pressure to the engine bearings and accessory drives.

PMA gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the adjacent input gearshaft.

IDGS gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the starter gearshaft. When the IDGS is not installed, the ID gearshaft is sealed and the mount pad cover is installed.

Fuel pump drive gearshaft

Direction of drive rotation is counterclockwise. The gearshaft receives the motion through the hydraulic pump drive gearshaft.

Oil scavenge pump

The oil scavenge pump is a removable assembly installed on the flange of the angle gearbox support. The pump has a separable housing that has a bush-mounted drive gear assembly which moves two pump gear stages.

The pump receives the motion through the idler gearshaft. The direction of drive rotation is counterclockwise.

The oil scavenge pump increases the scavenge capacity of the oil pump module and sends the scavenge oil to the oil tank.

External deoiler

Direction of drive rotation is counterclockswise. The deoiler receives the motion through the IDGS gearshaft.

The oil/air mixture flows through the deoiler that, with the centrifugal action, removes the air from the oil. The deaerated oil goes back to the oil system and the clean air is bled overboard.

Angle gearbox

The angle gearbox is installed at the rear of the main gearbox and engages with the powershaft on the engine.

The cast aluminum angle gearbox houses a bevel gearset. The bevel gearset transmits the power to and from the engine through a powershaft which is engaged to the HPC rotor stubshaft. The bevel gearset has a spiral gear mesh which drives a horizontal input gearshaft in the main gearbox.

Two metered jets supply pressure oil to the bearings and gears in the angle gearbox.

Operation

The external gearbox at run condition, transmits the power from the power shaft which rotates at high speed, to the accessories installed on the main gearbox.

At starter condition, the external gearbox transmits the power from the starter to the engine.

The external gearbox supplies the necessary speeds, torques and data checking for the accessories to perform their various functions.

Module Sub-Assemblies

Listed below are the module build groups with the associated work groups (marked *). The work group level is where piece parts are cleaned, inspected and repaired/reworked.

SNS | Part | |

|---|---|---|

Location | External Gearbox Module Nomenclature | |

72-60-10 | Main gearbox assembly | |

72-60-21 | * | Main gearbox case assembly |

72-60-22 | * | Starter drive gear, bearings, and housing assembly |

72-60-23 | * | Hydraulic pump drive gear, bearings, and housing assembly |

72-60-24 | * | Extension layshaft gear and bearing assembly |

72-60-25 | * | Fuel pump drive gear, bearings, and housing assembly |

72-60-26 | * | Oil scavenge oil pump drive gear and bearings assembly |

72-60-27 | * | Starter idler gear and bearing assembly |

72-60-28 | * | IDG drive gear, bearings, and housing assembly |

72-60-29 | * | Deoiler gear, impeller, bearings, and housing assembly |

72-60-31 | * | Deoiler case assembly |

72-60-32 | * | Angle gearbox support assembly |

72-60-33 | * | PMA drive gear, bearings, and support assembly |

72-60-40 | Angle gearbox assembly | |

72-60-41 | * | Angle gearbox case |

72-60-42 | * | Angle gearbox driving gear, bearings, and support assembly |

72-60-43 | * | Angle gearbox driven gear, bearings, and layshaft assembly |

Figure: External gearbox

External gearbox