Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-40-040-001 Angle Gearbox Assembly - Disassemble The Angle Gearbox, Disassembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts and parts with an interference fit. Let the parts soak before removal.

Discard all rubber seal rings, cotter pins and seal washers removed in this procedure.

Remove and discard the lockwire before parts are disconnected or removed.

Transportation covers/blanks must be installed immediately after the removal of the components.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Swivel vise | LOCAL | Swivel vise | ||

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10100 Base holder | 0AM53 | IAE 1F10100 | 1 | |

| IAE 1F10110 Stud | 0AM53 | IAE 1F10110 | 3 | |

| IAE 1F10114 Hydraulic cylinder | 0AM53 | IAE 1F10114 | 1 | |

| IAE 1F10123 Puller | 0AM53 | IAE 1F10123 | 1 | |

| IAE 1F10129 Pusher | 0AM53 | IAE 1F10129 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | LOCAL | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

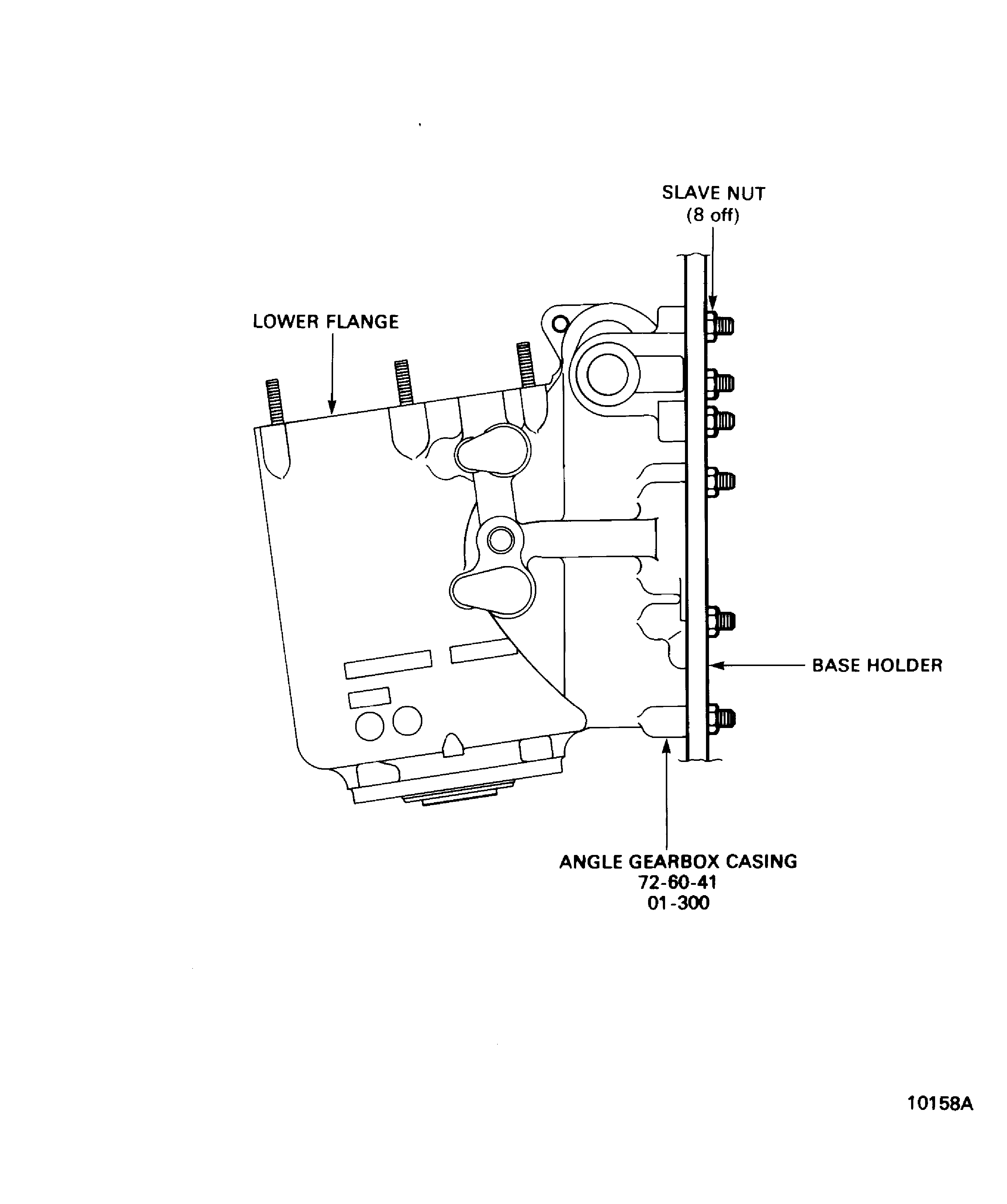

Refer to Figure.

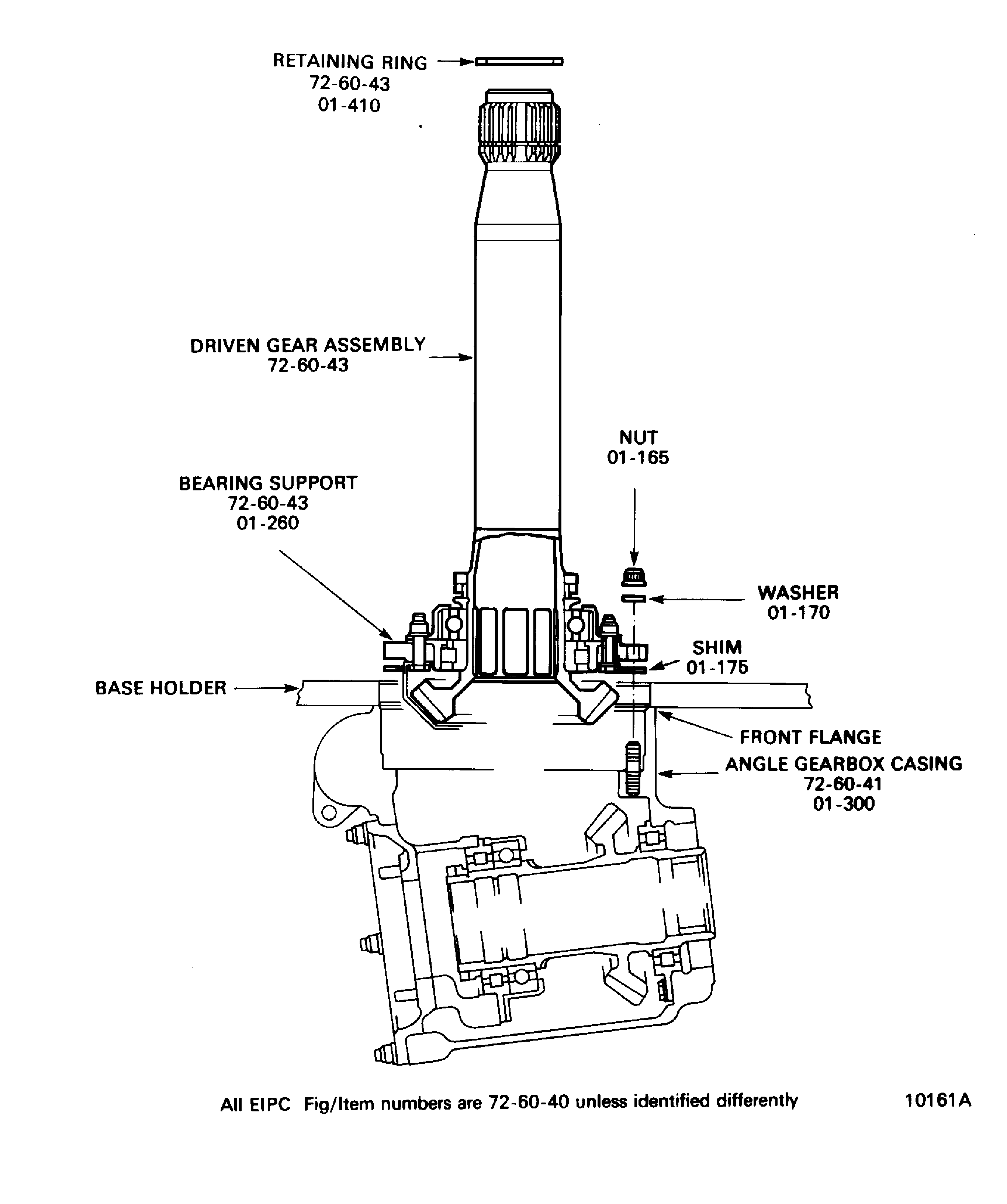

Align the guide pin and the studs in the front flange of the angle gearbox with the holes on IAE 1F10100 Base holder 1 off. Install the angle gearbox on the base holder.

SUBTASK 72-60-40-040-051 Install the Angle Gearbox Assembly on the Base Holder

Refer to Figure.

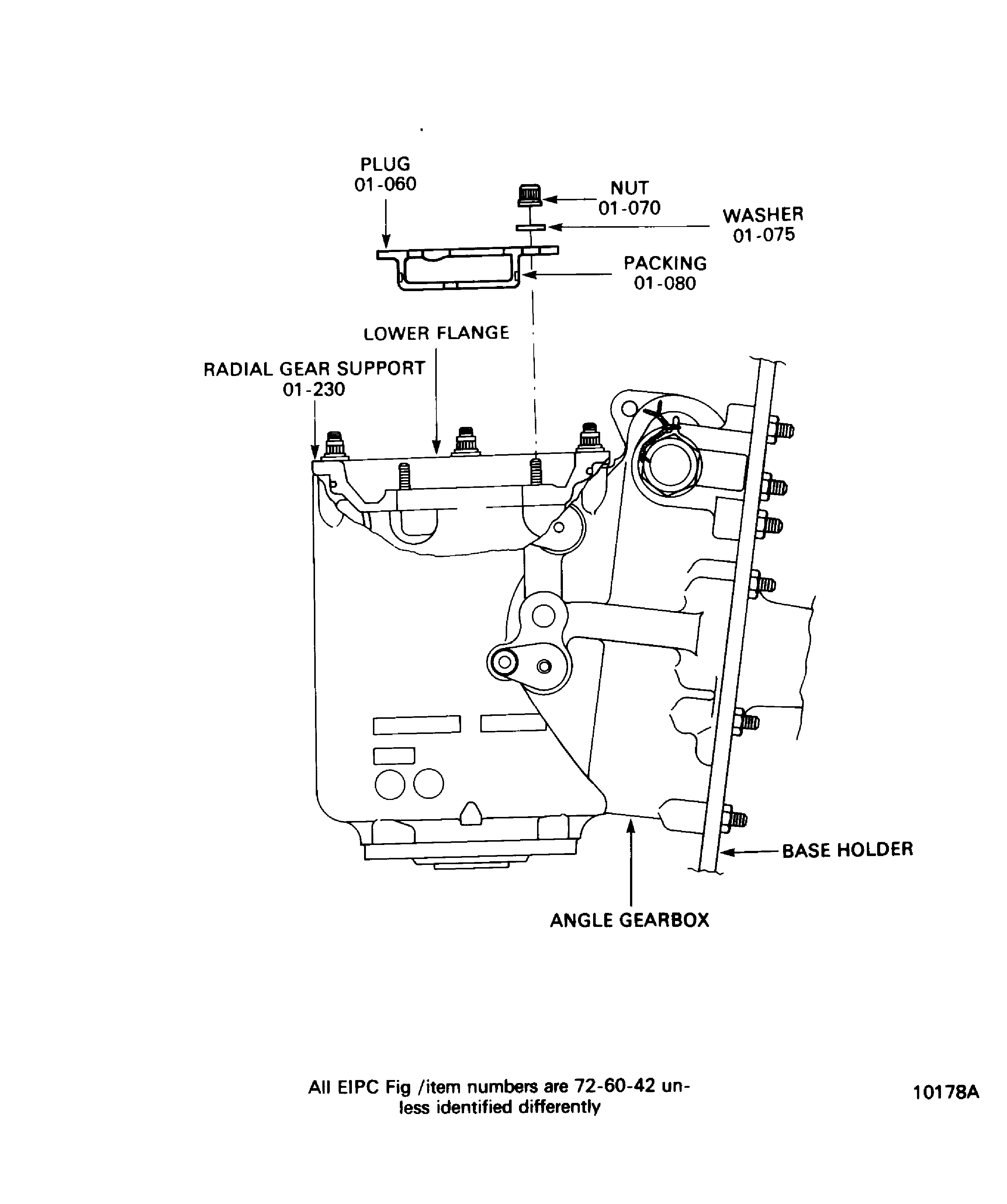

SUBTASK 72-60-40-040-052 Remove the Plug from the Lower Flange of the Angle Gearbox

Refer to Figure.

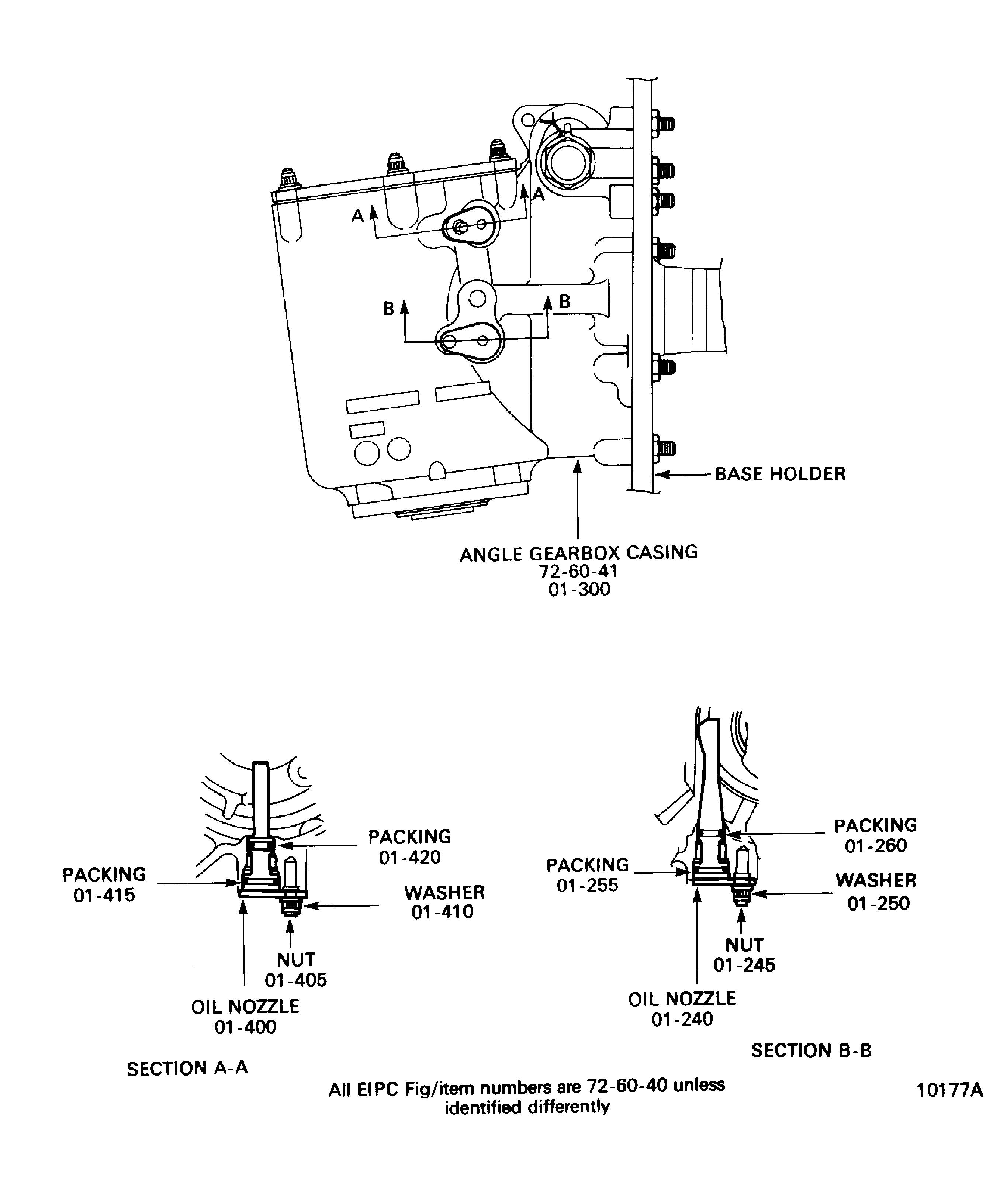

SUBTASK 72-60-40-040-053 Remove the Oil Nozzles from the Angle Gearbox

Refer to Figure.

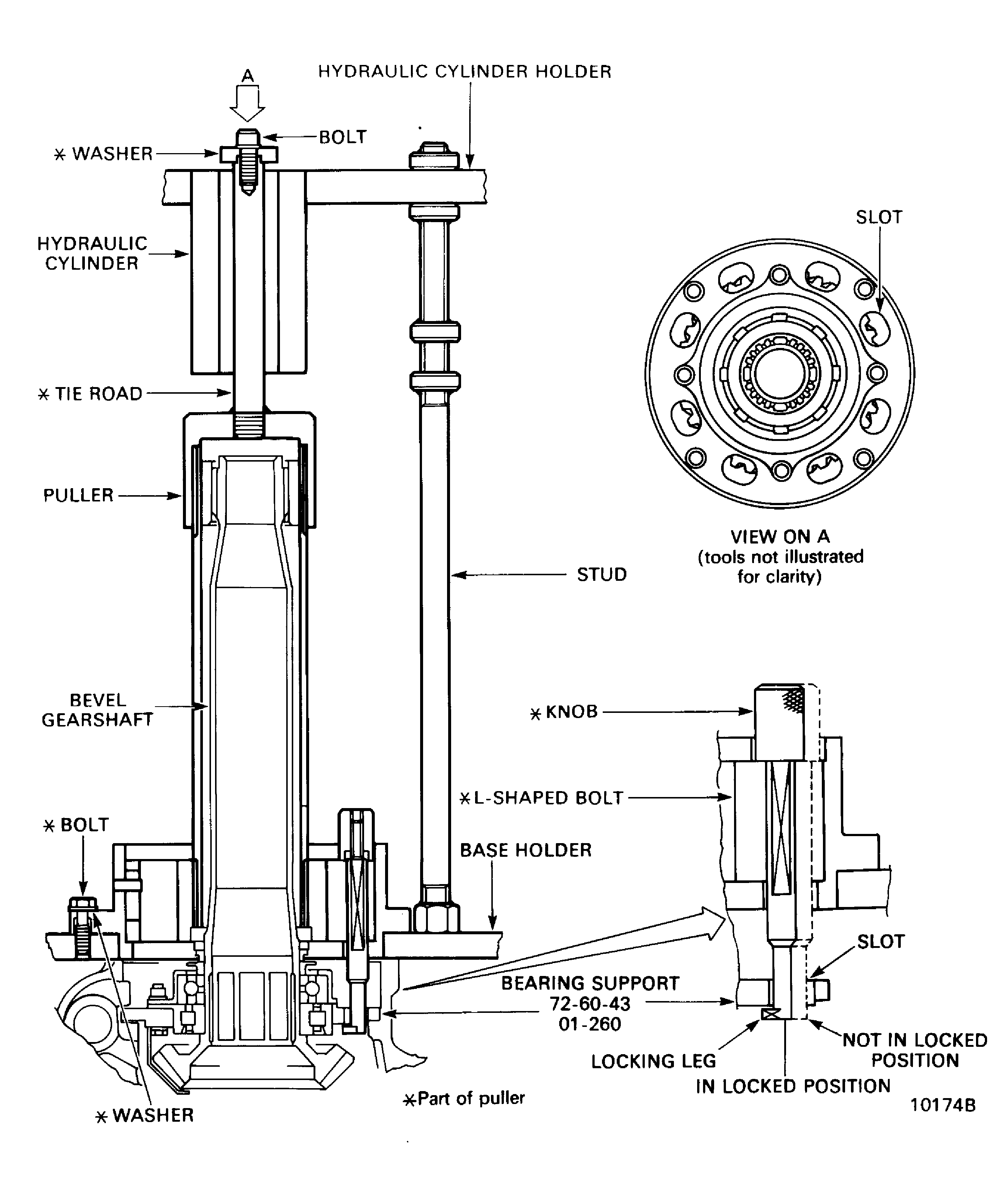

Install IAE 1F10123 Puller 1 off on the driven gear assembly.

Install IAE 1F10110 Stud 3 off on the base holder.

Install IAE 1F10114 Hydraulic cylinder 1 off.

Attach IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic cylinder. Operate the hydraulic pump until the driven gear assembly is disengaged from the angle gearbox casing.

Record the thickness of the removed shim. This dimension may be used as Dimension X during assembly of the Angle Gearbox.

SUBTASK 72-60-40-040-054 Remove the Driven Gear Assembly from the Angle Gearbox

Refer to Figure.

Record the thickness of the removed shim. This dimension may be used as Dimension Y during assembly of the Angle Gearbox.

SUBTASK 72-60-40-040-055 Remove the Driving Gear Assembly from the Angle Gearbox

Refer to Figure.

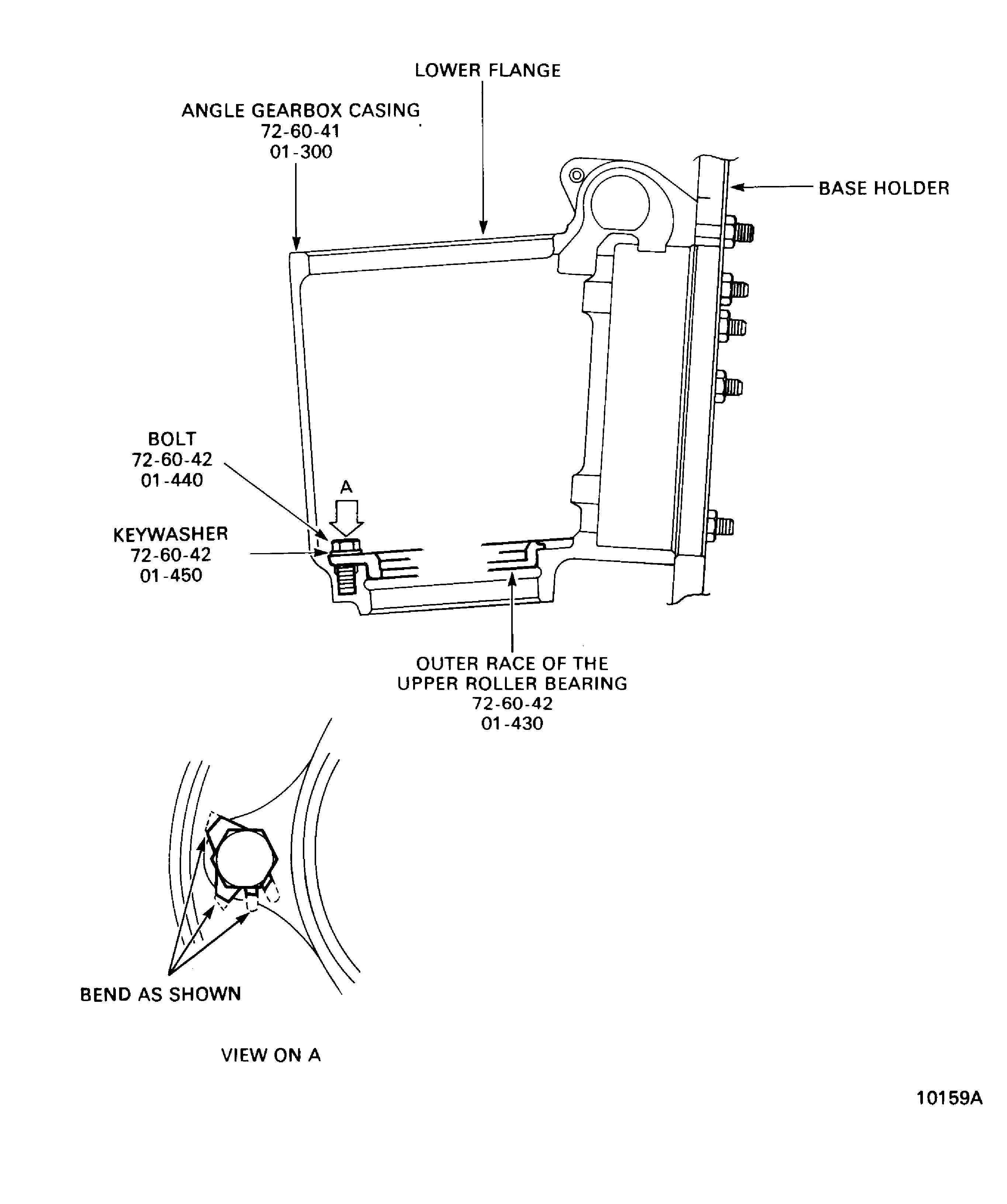

Remove the outer race from the angle gearbox casing with IAE 1F10129 Pusher 1 off.

SUBTASK 72-60-40-040-056 Remove the Outer Race of the Upper Roller Bearing from the Angle Gearbox Casing

Refer to Figure.

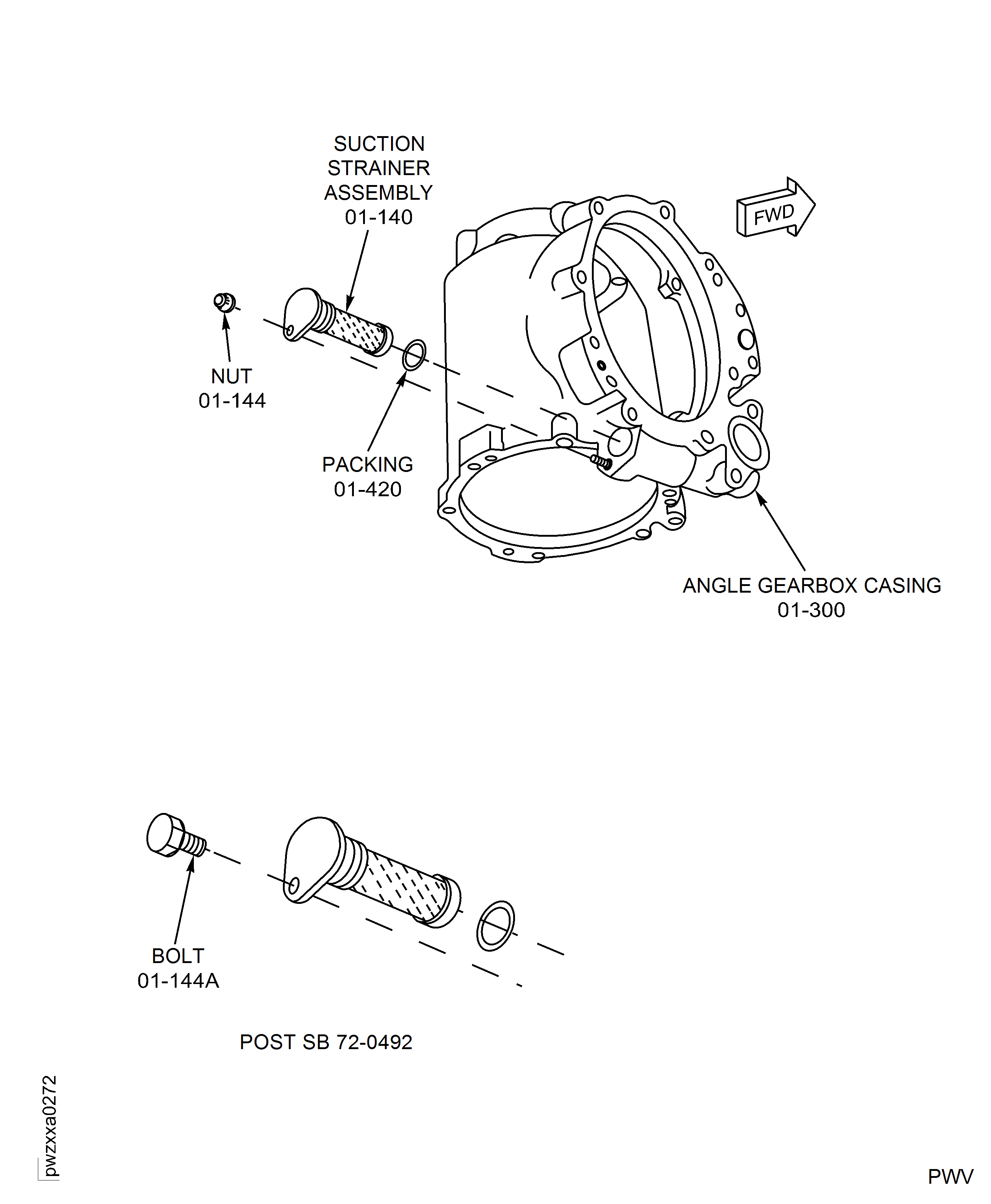

Remove the nut/bolt that attaches the suction strainer to the angle gearbox casing.

Remove the suction strainer from the angle gearbox casing. Discard the packing.

SUBTASK 72-60-40-040-057 Remove the Suction Strainer Assembly from the Angle Gearbox Casing

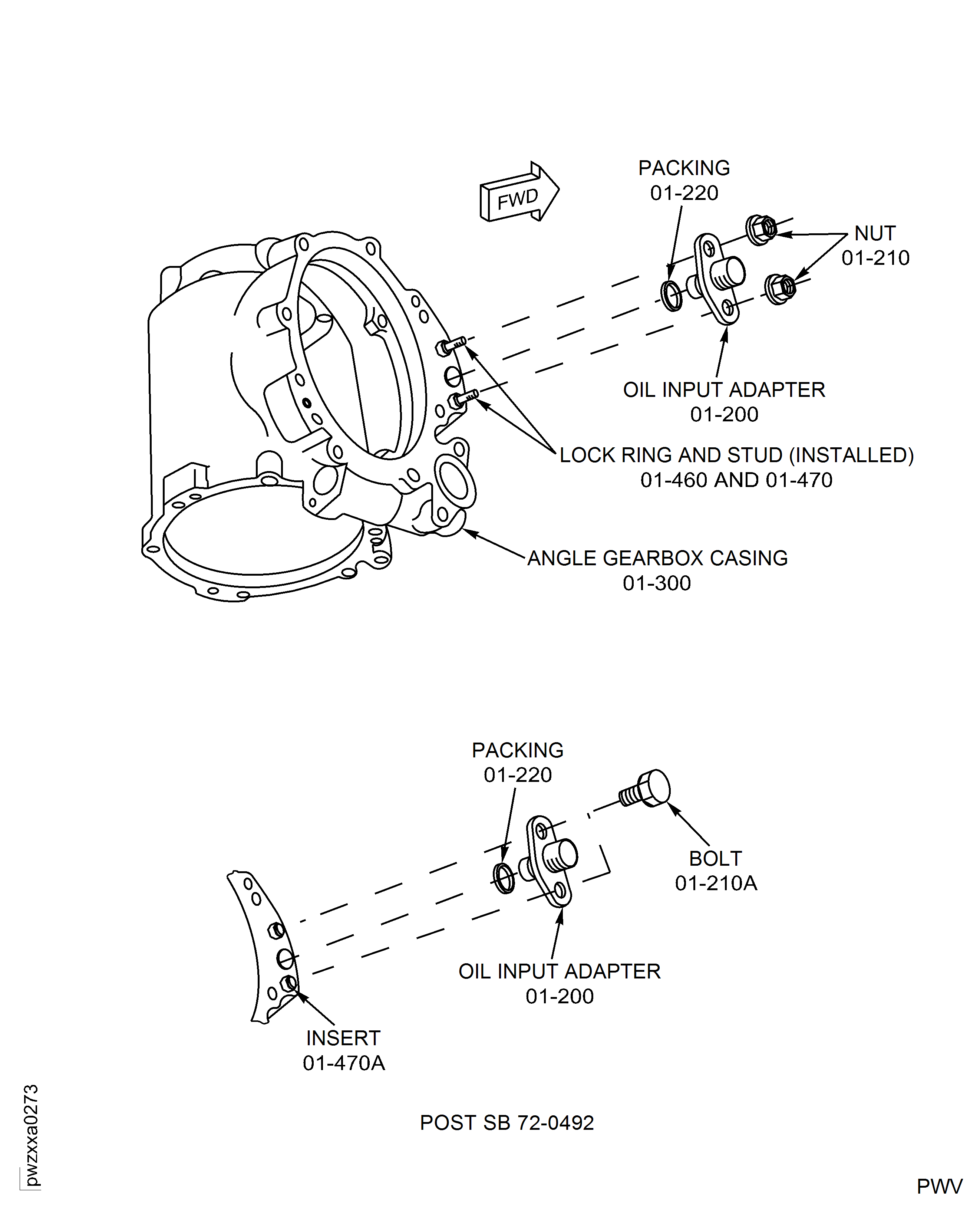

Refer to Figure.

Remove the two nuts/bolts that attach the oil input adapter to the angle gearbox casing.

Remove the oil input adapter from the angle gearbox casing. Discard the packings.

SUBTASK 72-60-40-040-058 Remove the Oil Input Adapter from the Angle Gearbox Casing

Figure: Install the angle gearbox on the base holder

Install the angle gearbox on the base holder

Figure: Remove the plug from the lower flange of the angle gearbox

Remove the plug from the lower flange of the angle gearbox

Figure: Oil nozzle on the angle gearbox

Oil nozzle on the angle gearbox

Figure: Remove the driven gear assembly

Remove the driven gear assembly

Figure: Remove the driven gear assembly

Remove the driven gear assembly

Figure: Remove the driving gear assembly

Remove the driving gear assembly

Figure: Remove the outer race of the upper roller bearing

Remove the outer race of the upper roller bearing

Figure: Removal of the Suction Strainer Assembly

Removal of the Suction Strainer Assembly

Figure: Removal of the Oil Input Adapter

Removal of the Oil Input Adapter