Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-21-300-027 Main Gearbox Casing - Repair The Oil Pressure Pump Bore By Bushing, Repair-027 (VRS5264)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-050 | 4B0053 |

02-050 | 4B0054 |

02-050 | 4B0055 |

02-050 | 4B0057 |

02-050 | 4B0400 |

02-050 | 4B0402 |

02-050 | 4B0423 |

Material of component

DESCRIPTION | RR SYMBOL | MATERIAL |

|---|---|---|

Accessory gearbox casing | A357/T61 (AMS4219) | Aluminium alloy |

Bushing | AA2024-T3 (AMS 4152K) | Aluminium alloy |

General

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Magnifying glass | LOCAL | Magnifying glass | ||

| Oven | LOCAL | Oven | ||

| Freezer | LOCAL | Freezer | ||

| Arbor Press | LOCAL | Arbor press | ||

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Bushing | 4L0023 | 1 |

Safety Requirements

NONEProcedure

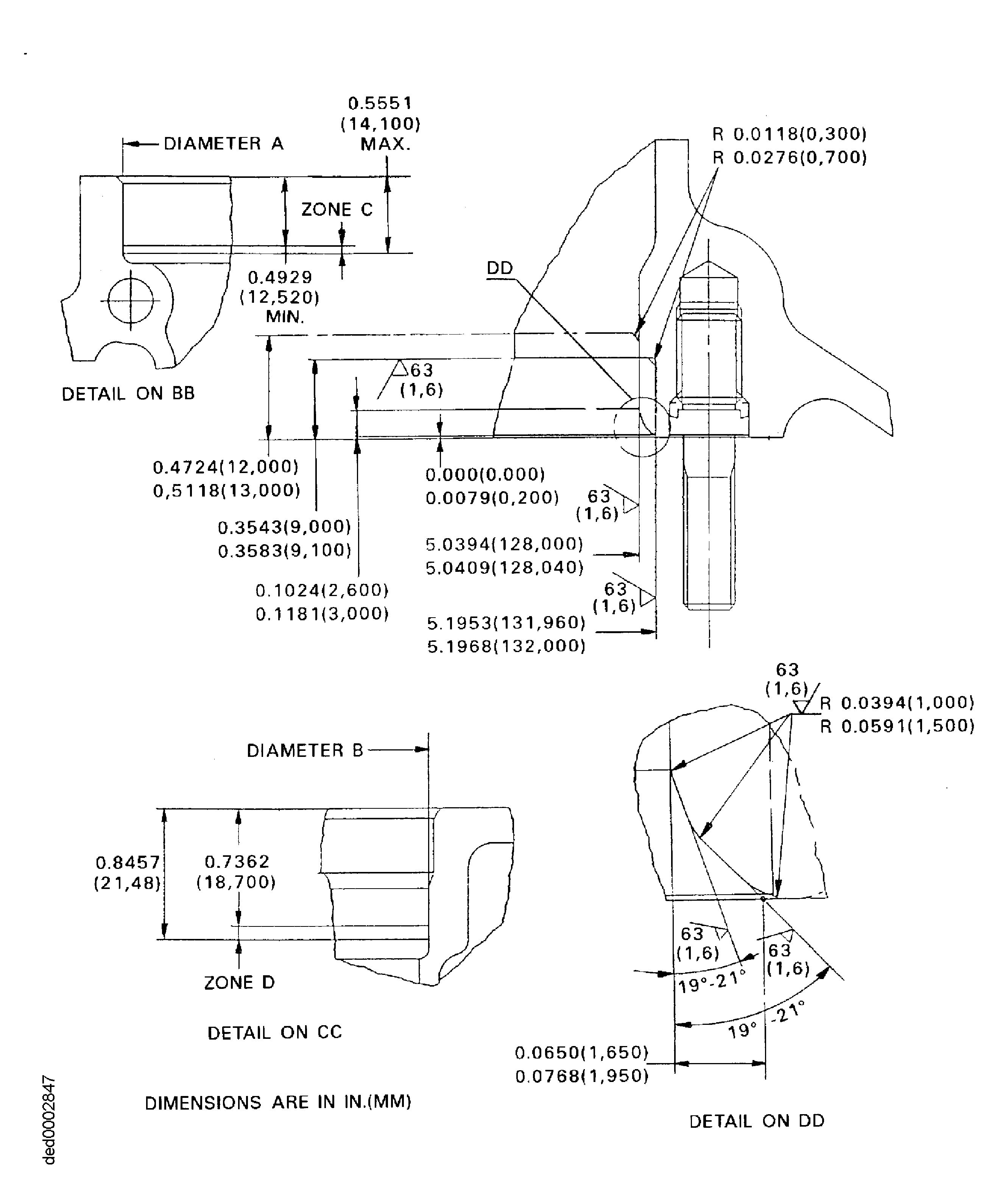

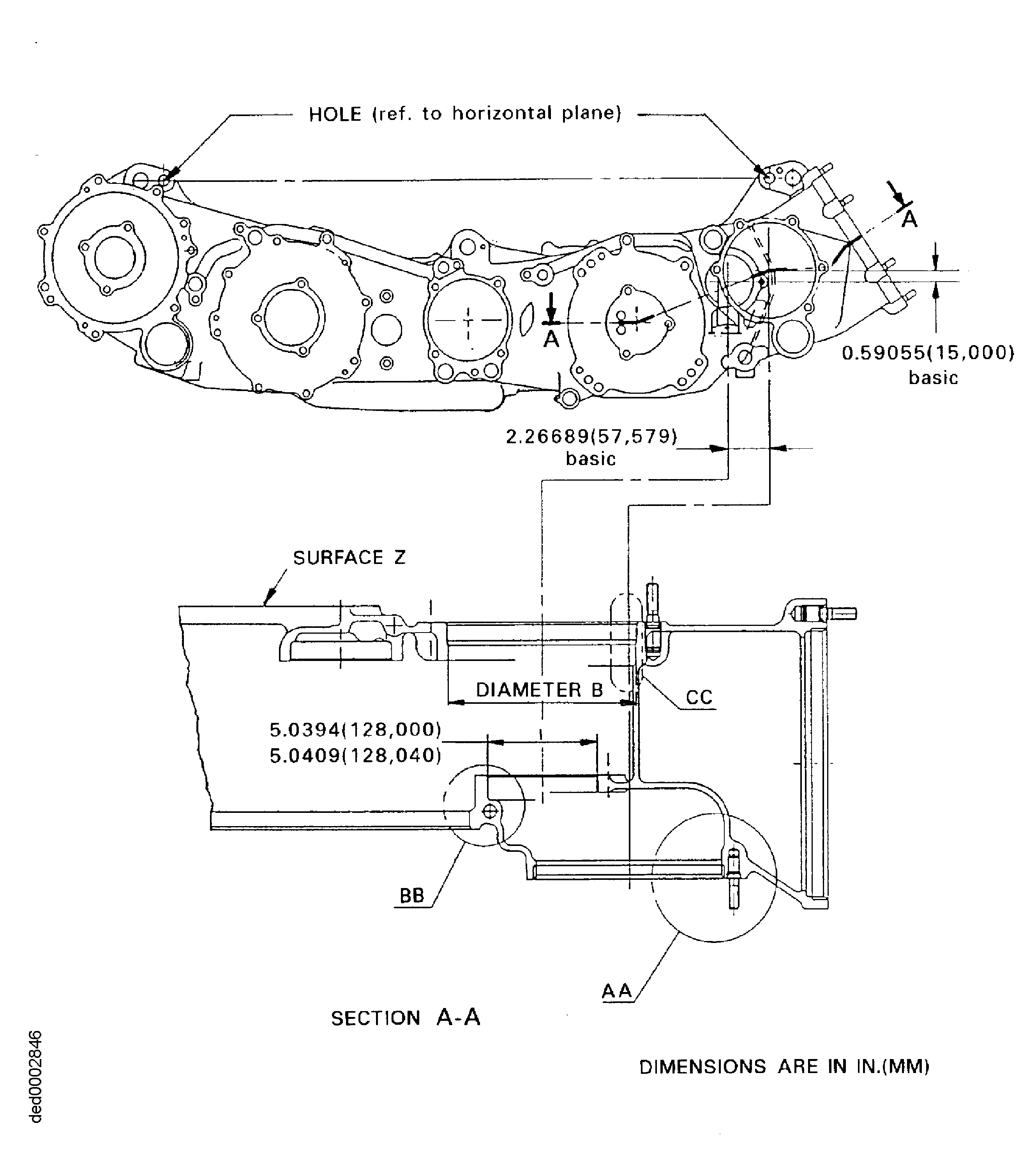

Refer to Figure.

The position of the bore must be within 0.0031 in. (0.080 mm) FIR in relation to diameter A index 15 and diameter B index 22 (if diameter A or B are damaged refer to zone C index 18 or zone D index 19).

The perpendicularity of the bore must be within 0.0031 in. (0.080 mm) FIR in relation to surface Z index 23.

Bore surface rough must be 63 microin. (1.6 micron).

Machine the oil pressure bore pump.

SUBTASK 72-60-21-320-114 Machine the Oil Pressure Pump Bore in the Gearbox Casing

Refer to the SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the machined surfaces.

SUBTASK 72-60-21-330-101 Apply the Chromate Conversion Coating

Refer to Figure.

Do not increase the temperature of the casing above 284 deg F (140 deg C).

Do not decrease the temperature of the assembled drift and bushing below minus 58 deg F (minus 50 deg C).

WARNING

DO NOT TOUCH THE HOT PARTS WITHOUT PROTECTIVE GLOVES.

WARNING

HOT PARTS CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.

WARNING

IMMERSE THE CONTACTED AREA IN COLD WATER FOR 10 MINUTES IF THE SKIN IS BURNED. IMMEDIATELY GET THE MEDICAL ATTENTION IF PAIN OR BLISTERING PERSISTS.Use an oven and/or a freezer to increase the temperature of the casing and/or decrease the temperature of the assembled drift and bushing.

Give sufficient back-up support at bushing bore area to prevent casing distortion when you install the bushing.

CAUTION

INSTALL BUSHING IN MACHINED BORE IMMEDIATELY AFTER REMOVAL FROM FREEZER, OTHERWISE BUSHING CANNOT BE CORRECTLY INSTALLED.Use drift and an arbor press to install the bushing into machined bore.

SUBTASK 72-60-21-350-127 Install the Bushing

Refer to Figure.

The position of the bore must be within 0.0016 in. (0.040 mm) FIR in relation to diameter A index 15 and diameter B index 22 (if diameter A or B are damaged refer to zone C index 18 or zone D index 19).

The perpendicularity of the bore must be within 0.0016 in. (0.040 mm) FIR in relation to surface Z index 23.

Bore surface rough must be 63 micro in. (1.6 micron).

Chamfer where necessary.

Machine the inner diameter of the bushing.

SUBTASK 72-60-21-320-115 Machine the Inner Diameter of the Bushing

Refer to the SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the machined surface of the bushing.

SUBTASK 72-60-21-330-102 Apply the Chromate Conversion Coating

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions