DMC:V2500-A0-72-60-4101-00A-920A-CIssue No:003.00Issue Date:2020-05-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-41-300-003 Angle Gearbox Casing - Replace The Damaged Studs, Repair-003 (VRS5099)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

To identify the consumable materials refer to the PCI.

NOTE

Tools for removal and installation may be purchased from ROSAN inc., 2901 West Coast Highway, Newport Beach, California 92663, USA

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| SM101-18 Removal tool | LOCAL | SM101-18 Removal tool | ||

| R1105W Wrench | LOCAL | R1105W Wrench | ||

| S101D12 Drive tool | LOCAL | S101D12 Drive tool |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077A APPROVED ENGINE OIL | LOCAL | CoMat 10-077A |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lock ring | LOCAL | MS51997E-104P | A/R | 01-360 |

| Stud | LOCAL | MS51551C205-10 | A/R | 01-370 |

| Lock ring | LOCAL | MS51990E105P | A/R | 01-380 |

| Stud | LOCAL | MS51551C205-10 | A/R | 01-390 |

| Lock ring | LOCAL | MS51990E105P | A/R | 01-400 |

| Stud | LOCAL | MS51551C205-13 | A/R | 01-410 |

| Lock ring | LOCAL | MS51990E105P | A/R | 01-420 |

| Stud | LOCAL | MS51551C205-9 | A/R | 01-430 |

| Lock ring | LOCAL | MS51990E105P | A/R | 01-440 |

| Stud | LOCAL | MS51551C205-14 | A/R | 01-450 |

| Lock ring | LOCAL | MS51990E105P | A/R | 01-460 |

| Stud | LOCAL | MS51551C205-9 | A/R | 01-470 |

| Lock ring | LOCAL | MS51990E105P | A/R | 01-500 |

| Stud | LOCAL | MS51551C205-10 | A/R | 01-510 |

| Lock ring | LOCAL | MS51990E105P | A/R | 01-520 |

| Stud | LOCAL | MS51551C205-13 | A/R | 01-530 |

Safety Requirements

NONEProcedure

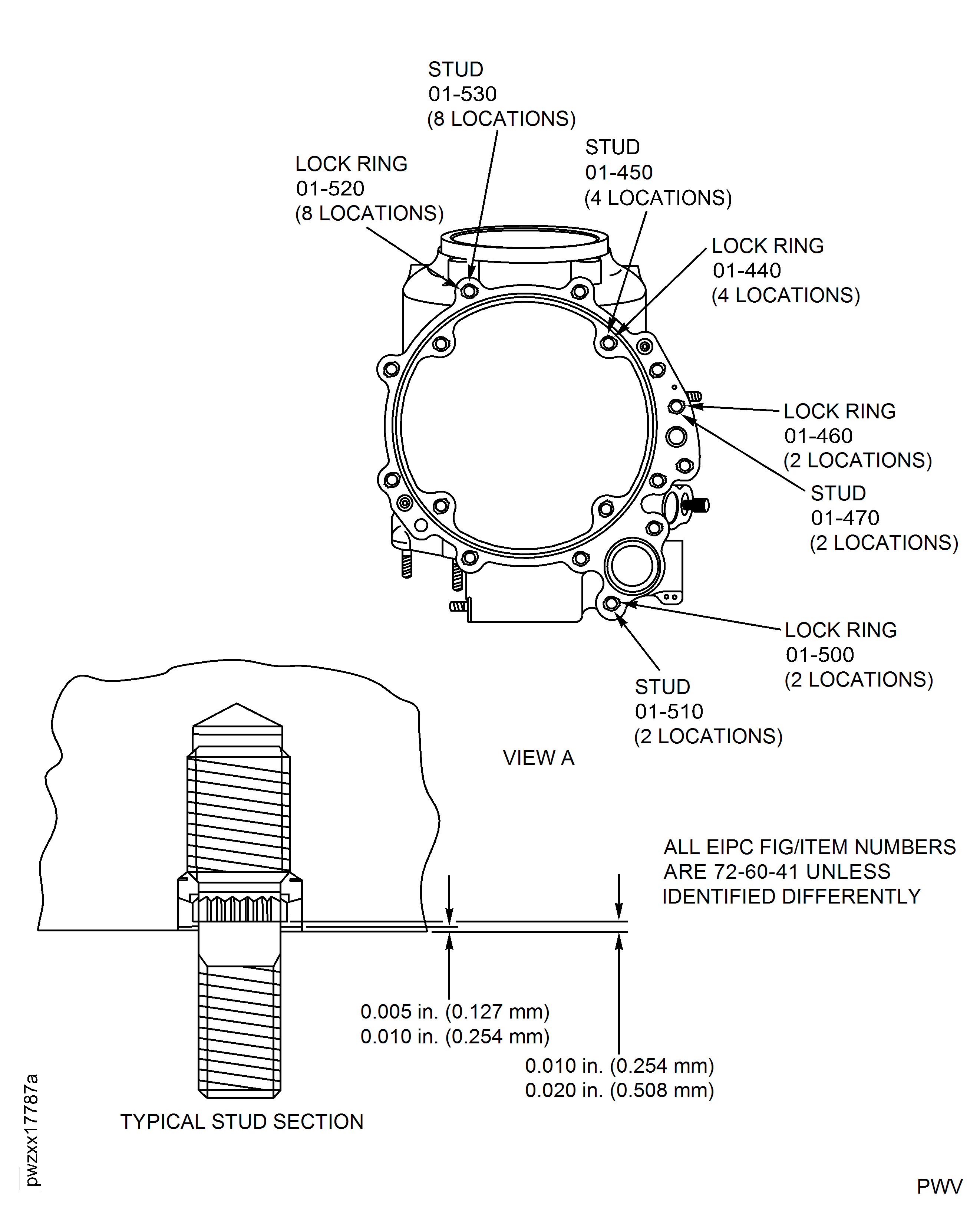

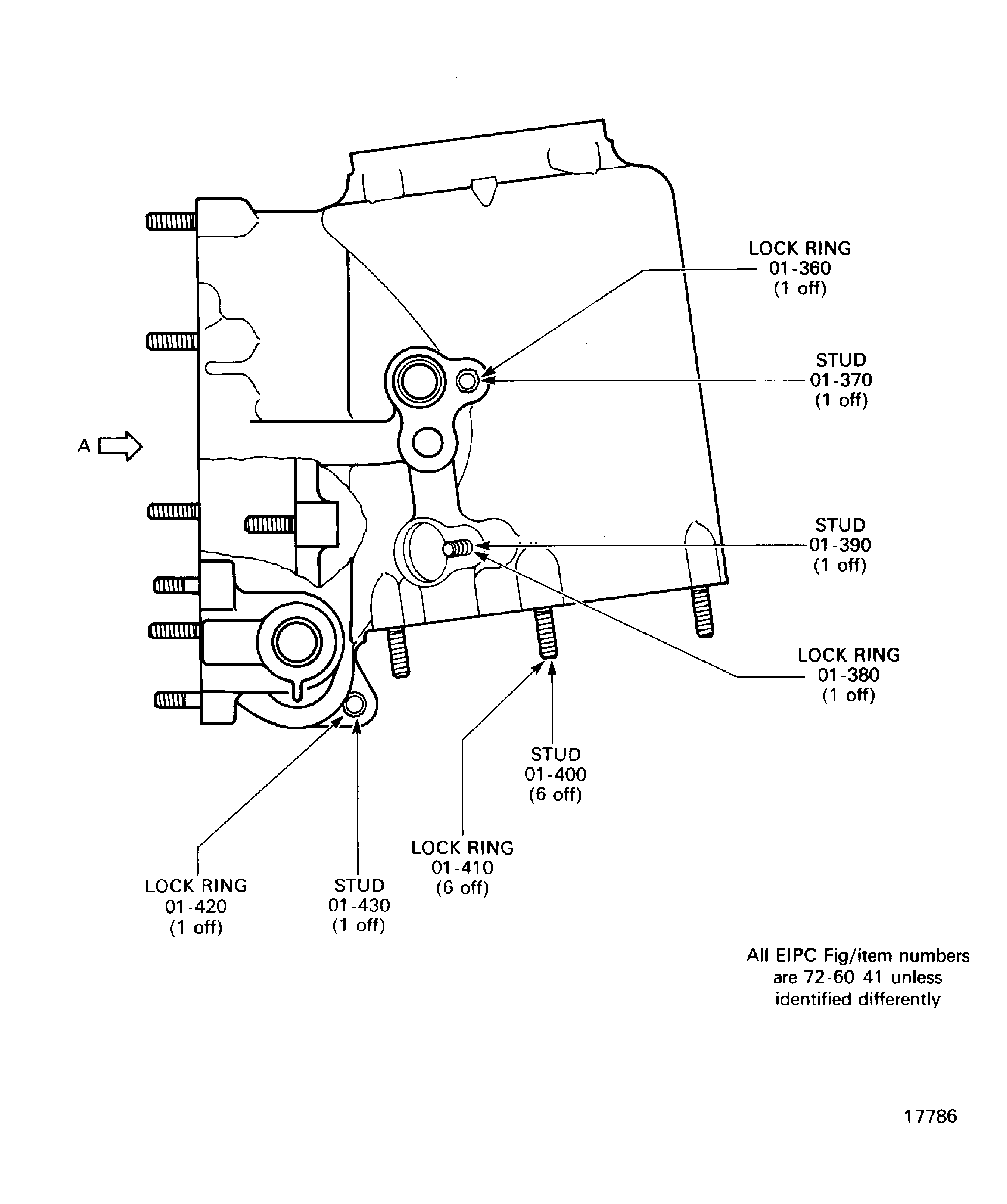

Refer to Figure.

SUBTASK 72-60-41-320-051 Mill the Lock Ring

Refer to Figure

The depth is given in Figure.

Stud must be perpendicular to flat surface of relevant flange within 0.014 in. (0.35 mm) each 4 in. (101.60 mm).

Use R1105W Wrench.

Install the stud.

SUBTASK 72-60-41-350-054 Install the New Stud

Refer to Figure.

SUBTASK 72-60-41-350-055 Install the Lock Ring

Do the touch up process if the anodic treatment has been damaged by stud installation.

Refer to SPM TASK 70-38-02-300-503.

Check the surface.

SUBTASK 72-60-41-330-053 Restore the Damaged Anodic Treatment

Refer to SPM TASK 70-23-05-230-501.

Do a crack test on the repaired area.

SUBTASK 72-60-41-230-052 Crack Test the Repaired Area

Figure: Replace damaged studs and lock rings

Replace damaged studs and lock rings

Figure: Replace damaged studs and lock rings

Replace damaged studs and lock rings