Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

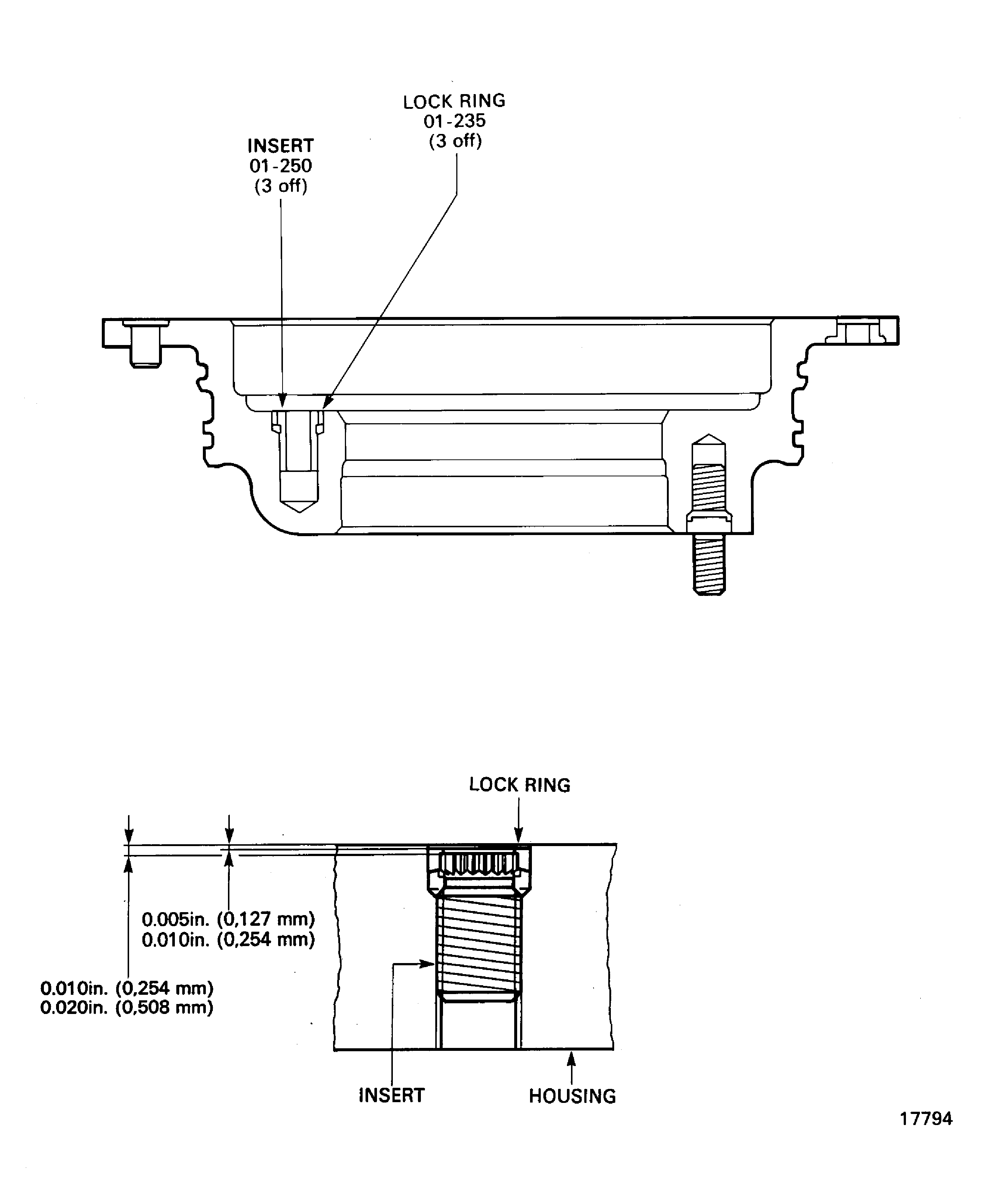

TASK 72-60-25-300-003 Fuel Pump Drive Gear Housing - Replace The Damaged Screw Thread Inserts, Repair-003 (VRS5048)

General

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| 5/16in. (7,937 mm) Drill, removal | LOCAL | 5/16in. (7,937 mm) Drill, removal | ||

| Square screw extractor, removal | LOCAL | Square screw extractor, removal | ||

| R1106W Wrench, installation | LOCAL | R1106W Wrench, installation | ||

| R206D Drive tool, installation | LOCAL | R206D Drive tool, installation |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-048 LUBRICANT | 0AM53 | CoMat 10-048 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lock ring | MS51990E106P | A/R | ||

| Screw insert | MS51991E206L | A/R |

Safety Requirements

NONEProcedure

Refer to Figure.

Use 5/16in. (7,937 mm) Drill, removal 1 off for lock ring.

Install the removal tool in drill press chuck.

SUBTASK 72-60-25-320-052 Mill the Lock Ring

Drive the Square screw extractor, removal 1 off into the insert.

Continuous pressure of withdrawn insert could cause lock ring to be forced out from its location. Break with a punch and remove the remaining portion of lock ring if it has been milled fully through and it does not lift out with the insert.

Apply the removal torque to the insert.

SUBTASK 72-60-25-350-057 Remove the Insert

Refer to Figure.

SUBTASK 72-60-25-350-058 Install the New Insert

Refer to Figure.

SUBTASK 72-60-25-350-059 Install the Lock Ring

Do the touch up process if the anodic treatment has been damaged by insert installation.

Refer to the SPM TASK 70-38-02-300-503.

Check the surface.

SUBTASK 72-60-25-330-052 Restore the Damaged Anodic Treatment

Refer to the SPM TASK 70-23-01-230-501.

Do a crack test on the repaired area.

SUBTASK 72-60-25-230-053 Crack Test the Repaired Area

Figure: Replace damaged inserts and lock rings

Replace damaged inserts and lock rings