Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-29-300-043 Deoiler Gear - Expansion Plug Replacement Repair, Repair-043 (VRS5704)

General

The practices and processes referred to in the procedure by TASK number are in the SPM.

Price and availability - none

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Safety Requirements

NONEProcedure

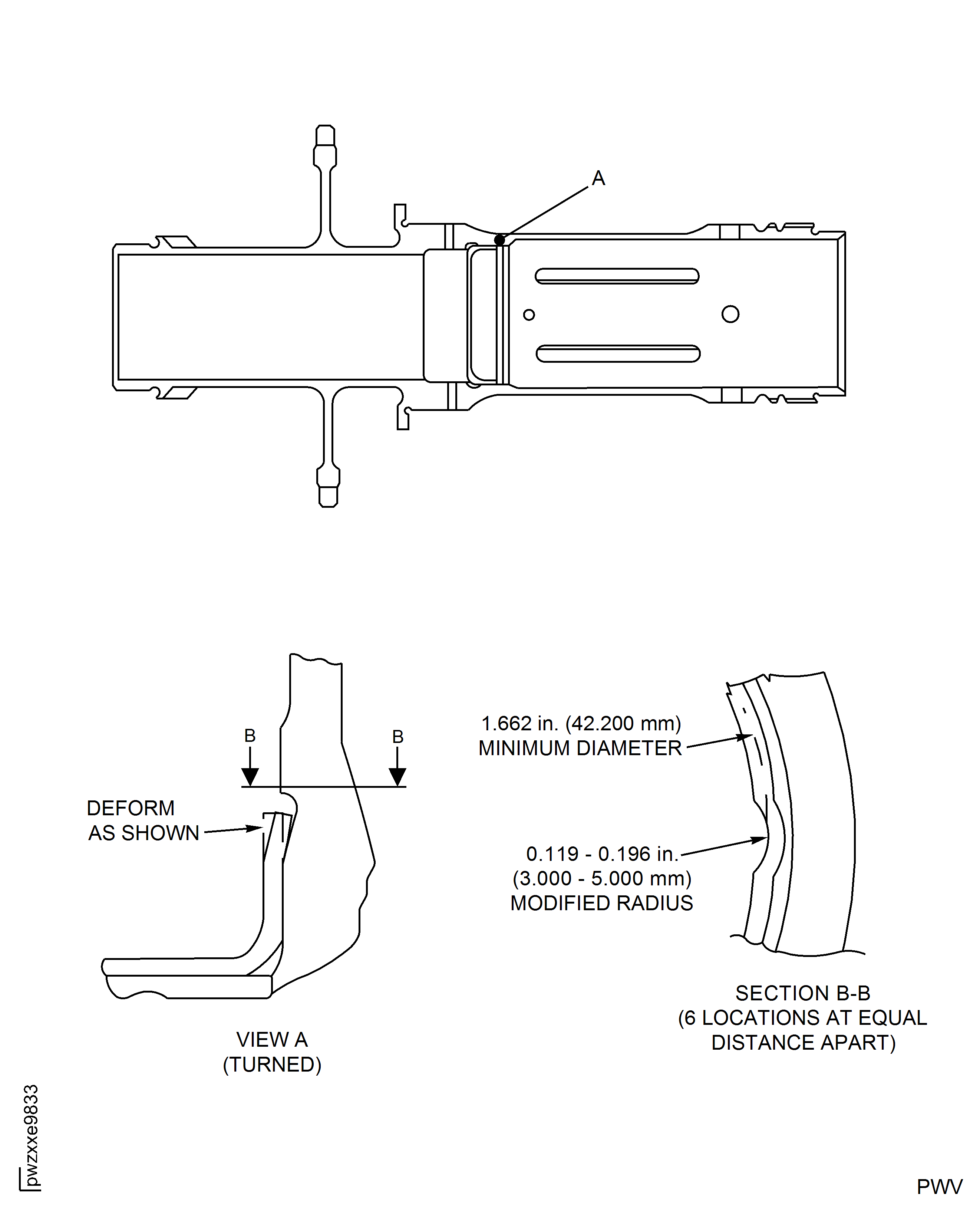

Refer to Figure 1.

If necessary remove the existing Expansion Plug. Be careful not to damage the inner diameter of the gearshaft.

SUBTASK 72-60-29-350-087 Remove the Expansion Plug (01-330) from the Deoiler Gear (01-290)

Do local FPI in accordance with SPM TASK 70-23-05-230-501, CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY). Cracks are not allowed.

The maximum serviceable depth of nicks, dents, scores and scratches is 0.002 in. (0.05 mm).

No burrs or high metal are permitted.

If necessary, blend the gearshaft to remove burrs or high metal. Repair according to VRS5167 TASK 72-60-29-300-025 (Repair-025).

After blending, do local FPI in accordance with SPM TASK 70-23-05-230-501, CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY). Cracks are not allowed.

Do a visual inspection of the Deoiler Gear groove as follows.

SUBTASK 72-60-29-220-157 Inspect the Expansion Plug Groove on the Deoiler Gear (01-290)

WARNING

BE CAREFUL WHEN YOU USE SHARP OR POINTED TOOLS. THESE TOOLS CAN CAUSE AN INJURY TO YOU.Refer to Figure 1.

Ensure that the Expansion Plug is properly seated.

Insert the Expansion Plug into the Deoiler Gear.

Using a punch, deform the Expansion Plug in six (6) equally spaced locations.

Ensure that there is no movement between the Deoiler Gear and the Expansion Plug.

SUBTASK 72-60-29-350-088 Install the Expansion Plug (01-330) to the Deoiler Gear (01-290)

Figure: Deoiler Gear - Expansion Plug Replacement Repair

Deoiler Gear - Expansion Plug Replacement Repair